Grout for Ceresit tiles: types and features of the application

Ceresit brand products are in great demand in different countries of the world, and Russia is no exception. First-class products can be easily found in any household or construction store, and the name Ceresit is already a guarantee that any product created in the company's workshops is of high quality, reliable and durable.

The brand gained fame and popularity thanks to a responsible approach to its work. It is not surprising that quality products covered a large volume of the building materials market. Among other things - the grout for Ceresit tiles, the types and features of the application of which suggest that the best product for hiding interstitial joints cannot be found.

Advantages and disadvantages

The fact that absolutely all products of TM Ceresit have excellent characteristics will be told by any professional builder and every man in the street who has dealt with repairs at least once in his life. The grout for tiles of this brand also has positive feedback.

The list of positive qualities include:

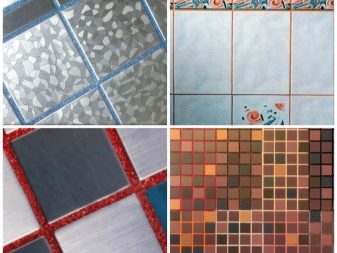

- Wide range of. The company provided an opportunity to choose each client exactly the type of grout that is needed for a specific case. On the shelves there are grout for ceramic tiles, artificial stone, mosaics and other decorative lining coatings.

- Species variety grout. It is necessary to choose the facing Ceresit not only on the basis of the material of its production, but also taking into account the peculiarities of the application. For example, Ceresit produces a moisture-resistant grout for premises with a high level of humidity (swimming pools, production facilities, and so on). Also in the range of the company there are grout, created specifically for use in conditions of low or, conversely, high temperature.

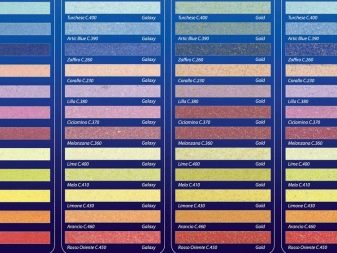

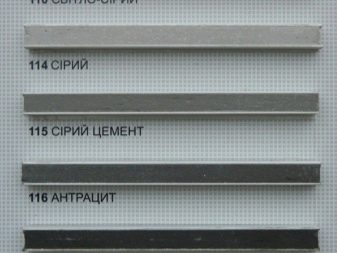

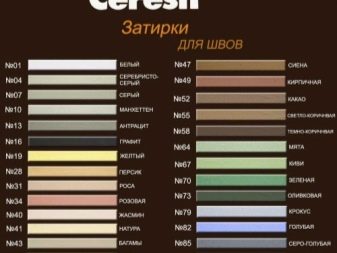

- Rich colors. It does not matter how the tile was laid surface: monophonic, multi-color, with or without a pattern.Under each type of decorative coating, you can choose the perfect color for the grout, the palette allows you to do it without much difficulty.

- Excellent wear resistance.

- Invulnerability to fungal infections.

- Excellent water repellency.

- The grout dries quickly, and after hardening it is easy to clean, dirt and all sorts of dirt do not stick to the glossy surface.

- For a long time, retains the original color and does not give in to deformations.

- It can be used both for external, and for internal works.

Ceresit grout has a large list of advantages, but this product has disadvantages:

- After complete drying, the color of the lining may change, and it does not always correspond to the color indicated on the package. For this reason, experts advise buying a grout in a store where you can always test any sample you like.

- Some types of grout are sold in paper bags. This is not always good, especially if the conditions specified by the manufacturer for storing and transporting bulk goods have not been met. Some buyers note that after opening, stones were found in the bags with lining, which indicates that the grout was in a wetted room and, having collected moisture, turned to stone.

Species

The modern building materials market is known for these types of grout from the brand Ceresit:

- CE 33 Super. Designed for inter-tile openings with a width of no more than 5 mm. Can be used on external walls. The ideal option for finishing the toilet and kitchen, is resistant to low temperatures, has excellent antibacterial and anti-fungal properties.

- CE 35 Super. Used for sealing joints between tiles, with a thickness of 4 mm to 15 mm. Possesses water-repellent properties, does not react to influence of sunshine and an atmospheric precipitation. Can be used in swimming pools. This type of grout should be chosen if you have to work with surface cladding with decorative stone, marble and other similar materials.

- CE 43 Super Strong. Material for tile joints (4-20 mm) of increased strength. It can be used in all weather conditions, because the grout has waterproof and hydrophobic properties, it is resistant to temperature extremes and exposure to sunlight. It is used for any materials lining, with the exception of marble and glazed tiles.

