Sizes of porcelain tile: choices

Porcelain stoneware is a fashionable and stylish material that does not cease to amaze designers with the possibilities of interior decoration. The sizes of tiles and sheets vary from a few tens of centimeters to a meter or more, for the modern interiors both the densest and standard samples of this material and the ultrathin sheets used for total cladding are offered.

Special features

Porcelain tile is called a reliable finishing material, the plates of which are externally similar to tile, but have a high strength factor.

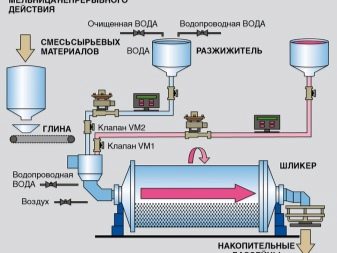

Elite material for interior decoration was given this name because the basis for the manufacturing process is nothing but natural granite chips.Then the crumb in the wet state is mixed and carefully pressed, covering the plates with a special composition. Masters use a complex technology that has been known since the days of porcelain production - firing after double or more processing to the flattest state.

Initially, the chemists who took up the business, the manufacturers of tiles from a small town in Italy, called their brainchild “gres porchelanatto”, emphasizing with the second word that the ceramic-granite composition reminds them of hard porchelanatto — porcelain.

The experiments of Italian craftsmen were caused by the fact that it became necessary to create a unique material with extraordinary characteristics and rare reliability in order to further improve the art of decoration and decoration.

Porcelain tile was developed as a material capable of withstanding the effects of an aggressive environment - chemicals and physical natural stimuli. This composition is resistant to pressure drops and temperature fluctuations, in addition, it can be repeatedly subjected to freezing and defrosting.

Porcelain tile does not melt, is not afraid of open fire and does not fade under the rays of the sun, is not subject to cracking and can even be ductile.

Product Parameters

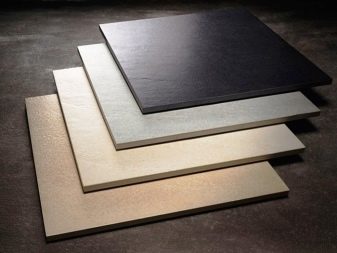

The first samples of porcelain tiles were produced small - with sides of 5x 10 cm, but gradually the range has expanded significantly. To date, such sizes of tiles as 30x30 and 40x40, 30x60 are constantly present and in demand on the market. They decorate mainly walls and work areas in bathrooms, corridors and kitchen rooms.

Recently, floor coverings are often made of an elongated shape of plates - 15 x 60 and 20 x 60 cm, imitating parquet of various types of wood. The greater the load on the floor, the smaller the tile used for finishing.

Offered to the attention of buyers and samples of large format, who came to the interior of industrial systems - 1200 x 300 and 1200 x 600 mm. They were originally in the construction of houses trimmed facades with ventilation gaps.

For small-sized kitchens and bathrooms, an increase in the linear dimensions of the plates means visual expansion of the space. This factor is taken into account by designers in modern projects for small-sized housing.

The most modern sheet finishing material is produced in extra large sizes - up to 3000 x 1000 mm. This allows you to cover completely with one sheet a rack in a bar, a shower zone in a bathroom, and in the dining room and in the kitchen a sink, an apron, and any furniture or worktop. Facing such laminate has made a revolution in the field of repair and decoration.

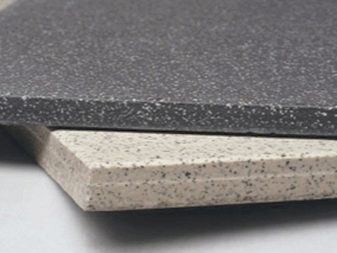

Obvious is the fact that other types of stoneware, superior in thickness, are the most durable. However, not all thick tiles are suitable for residential premises. When facing, it is necessary to correct sufficient strength and density of the material. Moreover, the cost often depends on the thickness of the sheet.

Standard types of industrial production demonstrate excellent performance in long-term operation in homes and apartments.

Government regulations allow the use of all types of porcelain, setting standards for thickness from 7 to 12 mm for residential buildings.

