Tile leveling system: the details of the process

When repairing an apartment, the decoration of the surface of the walls and the floor with ceramic tiles or ceramic granite plays a huge role. Dynamically developing technologies for the production of finishing materials offer a wide range of devices to simplify the process. Of course, the easiest way to realize your ideas is to hire a professional who understands the intricacies of the process. However, even if you have never done repairs, a tile leveling system can help you.

Special features

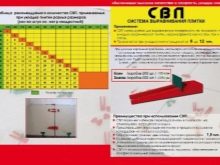

In contrast to the standard method of laying with the use of plastic crosses, the SVP has the form of wedges equipped with clips. The clamp is a T-shaped part, the upper part of which is easily separated from the lower part and removed after the glue dries.The lower part of the clamp, the base, remains under the laid tile until it is removed during the next repair. A wedge can be used ten to fifty times depending on the type of construction. With it, adjacent tiles are aligned in height, and the glue is distributed over the surface of the coating in a uniform layer.

The advantages of SVP are:

- The speed and ease of use compared to traditional methods.

- Uniform distribution and, as a result, savings of glue.

- After the adhesive mixture dries, the tile does not sag, does not bulge and does not deform under the weight of the furniture installed on it, since when it dried it was firmly pressed to the surface and fixed.

- The ability to reuse wedges the next time the system is installed.

- The abundance of reviews and video instructions for installation and dismantling of the system.

The disadvantages of such systems are:

- Large losses of time for installation and disassembly of wedges in the absence of experience in their use.

- It is possible to clean the seams and the front surface of the laid tiles from drops of glue and debris only after complete removal of all parts of the system protruding above it.

- Additional costs for the purchase and delivery of tile leveling systems.

- The unreasonableness of the cost of use when covering small areas in residential premises.

Kinds

There are various types of these systems:

- Wedge - reusable plastic wedges and clamps, which are used one-time, 3D crosses with an anatomical ring. Used for laying tiles whose thickness is from 5 to 12 mm. The lower part of the levelers is made in the form of a molded plastic part with a flat base and a protruding crossbar.

An incision is provided at the junction of the crossbar with the base for easier removal of the crossbar after solidification. The wedge has a horizontal incision in the expanding part so that the clamp moves freely along it, and the junction of two tiles is pressed. It is also made of plastic.

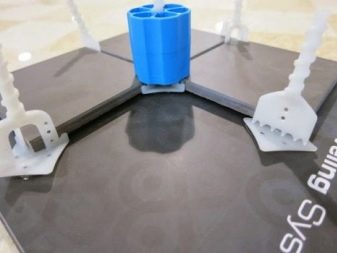

- Cap - plastic wedges with a locking lock inside. Used for tiles with a thickness of 5 to 25 mm. Represent a disposable corrugated rod and pressure cap with clip. For the tile of a given SVP, an additional device is needed, which can be both included and purchased separately.

- With manual screw tightening or the studs of the part are connected and tightened with a plastic nut or a metal stud by hand. For leveling adjacent tiles, a thread is used on the parts. The screw is tightened by hand, and when using a metal tile, a screwdriver of the required size or a screwdriver is suitable.

- Solid - non-collapsible wedges that are used one-time. The tiles are combined in height with the help of two movable latches located in the upper part of the system. This is the cheapest and easiest to use SVP, so it is perfect for lovers who first do the laying of the tiles with their own hands. When buying, you need to pay attention to the difference of license plates on the system. They must match the thickness of the tile used.

You can also make your own leveling system tiles from scrap materials. You will need aluminum wire, from which you need to bend a rectangular frame. The height of the frame is 1.5-2 mm and the width is 0.8-1 mm. The ends of the wire must be twisted into a small flagellum, which will be able to hold when installing the wedge.

To simplify the breakage after the glue has dried at the base, bite the frame at the right points with simple nippers. The bottom stop can be made from small scraps of metal profile, plate, or other remnants of flat material. A small plastic or wooden wedge is inserted under the wire twisting from above. In order to avoid its shift, it is also possible to enclose a small gasket from trimming fiberboard. In 30 minutes you can easily make up to 100-150 of such clips and save about 1000-2000 rubles for the purchase of SVPs from famous manufacturers.

Application area

SVP is used both in the repair of bathrooms, bathrooms and kitchens in ordinary residential apartments, and in the decoration of large commercial or industrial areas. The system is used to align the tile in a single plane by changing the thickness of the glue line by applying dynamic force to the joints of ceramic tiles. With the right calculations, a specialist will not only be able to lay ceramics much faster, but also more qualitatively, both on horizontal surfaces and on vertical surfaces, laying on which is an even more laborious process.

Comparison of domestic and foreign systems

The main difference of the domestic tile leveling system is that it consists of two simple parts: the lower part is enclosed under the tile and is disposable, and the upper part is a wedge or washer that can be reused. When using it, there is no need for any additional tools and accessories. All work is easily done by both professional tilers and unprepared people without special skills.

Removing the top of the system after hardening the glue can be done with any available materials., including hammers, tongs, and even a kick. Foreign analogues have a more complex structure. Clips are made both wedge, and similar to flexible petals. Consider the pros and cons of the domestic and foreign systems on the example of the Litolevel hovercraft produced in Russia and the Rubi Tille Level hovercraft manufactured in Spain.

