MDF panels: subtleties of choice and installation

Modern technologies are rapidly expanding the range of building finishing materials. Manufacturers offer a huge variety of types of decorative interior decoration - from cheap plastic to expensive varieties of natural wood or stone. The construction industry appreciated the beautiful, with a wide palette of textures material from the middle price segment with high performance qualities - MDF panels. Consider what is the advantageous difference between MDF and plastic, from which these plates are produced, what types they are and how to install them. We will get acquainted with various decorative options for MDF boards and wall and ceiling finishing options from laminated and perforated decorative panels.

Special features

MDF is a small dispersion fraction of wood shavings, pressed under high pressure without the use of the adhesive component in the form of phenol and formaldehyde. Wood waste is crushed. The small wood fraction undergoes heat treatment, as a result of which an adhesive fragment is released - paraffin or lignin. The glue fragment glues the mass, and pressing gives the necessary strength.

It is worth noting the environmental friendliness of MDF - the board contains only natural, safe to use substances: wood and carbide resins, which are not harmful to humans.

The process of industrial production of MDF is the same as the production technology of chipboard. The difference is that the particle board includes formaldehyde resins that are harmful to human health. For ease of use in the construction industry, chipboard is inferior in reliability of fastening them with screws. After some time of use, loosening of the holes and loss of screws are possible, it is impossible to repair this chip, you have to use another place for fixings. MDF plates have a more dense structure that allows you to securely hold the fasteners.

MDF board has such a property as durability, it is well resistant to mold and rot. This material shows sufficient water resistance, which makes it possible to use it even in rooms with high humidity, for example, in the kitchen. Plates of finely dispersed fractions of wood shavings have excellent performance characteristics: they do not warp or deform. Bringing a large payload due to strength, great advantage is the flexibility when heated to create curved coatings. The disadvantage is flammability.

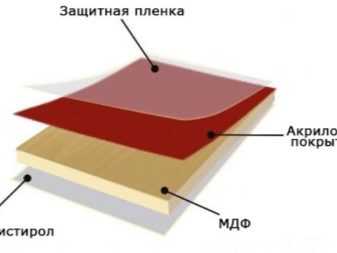

Melamine film or veneer is glued to the surface of the slab. The surface acquires a beautiful decorative appearance, but the disadvantage is the low resistance to mechanical stress. It is enough just to repair such damage by painting it with paint of a suitable color. Lamination with a film gives the slab an almost indistinguishable resemblance to natural material, while the price remains affordable.

The film has a variety of colors and textures, which justifies the widespread use of MDF panels for interior decorating.

MDF panels have gained great popularity due to the ease of installation. Even newcomers to the construction business without difficulty will be able to independently revet the walls or floor. Repairing broken multiple panels will require a simple replacement with new parts in the coating. The panels allow you to hide electrical and other communications under the inner frame. It is a hygienic material, easy to clean. It can be washed with ordinary detergents or wiped with a damp cloth.

Kinds

MDF panels differ in their specifications and sizes. Manufacturers offer three groups of this finish: one-piece, laminated and moisture-proof panels. Solid-pressed - homogeneous in structure, plates that do not have a decorative coating. They have good sound insulation performance and affordable price. In construction use for painting. After applying the finishing layer of paint moisture resistance increases.

Laminated MDF panels, on the one hand lined with moisture-resistant film with a different decorative pattern. Their technical parameters are much higher due to the coating, which is isolated from the access of adverse factors - moisture, temperature drops.Moisture-resistant panels are characterized by the highest density of wood fraction, which prevents moisture or steam from penetrating into the internal structure, which gives increased strength to the material. This is the highest price category.

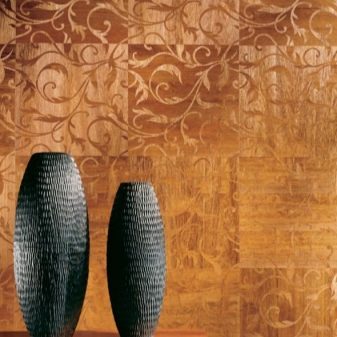

There is a separation according to the type of finish of the front surface. The most expensive - MDF panels, veneered with natural wood veneer. A thin section of wood is glued to the facade of the plate using a vacuum joint, adhesive composition or thermal pressing. The appearance becomes absolutely identical to the sawn timber, while the panel is lighter than solid wood boards.

