Porcelain stoneware drills: features and varieties

Porcelain tile is a versatile building material, which is produced by pressing granite chips under high pressure. This allows you to get a structure that resembles natural stone: such products are very popular among consumers. Processing such material is not always possible with a simple tool. For these purposes, drill bits are used for porcelain stoneware, about the features and varieties of which can be found on specialized sites. Such products are highly durable and perfectly process solid material.

Special features

Porcelain tile is widely used in modern construction.It is used as a finishing material, as well as in the arrangement of ventilation facades.

There are several distinctive features of porcelain:

- High strength. The material is able to withstand significant loads, as well as temperature drops. This allows it to be used inside and outside buildings.

- Abrasion resistance. This is achieved thanks to the monolithic structure, where all components are firmly linked.

- Uniformity and uniqueness of design. The surface of a tile can imitate various structures and materials.

- Minimal water absorption and no slip.

Particular attention should be paid to the strength of the material, since it affects the quality of processing. If we talk about cutting, there are several options here, since this process is a little easier to organize. When it is necessary to drill a hole, this can be done only with a drill on porcelain stoneware.

However, it should be understood that not all tools are able to process such dense material.

Many drills simply do not withstand the load, which allows them to be used only a few times.

Kinds

Processing of porcelain stoneware is a complex process that is not always possible to carry out with a conventional concrete drill. This is due to the monolithic structure of the material, which is not destroyed by such an impact.

Today, to work with porcelain stoneware, you can use several types of drills:

- Feathers. Only tools that are equipped with a pointed or diamond tip are suitable. However, they are not designed to work with such materials, so after creating several holes, you simply throw away the product.

- Ring drills. Outwardly, they resemble small cylinders with diamond chips. With these tools you can make a lot of holes (more than 100-150 pieces).

The working surface of the tubular drill has no slots and is a solid circle. This does not allow to qualitatively remove dust, which is formed during drilling. At the same time, there is also a strong pressure on the surface of the tile, which can lead to its cracking. For this reason, it is necessary to work with tubular drills at low speeds, periodically removing the tool for cleaning from dust.

- Diamond crowns. This is a universal tool that is most often used to work with concrete. It can also process porcelain.

The disadvantage of products with electroplated coating is the minimum service life. Structures fail after 5-6 holes. This disadvantage is compensated by the low cost, which allows you to stock products in the right quantity. When working with diamond crowns, you should not worry too much about excessive pressure, as it decreases due to special slots at the tool ends.

Processing of porcelain stoneware is also possible with the help of ordinary drills, which have pozavitovoy solder However, it should be understood that they are not intended for such materials, therefore their lifespan will also be limited to several drills.

After that, the tool can not be used as intended.

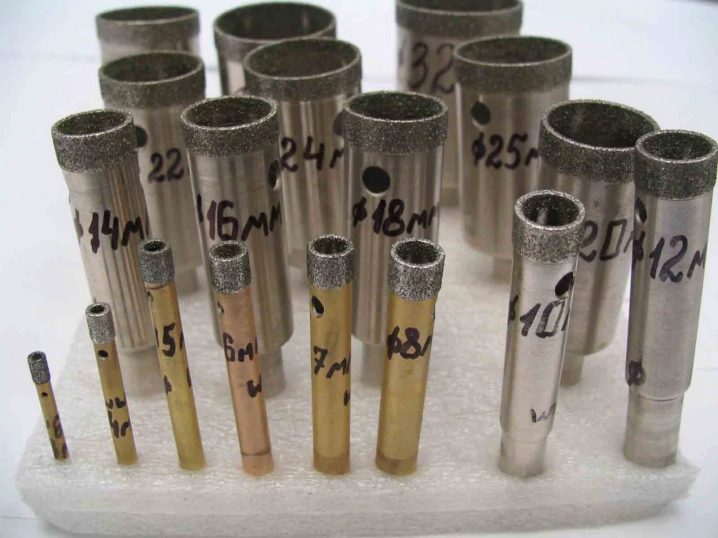

Dimensions

One of the criteria when choosing a drill for porcelain stoneware is the diameter of its cutting area.

Today the market offers many sizes of such tools, among which there are several popular options:

- 6 mm;

- 8 mm;

- 10 mm;

- 12 mm.

These types are the most sought after.If you analyze diamond crowns - the diameter of the drill varies from 8 to 150 mm (depending on the manufacturer). The most popular are cylinders 20-100 mm, which are intended for the formation of holes for water pipes in apartments or private houses.

Please note that the pitch of each drill is in most cases standard. However, there are models in which the diameter is measured not in millimeters, but in inches. This fact is important to consider if the dimensions of the hole must be accurate.

Which one to choose?

The variety of products with which you can drill porcelain tiles, not so great. This eliminates problems with choice.

The following options are possible:

- Small holes. If you need to make a hole under the dowel in the wall, then it is better to use tubular or classic diamond drills. They are produced with a small diameter, which allows you to create the necessary holes. Please note that the first type of tool is intended for dry drilling, whereas the work of the drill must be accompanied by the supply of coolant.

