Features and methods of installation of PVC panels

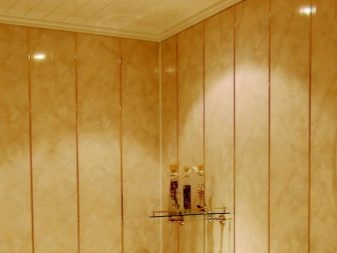

PVC panels - a cheap material, commonly used for decoration of residential premises and household units. With a relatively low cost of such plating decorative quality of the coating is quite high. These are practical and durable materials that are also easy to install - even a novice finisher can install panels with his own hands.

Advantages and disadvantages

Let us dwell on the advantages of plastic panels:

- Hygroscopicity. Plastic does not absorb moisture, it is not susceptible to rotting, mold does not appear in it and fungi do not reproduce,that is why the panels are mainly used in rooms with high humidity (in the kitchen / shower and bathrooms).

- Material has a long service life, it is wear-resistant and resistant to small blows. Of course, if damage is caused by a hammer or an ax, the panels will crack, but small mechanical impacts will not leave any marks on the surface.

- PVC panels for many years retain their aesthetic appearance - they do not turn yellow with time and do not fade when exposed to direct sunlight.

- Easy operation It is also a significant advantage - the panels are unpretentious in care, for their high-quality cleaning you can use the simplest detergents, but still you should not use abrasives and strong acid-base compositions.

- Laying panels does not take much time and does not require special skills and strength, even a non-professional can handle the work.

- Low price. And this is the case when reducing the cost does not entail a deterioration in quality.

- Security. By production of panels the most advanced technologies of processing of raw materials are used, thanks to which the product does not emit harmful and toxic substances. Hazardous materials are difficult to find even among fakes.

- Easy to fix coating - for this, it is enough to replace one broken panel, and not to remove the entire coating.

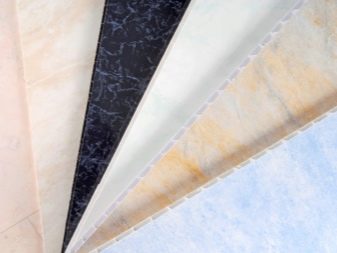

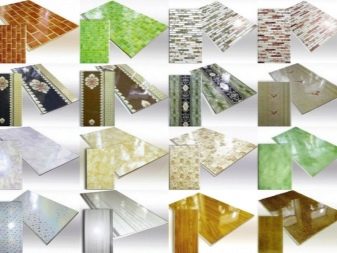

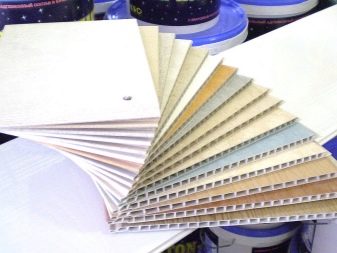

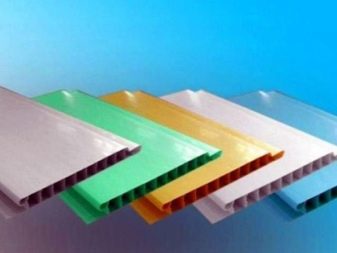

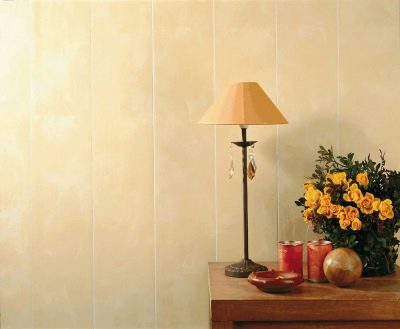

- The panels are very aesthetic - manufacturers put on the market products in the widest range, the abundance of colors and textures. Consumers can choose plates that mimic the texture of wood and stone. Many firms apply photo printing on panels, and some manufacturers produce non-standard products that differ significantly in appearance from the usual “official” versions.