- CE 40 Aquastatic. Designed for the rehabilitation of joints between tiles up to 10 mm thick.Immune to temperature variations, easily tolerates both high and low values. Due to such technical characteristics it can be used in rooms with heated floors or outside. Easy to clean due to dirt and water repellency.

- CS 25. Silicone-based product designed to seal the joints between the tiled plates from 5 to 30 mm wide. The ideal solution for use in the bathroom and kitchen area. It has excellent anti-fungal properties.

- CE 79 UltraPox. Epoxy grout, can be used to close joints of any width. It is characterized by increased resistance to abrasion, used for cladding of internal and external surfaces. Withstands exposure to chemicals that are present in cleaning products.

Application

Each package of Ceresit grout contains a detailed description of what the product is made of, how to use it, so it’s easy to work with such material.

As a rule, the instruction dictates the following usage steps:

- Grouting can be done only after hardening tile adhesive. If the installation was carried out on a cement-sand mixture, this time should be at least one week.

- There should be no residues of glue, dust, grease on the edges of the tile.For better grip, you can walk on them with a damp cloth.

- If the old lining is filled, the entire contents of the seams must be removed. Grooves should be equal in depth and width.

- You can pre-test whether the pigments of the grout will not stain the surface of the tile (this sometimes happens).

Preparation of the mixture is as follows:

- To mix the dry mixture well, you need to pour water at room temperature into it. The amount of fluid is taken strictly according to the instructions, otherwise the technical characteristics of the grout will deteriorate. The end result should not be a liquid consistency, but a solution, like thick cream, without lumps.

- If you need a small amount of the mixture, you can make it manually, but if you need large volumes, it is more convenient to mix all the original components with a drill with a nozzle or a construction mixer.

- After that, you need to wait 5 minutes, let the mixture "rest" and mix it again. To use the resulting composition, the manufacturer gives 60 minutes of time, after which the grout will begin to harden and become lumps.

Grouting

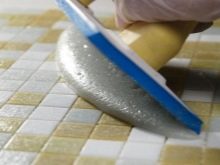

For work with facing solution for seams the rubber spatula is best suited. Such a convenient fixture applies grouting to the tile with cross-shaped movements. If a surplus is formed, it should be collected and reapplied elsewhere. To mix well, you need to leave it “alone” for 10 minutes. Next, the surface of the tile must be wiped with a damp sponge. Too much wetting rags are not worth it, otherwise the seams may turn out to be heterogeneous. For example, the white mixture will turn gray in places, and the dark brown one, on the contrary, will brighten. After the mixture has completely hardened (approximately one day), the tile must be rubbed again with a rag. The optimum temperature at which it is recommended to perform troweling works is from +5 to + 30 ° C, with the exception of silicone grouting, it can be applied at a temperature of +40.

Working with silicone grout includes the following actions:

- All surfaces adjacent to the seam must be covered with masking tape.

- Insert the polymeric rope into the grooves of the seams.

- The cone on the barrel with elastic lining should be cut so that its diameter coincides with the width of the seam.

- Then you need to evenly fill all the seams.

- After 10-15 minutes you need to moisten the sealant with soap and water and smooth out with a wet spatula, removing all unnecessary. After these manipulations, you can remove the masking tape.

- The thickness of the grout should be half the width of the inter-tile grooves.

- To remove fresh silicone grout, you need to use alcohol or acetone, and if it hardened, only a mechanical method will help.

Epoxy coating

Epoxy grout consists of two components that are in the same package. To prepare the mixture, you need to pour the hardener into the epoxy resin and mix everything thoroughly with a mixer. The mixture can be operated for 90 minutes. When filling the seams there should not be any gaps; the grooves should be completely filled with the prepared mixture. For these purposes, a special spatula for epoxy linings is suitable. This tool can be removed and unnecessary inclusions. You can also use the mounting gun. In this case, the mixture is applied in the same manner as the silicone grout.

Application of hydrophobic antifungal grout

The special compound for facing seams is applied as follows:

- At the first stage of operation, the seams are cleaned of all contamination, in difficult cases it is allowed to apply the fungicide preparation.

- The trowel should be evenly distributed in the grooves.

- Adjoining surfaces are pre-closed with masking tape.

- Spray with impregnation must be well shaken and filled in the joints with a special brush.

- After it is necessary to sustain a pause from 5 to 15 minutes and remove all excess impregnation with a damp sponge.

- To remove fresh dirt, it is enough to wipe them with plain water; only the solvent can remove the dried ones.

How to apply grout, see the following video.