Features of wall decoration with MDF panels

It is more common to hear about such material as MDF in the furniture industry. Now it is quite often possible to meet this material in construction, moreover as a decor. If the question of finishing remains unresolved, you should take into consideration wall panels made of MDF.

Special features

MDF (fine fraction) is made from the smallest wood particles, which are formed into a plate by pressing. The strength of such a compound is provided by lignin, which is released from wood fibers as a result of high-temperature heating.

Such wall panels have valuable characteristics that make them so popular.

- Security. Since the particles that make up the panel are derived from wood,and toxic chemicals are not used for their connections, such material does not pose a threat to human health.

- Practicality. At observance of all rules of operation of the panel serve rather long time. They perform a protective function, as well as improve sound insulation.

- Aesthetics. Different decor options can be selected in accordance with the design of the room.

- Ease of installation and maintenance. The installation does not require a cardinal change of the walls and occurs rather quickly.

- Environmental friendliness. Do not require special procedures for recycling, biodegradable.

- Efficiency. More accessible compared to products from the array. Do not require costs throughout their life.

- Masking construction defects of walls, wires and pipes.

- Variability. A wide range of models will allow you to find a suitable option depending on your preferences, destination and budget.

However, if a frame is used as the base, the area of the room is reduced. Water, and sometimes even higher air humidity, is able to stratify the internal structure of the plate. A blow to such a surface can cause serious damage up to the appearance of a dent or destruction.Of course, such a mechanical effect on the walls is a rarity, but in order to hang a shelf or cabinet on it, you will need to purchase special fixtures.

Therefore, it is so important to weigh all the pros and cons before choosing, to foresee problem situations that you will have to face.

Types of panels

The main difference between the panels can serve as features of their manufacture. They can be divided into several types.

Conventional (they are also called all-extruded) - are sheets of wood fibermade by the method of dry hot pressing. The surface of the sheets is not treated with anything, but very smooth due to the fact that the fibers are very small and tightly pressed to each other. But in color they are completely non-uniform, inclusions of fibers of different colors are visible, since all sorts of remnants of wood are used to make them. And the shade of the plates from different batches may differ slightly. This type of panels can be processed or used as it is for finishing non-residential premises.

Special - they differ from the usual ones in that they use a higher grade of wood for their production, and they also press them longer and under greater temperature.

These include several types of panels.

- Moisture-proof - its properties are comparable with plastic, since it is in no way affected by a moist environment.

- Heat resistant (i.e. resistant to fire). Unlike other flame retardant materials, instead of phenols and resins, they include paraffin and lignin, which are not toxic. These include products with marking KM1 and KM2.

- Flexible - have greater plasticity to create curved and arched structures. Can be single-layer and two-layer.

- Increased density (type kronshpan) - withstand heavy loads.

Any MDF panel for wall cladding can have a coating that not only gives it a certain aesthetic look, but also, to varying degrees, serves as protection from environmental factors.

Different materials can serve as a decorative coating.

- Film or plastic (melamine, PVC). In fact, plastic is a film of greater thickness. A material laminated in such a way can look almost like anything: imitate any natural material (stone, wood), be glossy or matte, smooth or textured, plain, colored or with a pattern (pattern). Laminated coating can have a holographic or 3D effect.

- Veneer - a thin layer of wood, specially processed - a quality product made of veneer on the basis of chipboard does not differ from an array of panels. However, it is this coating that provides the least protection against moisture or scratches. The veneer is painted in almost any wood shade and has an appropriate texture.

- Enamel or any other suitable type of paint - less durable than plastic, but in case of damage it can be restored locally or replace the painted layer with a new one completely. The coating is monotonous, but the choice of shades is huge.

Scope of application

MDF make furniture, doors, partitions. Thanks to different methods of installation, they can be fixed on almost any foundation - that is, the wall can be concrete, brick, and the like. Different in its properties panels can sheathe the walls, floor and even the ceiling.

Solid-molded raw panels used for wall decoration in non-residential, household and business premises. It is important that the room temperature is kept constant and dry.In conditions of high humidity you need to use a special type of products. Likewise, you can finish the bathroom or toilet, laminated sheets can be an alternative.