- Possibility of installation in small spaces - wall panels are great for creating niches in such corners of apartments where work with other materials is difficult.

- PVC plates are mounted together with ventilation grilles and sockets; they are not striking and harmoniously look in a common interior concept.

- Many advantages of PVC cladding panels associated with the installation of the frame. Due to the formation of an air cushion between the wall and the panels, additional sound insulation is provided, and the space itself can be successfully used for communication or insulation of the dwelling.

There are also disadvantages associated with the use of PVC panels:

- When exposed to fire, the material maintains combustion and at the same time releases substances hazardous to human health.

- The panels do not allow air to pass through, completely blocking its circulation and the necessary ventilation. That is why the scope of application of the panels is limited - they are not recommended to be mounted in bedrooms and children’s.

- In the southern regions, insects settle in the voids between the panels and the wall, which are difficult to remove.

- When installing panels requires the use of special tools and this is also considered a disadvantage. However, all the necessary equipment can be purchased at any hardware store.

Criterias of choice

The choice of plastic panels is great, in any building supermarket you can find a wide range of models of any colors and textures. Thanks to modern technologies, products are created that can give a gloss and emphasize the conceptuality of any room.

What you should pay special attention to when choosing panels:

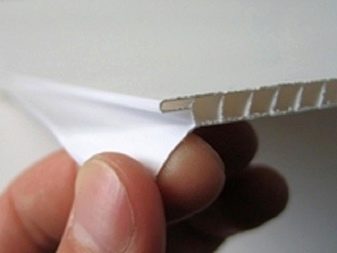

- PVC products are lightweight, but if the panels you purchase are too light, it may mean that you have a low-quality fake;

- there should be no coating defects on either side: chips, cracks and scratches indicate inadequate product quality;

- Acquiring panels, you should clarify the date of issue and labeling - it is optimal to acquire those where these values are approximately the same - even within the same model there can be a significant difference.

PVC panels in the vast majority of cases are produced in Europe and China. Depending on the manufacturer, the technical parameters of the product may vary, however The optimal characteristics are the following:

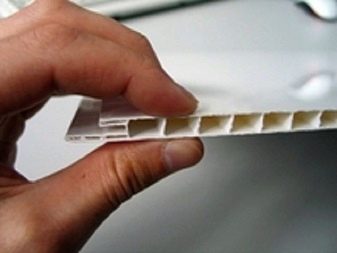

- front panel thickness - in the range from 1.5 to 2 mm;

- the number of ribs - from 20 to 29;

- lamella weight - from 1.7 to 2 kg per square. m

Experts do not recommend making a purchase if:

- stiffeners damaged and twisted;

- the line of the figure is not clearly expressed;

- the color of the panels inside one stack is different;

- the surface has cracks and scratches;

- The segments are of different sizes.

It is easy to check how strong the material is - just press it a little: normally, the front side bends and then returns to its previous position.If this does not happen, it means that the panel is deformed, there is a large amount of chalk in its composition and the service life of such a product will be small.

And a few more recommendations:

- the thickness of the plastic everywhere should be the same, any thickening and, conversely, more subtle places indicate low quality;

- the thicker the lintels at the cut point, the stronger and more durable the construction will be;

- cells should be perfectly smooth, without lumps and dents, so you should inspect all the panels, even if they are packed.

And of course, you need to choose the right texture and color. Very attractive options with a picture. On sheet panels from PVC in most cases put drawing. As a rule, it is printed on film, and then glued to the panel and laminated. Such panels can have a smooth surface or textured, they are very durable, and the price for them significantly exceeds analogues without a pattern.

