PVC panels: types and applications

PVC panels are a very economical and practical option for repairing baths and any other rooms, such as a hall, toilet or even a hallway, if you don’t want to spend a lot of money and effort on it. They are presented in a variety of colors from which you can find the best option. PVC panels have won the market for their popularity immediately as they went on sale, as they are versatile and economical.

Properties and specifications

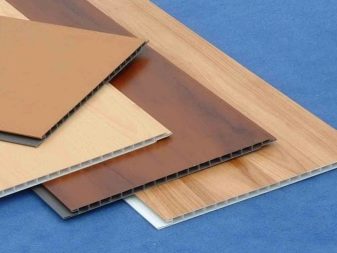

PVC panels include polyvinyl chloride, which is a lightweight and high-quality material. Because of this, often the ceilings in the rooms, in offices and in supermarkets are upholstered with these panels.Also on the PVC panels depict an interesting pattern using lamination, thermal printing and other modern technologies. After this material is applied matte or glossy varnish, which is a protection for the material.

Thanks to this treatment, the panel is not attached to rapid wear and is very resistant to UV rays.as well as any damage, for example, is protected from scratches. For the safety of human health and his family in the production of such PVC panels are not used harmful chemical components. Also, when painting surfaces, only water based dyes are used, which is also absolutely safe.

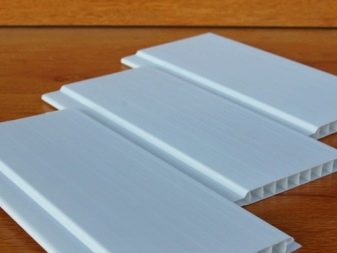

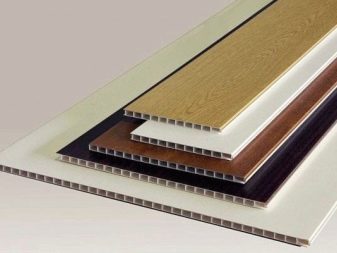

There is a difference of plastic panels used on walls and ceilings. It lies in the fact that the wall options are a bit stronger, and also they are not flexible, so these panels are able to withstand heavy mechanical loads. Also options for walls are thicker than for ceilings. The more polyvinyl chloride, the thicker the panel. The stiffeners inside the polyvinyl chloride wall panels are 1 mm thick, so cutting them with a knife is not so easy.

The length of this material is 3 meters, the width is only 10 cm, and sometimes it can reach up to 12.5 cm. Plastic wall paneling can be used for both external and internal processing of premises. In total, two types of this material have become popular on the market. This is a "Polish" and "European". The "polka" has a small castle connection, while the "European" has a much wider one.

The outer PVC panels have a seam. This is due to the fact that the material has a high coefficient of linear expansion. Therefore, the lining, which was not mounted indoors, should be changed by changing the temperature regimes. There is also another feature of the facade lining. It lies in the fact that the dyeing of raw materials with different colors occurs even during production, and is not applied from above as on other types. Because of this, the lining keeps its initial color longer.

Sheet panels consisting of plastic, have a width greater than that of plastic lining. Their length ranges from 105 to 405 cm. These panels are the most famous and consumable. Sometimes the surface of sheets is sent for special processing, but not all, but only some good manufacturers do it. Thanks to this operation, the panels become more durable and stable.

Glue and nails can be mounted sheet panels. The gap can be sealed with a sealant of the appropriate color or a narrow rail. Ordinary panels have a length of 260 and 270 cm, sometimes even 300 cm, and a width of about 25 cm. But it is also possible to use panels with a width of 50 cm for interior decoration. The side of the outer surface, coated with varnish and painted with paint, also forms a seam, which is not very noticeable when it becomes an assembled look.

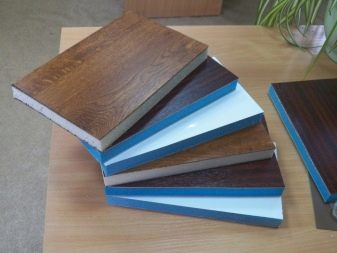

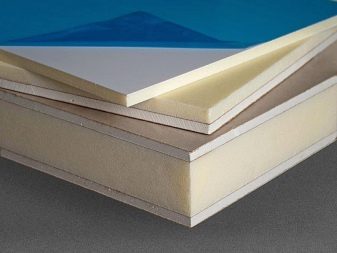

There are also a sandwich PVC panel GOST, which is modern and having high exploitation. The peculiarity of these panels is the presence of two sheets of plastic. Polyurethane foam or polystyrene foam is used as a variety of added substances, they give the material insulating properties. The degree of flammability of products is indicated on the packaging. The greatest coefficient has plastic lining.