- Large bore holes. Only diamond crowns will help you here.They can drill porcelain both on the floor and on the wall. A feature of this tool is the large diameter of the crown, allowing you to get a hole under the socket or water pipe.

Drilling can occur both in the presence of coolant and without it. It is only important to accurately mark the tile. If you have no experience, then experts recommend using crowns with a guide middle.

It allows you to accurately set the location of the tool, and also minimizes the probability of the crown slipping during operation.

The choice of the type of drill depends not only on its size, but also on the service life. If you need to make a few holes, then you can give preference to diamond crowns or drills. You can work with them relatively easily and quickly. When quantity is important, one cannot do without tubular models, but their use can significantly slow down the process, which is not always relevant at the construction site.

Manufacturers Overview

The quality of almost any instrument depends on the manufacturer and brand. Today, there are many modifications of drills for porcelain stoneware on the market, among which there are products of such companies:

- Bosch. The company's products is one of the highest quality in the world market.The manufacturer produces several types of drills that do an excellent job with the tasks. Among the whole variety one should single out tubular models, which are distinguished by their ability to cool themselves. To this end, olive oil is introduced into the structure of the material, which is released when it is heated and cools the drill.

- "Monolith". The products of the domestic company are of high quality. Products are obtained using the diffuse method, which provides high adhesion of metal and diamond grit. The use of this technology allows to increase the resistance to destruction by several times. The diameter of the drill can reach 70 mm.

- Hawera. The company has been producing drills for a long time. Products are characterized by high durability and high quality. Drills are supplemented with self-cooling. The products of this brand are distinguished by an optimal ratio of price and technical parameters.

Several more manufacturers can be found on the market, but it should be understood that the quality of their materials depends only on the scope of application.

When buying, pay attention to customer reviews, it will assess the technical parameters of drills.

Tips and tricks

Working with diamond drills and porcelain tiles requires adherence to various rules:

- Drill the holes under the toilet or outlet preferably with a drill. If you have a hammer drill, be sure to turn off the hammer mechanism. If this is not done, the tile will crack quickly.

- Use the tool that allows you to change speed. This is important when you operate annular drills. You can work with them only at low speeds.

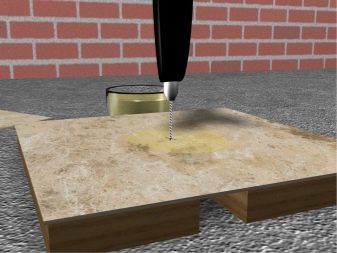

- In order not to damage the tile, it is advisable to put a sheet of plywood under it. Drilling at the same time should be carried out strictly perpendicular to the treated surface. Experts recommend the use of special frames-clamps that can hold a drill or other tool in the desired position.

- Tile drilling with a drill from the ends should not be performed, as this can lead to cracks. If you need to make a half-hole on the edge, then it is advisable to use diamond crowns.

- Porcelain tiles are drilled only from the front. If you perform the operation on the contrary, there will be a risk of small chips appearing on the decorative surface. They will affect the appearance of the product after installation.

- Cooling.To keep the tool for a long time, when working with diamond crowns should be watered with water. The professional tool for drilling is equipped with special channels through which automatic fluid supply is possible.

If you are using a conventional drill, you should take care of manual cooling. To do this, you can use an ordinary plastic bottle with water, in the lid of which there are several small holes. The feed is performed by spraying fluid over the surface of the drill.

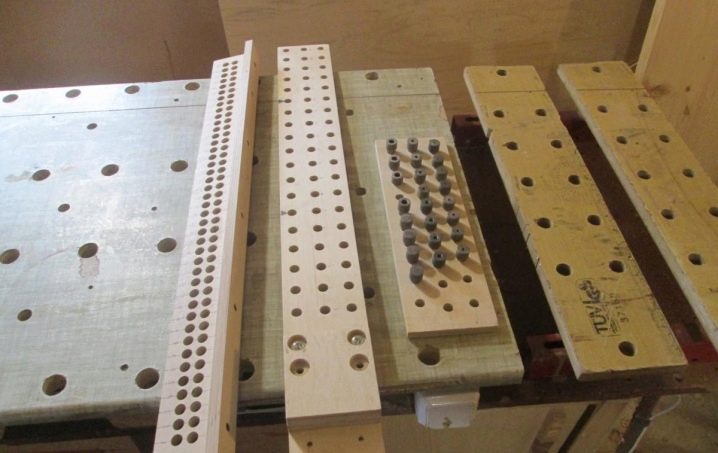

- To simplify the work when forming large holes, you should use templates. They are small pieces of wood in which several holes of different diameters are made. During the work with a tile these products are imposed over porcelain tile. This allows you to align the drill, as well as get the desired hole size.

- It is desirable to drill a tile only on 2/3 of its thickness. After that you just need to use a small metal pin. This will increase the service life of the drill.

Drilling porcelain stoneware is a complicated procedure that requires the selection of a quality tool. Give preference to drills only well-known manufacturers who have passed the test of time and are able to work without compromising quality as long as possible.

To learn how to drill porcelain, see the next video.