Standard sizes of MDF panels

Finished panels from recycled wood have been used in the repair and decoration of premises for more than a dozen years. Plywood, fiberboard, chipboard, panels of extruded sawdust - the range is very wide. These are environmentally safe, high-quality and durable materials, the release of which allows the use of affordable and cheap waste from the woodworking industry.

Working with recycled wood is easier than with natural wood, and its cost is much lower, making the material available to most Russians.

Over the past 20 years, MDF plates have firmly pushed conventional chipboard and fiberboard out of the market: finding the latest in stores is quite problematic, but MDF is represented in any building supermarket in a variety of sizes, textures and shades.

Special features

MDF stands for the fine fraction. The panels are made from medium-density wood fibers, pressed together under high pressure.

The material has all the advantages of natural wood, but its structure is heterogeneous and not solid. The raw material for the production of plates is fine chips, which are compacted on professional equipment with the addition of adhesives.

Merits

The density of MDF products causes a variety of applications in the construction sector, as well as in the manufacture of furniture.

MDF has many advantages:

- homogeneous structure;

- high noise insulation;

- thermal insulation properties;

- attractive appearance;

- ease of processing and installation;

- universality;

- environmental friendliness;

- hygroscopicity;

- hygiene.

Advantages of MDF

MDF, in comparison with similar building materials, has undoubted advantages.

In comparison with plywood

- has no external defects typical of typical plywood sheets (veneer overlap, cracks, falling out knots of wood);

- does not deform under the action of steam;

- different ideal geometry;

- more affordable prices.

Compared with wood

- uniformity of structure throughout the thickness;

- the absence of any knots, voids and other natural defects;

- the possibility of embossing the coating;

- resistance to mold and dangerous fungi;

- The difference in price reaches 80%.

Compared with hardboard and chipboard

- allows for edge milling;

- more eco-friendly material;

- differs in the increased density at the expense of what keeps the basis of furniture well;

- surface can be laminated;

- not deformed by moisture.

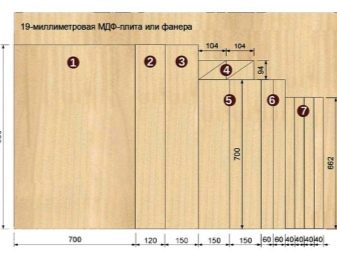

Standard sizes of plates of MDF

: Depending on the size of the MDF plate is divided into:

- reek - they have a narrow long shape;

- tiled - whether square or small rectangular;

- sheet - are large.

Classification by processing method

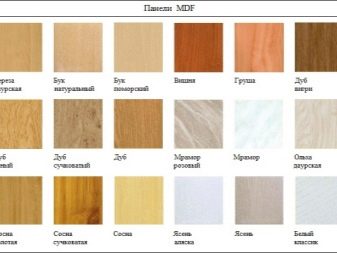

By the method of processing are distinguished:

- flat plates - obtained by pressing;

- embossed - are created using milling, stamping or application of decorative elements;

- laminated - are covered with a special protective layer consisting of a polymer film (transparent or matte);

- veneered - As a veneer, as a rule, valuable wood is used to imitate the texture of natural wood;

- painted - coated with special paints containing matte or gloss pigments, as well as anti-dust additives.

disadvantages

Despite the obvious advantages, the products have disadvantages. One of them is low resistance to burning and the influence of elevated temperatures. When a fire occurs, the panels are deformed, which significantly limits the scope of use of MDF: these plates are not recommended for installation near fireplaces, gas stoves and other sources of fire.

Another disadvantage of the panels is low wear resistance. The material is easy to scratch or crack the surface, so it should not be used for finishing places with high traffic or in homes with young children.

Size range

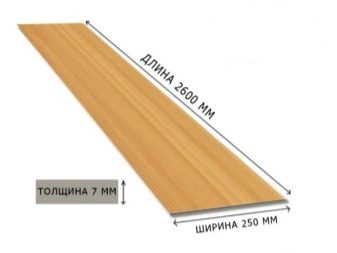

If we talk about the size, then their range is also quite wide. To date, the most common are:

- length - in the range from 2.4 to 2.7 m;

- width - from 150 to 900 mm;

- thickness - from 3 to 60 mm.

Length

The typical length of the wall panel is 2.62 m, at the same time, some manufacturers have established the release of products with a length of 2.44 and 2.8 meters. For installation, it does not matter, especially since the sawing is usually done directly in the store.

The parameters and dimensions of the plates vary depending on the manufacturer of MDF. So, for example, the popular Kronospan brand produces panels with dimensions of 2600Х200 mm, 2600Х325 mm, 2600Х153 mm and 2600Х200 mm. The manufacturer with the world name HDM offers panels with parameters 1300Х198 mm and 2600Х198 mm. Finally, the Russian firm "Union" produces panels in a single size 2600Х238.

Each of the manufacturers (within its size range) produces a variety of panels that differ in texture and color scheme.

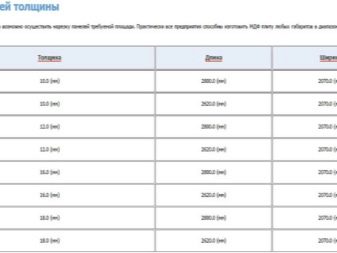

Thickness

Depending on the brand of the manufacturer and the model chosen, the thickness of MDF varies from 3 to 30 mm. In addition, individual companies produce veneered versions, whose thickness reaches 60 mm.