Advantages and disadvantages

This material has become so popular due to the large number of advantages.

- Versatility. Usually PVC panels are used as wall and ceiling finishes. This material can be used for lining the edges of doors and windows, used in the shower and bathroom, and also under the steps to create interesting shapes. Summer residents this building material is used for the formation of garden beds.

- Installation is quick and easy. Ordinary homeowners can now decorate a wall or some other surface. Work is done quickly and easily with smooth walls or ceilings. In such situations, they are fastened with “liquid nails”. To make curved surfaces more even, it is worth using a metal or wooden frame.

- Easy to care for. PVC panels can be wiped with a regular soap rag, but it is worth to beware of the panel joints, because these places are weak.

- Such panels are absolutely eco-friendly. This material is non-toxic, does not release harmful substances into the environment.

- Strength. This indicator depends on the correct choice. For ceilings, such material is slightly lighter.

- There is sound and heat insulation. These panels create good sound insulation and do not let the cold in the room.

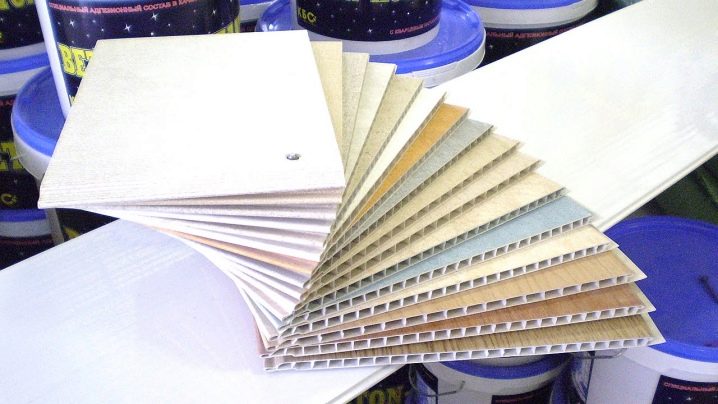

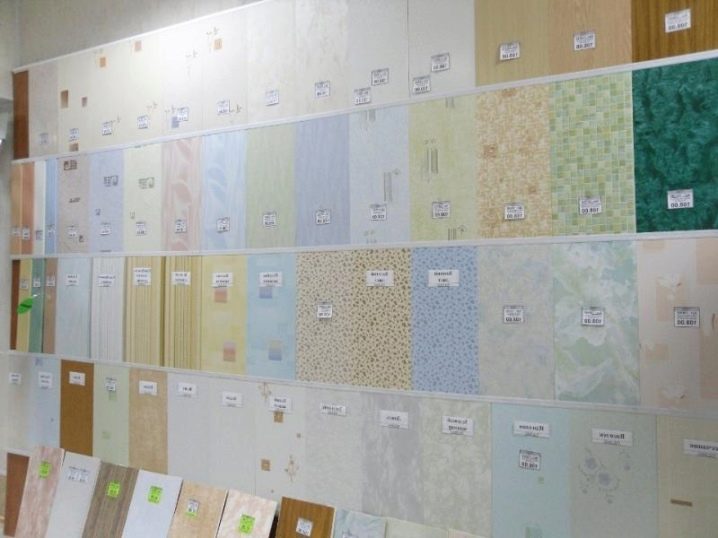

- A large number of colors and shades. The standard color of PVC is white, but manufacturers have created a huge number of colors for every taste of the consumer. At the moment, panels with drawings or with imitation of the texture of a stone or wood are popular.

- Moisture resistance. Due to the smooth surface they do not retain moisture.Since there are no pores on the material, dirt, mold and other harmful microorganisms do not linger on its surface. Therefore, they are often used in rooms where high humidity.

- Resistant to sudden changes in temperature. Plastic panels can withstand temperatures from -50 to +50 degrees Celsius.

Like other building materials, PVC panels have drawbacks.

- Instability to ultraviolet rays. White plastic panels after a certain period of time may turn yellow and lose their original appearance.

- Impact resistant. Such panels can withstand some loads, but they are not protected from the appearance of dents or scratches on the surface of the material.

- The composition of the material contains chalk, which is a decisive component of the strength of the product. The amount of chalk in the panels is determined solely by the manufacturer.