The slab can be faced with veneer and on the reverse side, but this option is rarely used in construction, such double-sided panels are used in furniture production. Veneered MDF veneer have a relief natural structure of this tree sawn. Another option is to apply veneer using “fayn-line” technology. Very thin cuts of wood are stacked on each other at a special angle with the addition of binders, then pressed. The surface is smooth, silky with a beautiful pattern of weaves of wood fibers.

Veneer increases sound insulation material, allows to achieve substantial savings when replacing natural wood. Caring for veneer panels is required the same as for fully wooden ones: to prevent ingress of moisture, to protect from mechanical influences with sharp objects. This material has high aesthetic qualities, you can pick up the necessary wood species and give the desired shade. A panel or mosaic on MDF panels is made from various types of veneer. The artistic and expressive value of such a facing is greatly enhanced.

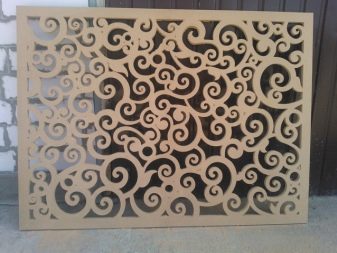

The most common type is laminated MDF panels. The lamination process is necessary to give additional moisture and durability. It consists in the following: a thin melamine or paper-resin film is placed on the finished panel, the film is fused into the upper layer under the influence of heat treatment, and the resin is cured. Laminated MDF boards have high hygiene, environmental safety, easy to install and maintain. They have a huge decorative potential, since lamination is produced not only on straight surfaces, but also on the structural elements of a perforated plate.

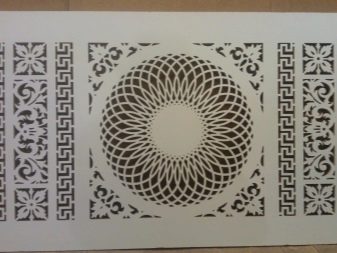

Perforation is used to achieve certain visual effects in the interior. The shape and size of the perforations have a significant variety, the consumer can choose the desired pattern. Holes have a geometric shape, floral ornament or another pattern. Carved panels in wall cladding or ceiling create an original design. With their help, you can give the room the unique features of the Oriental style.

Such panels are used in the decoration of office premises, replacing suspended ceilings. Perforation has a great influence on the acoustics of the room, which expands the scope of application to music salons and recording studios. Such panels are well ventilated, dry quickly if ingested. Allow to functionally divide the space with translucent partitions. It turns out spectacular lights.

Modern technologies allow the surface of the MDF board to be treated with paint, which is evenly applied using an airbrush. The facade of the panel is polished, covered with a layer of primer, followed by a layer of paint. Paint is used matte or glossy,automatic equipment allows to obtain a uniform uniform dense layer of the coating. Only weather-resistant paints with a hardener component are used. Special additives allow you to get a pattern of pearl streaks or metal textures.

For finishing, it is better to purchase ready-made factory-painted panels. In addition to the usual painting under pressure from the sprayer, apply a dry method of painting. A coloring pigment in the form of a powder is sprayed onto the surface of the panel, then treated with high temperature to melt the pigment. This method gives a high quality smooth even color. The last stage is drying in special humidity conditions.

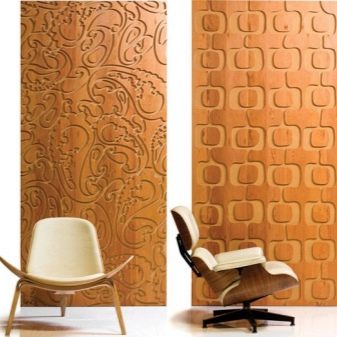

Of great interest to designers are milled MDF panels. These panels allow you to create 3D visualization of the plane of the wall or ceiling. This effect is created using a special method of pressing the embossed face layer. Paint or PVC film is applied on top. To create a stylish interior is enough to choose the right color MDF.

Find their use and laminated paper MDF.These plates do not resist moisture and heat, but in some rooms it is convenient to veneer the walls or ceiling. Covered with MDF paper are used where it is necessary to avoid the formation of condensation on the surface and the use of breathable material is desirable: dressing rooms, household storerooms and other rooms with dry air.

Colors and design

The design of MDF panels surpasses all the wildest assumptions. Modern technologies allow to imitate any of the known natural materials. All types of wood and any shade are presented in retail chains.

Veneer of rare and expensive wood is cheaper than an array and more and more consumers can afford it.

