Planes for drywall: types and features of use

Recently, the most popular building material used for interior decoration, has become drywall. This is a fairly simple material, but for its reliable and high-quality installation requires the presence of certain tools.

Planes for drywall are among those tools that are not always needed, but their absence at certain times can cause work to stop. Therefore, it is better to always keep these devices at hand and know their types and features of use.

Purpose

Gypsum plasterboards (gypsum plasterboard) are a rather fragile material, their edge part often crumbles or breaks. Therefore, despite the apparent power and strength, these products need to be treated with care.For the most even and high-quality joining during installation, drywall must be properly processed. It is for these purposes that the planer is used - one of the varieties of the rasp.

In addition, this device is necessary so that at the end of the laying work, the seams during surface finishing can be puttied without problems. A chamfer is removed by a plane on the edges of the drywall, as a result of which a recess is formed, which is filled with a putty compound, and in the future at the seams is eliminated the formation of cracks and bumps.

Planer Requirements

For the most efficient and high-quality installation process, it is necessary to know a number of requirements for a planer.

- The length of the working part of the tool. An important parameter that determines the speed of installation work. The length of the handle for different models can vary between 14 - 25 cm. Most of the working part is not always an indicator of the best results. The tool must, first of all, be easy to operate and conform to those sizes that are most acceptable to the master.

- The width of the cutting blade tool. It can be 1.5 - 4.2 cm.This parameter is completely dependent on the thickness of the building material.

- Blade material. This part of the device can be made of different types of steel. Blades made of tool steel are considered to be of high quality. They are much stronger in use and are guaranteed to ensure the formation of smooth edges.

- Body material. They can be plastic or metal. Products from various alloys will last much longer.

Currently, a large number of planes of various manufacturers are represented on the building materials market. For example, FIT 15025 is an inexpensive but easy-to-use tool; STAYER PROFI 18855 - a plane with a working part of high-quality steel; The KANTENHOBEL plane from Knauf is the most expensive and reliable tool; "Leader" is a domestic manufacturer offering quality and inexpensive tools.

Species

When working with gypsum boards, two types of planers are used: roughing and edging.

Peeling Planer is a tool that is used to level the edges of a sheet of drywall. Thanks to him, you can get a perfectly smooth edge, which simplifies the installation of sheets of drywall and the process of finishing the coating.

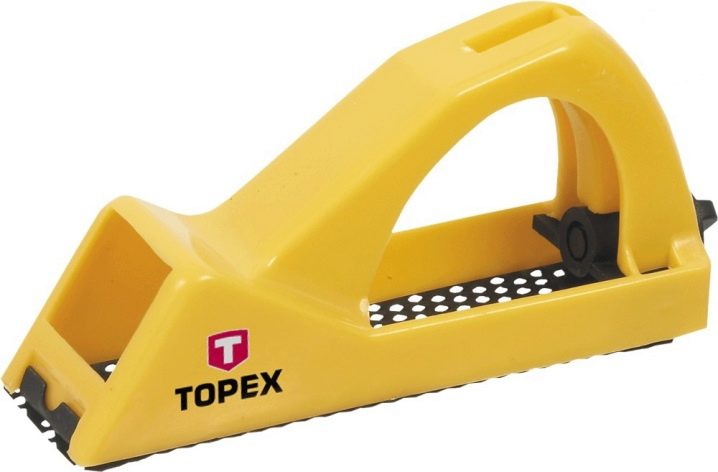

The rough planer is different in appearance: its working surface is located on the lower part of the tool and resembles a kind of grater, which has many pointed holes, and not blades, as in the edging model.

The structure of the grinding planer:

- housing;

- base - grater;

- pens.

In using this type of tool is simple: holding the sheet, slowly, remove all roughness and irregularities. It should be remembered that the plaster is not cramped like wood, but is carefully worn down.

Edging Planer used for leveling the edge of drywall, as well as chamfering, the bevel angle of which, as a rule, is equal to 45 degrees. Thus, an angular cut is made. The blades of this tool are in the form of a trapezoid, they can be shifted, which allows to achieve the required depth of processing.

Edging planer structure:

- housing;

- blade fixing screw;

- steel blades located on the side of the tool.

Edged plane with a blade of quality steel can also be used in the processing of soft wood.

In addition to the factory tools, you can make a plane with your own hands. It is necessary to have:

- metallic profile;

- small wooden beam;

- scissors for use on metal;

- screws and screwdriver.

- The profile is measured. It should be 2 times the required length of the working part of the produced tool.

- The profile is incised in the middle with scissors, then bent, but not folded.

- On one side of the screwdriver is a lot of through holes, attaching the profile to a wooden beam. The more they are done, the better will be the performance characteristics of a homemade peeling planer.

- Then the profile is folded in half along the notches. Two parts of the profile are fastened on the sides with self-tapping screws, and sharp corners, if any, are bent. All irregularities are trimmed.

- For convenience, the profile can be wound with electrical tape.

How to use

There are several rules for the use of edging planes for processing drywall, with which you need to read:

- when processing the sheet of drywall should stand edge to the master;

- on the edge of the traverse, chamfer;

- a recess 5–11 mm wide appears at the interface of the two sheets;

- sheets of plasterboard are required to be attached as tightly as possible to each other;

- at the junction of the sheets is glued serpyanka, which acts as a seal;

- a layer of plasterboard putty is applied to the serpyanka tape.

- after the putty has dried at the joints, the entire surface of the drywall is covered with plaster.

When moving the tool, lightly press on the rear handle. The front serves as a guide and an object for adjusting the thickness of the layer to be removed. The device tool allows you to change blades as the cutting part is worn. Difficulties with the acquisition of new such blades do not arise, their cost is small. At observance of the scheme of work with the edging tool joints turn out strong and imperceptible.

With the peeling plane, the process of GCR processing is somewhat different:

- a sheet of drywall set edge up;

- the plane is placed on the cut sheet;

- tool pass through the edge of drywall.

To ensure high-quality processing of the edge of the sheet, the plane should be pressed to the surface slightly. Sometimes, in order to achieve optimum results, it is necessary to walk along the edge of the surface several times.

How to choose

When choosing a planer should pay attention to the following characteristics:

- The blade in the edge of the plane should be made of quality steel, best tool. It should change without difficulty, and such details could be easily acquired.

- The optimal grater width in the peeling planer is no more than 3 cm, and the length is 25 cm.

- In the edging tool, the handle must be strong and comfortable, and the plane must be comfortable to lie in your hand so as not to cause inconvenience in the process. To check this characteristic of the handle, the plane is taken in hand and imitate the movements of material processing.

- For long-term operation more suitable products with a metal casing. The handle can be plastic, although very often after the purchase, plastic handles are independently replaced with wooden ones.

- An important criterion when buying this tool is its price. The price range is wide depending on the manufacturer and the quality of the materials used. You should not choose a tool that is too cheap: the quality of steel in it leaves much to be desired. The level of processing the edge of such a tool will be below average.

How to make a drywall plane with your own hands, see below in the video.