Of course, for the design of an apartment or house, it is important that the walls complement the decoration of the room. In the living room you can show all the variety of decor of such panels. Veneer or film coating under the tree perfectly complement the classic interior. There will be by the way matte neutral shades. For modern areas, you can choose a bolder solution. Bright painted surfaces or glossy film with a pattern will put the accents in the right places. Practical relief mottled coverings are conveniently placed in the kitchen, in the hallway, hallway and other common areas where dust and dirt accumulate the most. They are very easy to clean, and small scratches will be simply invisible.

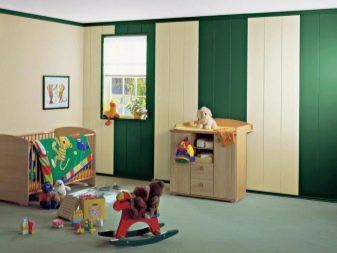

MDF panels can be easily mounted in the nursery or bedroom, because this material fully complies with sanitary and building standards. And with the help of well-chosen colors, you can calm the child or, conversely, create a mood for active educational games.

In public places: schools, hospitals, train stations, theaters, as well as corridors to evacuate people, in addition to ensuring environmental safety and a pleasant appearance, the panel

MDF should have such properties as low flammability, flammability and ability to spread flame and low formation of smoke and toxic products.

Fireproof chipboards can be fixed directly next to stoves, fireplaces, heating boilers. However, from simple room heating elements (pipes or batteries), even the usual kind of harm will not.

How to cut?

In the process of installation there are situations when building materials need to be customized to the desired size. And to install the first panel, you need to cut off a part of it (comb). According to experts, cutting MDF products is practically no different from cutting wooden products.

Some difficulties may still arise during this process.

- The edge along the cutting line may crumble.

- The film coating under the action of tools can peel off or crumple. Especially if the quality of adhesion with the panel itself is poor.

- The glossy surface is very easy to scratch, and therefore requires special care.

If you are afraid of not coping and spoiling the products, you can purchase products of the desired format or contact a specialized organization (for example, a furniture workshop) where you can be helped for a fee.

For cutting with your own hands you need to make a markup. To make the calculation correct, you will need: a ruler, a square, a tape measure, a level or a laser level. Cut the cut line so that it can be easily erased. At the same time, the decorated side should not be on the bottom so that there are no scratches on it. We put it on the workbench, securely fix and proceed to cutting. To make the cut more even, it can be glued with scotch tape, or with a tool immediately along the pressed bar.

The main controversy concerns tools. You can use any tool used for this purpose in the woodworking industry.

For this fit:

- hand saw (both for wood and metal);

- jigsaw (conventional or electric);

- a circular saw;

- frezer

A large, constant amount of work in order to save time and effort is best done with power tools. One-off work can be done manually. The main thing that the teeth at the nozzles were small.We start from any side, we carry the saw smoothly, without jerks. Small chips and irregularities on the film can be cleaned with sandpaper.

How to install?

You can install MDF wall panels in two main ways:

- glue;

- put on a metal or wooden frame.

In the first case, glue is needed, suitable for working with wood products. They can not only glue, but also align the grooves in the places of screwing screws. Glue can be colored or transparent.

In the second case, a wooden crate or metal construction is applied to the wall. The advantage of wood is ease of installation, environmental friendliness and the use of fewer hardware and connecting parts. But wood is more expensive than metal, so this method is less affordable. Installation of a metal frame has its own difficulties - it requires a certain skill and the acquisition of special tools.

Let's look at the process of fixing MDF wall panels on a frame basis in more detail.

- The working wall needs to be prepared. Remove skirting boards and switch boxes and sockets.Take care of the withdrawal of wires for outlets, which will be located on the panels. Damaged wall trim must be cleaned to the ground.

- The wooden slats or bars that you will use must be pretreated to make them resistant to mold, mildew or pests.

- Additionally, you need to take care of fasteners slats to the wall. For wood, you can use screws or dowel-nails.

- We start with angular vertical slats. They are put in pairs to form an angle. Having made a marking, we drill holes in the wall under the hardware (with an average step of about 7 cm) and lay plastic sockets for the screws in them.

- We attach the rail to the wall, transfer the markup to it and drill it, connect it with the wall.

- Horizontal parts are mounted in the same way.

- Door and window openings deserve special attention. Reiki is fixed along their perimeter, regardless of whether they have a step mark or not.

