GVL for Knauf floor: characteristics and technology of application

Sooner or later every dwelling needs repairs. No quality repair can not exist without a flat floor. If the floor is properly leveled, almost any material can be used to finish it. The screed in this case can be not only wet, but also dry. The second type can be presented in the form of GVL for the floor Knauf. Consider the characteristics and technology of this material.

Features and benefits

It's no secret that leveling the floor and its preparation for the final part of the repair are among the initial stages of repair work. That is why it is necessary to approach the screed with particular responsibility. Dry screed, in which use gypsum-fiber sheet, is a modern way of preparing the floor. Unlike classical concrete, GVL has a lot of advantages.

We list the main ones.

- When using this material from a well-known brand, building materials (for example, sand, cement, gravel) are not blocked up.

- Laying gypsum fiber company under consideration is not as dirty and painful process as a concrete screed. This can not but rejoice, as many are hesitant to do repairs only because of the large amount of debris and dust, which is rather difficult to get rid of in the future.

- When leveling the floor with concrete, you will have to wait more than one day until the screed is dry, especially if the layer is thick. In the case of gypsum-fiber panels, you can almost immediately cover the surface with a finishing material.

- At the expense of GVL, the neighbors below will hinder you less, and you will not give them discomfort. This material perfectly absorbs noise.

Species

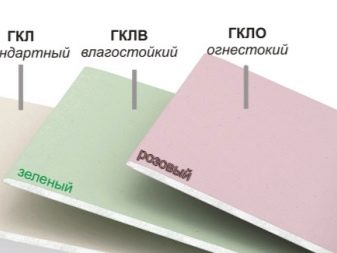

Knauf is a reliable supplier of building materials of various types. To whom, if not specialists, know which type of tie is better to use for leveling the floor. This brand produces two types of gypsum fiber sheets. Consider their features.

Standard

These materials are used for most types of residential and industrial premises. These rooms should have a normal level of humidity. Panels of this type have high strength and wear resistance, with proper operation, such a floor will last for many years. The size of the produced materials is mainly 2500x1200x10 mm.

Moisture resistant

GVLV plates are treated with a special solution that does not allow moisture to be absorbed. Due to this, the material can be used in rooms with high humidity (for example, in the bathroom, kitchen, shower). In addition, these panels can serve as noise and moisture insulating material in attics, basements and garages. GVLV produced in two sizes: standard and small format (1200x600x10 mm) for more convenient operation.

Superlist has a unique installation system, which greatly facilitates the work and shortens the repair period.

The size of the super sheet is 1200x600x20 mm.

Characteristic

The characteristics of gypsum-fiber panels can be assessed based on their advantages. Consider the main advantages.

- Durability due to the presence of a reinforcing substance (cellulose) in the GVL composition.

- Versatility. Despite the fact that initially this material was used to level the floor, today it can be used to finish walls and ceilings, if necessary, you can paint the surface.

- Ability to maintain a microclimate in the room. Due to the special moisture-resistant properties GVL able to absorb excess moisture. When the humidity in the room is insufficient, the material will give it back.

- Increased viscosity. Due to this characteristic it is easy to work with the material. It does not crumble or crack.

- Lack of combustibility. This property characterizes gypsum fiber as a safe material: it does not ignite, it is difficult to light it even on purpose.

- A light weight. You do not have to use force to move the material. This fact greatly facilitates installation.

- Frost resistance. Even with numerous freezing and thawing, these sheets do not lose their properties. This allows you to mount them in cold rooms, country houses and garages.

Subtleties of work

The uniqueness of GVL is that they can be laid on almost any floor, including wooden.It is necessary to take into account several features of the technology laying material. This is true if there are special requirements for the insulation of the room. This is where additional material comes to the rescue (for example, polystyrene). It should be noted that the height of the floor in this case will increase significantly.

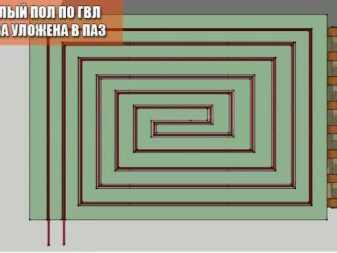

Gypsum fiber panels are great for installing underfloor heating.

