Socle tile: subtleties of selection of finishing materials

Today, the construction market is replete with a variety of facade tiles. However, the choice should be made, guided not so much by personal preferences, as the appointment of the material. So, to the tile for the socle there are high requirements with respect to strength, wear resistance, weather resistance.

Special features

A plinth is the lower part of the facade, usually projecting slightly forward. This is a kind of “layer” between the foundation and the main part of the building.

The base more than other parts of the facade is subjected to mechanical and shock loads. In winter, it is not only exposed to low temperatures, but it also freezes into the ground.

At the time of melting snowas well as during the precipitation, the basement experiences an active effect of moisture, and in most cases there are particles of road reactants and other aggressive components in the melt water.

All this causes increased requirements for strength, frost resistance, chemical inertness and moisture resistance of the finishing material for the basement part. And since it is inextricably linked with the facade, it is important that the material was characterized by visual appeal.

The socle tile which can have various design, imitate this or that surface and be made of various structures corresponds to these requirements. Only the high density of the plinth tiles, the greater thickness compared to the facade counterparts, and, accordingly, the improved strength indices remain unchanged.

Along with the increase in the thickness of the material, its heat and sound insulation characteristics increase.

The obvious advantages of tile for the decoration of the basement are:

- reliable protection of the building from moisture penetration;

- improving the thermal efficiency of the structure;

- most modern materials are non-flammable or have a low flammability class;

- increased strength characteristics, wear resistance;

- weather resistance;

- simplicity of installation - the tile has a convenient size (its height usually corresponds to the height of the foundation);

- easy maintenance - many surfaces have self-cleaning surfaces, most of them are easy to clean using a stiff brush and water;

- Long service life, averaging 30-50 years.

The disadvantage is the greater weight of the material, which requires additional strengthening of the foundation. However, you can always find a lighter option and, perhaps, resort to reinforcing the foundation.

For example, if the strength of the foundation is not enough to install a clinker tile, it may be enough for mounting a lighter base metal siding.

If necessary, you can pick up panels with imitation of the same clinker.

Kinds

The tile for the base can be made of various materials. Consider the most common types of tiles.

Clinker

This facade tile appeared as an alternative to the more expensive and heavy facing brick bricks. It is not surprising that it mimics the brickwork, although there are also options for stone.

At the base of the clinker tile is clay, which is subjected to high-temperature roasting.The result is a high-strength material, which is characterized by low moisture absorption, heat resistance, frost resistance. In its reliability, it is comparable with granite slabs.

By itself, the material does not have high thermal insulation qualities, therefore, requires the use of insulation. But today you can also find a thermal tile - an improved sample based on clinker, equipped with a layer of polyurethane or mineral wool insulation. In addition to this two-layered version of the thermal, there are three-and four-layer, which are equipped with additional plates of stiffness and fire-resistant inserts. The brick tile differs in high cost which, however, pays off the long period of operation - 50 and more years.

Polimerpeschanaya

Having sand in the composition, the tile has a light, good vapor permeability. The low weight of the product makes it possible to install it even on non-reinforced bases, as well as supporting structures with a small margin of safety. The presence of polymer resins provides strength and moisture resistance of the product, its ability to maintain the integrity and geometry when exposed to high and low temperatures.High plasticity protects tiles from chipping and cracking. It is mounted both in the dry, and wet way.

Hyperpressed

This tile is also characterized by low weight and durability, has high moisture resistance, as well as an attractive appearance. It looks very similar to clinker tiles.

Stone

This tile is made using natural or artificial stone. Natural stone, however, is less and less used for decoration. Despite the large margin of safety, it is too heavy, difficult to handle and care, can have a radiation background and, finally, has a high cost.

But if you still decide to use natural stone, choose a flagstone finish. This is a group of stones, having the form of plates of irregular shape, the thickness of which rarely exceeds 50 mm.

Worthy analogues of the material are porcelain stoneware, bassoon, which are varieties of artificial stone. The main components of such materials are crushed granite and other natural stones, as well as polymer resins. The result is slabs that are not inferior in reliability to the natural counterpart, but lighter, more moisture resistant and less costly.

