3D MDF panels: modern solutions for the interior

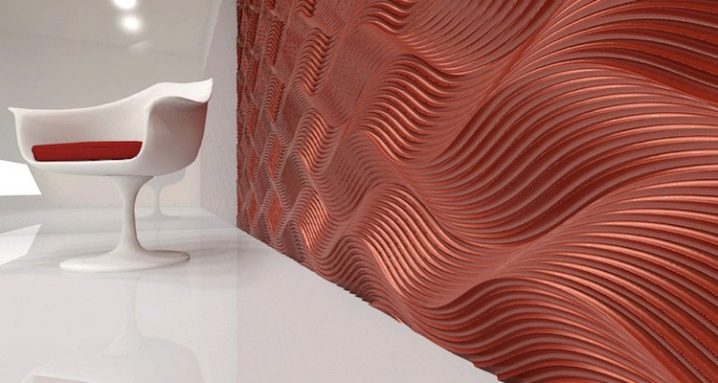

3d MDF panels are in great demand today and are considered the most interesting solutions for finishing. These products are relatively young, but due to their excellent performance, they quickly became popular all over the world. Such panels represent a huge number of opportunities to transform the interior.

Specifications

MDF wall boards attract with their cost, which is much lower than the price of panels made of real wood, but the quality they do not differ at all. Every year, the production of such casings is improved, due to which they become much more stable before moisture and temperature changes. All this is possible because of the special coating of the polymer film, which increases the life of the material.

The lifespan of 3D panels is unlimited. Due to its resistance to mechanical damage, the panels can serve up to one hundred years.

They are very easy to mount. Install them can anyone who does not have special knowledge to repair. Products are glued to the wall with liquid nails.

The composition of such products are environmentally friendly, natural materials.that do not carry any harm to health. Also, panels can provide sound insulation, which is a big plus for panel houses.

What is MDF material

MDF cladding materials are produced on the basis of wood fibers and organic compounds, which serve as binding components that promote solidification in the process of pressing. After the initial stage of creation, the tiles are machined.

MDF panels are characterized by their smoothness and uniformity of the surface due to which they are an ideal material for the following:

- molding;

- coloring;

- pasting (for example, glossy film).

These plates are very often used in the production of a large number of facade and structural elements.They are in demand in the furniture industry, they are used for the manufacture of decorative elements of the interior (tiles for ceilings, panels and plinths) and in the production of structural elements.

The most attractive products made from this material are considered 3d plates. Their high demand is due to high quality, beautiful and elegant design, as well as simple installation.

Another significant advantage is resistance to water, so that they can be safely placed in the bathroom.

These panels can be easily trimmed to any desired size or you can place an order for plates according to your parameters.

When mounting these panels can be connected so that their joints could not be seen. MDF can be painted in any color. It is possible to order the color you want.

Due to the natural materials in its composition, these panels allow the walls to breathe. This material is an excellent thermal and acoustic insulator.

Advantages and disadvantages

MDF paneling is a versatile finishing material with which even an element of luxury can be added to a simple home design.

They have many advantages, because of which the choice of many consumers falls on these panels.

3D panel features

Before finishing the wall it is not at all necessary to prepare, a rough finish is enough. With all this, the surface that you are going to make out may have irregularities: the panels will ideally cover all defects. Due to the possibility of combining panels with other materials, a unique and original design is created. Leather, gypsum, natural wood veneer, PVC film can be used as a topcoat.

Facing provides a heat insulating effect. Attaching it to the crate, you can take the space between the wall and the facade with insulation.

Due to its volume - from 18 to 30 mm, such a finish can visually change the size of the room, for example, make a small room large.

It is worth noting the disadvantages of this material:

- most 3D plates do not tolerate moisture and aggressive external influences;

- the cost of these panels is quite high;

- in spite of their stability, it is not recommended that they get sunlight;

- require constant care, as in the convex places dust accumulates very quickly.

Kinds

There are several types of 3D panels, now we will consider them.

On gypsum fiber

Material for wall decoration from the inside is decorated with plaster patterns of any shape. There are a huge number of styles of data panels. When installing you can paint them with acrylic paints that will look very nice.

Of the minuses of this material it is worth noting that this material is very weak and fragile.

After mounting, all joints should be filled with a special putty compound. Such finishing is not recommended for rooms with high humidity. They are not suitable for furniture.

Woody

The most expensive type of plating. But their quality and unusual design justifies the cost. Products are pretty weighty, fit perfectly into the classic interior. The material itself is not very thick, it must be applied in ten to twenty layers to get the desired result. Plates are a complete copy of real wood.

Bamboo

The most cost-effective panels produced on the basis of carefully chopped shoots of the plant.This finishing material is distinguished by its strength and lightness.

PVC

The basis for the plates are polymers. By their characteristics, they are very similar to their counterparts from aluminum; they give the possibility of creating an unusual effect. There is also a choice of tint combinations. Plastic panels are very resistant to temperature changes, durable, easy to clean. Products differ from the rest of their plasticity and weightlessness, allow you to create the most complex patterns.

Fluorescent paint panels

This option is relatively young. Due to the fluorescent paint, at night this skin will glow beautifully. The plates are very expensive, but if you want to make your interior unusual, they are the perfect solution.

Application

3D panels are often used:

- To create partitions of different parts of the room.

- To create an original and unusual look of the surface. Some people trim these panels even cabinets, which makes the interior a luxury and modernity.

- Very often, this finishing material is used to finish the areas where there is a fireplace.

- In the living room to give chic and sophistication.

Such plates can be used wherever you please. Usually they are used in places that you want to highlight. It all depends on the consumer’s imagination.

Production

FP skins are made of various materials, but gypsum and MDF are most popular.

The technology on which the plates are created is completely analogous to the production of frame facades for kitchen furniture. The sheet is taken as a basis 280x120 cm and under the influence of a milling machine the panel is processed and ground. Then it is covered with a special varnish that protects the surface. Thus, 3D drawing turns out - the volume panel turns out. With the help of modern equipment products are made of high quality.

Often used in the production of decorative plaster. Decorative elements are added to it and, ultimately, the most stable and complete panel is obtained.

MDF panels are covered with veneer and slightly coated with a bump, resulting in a perfect shade. Some companies produce panels with the help of experienced craftsmen who modify the projects manually.

The plate thickness can reach three centimeters, but at the request of the customer, its size can be changed.

3D claddings are increasingly gaining popularity in the finishing of walls inside buildings. They create a truly unusual, modern and sophisticated style in the interior of the home. If you are bored with classic design, then you can diversify it with such panels by choosing your own option from a sufficiently large range or place an order.

Installation

The installation of the panels depends on the design idea and the quality of the wall - how smooth it is.

There are three options:

- On the frame - can be installed on walls made of plasterboard, concrete or brick foundations of any curvature, on average “eats” up to 35 mm.

- On mounting plates - avoids the gap between the wall and the panel. The surface must be pre-aligned. During installation, additional first and last plates are required.

- Glue is a convenient solution for fixing non-solid sheets, and individual plates of small sizes no more than 800x800 mm.

Beautiful examples

- Bamboo versions of wall panels look very stylish. In addition, it is an environmentally friendly finishing material.

- Option from MDF will cost you quite inexpensive. In today's market a wide range of such products.

- Gypsum panels fit into many interior styles. They are considered very reliable.

Read more about 3D MDF panels in the video below.