It is not recommended to use materials of increased thickness: 10 mm thick sheets will do. Dry screed trademark allows you to hide all engineering systems, which is absolutely impossible with the traditional screed. Anyone who has dealt with a dry screed from a famous manufacturer at least once is unlikely to want to fill the floor with concrete. Even a teenager will cope with the installation of a GVL Knauf. The process does not take much time and effort, the room will soon be ready for further work.

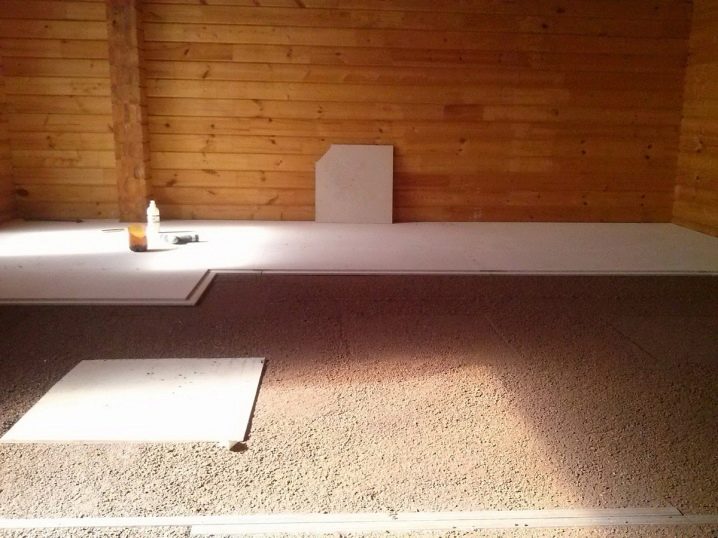

Foundation preparation

Despite the ease of working with gypsum-fiber panels, the base for their installation should be well prepared. At first it is necessary to lay a heater and install guide rails. As the insulating material can be used expanded clay.It is placed on a water-holding surface. This may be a simple film or roofing felt. In some cases, you can use glassine.

The wooden bar will serve as guides.which considerably facilitate work, allowing to lay down a material exactly. In addition, the bars serve as guidelines for laying insulation. After the expanded clay is laid throughout the room, it must be leveled and tamped. It is important to pay attention to the corners of the room.

Installation

As with any repair process, installing a dry screed requires maximum concentration and patience. Incorrectly laid sheets and a poorly prepared base can play an unkind joke with the landlord. Before you start laying GVL, it is necessary to arrange a mounting tape around the perimeter of the room. It absorbs unnecessary noise, protects the floor from changes in humidity and temperature.

Installation of panels should start from the corner near the entrance door face up. Sheets are fixed with screws and a screwdriver. An ordinary screwdriver is also suitable for this, however, the installation process will be significantly delayed in this case.After the first layer of GVL has been laid, it should be lubricated with an adhesive. Then a second layer of material is laid with an offset of 25-30 cm. Knauf company produces a “superfloor”, which already consists of two layers and makes it possible to significantly simplify the installation of gypsum sheets.

The only drawback of this material is its cost (it is much more expensive than standard panels).

Expert advice

Before you start working with a dry screed, it is necessary to familiarize with some nuances of the given building material.

- When installing the gypsum fiber liner, it is important to ensure that the gaps between the sheets do not exceed 2 mm. After installation of the finishing floor covering it is necessary to putty all seams and caps of self-tapping screws.

- Glue solution should not exceed the norm, all excess should be immediately removed, not allowing the glue to accumulate in the joints and gaps.

- The surface of the screed must be primed. In this case, the primer must be combined with a specific adhesive solution.

- When installing a heated floor, it is necessary to use additional insulation to minimize the heat loss.

How to choose?

Currently, the building materials market offers a wide range of products.When choosing a Knauf dry screed, give preference to proven suppliers who can provide a certificate of quality and are responsible for the quality of their goods. In order not to run into a fake, purchase building materials only in specialized stores that have the necessary license. The experience of professional builders and finishers shows that GVL is the most affordable way to level the floor and walls. In addition, you will incur much lower cash costs than using liquid screed.

Installation technology GVL for floor Knauf, see the following video.