Tile profiles: selection criteria

Tile trim profiles are also called layouts or trim. They cover the tile on two or three sides, masking the raw edges. Layouts - a characteristic feature of modern repair. Let us see what these details are useful for, how they are, and on what basis they need to be chosen.

Benefits of using

Making the tile joints in the corners, you can do without a profile. Such an approach is justified when decorating walls with expensive or embossed tile.

Masters are not advised to abandon the layout only because of its appearance, because it has a lot of advantages:

- Profiles make the bathroom safe. The corner of the sharpened tile is sharp, it is easy to get hurt about it, slipping on the wet floor. The layout, on the contrary, smoothes such areas.

- It is more convenient to use the profile than to grind the edges of the tile at a 45 ° angle.

- Finishing looks more interesting. The line of connection turns out accurate, and the corner which is suitable on color and invoice can emphasize beauty of a tile.

- Profiles securely close the gaps, protecting the inside of the wall from moisture. This eliminates the risk of mold or mildew, and also prolongs the life of the tile.

Types and forms

Layouts under the tile are decorative and functional decorative. Decorative made of PVC or ceramics and are used to decorate and mask the butt sides. These include a curb for a bath. Functional and decorative profiles are made of metal. They are not only beautiful, but also practical. Such elements do not allow the joints and edges of the tile to collapse, give the correct shape to the outer corners, fasten different floor coverings to each other.

By appointment, all profiles are divided into several groups:

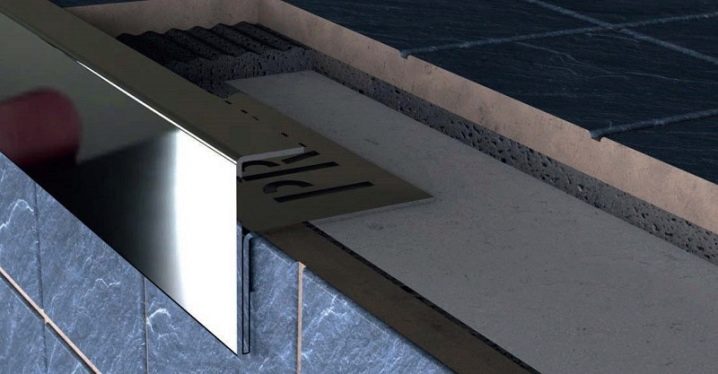

- External edging. They are designed for the design of protruding corners. Such elements consist of two parts: a perforated groove for the tile and the outer side. They protect the tile from damage and perform a decorative function.

- Internal edging. This type is used less frequently than the previous one. The concave front part smoothes the transition between the sides of the corner part. Such profiles often make the junction of the bath with the plane of the wall.

- Final corners for steps. They protect the edges of the tiles from damage. In combination with rubber pads, they make the stairs less slippery. Such elements are desirable to use only indoors.

- Compensatory. This type hides expansion joints that compensate for tile size changes due to temperature difference. Such profiles are necessary in spacious rooms. They are also distinguished by the presence of decorative overlays.

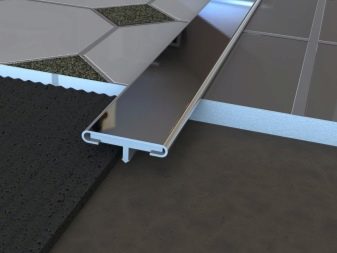

- Docking. Such products are indispensable when combining tile with another material. With a flat line of docking, they use hard layouts made of steel. Flexible plastic and aluminum profiles are used when the boundary between materials passes along a curve. Recently, a fluid docking profile has appeared, which is a mixture of corkwood particles and glue.

Masters put it on the place of the joint coatings, and when it hardens, remove the excess.

Metal layouts for tiles have a different section. Its shape is determined by the function of the part.

In stores you can see several options:

- T-shaped layouts are used as docking and compensatory. The small thickness of the upper part and hidden fastenings make it almost imperceptible. The most popular parts made of aluminum, brass and steel versions are also available. Profiles 10-14 mm wide can be bent.

- U-shaped profiles are made of aluminum, brass and steel. They are used as connecting and end. They are framed by open edges, external corners and steps.

