Starit Litokol grout: advantages and disadvantages

Epoxy Zatirka Litokol Starlike - demanded product, widely used for construction and repair. This mixture has many positive characteristics, a rich palette of colors and shades. Most of all, it is suitable for sealing joints between tiled and glass plates, as well as for facing with natural stone.

Features, Pros and Cons

The material is a mixture of epoxy-based, consisting of two components, one of which is a combination of resins, modifying additives and filler in the form of different fractions of silicon, the second is a catalyst for hardening. Working and operational properties of the material can be applied to the outer and inner lining.

The main advantages of the product are:

- low abrasion;

- resistance to freezing temperatures (up to -20 degrees);

- trowel operation is possible at high temperatures (up to +100 degrees);

- resistance to mechanical stress, in particular, to compression and bending;

- absence of defects (empty cavities and cracks) after polymerization;

- UV protection for plating;

- various colors, the ability to give a metallic effect (gold, bronze, silver);

- increased water resistance;

- resistance to acids, alkalis, fuels and lubricants, solvents.

The use of epoxy grout Litokol Starlike prevents fading and yellowing caused by direct sunlight, in addition, provides easy cleaning and washing of coatings.

Another positive quality of the mixture is dirt-repellent property. If splashes or liquids such as wine, coffee, tea, berry juices are spilled on it, the dirt is not eaten into the surface and can be quickly washed off with water. However, since stains may appear on porous and easily absorbing surfaces, small patches are first put on before sealing the seams.In such a situation it is not possible to use colors that contrast with each other.

The material when hardening is actually not subject to shrinkage, which is especially valuable if you use a tile without an edge.

Unfortunately, the material has disadvantages too. This concerns the following points:

- epoxy grout can form ugly stains on the plane of the tile;

- due to the increased elasticity, it is difficult to level the mixture after its application and this can only be done with a special sponge;

- incorrect actions can lead to an increase in the consumption of the mixture.

All these moments can be caused only by the inexperience of the master conducting the work, therefore the independent use of the material is not always important. In addition, the trowel mixture is purchased with a means for removal, so its cost can be quite high. Such a common disadvantage, as a rough surface, which occurs during the polymerization of Litokol Starlike mixtures, is deprived only of Starlike Color Crystal grout, since its composition contains small-fractional components that provide smoothness after curing, which cannot be said of other products.

Species

The manufacturing company offers several types of material, each of which has its own distinctive qualities and features.

- Starlike defender - is an antibacterial trowel mixture for ceramics. It looks like a thick consistency paste. Designed for joints from 1 to 15 mm. This is an acid-resistant two-component composition for different types of tiles, which has high resistance to UV light. This material is characterized by good adhesion, does not emit toxic fumes, provides a uniform color lining, destroys virtually all bacterial microorganisms.

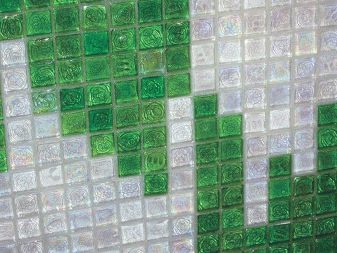

- Starlike C. 350 Crystal. The product is a colorless blend with the effect of “chameleon”, it is intended for transparent bases, glass compositions of smalt of a decorative nature. The advantage of grouting is the adoption of the color of the tile laid and the change in its own color. It is used for seams 2 mm wide and no more than 3 mm thick. It looks especially impressive on the highlighted planes.

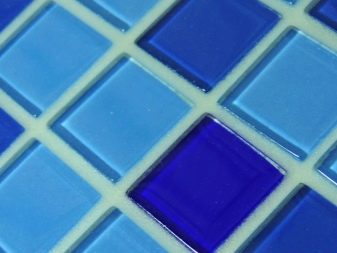

- Litochrome Starlike - the mixture is a two-component, used for external and internal coating, ideal for a bathroom, swimming pool, vertical surfaces of kitchen worktops and cabinets. It is a functional and durable material for interglacial joints.Special additives in the product make it possible to achieve an interesting optical effect. Especially the mixture is relevant for mosaic fragments and tile, is available in different colors (up to 103 shades).

- Starlike color crystal - translucent grouting composition, created for sealing seams of any kind of glass mosaic, is able to take the necessary shade within the boundaries of the overall color. The color of the stitches changes with light, which allows you to create original external effects. The mixture can be used not only for glass panels, but also for other decorative items. Due to the fine fraction, it forms a smooth surface, has zero moisture absorption, can be used in cases when high hygienic coatings are required, seams of 2 mm in size are allowed.

- Epoxystuk X90 - this product fills the joints in 3-10 mm with external and internal installation of cladding, suitable for floors and walls. It is optimal for any type of tile. The two-component composition contains epoxy resins, as well as additives of granulometric quartz, which gives it high adhesion properties. The mixture hardens quickly, and the excess paste can be easily washed off with plain water.

In addition to tile, the material is used for laying plates of natural stone.

The area of use of this product is quite large - swimming pools, window sills made of granite and marble, kitchens, bathrooms, industrial and other rooms that require special strength and durability due to aggressive environmental influences.

At the moment, the manufacturer Litokol Starlike released an innovative product - grout based on a water dispersion of polyurethane resins, which can also be used for glass mosaics with joints 1-6 mm in size. Such a composition is ready for use, does not contain aggressive and corrosive components, when filling joints with it, the mixture does not remain on the surfaces, thanks to a quartz sand filler.

When using different materials, the method of application may differ in the same way as the thickness of the seam.

Using

The preparatory work is reduced to cleaning the joints from dust, residual mortar and glue. If the laying work has been done recently, it is important to wait until the adhesive has completely dried. Clearances should be free by two thirds.

If you decide to use the material yourself, then it is advisable to carry out the preparation of the mixture and further work according to the instructions:

- the hardener is poured into the paste, while trying to clean the bottom and edges of the container with a spatula, for this purpose, steel tools are used;

- mix the solution with a construction mixer or drill;

- the mixture must be applied within one hour;

- under the tile, the composition is applied with a spatula with teeth, corresponding to the size and thickness of the tile, the fragments are stacked with considerable pressure;

- interdigital gaps are filled with a rubber spatula and they remove the excess solution;

- if it is necessary to process a large area, it is wiser to use a power brush with a rubberized nozzle;

- cleaning of excess grout is carried out quickly, while the mixture retains elasticity.

When working with Litokol Starlike grout, the temperature should be considered, the optimum amplitude is from +12 to +30 degrees, the solution should not be diluted with a solvent or water. This product is not used if the surface may come in contact with oleic acids.

Also, the manufacturer warns that both components of the grout can cause health problems, so during the work process, you must use special tools to protect the eyes, face and hands.

Reviews of this material are rather contradictory, however, in most cases they are positive: there is a perfect insulation of moisture, strength and durability of the seams. These are really high-quality products and, with skillful use, they are ideal for various rooms and types of decoration.

Below is a video on how to properly rub the seams with a Litokol Starlike grout.