Cement tile: features and application in the interior

Familiar cement tile is an original building material used for floor and wall finishing. This tile is made by hand. However, none of us thinks about where, when and by whom it was invented.

From the history of the material

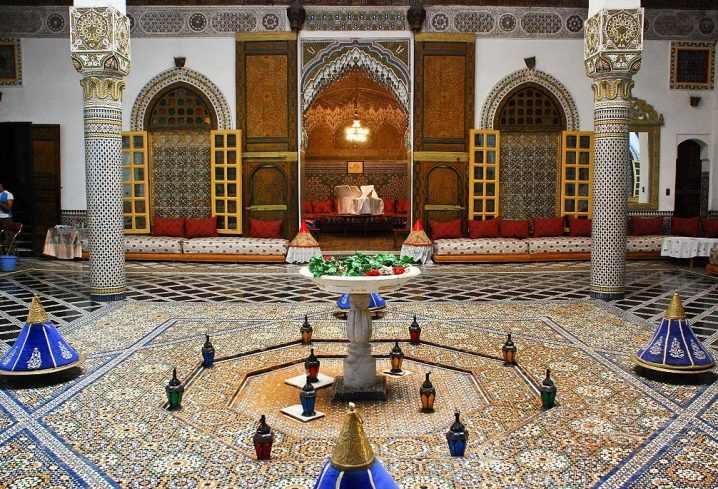

Cement tiles were invented in the Middle Ages. The method of manufacture was born in Morocco. Production was based on the traditions and colors of this African country.

Because of the wars and the migration of the plate was in Europe. It was there that she became very popular at the end of the XIX century. She was often chosen as a finishing material for houses in Spain, France, Germany. Then the art nouveau style appeared in art, and such finishing material lost its popularity for a long time.

Modern tendencies

Now the situation has changed. At the moment, there is a process of reviving the popularity of this finishing material. Now such a plate again put in the bathroom and toilet. This fact is associated with the fashion of antiquity and handicraft.

Along with the growing popularity of classical ornaments, various fashionable patterns are becoming relevant. This finishing material is used for interior decoration of premises for various purposes.

Cement tile fits perfectly into the interiors of different styles. Very widely it is used by designers to create an interior in the Mediterranean and Moorish styles. Natural colors are used for interior decoration. They have a soft, delicate color.

The top layer of the cement tile is matte and uneven, so it can be safely laid on the floor of your bath or toilet. The risk of slipping on it after taking a shower and falling is reduced to almost zero.

Manufacturing process

Making tiles is a very entertaining process. It is made by hand, this explains its value. On the manufacture of each takes about three minutes of work.

The method of manufacturing is the same as a hundred years ago:

- First of all, metal is made into a form. It has an outline of the ornament of a future cement product. This is a kind of pattern. Workers prepare a colored solution, which consists of prepared cement, sand, fine marble chips and natural paints.

- The matrix is placed in a metal mold and filled with colored cement. Then the matrix is carefully removed, gray cement is placed on the colored layer. He plays the role of the basis.

- Then the mold is covered and pressed. Thus, the main and decorative layers merge together. The result is a tile.

- Almost finished cement tiles are removed from the molds, soaked for a while, and then carefully folded. She should then dry for about a month. After complete drying, the cement tile is ready.

It can be used for finishing various rooms. Cement slab is very popular in the decoration of internal and external surfaces of buildings. It is appreciated for its excellent performance and beautiful design. Due to the fact that this finishing material is not burned, but only dried, the dimensions of the plate remain the same.

Laying technology

Tile should be put only on a flat and dried basis.Otherwise, it just disappears, and you have to start all over again. Lay individual tiles at close range, the seam width should be about 1.5 mm.

To level the cement tile it is not necessary to knock on the material with a hammer or hard objects. In order to align the laid tile, just gently push it with your hands.

The production process of cement tiles is carried out manually using natural paints. Tiles may vary in color from each other. Therefore, in order for this fact not to be so striking, it is necessary to take tiles in turn from different drawers.

Cement tiles should be placed on a layer of special glue. Two days after laying, the cement tile must be well washed with special products intended for this purpose. As soon as the finishing material dries out properly, it should be lubricated with a special substance. It is well absorbed into the tile, protects from moisture, will prevent the appearance of spots during the grouting.

In the process of grouting, you should not use colored compounds, as they can leave ugly stains on the tile.At the end of the work, the grouting remains should be washed off, and a special protective agent should be applied again to the top layer of the tile.

For how to lay cement tile, see the next video.

Manufacturers

Among the most popular companies producing cement slabs are the following:

Anticdesigns

Enticdesigns is a brand of finishing building materials, founded in Spain in 2005. The brand is engaged in the manufacture of tiles together with the workshop, located in Cordoba, where more than one generation of true craftsmen works. Cement tiles offer something that other building materials cannot provide. During operation, it begins to be covered with a beautiful touch. Due to the growing recognition of the value of manual production, such tiles are in trend again.

Modern buyers are becoming more demanding. The company values its customers and offers them only the brightest colors and original design drawings. The work of Enticdesigns designers is dedicated to the creative search for new and outstanding, therefore the shades and patterns of these products satisfy the tastes of even the most capricious customers.

Marrakech design

Spouses Per Anders and Inga-Lill Ovin founded in 2006 the Swedish company Marrakech Design. Scandinavian businessmen rightly believed that the revival of this building material is associated with the general trend of increasing demand for unique and custom-made projects, interest in antiquity and ancient ornaments. In addition, cement tile can be easily adapted to the individual preferences of the client, the feedback on it is mostly positive.

This finishing material is very beautiful. Covered with a coating over time, it only gets better. In the Scandinavian countries, tiles are used mainly for the interior decoration of non-residential premises. Sometimes she revets the walls of bathrooms and toilets.

Popham design

In America, this type of finishing material began to be applied quite recently. The interest in it is easy to explain by the fact that modern people are more and more interested in antique, hand-made things. Well, is it possible to compare tiles made by hand by craftsmen and its analogue of factory production? Of course not.

If we talk about design, then US residents understand that this fashion has come from distant countries, so it is necessary to adjust it to the American lifestyle.This is the main task of Popham Design: to combine the traditions of production with fashionable design and shades. Fashionable ornaments are used in architecture and design for the design of various premises. It gives freshness and newness. Tile colors can be combined. This gives the masters of design and architecture the opportunity to introduce new materials into their works.

Mosaic del sur

Designers of many Russian companies use Spanish cement tiles Mosaic del Sur in their works. The use of this finishing material is associated with the influence of Moroccan fashion. Vintage patterns and intricate ornaments allow you to use this material in interiors decorated in oriental, mediterranean and modern style.

Luxemix

In 2015, the company Bisazza (Italy), producing glass mosaic, also took up the mass production of cement tiles under the trademark Luxemix.

Peronda

Peronda is a giant enterprise that produces various tiles in the Iberian Peninsula. The most successful collection of this company, created two years ago, is called Harmony.

Use in the interior

Today it is difficult to imagine a modern toilet or bathroom without a tile on the walls and floor. Such a room looks out of date, too simple and boring.Cement tile, made in the form of a decorative brick, for example, is a very practical, beautiful, original finishing material. Modern stores of building materials offer our attention a rich assortment of this type of design.

Everyone can easily choose a tile for the floor or walls. Lay the tile yourself or resort to the help of experts. The delightful design of your bathroom or toilet is no longer a dream, but a reality.