African wenge tree - very rare expensive materialEven the veneer of this tree is a very expensive component of the finish. Its natural beauty and richness of a dark chocolate shade with fibrous light veins successfully copies the laminated MDF board. Inexpensive products can be used in the decoration of wenge to a wide range of consumers. Rich dark color perfectly accents the design elements.

To create noble interior solutions in bright colors, the ideal choice would be light oak. Veneer or laminate imitation are indispensable in Scandinavian design and for the interior decoration in the style of a chalet, Provence, country. Light oak oak panels can be used for wall cladding, floor and ceiling with structural beams. For such a design, it is necessary to select the same texture and color of wood, otherwise the harmonious ensemble will not turn out.

It is better to finish classic interiors with rich tones of wood. darker colors are bog oak or walnut. Maple and ash have almost white color, the massif of these species is rarely used because of its soft texture, MDF panels allow to use these wood species more extensively in finishing. Light shades contrast beautifully with the dark tones of wenge or red mahogany, kempas, dussies, padukas. Beech, alder, pear and cherry have a delicate pink shade. Yellow color is present in the wood of teak, chestnut and olive, which has an unusual zigzag pattern of fibers.

Italian walnut has become a popular finish in designer interiors.The color of this wood has an interesting picture of the location of the fibers. Pleasant rich light brown color gives a calm color range. Such a finish looks expensive and elegant. It goes well with beige, green and orange colors.

When combining different types of wood flooring should be considered the compatibility of colors. For a contrasting design it is better to stick with the traditional - light with dark. The nuance combination is more complicated, it is necessary to select it according to the harmony of fibers and shades. The surface can be polished or have a matte texture, gloss gives the active vector finish, matte silkiness adds a component of comfort and tranquility. MDF panels provide an opportunity to decorate your interior in a completely original way: imitation of natural wood with perforation.

MDF panels can be decorated with natural stone or brick, have a pattern of strict or cyclopical laying. These imitations can be used as inserts in wall decor. Embossed brick or stone wall, made of decorative MDF panels, will replace the real masonry, without changing the load on the supporting structures, will speed up the finish and reduce the cost of work.

Lamination allows known natural materials to impart an unusual texture: shine wood or stone. Ultramarine or metallic color brickwork. The panel can have a transition of texture and color. The stone will be interspersed with oak or alder, creating amazing combinations. In the same space, the walls and the ceiling will begin to contrast and attract attention.

Variations of color gamut of MDF panels are endless. When used in finishing it is not necessary to purchase all panels of the same color. Today, a combination of several contrasting or nuanced colors is fashionable. Here it is worth being guided by the color spectrum, where the neighboring colors or opposite colors are harmoniously combined. For beginners, it is better to limit to a maximum of three different colors, only professional designers can competently use a large color gamut.

The panels have a matte or glossy surface finish. Gloss can be both color and imitate silver metallic luster. The latest proposal of designers - high-gloss panels that look like glass and have excellent reflectivity.Such panels today at the peak of popularity, they look good next to heavy stone or brick masonry.

Glossy colored lining with white or black plaster looks no less impressive.

MDF panels with embossed pattern became a real hit of modern interiors. They compare favorably with decorative plaster in that they are easy to dismantle if the lining is tired or has become unusable. Rather large relief structure gives the effect of 3D in the room. Such panels should be used in the form of panels or a series of inserts in a smooth finish. A wall or ceiling with a relief pattern will add cosmic features to the room.

Panels can be embossed, similar to vinyl wallpaper. Embossing in the form of monograms will decorate the classic interior. These panels will be an excellent substitute for paper wallpaper. The advantage of finishing the panels is that it is not necessary to pre-align the walls and the panels are easy to clean, unlike wallpaper. Imitation of silk-screen printing in 3D will become a fashionable detail of the design of the internal space.

The surface of the panels can be decorated with photo printing. Photo print allows you to play any image.The same pattern constitutes carpet compositions or beautiful landscapes in the form of a panel of several panels. Imitation of frescoes and mosaics of various colors and textures will be a virtue and will give a unique interior. Photo printing is a very resistant coating, it is glossy and matte.

A panel with a natural landscape on the wall will expand the boundaries of space. Oriental mood will create a pattern in the form of an ornament on the walls. Such panels should be sheathed all the walls and ceiling to reproduce the atmosphere of fabulous Asian palaces. African motifs emphasize animalistic images. Black and white city photos are very fashionable today.

Panels with a photo printing can be picked up for every taste. A large figure is better to use in the form of small inclusions. A viewport can occupy an entire wall or two opposite walls.

