How to choose a two-component tile adhesive?

The right choice of adhesives for tiling ceramics of various premises plays an important role in the process of their finishing. An example is a special two-component elastic adhesive for ceramic tiles, which compares favorably with traditional sand-cement mixtures with the addition of PVA.

Special features

Such composites should have a high ability to adhere, superior to other types of adhesives, and the ability to firmly hold on smooth, non-absorbent surfaces. Such materials include glass surfaces, the glazed side of tiled ceramics, and dense stone.

The elasticity of the mixture should be such that it can stretch without cracking, absorbing slight deformations of the base, including temperature.

Due to the high content of binding components, the bulk of elastic mixtures is waterproof and frost-resistant. They can be used instead of conventional adhesives, which is why the quality of facing works is significantly improved. In addition, they greatly facilitate and accelerate the process of work in comparison with any other types of adhesives. Working with them, you can get an additional 5-10 minutes to adjust the tiled masonry.

The use of composites such as quartz sand, andesite or graphite, as well as a variety of polymeric plasticizers give them greater plasticity compared to conventional analogues.

How to choose?

Strong bonding between tiles and surfaces is a basic requirement for all adhesive compositions intended for this purpose. However, its implementation largely depends on the degree of elasticity of the tile adhesive, because the likely temperature drops can give some mobility to the base on which the tile is mounted. This may lead to detachment or cracking of the ceramic cladding. Therefore, the use of elastic adhesive composites protects the tile layer from deformation.

When choosing between a cement-based compound and epoxy glue, preference should be given to the latter because of its greater plasticity.

Single component formulations

One-component paste-like compositions, which are commercially available in ready-to-use form, are distinguished by their great convenience. They are ductile enough to extend the service life of the facing coating and protect it. They do not require mixing, you can work with them immediately after purchase..

This ready-made glue is most suitable for interior decoration with a small area. It is used for fixing tile cladding in bathrooms and kitchens, when it is necessary to minimize the amount of dust when working.

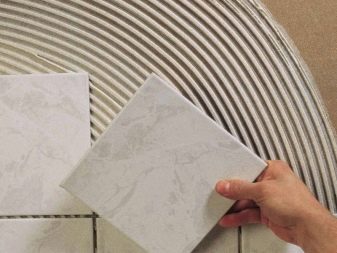

Single-component mastic compositions on a latex basis or on the basis of other petroleum products, are distinguished by increased fixing properties, are very elastic and waterproof. They are easily applied on a pre-primed base with a thin layer and do not create inconvenience when working with them. The tile is pressed to the adhesive layer, and then it is tapped lightly on it. The excess composition is removed with alcohol, white spirit or acetone.

Polymer cement solutions

Cement-based compositions, which sometimes have plasticizer additives, are cheap, fast-curing white tile adhesives with a relatively low level of elasticity. They are based on white cement with additives to increase the viscosity and elastic properties of the composition. Such mixtures are often used to create mosaics.

If there are no plasticizers in this composition, then it freezes very quickly.. If, for example, there is a bucket of such glue, then it is very likely that it will be possible to use only one fifth of this volume.

Glue with cement base

It is the simplest type of cement mortar, consisting of cement and refined sand. A massive ceramic granite tile, natural stone or its artificial analogue and large format tile are laid on it. High grasping characteristics of such a composition can be significantly enhanced by adding slaked lime to it.. The result will be a very highly elastic mixture capable of facing in the horizontal and vertical plane. It can be used for interior decoration as well as for exterior work, for example, facade.

Besides, The performance characteristics of such a mixture, in addition to lime, can be improved by adding PVA glue, liquid glass or latex to it. However, you can be mistaken with the proportion. Therefore, it is better to purchase a ready-made dry formulation with improving ingredients added to it.

Liquid Nails

Any adhesive compound adheres worst to a smooth surface. The creation of high-quality adhesion requires roughening of the substrate processed by the adhesive. For such work, it is advisable to purchase glue in tubes and tubes for building guns. Such compositions include liquid nails.