It is fair to note that the weight of ceramic granite still remains considerable, so it is used only on solid foundations. Thanks to modern technologies, tiles made of artificial stone imitate any natural surfaces - granite, slate, surfaces of processed and coarse stone, and so on.

Resin based plate

This facing tile is distinguished by its flexibility and elasticity, which makes it possible to use it for cladding of semicircular and round elements of the base. Externally, they mimic brickwork or "torn" stone.

Decorative tiles can be cut with construction scissors, which facilitates the installation process. Installation is carried out wet on a special glue, no inter-seam gap grouting is required, so an impressive monolithic surface is formed. Under the product can be laid a layer of insulation. Under the tiles can be concrete or plastered surface.

Ceramic

The ceramic tile differs in environmental friendliness and moisture resistance. In its reliability, it is slightly inferior to one of the most durable clinker tiles. However, unlike the latter, ceramic tiles have a lower thermal conductivity.

Externally, imitates stone surfaces, is fixed only on the batten.

Side panels

PVC can be used as the basis of the material (rarely, it is better to refuse from the purchase), metal or fibrocemetsy frame. Fiber cement boards are stronger, more durable, but have more weight and higher cost. Metal siding products, however, also withstand increased load, have anti-corrosion protection.

Styling tips

It is possible to save and display the best technical characteristics of the plinth tile only if the installation technology is observed.

Wet way

This process includes several basic steps.

Wall preparation

The surface is leveled, the old coating is removed, and the wall is processed in 2-3 layers of primer. Then a layer of heat and waterproofing materials is laid, on top of them is a metal reinforcing mesh.

Wall marking, preparation of materials

In accordance with the size of the tiles, the basement is marked. Do not neglect this stage, because the only way to achieve perfect appearance of the base.

After the marking is done and tested, proceed to the preparation of the adhesive composition. It is recommended to use a special frost-resistant adhesive for the socle tile. It has good adhesion, can withstand 150-300 freezing cycles and ensure reliable fixation of the tiles.

Preference should be given to compositions from reputable manufacturers, before you buy, make sure that the storage conditions are properly respected by the seller.

Remember that even the highest quality and expensive tiles will not be able to protect the base, if you choose a glue of dubious quality. The material will simply move away from the wall.

Tile fixing

In the case of wet installation, the glue is applied to the wall (the glue stain should be slightly larger than the tile to be glued). The same or slightly smaller layer of glue is applied with a notched trowel on the back side of the tile. After which it is pressed against the surface and held for several seconds.

The tile is laid with gaps, the uniformity of which is achieved through the use of beacons or a steel bar with a round cross-section of suitable diameter. Usually interstitial space is 12-14 mm.

Grout

After the tile dries, the space between the seams is treated with a trowel compound.

Thus, the clinker tiles are mainly laid.

Hinged system

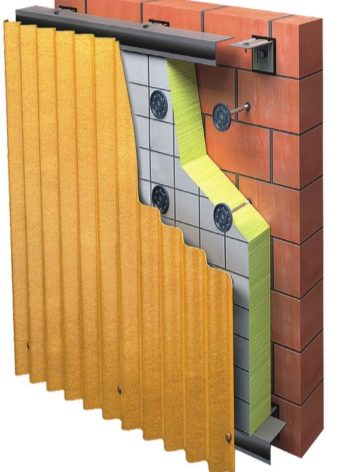

Most of the modern tiled materials are mounted on a crate constructed on the surface of the walls of the building. The frame is built from metal profiles or wooden bars. It is fixed to the walls by means of clamps.

After mounting the frame on the bolts, self-tapping screws or special fasteners (for example, movable slide), the front plates are mounted. Design of corners and other architectural elements, as well as window and door slopes allows the use of additional elements.

The advantage of the hinged system is the absence of additional load on the foundation, which cannot be said when fixing the plates with a wet method. It is possible to fix the panels, regardless of the characteristics and condition of the wall covering of the building, as well as to hide minor defects and differences in the height of the walls.