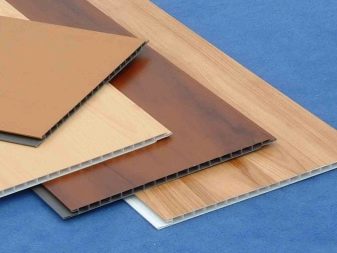

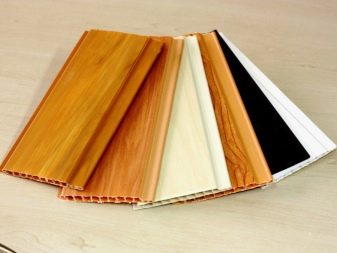

The most common options for panels are wall and ceiling. These modifications are not interchangeable, the sheet of wall panels is not universal, it is not recommended to be used for cladding the ceiling, and vice versa, the ceiling plates are not suitable for installation on walls.

There are no strict requirements for stiffness to the panels for finishing the ceilings - they are practically not subjected to physical exertion. Their standard sizes are:

- thickness - from 3 to 5 mm;

- width - from 125 to 380 mm;

- length - up to 10 m.

The parameters of the wall plates are different:

- thickness - in the range of 6-10 mm;

- width - from 250 to 300 mm;

- length - less than 6 meters.

Wall panels often have a greater thickness, since when covering with wide plates, the coating visually appears smoother and more intact (since the number of joints is smaller). At the same time, many decorators prefer a narrow sheet, since it is easier and faster to work with it.

At prices for PVC panels there is a noticeable scatter - the cost of the product is influenced by wall thickness, as well as the type of printing and brand.

Preparation and calculation

At the stage of preparation of finishing works, it is very important to correctly measure and make an accurate calculation of the required number of panels and related materials. This is necessary in order to avoid unnecessary costs for the purchase of unnecessary products.

Installation of PVC panels provides for their location vertically and horizontally - it completely depends on individual taste preferences.

If you decide to dwell on the vertical layout of the plates, the calculation is carried out as follows: the perimeter of the room is measured, the width of the door and window openings is subtracted from the value obtained and the difference is divided by the panel width. As a result of such calculations, the number of panels required for finishing is obtained. However, we must add about 10% for the space above and below the openings.

For a horizontal location, the area of the room is calculated, from which the area of the openings is subtracted, and the resulting value is divided by the area of the panel.

Again, 10-15% is added to the received quotient in case of damage to the coating, that is, in reserve. Keep in mind that when installing horizontally, you will have to cut panels, so there may be a lot of trimming at the exit.

Consider an example of the location of the panels horizontally. Suppose we need to revet the walls in a 6x8 meter room with a ceiling height of 2.5 m. There are 4 windows in the room with a size of 1.2x1.8 m and one arch with parameters of 2.2x0.9.

For finishing, panels of 250x30 cm were purchased.

Total S walls will be:

(6 + 6 + 8 + 8) x2.5 = 70 sq. m

S window and door openings:

1.8х1.2х4 + 2.2х0.9 = 8.64 + 1.98 = 10.62 sq. m

S to the finish will be equal to:

70 square meters m. -10.62 square meters. m. = 59.38 sq. m. m

Next, we calculate the S panel:

2.5x0.3 = 0.75 sq. m

Accordingly, for the work you need to buy:

59.38 / 0.75 = 79.17 panels.

After rounding the resulting value in the direction of increasing, we have 80 pieces, we should add 10-15% to this and we will get about 100 panels.

Tools and accessories

To work with PVC panels must be prepared. As mentioned, the use of this finishing material involves the use of professional tools, namely:

- perforator - will be needed when forming the frame;

- screwdriver - it is used when fixing panels to bars or metal profiles (a puncher can cope with this task, but it is rather heavy, therefore it will not be easy for a finisher with a little work experience to cope with it);

- jigsaw with small teeth or a circular saw;

- string with an angle of 90 and 45 g;

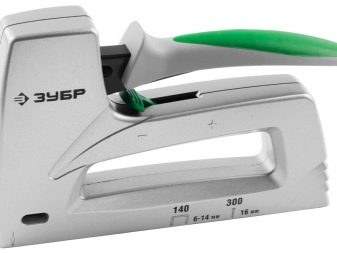

- stapler - it is used at installation of an obreshetka from wood;

- rubber mallet - Required to remove jammed plates; if such a procedure is carried out manually, then there is a high probability of breakage of the batten and the panel itself;

- putty knife - it is used to bend the profile when you need to insert the latest panel.It is best to use a tool with a length of 80 to 120 cm.