The photo gives perspective and visually enlarges the room, removes the monotony of the finish and forms a special mood of the internal space.

MDF panels with a surface identical to metal are an indispensable element of the decor in high-tech industrial styles - high-tech and loft.Gold and silver glitter in combination with dazzling white or black panels will add emphasis to the luxurious furnishings of art deco. In small apartments, shiny stripes on the ceiling or on the walls will visually impart a gradation of hidden space. Decorative panels should be combined with simple monochrome textures.

Dimensions

A large variety of MDF panels led to their widespread use in construction. Under the various needs of the construction industry, panels with appropriate dimensions are manufactured. The dimensions and weight of the plates are standardized and regulated by the technical standards of production.

Wall claddings are available for wall panels with dimensions of 2.62 meters in length. A number of manufacturers offer panels of 2.8 meters and 2.44 meters in length. The width corresponds to the type from P-1 to P-5.

P-1 | 100 mm |

P-2 | 125 mm |

P-3 | 150 mm |

P-4 | 175 mm |

P-5 | 250 mm |

MDF plates are available in length and width of 1.5 meters x 0.1-0.9 meters. The size of the slab depends on the surface texture - embossed, perforated and panels with imitation of natural stone reach sizes 2.8 by 2.07 meters. Square panels for decorative panels have other sizes - from 29x29 cm to 95x95 cm. The thickness of laminated and painted panels varies from 3 mm to 30 mm.

Veneer coating involves increasing the width of the panel in some cases up to 60 mm.

The weight of the panel depends on the size, the presence of veneer or relief. To get an idea of the average weight of this finishing material, you should focus on the weight of 16 kg of the panel with dimensions of 2.8 x 2.05 x 0.003 meters and weight of 142 kg on the dimensions of 2.8 x 2.05 x 0.028 meters. For the ceiling, thinner and lighter products are used; for walls, panels with a high coefficient of strength and resistance to mechanical stress are used. If you need to create sound insulation using MDF, it is necessary to select the maximum thickness of the plate. Of course, the weight of this design, if the height of the room is large, will be significant.

Pay attention when calculating the weight of the lining is necessary on the decor panel. Lamination and painting slightly increase the weight. Veneer, relief increase this figure. Perforation, on the contrary, reduces the weight of the structure. For smaller surfaces, smaller panels or slabs are chosen, since the cuts will violate the decorative finish and create difficulties in sealing the seams. Premises of a large area is better to make large-sized plates and panels.

The differences in the method of laying

MDF for construction purposes is produced in the form of sheets, tiles and wall paneling.Each type of product has its own size, method of laying and is used for a particular type of work. At the same time, they all retain the same technical characteristics: environmentally friendly composition, have high strength and elasticity, good decorative qualities. The difference lies in the size and methods of attachment to each other and to the surface of the wall or ceiling.

Leafy

The most expensive of the above types of products - sheet MDF. It is the basis for the creation of highly artistic panels or embossed insert. Sheets have a large size - height up to 2.8 and length up to 2.05-2.9 meters. When ordering at the factory, you can make sheets according to individual sizes and with an exclusive pattern.

Sheets can weigh up to 142 kg depending on thickness.

Sheet MDF is used for wall decoration in large rooms. to create a certain decorative effect seamless finish. The sheet is mounted directly on the butt-to-butt-trimmed and antiseptic-treated wall, since it does not have connecting slots. The best option is the partial inclusion of such a finish in the wall covering due to the bulkiness and price of the material.

Tile

Similar technical characteristics has MDF. Difference from sheets has the form of a square or a rectangle of various sizes: from 0.5 x 0.5 meters to 0.95 x 0.95 meters. The tile has no connecting grooves and is mounted on the prepared wall. Convenience of work with this product - in the sizes, convenient for installation, and lightweight. If the installation of sheet MDF will require the participation of two or more workers, then one person will cope with tile laying. It is enough just to calculate the necessary number of copies for finishing, knowing the area of the finished surface and the size of the tile.

The surface texture has standard colors and sizes as tile. It is convenient to make mosaic panels from MDF tiles of the same type, but with a different color or texture. The versatility of this finishing material - in the possibility of application in the room of any size and configuration. On the market of finishing materials MDF tile is presented in the widest range, has a lower cost compared to MDF sheets.

Clapboard

The most popular is cheap and beautiful batten material - MDF lining.It has excellent technical characteristics and a wealth of decorative finishes. Reiki have dimensions of 2.4 x 0.11 meters and beyond. Standard length is 2.6 meters. Lining is used for decoration and walls and ceiling.