The thickness of sheets or plates of porcelain stoneware can be different - from 3-5 mm to the densest, reaching 30 mm in the section. Usually put material on the floor from 10-11 mm.

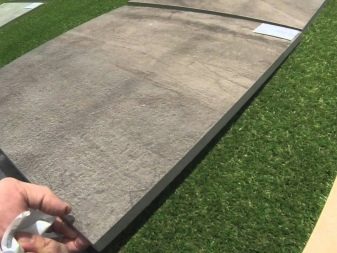

If the thickness of porcelain tiles is not less than 18-20 mm, the use of the material gives excellent results, including in the external environment, for roofing and terraces, while the granite can be laid on the ground and grass, stones and other surfaces.

Standards and different manufacturers

Initially, dense porcelain stoneware was produced by manufacturers for use at industrial facilities - they covered the floors in technical premises. Despite having many excellent properties, the material is a little aesthetically inferior to beautiful tile.

Then the situation quickly began to change with the advent of high-quality equipment and new technologies. The European construction market has offered to use curlite - the thinnest facing material based on ceramic granite.

Not so long ago, granite cladding consisting of a material from 3 to 6 mm thick, developed about 8 years ago in European countries, became available to consumers in Russia. She presented to consumers Russian Vincon company. This is the official manufacturer of sheets with thickness up to 20 mm.

Granite tiles are produced in the form of linear and complex geometric shapes, with varying degrees of surface roughness. They put pictures on it and use textures, change the dimensions of the sheet in a big way and reduce the thickness.

The work on decorating the premises with stone and similar finishing compounds requires a serious investment of time and effort.

In order to begin installation, you must first remove the old layer of ceramic coating, then prepare the surface, only then you can begin to lay a new coating.

Therefore, in order to save money, nowadays thin ceramic granite is often used, which can be put on top of the old layer without removing it.

In order to obtain a compact composition, a new technology was invented, similar to that used in metal rolling. A dry mixture in the form of a powder from a crumb under a huge pressure of 15-20 thousand tons is pressed into sheets, and then kilned in a kiln. The pressure removes all the air from the powder. The finished sheets are completely flat, perfectly revet any surface, bend and cut straight on the spot with an ordinary glass cutter.. Steps can be finished in a comfortable seamless way.

The weight of a square meter of thin porcelain stoneware does not exceed 14 kg, and the standard sizes of sheets are 333x300, as well as 150x100 or 150x50 cm. The weight of a sheet with dimensions of 3 per 1 m will be equal to 21 kg. To enhance interaction with glue and perfect adhesion to the surface, ultrathin stoneware can be supplemented with fiberglass.

As for the performance characteristics of the composition, they are no different from those of a more dense ceramic granite. Thin material is able to provide reliable protection from moisture in the interior, it does not crack and does not burn, retains an attractive appearance for a long time. For cladding windowsills, doors and partitions in houses, a plastic sheet of reduced thickness fits perfectly.

Replaced unexpectedly for builders such porcelain and other materials, for example, when finishing the walls of plaster unstable to moisture and bold plastic, which is prone to rapid fading. Therefore, the production of ceramic granite sheets is established in many countries of Europe and the world, the scope of application of modern samples is expanding.

In Moscow, several metro stations are decorated using porcelain stoneware. Stylish material covers columns and walls, as well as ceilings in tunnels.

Lining requires vacuum equipment, quick sticking to the surface and special skills in work, because the material bends easily.

In order for porcelain tiles with a thickness of 4-5 mm to be properly placed on the surface of walls or the floor, the plane must be perfectly flat.

What to consider when choosing?

The range of the proposed tiles is so wide that it is easy for the buyer to get confused when choosing the right grade. The market is replete with all kinds of decorative tiles, and fashionable granite. To understand what material is needed in a particular case, it is important to take into account its characteristic properties.

The difference of porcelain stoneware from ordinary tiles consists primarily in strength and ability to withstand truly enormous loads. The hardness of porcelain stoneware is compared with quartz and other crystalline structures.

For this reason, to cover the floor, builders advise to buy plates made of porcelain stoneware.