Due to this diversity, each consumer can always choose the best option, taking into account the dimensions of their premises.

By the way, the thickness of the panel is quite important when choosing a suitable finishing material: the weight of the product and the load it can withstand depends on it.

Standard panels weigh:

- with a thickness of 3 mm - 16 kg;

- 6 mm - 31 kg;

- 12 mm - 60 kg;

- 22 mm - 106 kg;

- 28 mm - 142 kg.

Under the brand name Kronospan, panels of 7.8, 9 and 14 mm are produced. Among the products HDM you can find narrow MDF plates (only 6 mm thick). Individual manufacturers have models with a thickness of 10 and 18 mm.

Width

The standard width of the panels is 150-190 mm, very rarely in the free market you can find MDF 900 or 1200 mm. The width largely determines the aesthetics and decorativeness of the finish: the wider the panel, the smaller the surface of the joining seams and the smoother the surface.

Scope of application

The extremely positive performance properties of MDF, combined with environmental friendliness and affordability, have determined the popularity of these plates in a wide variety of construction, interior decoration and industry sectors. A wide range allowed the use of panels everywhere during repair and finishing works, as well as for the manufacture of furniture.

The ability of sound absorption and thermal insulation led to the use of material for the production of wall plates, doors, interior partitions and other decorative elements.

MDF, due to the high density, is considered the best material for the production of joinery. Also, the panels are used for rough laying of flooring and finishing wall leveling. And, of course, panels are widely used in the creation of office and cabinet furniture.

The hygroscopicity and resistance to mold and fungi has led to the fact that the plates have become popular in the manufacture of furniture for medical institutions, laboratories, and living rooms with a high moisture content (bathroom and kitchen).

The use of MDF is wide and diverse:

- panels of sheet type are widely used for laying ceilings and floors;

- very common wall decoration MDF-plates;

- used as a connecting material for the formation of frame facades;

- manufacture of all types of furniture;

- for soundproofing of premises - panels significantly reduce the audibility between rooms, therefore they are used in panel houses, as well as for covering the walls of the parent bedroom in houses with children;

- unusual scope of application of the material - the restoration of old steel doors, MDF is used as a coating, transforming and renewing the look of an old door that has lost its luster;

- for arrangement of slopes.

When using panels, the parameters of length, width and thickness of the material come to the fore. If there are practically no restrictions for facing the walls (the size of the plates depends on the personal preferences of the owner of the room), then for other categories, the scope requires specific sizes:

- kitchen aprons - optimal use of plates with a length of 3 m, a width of 60 cm and a thickness of 6-10 mm;

- countertops - this element is subject to loads and pressure, therefore a panel thickness of 28-38 mm is required here, the parameters of length and width, as a rule, are 1 meter and 60 cm, respectively;

- the doors - MDF interior doors are made in accordance with the accepted standard: thickness is 35-45 cm, length - 190-200 cm, and width - 70-90 cm.

The material belongs to the category of wear-resistant, however, it is noted that it is morally obsolete before it wears out physically. That is why it (in the overwhelming majority of cases) is used for cladding non-residential premises: the hallway, corridor, bathroom, loggia and balconies, as well as household blocks.

Tips and tricks

In accordance with how exactly you decided to use MDF boards, it is necessary to take into account the parameters of the panel. In each case, you should focus on the highest possible rates:

- So, painted panels will be optimal for the manufacture of furniture for the kitchen. They are hygroscopic, do not deform and do not crack with frequent contact with water.

- But for shower cabins and bath cabins this is not enough - here it is better to purchase laminated plates, which are characterized by high moisture resistance, and the lamination should be double-sided in order to protect the product from the outside and from the inside.

- When working on furniture facades, use veneered versions. If we are talking about facing a large amount of the surface area, then the standard tile MDF is quite suitable.

Of great importance and manufacturer of plates. High quality are distinguished by models of Swedish, Polish and German manufacturers. By the way, companies from these countries have their representative offices in Russia, so the cost of their products is available for the majority of our compatriots.

Considerable market share is Chinese products. It attracts with a low price, however, its quality does not always please consumers with wear resistance and durability.

On the shelves of hardware stores you can find a lot of Russian-made products.Small companies produce MDF panels, the quality of which is often not inferior to European counterparts. Unfortunately, sometimes a model of inadequate level with low moisture resistance and short service life is hidden under the external attractive appearance.

Regardless of which brand you decide to give preference to, it is worthwhile to carry out the most thorough inspection of the panels upon purchase.

The inspection procedure is as follows:

- inspect the product and make sure there are no various chips and cracks;

- the surface must necessarily be smooth and smooth to the touch, any depressions or, conversely, the hillocks serve as sources of deterioration of the strength of MDF and reduction of its operational parameters;

- the appearance of any smell from the plates.

It is necessary to examine the certificates and documentation on the panel, in particular, to focus on such an indicator as the degree of swelling of the panel upon contact with the liquid. Its optimal value is 17%.

And, of course, the choice of panels depends on the degree of skill of the dresser. If this is your first encounter with this material (and in general you have little experience in finishing),then give preference to thick models: they are stronger and more reliable. In turn, thin MDF plates are quite fragile and can break from illiterate handling.

How to mount MDF panels on the wall, see the following video.