- The alignment of the vertical rails and crossbars is checked using a level or plumb. Irregularities at the joints of the rails are necessarily ground with a plane.

Technology mounting metal frame has its own characteristics.

- The process itself is similar to the installation of wood. However, for metal construction, you will need CD profiles and UD guides.

- CD profiles are inserted into the vertical racks (UD) and pushed to the required place.

- Then we drill holes in the wall by analogy with wooden lags. For fastening to the surface of the wall used long screws. And between the profiles are connected short. For a CD profile, connectors are needed (they are also called ears).

After the installation of the frame begins laying panels.

- Should start from the corner. The panel with the sawn-off comb is placed first, and the next one is attached to it with the help of a lock in which the comb of one workpiece is combined with the groove of the other.

- The panels are fastened with small nails (if the frame is wooden) or with clamps (if metal).

- To attach the last two panels correctly, the last one needs to make the comb less wide. Then connect both at an angle and click on them, straightening the connection.

- The last blanks should be tightly moved to each other and fixed with screws to the frame.

- The gaps in the corner, as well as between the wall and the floor (ceiling) are closed with the help of corners and decorative baseboards (they can be glued).

Tips

To install the MDF panel correctly, use the advice of professionals.

- For reliability, the panels along their length must be fastened along vertical slats or profiles.

- Additionally, when installing the panels on the frame, you can insulate the walls with foam or sheet foams, to increase the level of noise insulation. They can be fixed in the cells between the slats. Such sizing reduces heat exchange with the external environment and reduces the cost of maintaining the heat in the room and its air conditioning.

- If pipes are hidden behind the panels. Profile height must be calculated from the thickness plus margin. It is better to place the wiring in special protective pipes, since ordinary MDF does not protect against water ingress.

- Since the laminated panels are vapor-proof, a fungus or mold often develops behind them. This is also influenced by the material of the walls. Brick passes moisture, so it is necessary to apply a primer. And the gaps between the wall and the panel in the bathroom or kitchen are better treated with sealant.

- With adhesive installation method, the wall surface should be perfectly flat. If this is not the case, the wall panel will, of course, hide them, but there will be gaps between it and the wall.

- When distributing panels, you need to take into account the figure.For example, the direction of wood fiber. Perhaps the alternation of vertical and horizontal pattern - it looks creative, but in most cases it is better to select the details carefully.

- If part of the wall is sheathed with panels, pay attention to the visible part of the edge. It should not remain unprocessed, since it is from this place that the deformation can begin. If the factory coating is broken, you need to take care of it yourself. Usually, the edge is made of polymeric tape material. It can be in contrast or in the color of the front.

Beautiful examples of finishes

Since such material as MDF was created as a cheaper replacement for wood, all kinds of coatings that imitate wood, not only visually but also to the touch, are very popular. All sorts of wood shades - pastel yellow, beige, brown - can form the background basis of any interior.

If the decorative wall covering painted in discreet colors seems dull, you can use brighter ones. Nowadays, you can find panels of MDF of almost any color.Soften the color, make it less intrusive, using a matte finish. The main task of this interior is to maintain a good mood, to charge with energy.

It is not necessary to cover the wall completely. Sometimes, to revive the interior, several color accents are enough, the main thing is that all the details are combined with each other.

Of course, the most spectacular design of the walls will be gloss. Such a surface requires more attention from the hostess, but the mirror shine will always attract all eyes to itself. According to the degree of spectacularity, only panels can be compared with it, the surface of which creates an abstract or geometric pattern. Similarly, you can decorate almost any room - from the living room to the bathroom.

It is important - do not overdo it with such details, because the main thing is that the house has a comfortable, cozy atmosphere.

An alternative to gloss can be a coating with a delicate pearly luster. It looks elegant and sophisticated.

Wall panels need not be strictly horizontal or vertical to the floor. The diagonal layout looks pretty fresh and interesting.

Facing from MDF can favorably highlight any particular zone, attract attention to it, especially if it finds its continuation not only on the wall, but also on the ceiling. This method of zoning proves once again that such a coating is well combined with different types of finishes.

Making the bottom of the wall paneling has become a classic, which is very popular. Relief processing of facades can be complemented by the same motifs on baseboards, fillets and porticos - together they will make a wonderful ensemble.

For details on the installation of MDF panels, see the following video.