Hinged systems usually assume that a small air gap of up to 25-35 mm is maintained between the facade and the wall. The system is called ventilated and allows you to improve the performance of the building.

Often, insulation is laid between the wall and the crate, which also improves the thermal insulation characteristics of the building.

When arranging the lathing, it is important that the metal profiles are made of moisture-resistant materials (aluminum, stainless steel) or coated with anti-corrosion powders.

Wooden lathing is used less frequently due to lower strength characteristics, it is suitable for covering a small base plinth and does not include the use of heavy facade plates. In addition, wooden elements should be carefully processed with fire retardants and compounds to increase moisture resistance.

First, the installation of the plinth tile is carried out, and only after that the facade cladding. This is due to the need to organize a reflux, which protects the protruding part of the cap from moisture, and its facing.

Dimensions

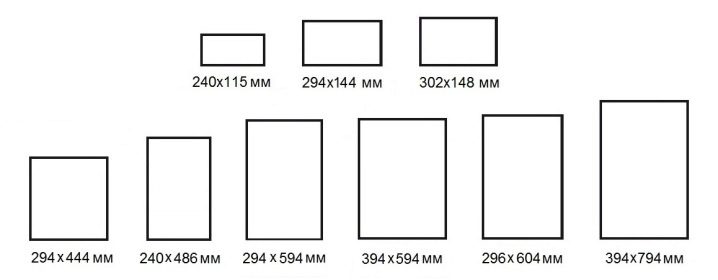

There is no single standard approving the dimensions of basement materials. Plates of different types and manufactured under different brands are distinguished by their dimensions. Unity is observed when it comes to coating thickness.

The thickness of the plinth tile is usually 1.5-2 times greater than the thickness of the similar material of the facade.Tiles of this type must have a thickness of at least 17-20 mm.

In general, there are 3 main dimensional types of basement tiles:

- large size (their length can reach 200-250 mm);

- mid-size (length ranges from 80-90 mm to 10-120 mm);

- small (usually correspond to the size of the facing brick or have slightly larger dimensions).

This division is very conditional, usually for each type of tile has its own size ranges.

How to choose?

Before you buy a tile, you should decide how the material will be laid, to clarify the bearing capacity of the foundation. Unfortified floors, clearly, cannot withstand heavy slabs based on stone or cement. Ideally, with the option of facing the facade and basement should be determined at the stage of developing a plan of construction.

When you come to the store, make sure that you evaluate or offer you a material intended specifically for outdoor work. As a rule, it has a special label "snowflake", which indicates the cold resistance of products.

Ask the seller to present certificates and other documents confirming the originality of the products.To buy, of course, better products of well-known manufacturers. Leading positions in the market are German and Polish companies. The use of tiles should not be limited to less than 20-25 years of operation.

If you need to glue the tiles, and then wipe the seams, choose frost-resistant compounds of the same brand.

If you can not decide on a shade of tiles, choose those that are darker than the main finish. This option usually turns out to be a win-win. Preference should be given to materials, the shade of which occurs in the firing process without adding pigments (if we are talking about clay-based tiles).

Tiles with painted surfaces should be protected by a reliable transparent polymer layer (as an option - to have a ceramic coating). Only in this case, we can talk about preserving the color of the material during the entire service life of the basement facade.

Beautiful examples

Houses, the socles of which are finished with natural or artificial stone, always look thoroughly, respectable. The rest of the facade is usually faced with brick, plaster or stone (or materials that mimic these surfaces). At the same time, it is important that the stones in the basement part be larger compared to the elements of the facade decoration.

Sometimes for the decoration of the basement and the facade are used the same in structure, but different in color materials. The color scheme can be both close and contrasting.

A smooth brick on the facade is harmoniously combined with a similar material on the basement part. True, the brick here can have a grooved. In other words, the facade should become a calmer background for a textured, attention-grabbing socle tile.

You will learn more about the basement tile in the following video.