In addition, matte material with any relief does not abrade and does not crack, even after prolonged use. Ceramic granite of standard thickness has been serving for decades without needing to be replaced..

Both materials, both tile and porcelain, appeared as finishing coatings more than a hundred years ago, having established themselves as durable materials that do not absorb moisture. But external facades and walls, on which snow falls in large quantities and along which water flows, need to be protected from destruction. Therefore, the conclusion is obvious - again, porcelain stoneware will be applied.

An ordinary tile with granite composition is incompatible with its ability to withstand changes in temperature, frost and extreme heat.

The only advantage of decorative tiles can be considered a variety of applied patterns and a wide color palette. Gloss, relief and complexity of texture, intricate patterns and unusual colors are among the strengths that are taken into account when choosing a colorful tile. If we talk about the relative cost, it depends on the quality of a particular type of product.

In addition, the tile weighs significantly less, which reduces the load on the floor. For comparison, thick porcelain has a specific weight of more than 2400 kg / m3. The specific weight of a specific sample is calculated as the product of density and volume. The volume, in turn, is the product of three parameters - thickness, length and width of the plate.

Porcelain tile is divided into the following types:

- Technical. A material with a rough surface at low cost. It receives minimal processing, almost does not grind, but is absolutely resistant to any aggressive media.It serves well in workshops and warehouses, in places where workflow is constantly going on and people are actively moving.

- Matt. The composition is processed with a grinding wheel with a large grain. Such material also does not have a high price, while meeting the requirements of a solid residential building or apartment. The decorated room can be shown to the guests, this coating looks great.

- Having a certain structure. This type of porcelain stoneware should not be less than 10 mm in density, otherwise embossed depressions will lead to thinning of the tile layer. Often structured look is painted in complex colors under the tree and leather, fabric and metal, decorating with gold leaf and etching patterns. It is in high demand among consumers due to its not too high price with an impressive variety of samples.

- Polished and glazed. These are the most elite types, which outwardly immediately give the impression of luxury and chic. The only disadvantage of polishing is that it cannot be used on the open surfaces of swimming pools and terraces, subjected to constant moisture, although the cost of the material is the most expensive.Glazed porcelain is the composition, the brightest and most colorful of all. When firing, coloring chemicals are additionally introduced, giving the plates different shades and aesthetic design.

For interior decoration in stylish interiors, this tile is the most preferred type. Treats expensive and high-quality coverings.

Overall dimensions are determined with the help of devices, and how smooth the surface of the tile can be checked by folding one plate of two different packages with the front surface to each other. Clearances and reels should be absent, and the perimeter should completely coincide.. In this case, you can purchase material to decorate your home. The main thing is to choose quality material. Under all conditions, a difference of 5 mm in thickness will not be an obstacle.

For roofing and laying the track in the country still need the most dense stoneware - about 20 mm in thickness.

Experts believe that porcelain is a material that clearly demonstrates that there is an optimal balance between price and quality, and its durability is another additional advantage.Therefore, from all points of view, it is advisable to choose this material for finishing walls and facades, floors and other surfaces in interiors.

Examples in the interior

The flooring in the living room is of brown granite under the parquet. Large-format plates, completely imitate wood. The sofa, walls and curtains are decorated in soft pink colors, harmoniously combined with the color of the floor.

Facing the walls and floor of a large format plates of thin porcelain. Square long table covered with the same material. The sheets are light polished, with a characteristic marbled pattern.

Kitchen in black and white, decorated with stoneware tiles and mosaics. A mirror floor of square slabs in asphalt tones with white lines, a working area of ceramic mosaic of the same tone. Black and white furniture made of durable plastic, with silver metal legs. A chandelier with a semicircular red shade, red appliances on the table and a picture on the wall in a white-orange-red tint complement the design.

Facing the staircase brown-red granite. Walls and floors cover large sheets of thicker material.

Modern bathroom, decorated with large format granite.Drawing on sheets of gray-white, marble. Oblique lines-strokes on the surface of the material serve as a visual dominant and complement the rectangular proportions of the bath, table and mirror. The matte surface is unusually combined with clear glass that separates the shower cabin from the rest of the room.

For information on how to choose a stoneware tile, see the next video.