- Characteristic smell. When you buy and use panels for several days there is a specific smell, but then it disappears completely.

- This plastic can not be called absolutely safe, according to many manufacturers. It should not be used to design children's rooms.

Varieties and application

At the moment, three types of PVC panels have become popular in the market of building materials.

- Rack. To attach this type of panels directly to the surface of the wall, you must use a metal bracket. This panel has a length of from 1 to 12.5 meters, width - from 15 to 30 centimeters, thickness - no more than 1 centimeter. If you use this view for finishing the room, it will visually look higher or lower, depending on the position of the panels themselves.

- Under the tile. The size of this type can be from 30 cm to 1 meter. The way to finish the room is the same as that of the rack panels, but differs in its result. Such PVC panels can be laid out with an interesting pattern in the bathroom or in the kitchen.

- Leafy. These panels are recognized as the best of all the above types. To install this material on the wall or ceiling, you need glue and nails. The thickness of the sheet panels is from 3 to 6 millimeters.

Also, PVC panels can be divided by decoration.

- Seamless. Such panels are very popular and look expensive. Perfectly look seamless panels with a matte surface.They are both for the floor and for furniture.

- Relief. They look exactly the same as wood, but their price is much lower. At the same time, they can be used even if the walls have a certain curvature. Embossed laminated panels offer very accurate imitation textures.

There are also several types of panels depending on the design.

- Monochrome. They are ideally suited for the decoration of rooms in which practicality and minimalism are valued. To give a one-color solution originality and beauty, you can make colorful shelves on your own or use pictures.

- With an image. Such panels often imitate the appearance of a stone or fabric, but there are also those that attract attention with a spectacular print, for example, clouds. But it may be difficult to install them, since it will be necessary to accurately calculate their position, then the drawing will be solid.

PVC panels are used in bathrooms, in showers, in the kitchen, they are also often used for decoration of offices, restaurants, supermarkets, schools, gyms, hospitals and other premises.

These products are universal, so they can be used even in unusual places, for example, summer residents use this material in their gardens. Also with their help, you can create an original interior.They are environmentally friendly.

Sizes and decor

PVC panels can be divided into three standard types, namely:

- lining;

- leaf models;

- rectangular or square tiles.

The wall paneling is about 3 m long, width is from 10 to 12.5 cm. The “European” variant, which has a large lock, is more in demand on the construction market than the “polka” with a narrow lock. If you use PVC panels with a length of 260, 270 or 300 cm and a width of 15 to 50 cm, then during installation there will be no seams. Square or rectangular tiles have become more popular. They are used mainly for finishing the kitchen. They are very convenient for installation, and are also light in weight. Their length is 30 cm, as is the width, and sometimes these dimensions reach 100 cm in length and width. Sheet panels, in which the top layer is quite resistant to impacts, and also is smooth, have a length of 150–405 cm, a width of 80–203 cm, and a thickness of 0.1–3 cm. These dimensions are standard for sheet panels.

Also important are the sandwich panels. They are the most useful material for partitions in rooms or cladding of windows. They are not just won their popularity. All thanks to their high class and excellent quality. Also, such products look very elegant.This view is also standard and has dimensions: 3000x1500 mm, 3000x1150 mm and 3000x900 mm, thickness - 10, 24, 32 mm, respectively.

The decor of PVC panels is diverse. There are models with a brick color, as they look quite stylish and look great. This type of material saves floor space, is easy to install, and is also versatile. It can be used in any room: from the hallway to the loggia. Even these products have a very large number of colors and sizes, so you can choose an option for every taste. In addition, this view is much cheaper than decorative brick.

There are also models that mimic the surface of natural stone or natural wood. Dark color versions of natural wood are in great demand. They look very realistic and are more often used in corridors, living rooms and kitchens. Rack, tile and sheet panels are often represented by coloring under a natural material.

The design “ragged limestone” is mainly used for facing fireplaces and arches. Also this material can be used for exterior decoration.The bathrooms look good pattern "Jurassic stone." Today, mirror and transparent PVC panels have become popular, as well as the kind of "panda".

Among the most popular colors are the following:

- wenge;

- red;

- black and white.

Often, panels that mimic the surface of materials such as bamboo, pine, blue marble, slate, and others are used. The cut of the stone fascinates with its beauty.

Manufacturers

It is very important to choose a good manufacturer before starting work. In order not to be disappointed in the quality of the building material, one should get acquainted with the main manufacturing companies that produce a quality product, and generally have only positive feedback.