Working with these composites requires neither serrated spatulas, nor separate containers for mixing them. Acrylic-based gel adhesive polymer is applied to the surface of a wall or tile in the form of strips or drops. The name “liquid nails” is a composition of this kind because it creates a point-like connection of the tile with the base. They are easy to use and provide gluing cladding tightly..

Liquid nails are a separate type of modern binder composites on a neoprene basis with the addition of polymers and synthetic rubber.This type of glue belongs to toxic substances, has an unpleasant odor, and it should be handled with the use of protective agents. Water-based liquid nails are used in dry rooms for minor restoration work, as they do not tolerate moisture.

Dispersion adhesive mixtures

Dispersion bonding mixtures are paste-like tile adhesives. This form of delivery of this product completely eliminates the mistakes of consumers, manifested when trying to independently connect the components of other types of adhesives.

These mixtures are composed of organic binders in the form of polymers, bitumen and various types of tar. In their composition there are high-quality modifying additives and mineral fillers of natural origin in the form of quartz and silicate sand, as well as graphite and andesite.

For laying tiled ceramics, dispersion mixtures are an excellent glue, which makes it possible to veneer plastic, wooden and metal surfaces with low consumption of the binder composite. With it, you can update the tile flooring and walls directly on the old tile.

The disadvantage of dispersive adhesive mixtures is the lack of the possibility of their dilution, thickening or mixing with other ingredients, as well as the long duration of their hardening, which can last up to 7 days.

Epoxy Bonding Compounds

For those situations where the tile is mounted on plywood, DSP or wood, the use of reactive adhesives, formed as a result of the reaction of two different components, becomes a more rational option. This, above all, should include a universal epoxy adhesive composite based on resin, formed after mixing it with a hardener. The content of the latter depends on the setting time of the composition, therefore should not increase the concentration of this component. Otherwise, they will not even be able to smear the tile - it will just harden.

Epoxy tile adhesive composition is not only a two-component - it can be a multi-component cementitious composition consisting of several grades of epoxy resins with additives and a catalyst-curing agent. The “epoxy” of modern varieties is also enriched with various modifying and plasticizing additives and additives from fillers and solvents.

Forms of delivery of epoxy compositions are sets of paste-like or liquid mixture and catalytic hardener, packaged in separate containers and sets, which include resin, hardener and filler.

As the latter, additives in the form of quartz sand, cement, alabaster, aerosil, various fibers, marble chips, sawdust, metal powders, microscopic hollow balls - microspheres can be used.

The advantages of epoxy glue include its ability to securely fix tile coating, mechanical strength and elasticity, resistance to UV and aggressive chemicals, frost resistance and water resistance, as well as the ability to be used as a grout.

Among the shortcomings of the epoxy adhesive composition, it is necessary to note the need to prepare it manually, the high cost, sensitivity to errors in respecting the proportions of its ingredients and the impossibility of removing this composite from the surface of ceramics after it has hardened.

Epoxy glue has such significant adhesion indicators that it allows the installation of tiles on a variety of bases: wood, plywood, concrete, plastic, metal surfaces and glass.

Regarding the specifics of the use of epoxy adhesive composite, it should be noted that it is desirable to use it, given the air temperature. For example, at 25-35ºС, the curing of the glued surfaces takes on average about 5 minutes, and the curing time is about 1 hour.

Epoxy adhesives in liquid or paste form should be applied to the tile surface with a brush, spatula or sprayed with a gun.

The reaction between epoxy and hardener is irreversible, so installation work using this type of glue requires a certain amount of professional skill and appropriate skill.

Epoxy composite is an ideal adhesive composition for working with glass mosaic, bright types of decorative smalt, elite ceramic coatings, elegant stone and marble decor types.

It should be noted that whatever composition of adhesive is chosen, it is necessary to work with it carefully, using safety tools for the respiratory tract and hands. Otherwise, the consequences may be unpredictable.

How to breed a two-component epoxy adhesive, see below in the video.