SVP Litolevel (Russia)

Pros:

- low price (from 500 to 1000 rubles. in various stores for a set of 150 pcs.);

- reliability (the design is simple and durable, with delivery there is almost no chance of damage to the parts);

- ease of use (even an unprepared person will understand the instructions and be able to immediately get to work);

- the ability to continue work the next day (the area of the base of the clip is small but strong, so it can be inserted even into the already dried glue);

- eliminates the use of additional tools (during installation, you only need hands, and when dismantling the upper parts, you can use any available tools).

Minuses:

- The low quality of the products (it is easy to tear the threads if a little more effort is applied than the system requires);

- screed breaks are possible when removing the washer (when removing the rest of the system, it is necessary to strike a blow clearly at the seam line, and if you deviate and strike at an angle, it is possible to break the tie in the wrong place)

SVP Rubi Tille Level Spanish production

Pros:

- high quality of material and innovative technologies (higher quality plastics, reliable fastenings);

- the possibility of fixing tiles of different thickness (flexible petals allow you to securely fix even tiles of different thickness);

- easy disassembly (before use, nylon ties should be placed in water for 30 minutes: thisincrease their elasticity and reduce the risk of tears during installation, and they are easily removed with pliers after the glue dries);

- always torn in the intended place (qualitatively implemented construction of the weakening of the screed).

Minuses:

- high cost (from 5000 rubles for a full set of 100 pieces in various stores);

- weak retainer (when the glue hits the retainer, it ceases to hold the tile in the desired position);

- service life by 6-7 times (unlike simple wedges or washers, caps can be reused a maximum of 7 times, for more they will not be enough);

- the impossibility of long interruptions (it is almost impossible to insert screeds into dried glue due to the large area of the base of the clip, and the glue inserted the day before becomes quite brittle and tears).

Operation Tips

As a rule, laying tiles using SVP is quite simple. You must follow the instructions, and you will get a beautiful smooth laying with your own hands. Of course, instructions for different types may vary significantly.

Below is a method of using wedge systems with all the tricks and explanations:

- Prepare glue for tiles according to the instructions on the manufacturer's packaging.Do not change the proportions of the ingredients, as they are calculated as a result of many studies and years of experience.

- Apply the prepared glue on the work surface (wall or floor), evenly distributing it with a notched trowel. Also apply glue to the surface of the tile itself, which will be applied to the floor or wall.

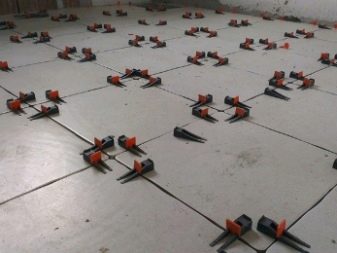

- Lay the first tile using a level or plumb if it is laid on the wall surface. For a uniform indent from corners use small plastic crosses which are on sale in any hardware store.

- Under the first tile, place the clips on the sides from which adjacent tiles will be attached to it. Accordingly, if the tile is angular, then only two adjacent ones dock with it, but if not angular, then the adjacent tiles adjoin it from all four sides. It is necessary to retreat from the edge of 0.5 - 1 cm to give space for tightening and fixing with clamps.

- Install the second tile, following the same algorithm of actions. Then insert the wedge into the clamp, push it until it stops or click and lock in this position.

- Make sure that the wedge fits tightly to the bottom surface of both tiles, only in this case the self-leveling system will work as needed.If the wedge fits on only one tile or does not fit on their surface at all, try to extend the wedge and install it again. If this action does not help, remove the tile from the glue and install a new clip.

Remember that the use of tile leveling system is advisable only if there are no large differences in the height of the surface on which the tile is being laid in the room. And also the efficiency of the system depends on the quality of the ceramics itself. The higher the quality of ceramics, the fewer defects, chips and tubercles on it, the easier it is to work with SVP.

Never attempt to level the height difference on a wall or floor surface with tile adhesive. For this alignment, use a coupler or special self-leveling mixture.

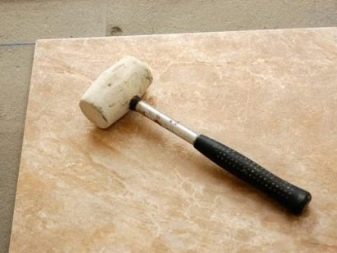

- Further placement of tiles and clips with wedges is done similarly to the first two. For a more accurate alignment, you can use a rubber hammer that knocks laid tiles on each side.

- The ideal indoor temperature for tile laying is 18-24 degrees Celsius. The closer it is to this value, the less such problems as premature setting of the glue or freezing of water in the adhesive solution.When carrying out work, have a damp cloth on hand to quickly remove traces of glue from the front surface of the tile, which can be removed after drying. Lay the tiles in a well-lit and ventilated area.

- After the glue dries out with a neat blow of a hammer or any other improvised tool, break off any part of the alignment system that protrudes above the surface. You can also use forceps, you can even with an effort to kick on the protruding part of the leg. It is very important to strike or apply force along the seam line. This eliminates the break of the clamp in an arbitrary place and the deformation of the already laid tiles.

Wedges can be reused after cleaning from debris and glue. They can be cleaned both manually and using a washing machine and powder.

- After removing all parts of the SVP from the surface of the laid tile, the joints should be rubbed with a special mortar. Apply it to the seam with a small rubber spatula and let the mixture dry. On average, this requires a day. After drying, wash the floor with a damp cloth.

As you can see, the use of SVP does not require special skills or skill. The maximum effect is achieved with minimal effort. Of course, before working you need to study the reviews about a particular system, choose the appropriate option and follow the instructions clearly. And also do not forget about safety, and then the repair will bring you not only benefit, but also pleasure.

How to make a tile alignment system (reusable) using your own hands, see below.