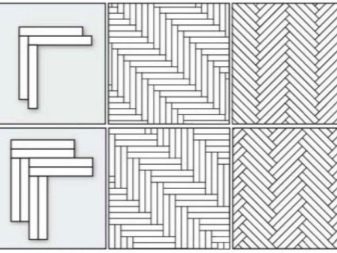

It can be laid both horizontally and vertically, and for greater decorative effect in the “Christmas tree”.

The scheme of laying in the "herringbone" is of two types. The panels are laid at an angle of 90 degrees relative to each other, the ends are adjacent to each edge of the longitudinal side. Another option involves the location of the rails at any other angles, while the ends are cut at the same angle and set butt. This installation requires a certain skill, so that the lining is smooth with the same inclination. You can pre-cut several rails, clean the edge of the cut and begin the installation.

Lining is characterized by ease of installation, ease of construction and individual elements. Easily shortened to the right size. On the side faces is equipped with special grooves for connecting the rails to each other without a gap. To ensure strength and to avoid deformation of structural parts, the rail is mounted on a frame of bars.This eliminates the need to level the wall and allows you to hide communications inside the frame.

MDF rail for all ease of installation requires compliance with installation technologyso that the rail does not lead. The decorative qualities of the coating depend on it. The location of the slats has an effect on space modeling. Horizontal layout will lengthen the wall or ceiling. The transverse arrangement on the ceiling will make the room wider.

Vertical mounting of the wall paneling will visually make the room higher.

Regardless of the type of product, MDF is an economical finishing material. It does not require careful preparation of the surface of the wall, as for painting, or labor-intensive, as is the case with ceramic tiles. Easy to assemble, the work takes a little time and does not require professional skill. For cladding is not required to purchase additional building mixtures or glue, only screws and bars ,. This is an affordable support material. In the course of work dust and dirt is not formed.

How to choose?

A large variety of MDF panels makes you wisely choose the choice of finishes for a particular room.It is necessary to take into account the temperature and humidity conditions in the room - moisture-resistant panels should be selected for exterior decoration of the loggia or kitchen, and average values are sufficient for facing the surfaces inside. The decor of the panels should also correspond to the purpose of the room. In the decoration of the walls and ceiling is better to adhere to the same style design.

MDF, decorated with veneer, will give the living room or office the necessary solidity. There is no increased air humidity, so it is not necessary to spend money on moisture-resistant MDF, but noise protection is required, therefore, you need to pay attention to this indicator when buying. Expensive finish will emphasize the wealth of the owners. The veneer of light oak or Italian walnut is an indispensable attribute of the interiors, designed in the classical style and fashionable minimalist design.

MDF plates are trimmed with interior partitions that do not have entrance doors to create isolated zones in such transforming spaces. Partitions get the necessary massiveness when choosing panels saturated colors. Such zoning provides sufficient sound insulation.Behind the partition of the panels you can arrange a bed, while the light from the kitchen will not interfere with rest. The high decorativeness of MDF plates makes the ordinary pier the main accent of the decor due to the beautiful noble color and interesting pattern of wood fibers.

For decoration of the apartment, where the hall and kitchen are combined, instead of interior partitions, a perforated MDF slab is installed, painted or laminated on both sides. In this case, each side can have its own texture and color, corresponding to the rest of the finishing of its zone. Installation of perforated plates on the ceiling of the bedroom with spectacular lighting will be a real decoration of the interior. The chic elements bring a metallic finish and a combination with the pure white color of the rest of the finish.

For interior decoration cottages or attic in a country house should choose cheap laminated or painted rack products. Hosts without assistance will be able to sheathe clapboard walls of the room. It is necessary to acquire material with high moisture resistance for unheated premises in winter, so that temperature fluctuations and high humidity in the spring-autumn period will not deform MDF.The same requirement applies to the design of the apron in the kitchen. We need to take care of insulation of the finishing material from heating - MDF can ignite not only from open fire, but also from strong heating.

In the children's room, you can allow yourself to show imagination in choosing a pattern and color, move away from stereotypes, and instead of a boring traditional interior, create a bright and cheerful atmosphere. MDF plates are perfectly washed, this quality is very useful in the children's room. You should not pick up expensive facades of natural or laminated veneer, prefer bright glossy plates or slats. Doorways are painted in one of the colors of the panels or pick up cash from the same material. Designers recommend to pay attention to the panels of suitable subjects: for the boys - the sea, for girls - the fabulous scenes.