The following manufacturers are in great demand:

- "Metal Profile";

- "Century";

- Isotex;

- Artpole;

- AGT;

- Shanghai Zhuan;

- Racoon Plastik;

- Polimerpanel;

- Pareti;

- BellerPlast;

- Plastek;

- "Plast Decor";

- KronaPlast;

- "Aquaton".

Criterias of choice

When buying PVC panels worth paying attention to the cost of the goods. The higher the price, the better the product.

In order not to be mistaken in the choice and not to be deceived, it is necessary to familiarize yourself with some points of purchase.

- Mandatory panel thickness.Universal vinyl thickness for walls should not exceed 10 mm, and if you need to choose a building material for the ceiling, then you should pay attention to the thinner one.

- The strength of the front surface. This is important and necessary for building materials to withstand damage and shocks, while at the same time there are no dents or scratches on it. If you can see the stiffeners from the outside, then such panels are best not to use for wall lining. It is better to use them for ceilings, but such work will not look very good and of high quality.

- The number of ribs, their position and stiffness. The rigidity of a building material is very dependent on the number of the edges. The largest distance that may be between them should not exceed 10 mm.

If during transportation the ribs got a little bit wrinkled, lost their shape, then dents will be clearly visible on these places.

- The uniformity of coating the surface of the material with paint indicates how the paint was applied to the panel. Most manufacturers cover the surface from the front, instead of adding a color-giving element to the polymer composition.This is bad because the paint can easily peel off the surface while working with a material. Also, because of this PVC coating, the panel may burn out, and the paint will be unevenly positioned, which is another drawback of this work by the manufacturer.

- When buying a building material in the store, you need to ask about its weight. This can help determine the stiffness of the ribs and the thickness of the walls of the material. The optimum weight of PVC panels should be 1.1–1.5 kg / sq. m

- Are the panels firmly connected? It is better to check the strength of the connection of PVC panels during the examination of the goods.

- What percentage of chalk contains material. Many professionals claim that the percentage of chalk in the product should not exceed 20%. If this percentage is higher, then there is a high probability that this material is quite fragile. Chalk is very affordable and not expensive, so some manufacturers, to reduce the cost of their products, add it more than required by the rules. Bending a corner of the product, you can check the amount of chalk in it. If there is no white strip on the plastic, the panel contains the required amount of chalk.

- Panels containing toxins.Nothing bad if sealed lining has a characteristic, but not too strong smell. But if a specific smell comes from panels that are exposed in the form of a sample, it immediately becomes clear that this material contains toxic substances and it is better not to acquire it.

- Brand If the product is from a well-known seller, then there is a great chance that the material is of quite good quality. After all, in order to earn such fame, the manufacturer has long worked on the quality of its goods, and values its reputation, and therefore offers only high-quality products for wall and floor use.

- Product decor. Facing panels must be thermotranslated. They belong to the economy class. Thanks to thermal printing, you can choose a different decor. The drawing is not afraid of exposure to ultraviolet radiation, and is not erased with time. Variants with a frieze are in demand because they are decorated with various prints. Typically, such products imitate the surface of marble, tile or natural wood.

Models of MDF have much in common with PVC panels, so when choosing them, you can also use the above selection criteria.

Installation and work tips

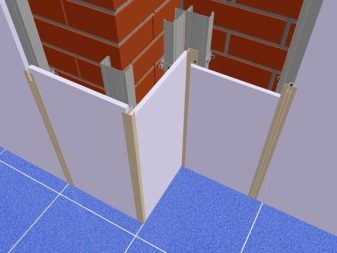

First you need to prepare for the work itself. Before installation there is no need for special preparation of the walls. But you need to very accurately measure the surface to be cleaned, and also accurately calculate the number of panels. Still need to decide how the installation will be made.

If the ceilings and walls are smooth and without errors, then the panels can be glued. But if it is necessary to give the room even parameters, it is better to assemble the frame. In this way, the rooms will have an aesthetic look, and all irregularities on the surface will be hidden and invisible.

To work you need tools such as:

- step ladder;

- drill;

- hacksaw for metal;

- roulette;

- knife;

- self-tapping screws;

- hammer.

All these items need to be purchased before starting work. Once all the tools are on hand, you can begin work. Usually for the installation of the ceiling use panels with a width of 100 mm. It is better to measure lines through 0.4 m. For a start, it is worth noting the lowest point on the ceiling and from it to put marks that will be equal to the width of the panel. Then you need to note the points where the anchor or dowel will be installed, which are important for fastening the frame.