- L-shaped have the same function as the previous group.

- L-shaped or starting are convenient when working with large tiles. They do not allow the first horizontal row of tiles to “slip” under their own weight.

Materials

Basically, for the manufacture of corners under the tile using aluminum, stainless steel, brass, PVC and ceramics. Each of them has strengths and weaknesses. Consider them in more detail.

- Aluminum. All types of profiles are made from this metal and its alloys. It is rather strong and durable material, not subject to corrosion. Aluminum joint profile can be used for curved joints of the floor covering.Color spray is applied to the outer side of the parts. Mainly used shades of noble metals, but sometimes you can see bright colors.

- Brass. It is a durable, wear-resistant, corrosion-resistant alloy. It can withstand high mechanical loads, because it is suitable for the design of the flooring. The material protects the corners, edges of tiles and seams from damage. Brass profiles are natural, polished, chrome-plated and coated with bronze.

Brass is an expensive and high-quality material. In the interior, it looks stylish and luxurious.

- Stainless steel. In terms of technical characteristics, it is similar to brass, but more durable. Such products serve more than ten years. Stainless steel profiles are matte, glossy, polished and embossed. Metal and brass corners are convenient to use with heavy cob tiles.

- PVC profiles divided into soft and semi-rigid. The main disadvantage of the first is fragility. Details from this material differ in the low price and a variety of flowers (from white to dark green and a Bordeaux). PVC profiles are easy to install, do not deteriorate from water and do not require special care, but may turn yellow with time.

- Ceramics. It is mainly used to design the transition between the bathroom and the wall. Such products are beautiful, durable, but can break when struck. Details from this material are easily selected to the tile of any shade.

Dimensions

The size of edging profiles is characterized by two sizes. The first shows the width of the groove under the tile, the second - the length.

The size of the groove varies from 8 mm to 12 mm. Masters recommend selecting a profile 1 mm wider than the thickness of the tile. If the tile is still not included in the groove, its edge can be carefully grind off.

Standard length of parts - 1 m and 2.5-2.7 m.

Choosing curly L-shaped and T-shaped profiles, you should pay attention to the figure after the article. It is equal to the height of the part. Profiles are available in heights of 6, 8, 10, 12, 15 and 20 mm. Here the same rule is observed - tile thickness + 1 mm.

On the U-shaped profiles indicate two numbers, for example, 10x10, 12x12, 20x10. The first shows the height of the section, the second - the width.

The standard size of the cross section of the ceramic corners is 5x5 cm, the length is equal to the width of the tile and is 20 cm or 25 cm.

Colors

The richest palette have soft plastic parts. In the assortment of stores you can find more than thirty colors, both bright and pastel. There are layouts with imitation of metal surface, different types of stone and ornaments.This allows you to choose a profile that fits perfectly with the design of the tile. Semi-rigid corners are available in only 5-6 colors.

Ceramics is almost the same plastic as the number of shades. Among them there are not only white and a few gentle whitened tones, but also rich colors, including black. In addition, ceramic borders are decorated with paintings, embossed patterns, gilding and even rhinestones.

The range of shades of metal parts is not so wide. It mainly consists of the colors customary for this material (variations of gold and gray). In the catalogs are often found: chrome, silver, bronze, gold, black.

How to choose?

Minor details can distort the overall look of the interior, so you should not buy profiles for ceramic tiles at the last moment. Designers advise to select them as carefully as tile.

Buying expensive tiles, you should not save on the corners. Plastic layouts make the interior a bit clumsy, even if combined in color with ceramics. Metal parts look stylish in any conditions (even next to cheap tile).

Metal is durable. It will last at least ten years, while plastic will lose its appearance in five years.The metal edging will also reliably protect the edges of the tile from chipping. Therefore, such products are more expensive: aluminum and steel layouts 2.5 m long - from 1000 rubles, brass - from 2300 rubles.

Before buying it is important to carefully inspect the part. It should be smooth over the entire length. It is worth remembering that the size of the groove or the height of the profile must exactly match the thickness of the tile.

How to install the corners on the tiles with their own hands, see the following video.