Mounting methods

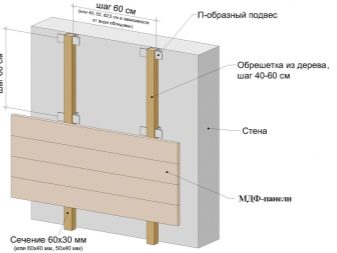

The method of installation of wall and ceiling panels is almost the same. The only difference is that metal profiles and suspensions are used for the ceiling. For the walls enough crates of bars. Between the ceiling and the panels left a larger gap for the placement of electrical wiring.

The following tools are required for installation: a pencil, a level puncher, a hacksaw on wood and metal, a right angle triangle, screws and dowels.

For facing the ceiling, they draw a line of the level of the ceiling plane along the walls around the perimeter of the whole room. The ceiling is laid out on squares 1 x 1 meter. A metal profile is attached to the lines. Suspensions are mounted at intersections. The height of the suspensions is taken at least 10 centimeters for the safe placement of wiring and lamp bases. If the height of the room does not allow to lower the ceiling to such a height, it is better to choose a different finish due to the flammability of the material.

For wall panels, the frame is made of wooden beams. Particular attention is paid to the first guide batten. It must be strictly perpendicular to the laths of the cover; for this, a triangle is required. First, the obreshetka bars are fastened in increments of 45 centimeters to the wall in a horizontal or vertical direction, depending on the direction of the MDF rail. Bars are installed on the wall with dowels or screws.

After assembling the frame or crates, MDF is measured out, cut to size.Installation of vertical lining starts from the corner of the entrance door, horizontal laying - from the floor, regularly checked by the level of correct installation of parts. In places of contact with the rail, a klyimer is installed on which a screw is screwed. This ensures rigid attachment of the rail to the frame. The last detail is measured and cut in place, since it is not always possible to calculate the gaps throughout the entire wall or ceiling.

Another installation method is glue. It involves leveling the wall, primer and the use of glue - liquid nails. Glue is applied on the back surface of the plate. Then the plate is pressed to the wall and immediately it must be removed to finally glue in 5 minutes. It is more convenient to spread several panels at once to speed up the process of setting the glue.

MDF has to be cut to size. In order to avoid chipping of the front layer during cutting, it has a decorative side up. Additional elements are laid between the plates, in the corners of the walls, near the door frame. Sheet and tile MDF are supplied with special fittings for joints - a corner and a plinth, which are selected by color and texture.

To ensure long-term operation of the panels, the wall or floor slab is pre-coated with an antiseptic. This will prevent mold or mildew. Before mounting panels or plates in the right places cut holes for lamps or sockets, the standard diameter of which is 67 mm. The hole is drilled with a drill bit. To ensure the rigidity of the outlet under the hole, the timber is packed in order to avoid bending the panel. The wiring is attached to the floor slab, the wires are placed in a corrugated hose.

Panels are used for facing arches. To do this, the rail of the desired size is slightly heated, it becomes plastic, then it can be bent to the desired radius. Then the glue is fixed in the opening. MDF plates can be used for finishing the floor, their installation is carried out according to the technology of laying parquet. On an open balcony, it is better to use plastic panels, and a glazed loggia is trimmed with moisture-proof panels on a metal frame to avoid exposure to moisture.

Painting

Painting is required in two cases: the old decorative coating is spoiled and the lining was made with unpressed MDF solid-coated plates.In the first case, the damaged surface is ground, wiped from debris and a layer of primer is applied for painting. After drying, apply several layers of paint. Paint for MDF has an optimal ratio to the hardener 1: 9.

At least 8 hours is allowed for drying of each layer, it is desirable to apply a layer of polishing or varnish on top.

For the second variant with the untreated MDF surface, the technology is the same, only grinding is applied according to the actual state of the material. Manufacturers offer already polished slabs. It is necessary to make the processing of the joints, if any, then proceed to the priming and painting. Paint for MDF should be on polyurethane resins, alkyd or oil based or nitro enamel.

Care Tips

MDF panels are very easy to clean. Wet cleaning is suitable for removing dust from all types of surfaces. In case of persistent dirt, they can be washed with any detergent and brush. The latter must be done more carefully on veneered panels. Lacquered veneer is wiped with a damp cloth without the addition of soap. The veneer, covered with wax or oil, is periodically treated with special means for the care of natural wood and every few years update the oil or wax coating.For other types of finishes no special events are required.

How to trim the walls with MDF panels, see the following video.