The frame must be placed perpendicular to the mounting panels. For ease of marking, professionals advise instead of tags to draw a thin cord. To use it, you need to rub the cord with colored chalk and attach it to the marked wall. After this procedure, a well visible mark will remain on the surface.

For the finish to be of high quality, the correct assembly of the frame is necessary, which is similar to the combination of profiles.

Profiles can be of different types: made of wood or metal, as well as to be represented by plastic crate. Each material is suitable for certain conditions of use. For example, it is better to install a timber frame in rooms where there is low humidity. This material must be processed by impregnation of high quality, which will protect it from moisture and reproduction of various microorganisms. If you still use a wooden frame, then the fastener must be made every 0.6 m. You can use the lining, if you need the right level. Wood material is slightly worse than plastic or metal.

Plastic profiles have some advantages: low price, light weight, just attached, can withstand moisture, temperatures and other factors.This installation is made every 0.3 m. Tools for fasteners are fixed after 1 m. Installation of profiles is set at an angle. This will check the evenness of the joints. Since PVC panels are lightweight, it is not necessary to build a strong frame.

For the installation of PVC profiles should adhere to the following rules:

- it is better to start installation when the panels “get used” to room temperature, especially if the building material for a long time was in a room where the temperature was below +10 degrees;

- lamellas must be mounted perpendicular to the frame;

- it is necessary to perform ventilation cuts in the event that the room has high humidity;

- since the material can change its shape with temperature, it is necessary to leave 5 mm for the gaps;

- if panels without a pattern or pattern, then installation can be done arbitrarily, but if there is a pattern on the panel, then it is better to start from the left corner and continue towards the right one;

- PVC panels cannot be used for installation in rooms where the temperature reaches +40 degrees and higher, for example, in baths or steam rooms.

Installation of PVC panels on the ceiling

Once the frame is installed, you can begin the installation of the panels themselves. It is necessary to begin work with an extreme strip, it is attached in a corner, to cross-section material with the help of self-tapping screws. So, the next panel will be installed in the groove of the past. This procedure should continue until the opposite wall is fully processed.

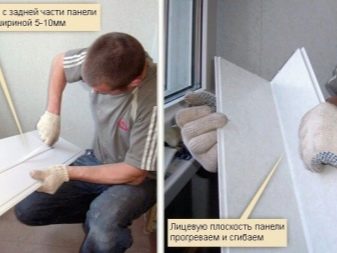

If necessary, the last panel can be trimmed., but only when it does not fit the size. Since the material is brittle, it is prone to scratches, cracks or dents. Therefore, when working with panels, you should not press down hard. It is recommended to take a clerical knife, as well as it can be used to move the panels in the right direction.

After the last panel has been attached, you can take up the installation of the plinth. It is fixed with the help of "liquid nails", which are applied to the inside and attached to the ceiling. After they need to hold for 10 seconds, and the excess glue to remove gently. "Liquid nails" dry quickly enough, so removing excess material from the surface should be done quickly.

Wall processing

Owners of houses or apartments can quickly make the interior of a bathroom or toilet practical and comfortable, and all this thanks to the PVC wall panels. It is very convenient to wash them, they will serve for many years. Installation of the walls is very similar to the installation of the ceiling.

A frame is also installed on the wall that has already been treated with antimicrobial agents. It can be plastic or metal. This is at the discretion of the user. The first panel is inserted with the angle into the profile, followed by other products. They are fixed on metal guides. To do this, use the claymore. The last panel is glued to the U-shaped corner. After this procedure, you can start installing the corners and make slopes. Dismantling is carried out in the same sequence.

Difficulty can provide a wall where there are any sockets or switches. In this case, as soon as the finishing plates are attached, it is necessary to put the box and lay the electrical cable.

When the panels will be installed, you need to cut a hole where previously there were marked places for switches and sockets. Such places are difficult to wash and paint.The panel can be made in the form of a panel and hang on it various crafts.

Examples in the interior

The lining of the kitchen is qualitatively made of a PVC plastic panel with a half-wall pattern. Such a room interior looks very impressive and aesthetic. It can also be supplemented with a Provence photo print.

This living room is decorated with vinyl siding. The room looks very gentle due to the bright colors of the material.

Beautifully look decorative PVC panels with a pattern. Everything looks very high quality and expensive, but with a simple design.

On the PVC panels for the walls of the bathroom and the secrets of the choice of plastic, see the following video.