Auxiliary tool:

- measuring tape;

- pencil or marker - for marking on the panels;

- level - to measure deviations from the ideal geometry of the coating;

- angle, moldings, clips, piping;

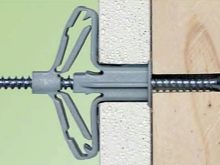

- elements for fasteners (dowels, screws and clamps).

To grind the joints between the panels, use a sealant and a tool for applying it. Many experts recommend adding antiseptic to prevent the appearance of mold and other pathogens.

Mounting methods

Work with plastic panels begin with surface preparation. To do this, they will certainly remove the old coating, close up all the existing cracks, chips and cracks - only then the finishing coating will have a perfectly smooth and smooth look, and most importantly, it will become durable. For the prevention of mold and moss, the base is recommended to be coated with solutions with fungicides. - it is a strong antiseptic, which for many years will save the house from the appearance of "intruders".

At this preliminary stage of work ends, then the frame is mounted and the panels are directly laid down,and for this purpose it is necessary to determine the location of the racks of the core.

For ceilings and walls, markup is carried out in this order:

- First, fix the point at a distance of 2 cm from the floor or wall, and already through it draw a straight line around the perimeter. It is at this stage that the construction level and the masking thread will be needed.

- When marking the walls exactly the same line is carried out under the ceiling.

- Further, in 30-40 cm steps, draw transverse lines - they will become “beacons” for the construction of the frame.

Walls

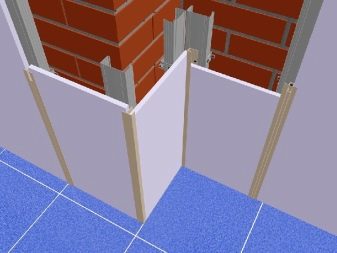

When finishing the walls with PVC panels, first of all install the batten. Most often for it use wooden slats, at least - metal profiles (the second can be bent, the first - no).

Exactly according to the marking with a perforator, holes are made for fasteners with a pitch of approximately 40-50 cm, after which the frame element is mounted to the wall. At this stage it is necessary to provide places for fixing the wires and to make sure that they will not be protruding beyond the crate.

In order to create an additional layer of sound and heat insulation between the slats, special materials should be laid. They can have a different structure and, accordingly, are also attached differently (with dowels or with glue).After that, panels are laid directly on the box.

If desired, you can use the frameless method and glue the slabs directly onto the walls - straight to the concrete. This is quick and convenient. However, it should be noted that the treated surface must have an ideal geometry - any irregularities degrade the quality of adhesion and ultimately reduce the service life of the finish.

In the frameless method, use liquid nails or special glue for PVC. It is very important to use those compounds that do not contain solvents. Otherwise, the plastic will gradually collapse.

Work with this type of installation is carried out in the following sequence:

- cleaning the old coating, priming and drying;

- preparation of the adhesive solution with the obligatory observance of the instructions and the specified proportions of the substance;

- Depending on the consistency of the solution, a tool is chosen for application - this can be a brush or a paint roller or a spatula;

- using an adhesive, fix the corner piece to the concrete wall, to which an ordinary element is subsequently attached with the help of built-in slots;

- panels with effort press for 10-15 seconds and allow to grab;

- by analogy mount all remaining tiles;

- fix decorative element;

- The seams are treated with grout or sealant, which act as a decorative connector.

This method is recommended for facing the corridor and other rooms with a normal level of humidity. Do not forget to cut the holes for the sockets, and also try to bypass pipes and similar elements.

Ceiling

It is possible to sheathe the ceiling with plastic panels in the same way as in the case of walls - with and without a frame.

The frame is required to be assembled in rooms with a high rate of humidity and in less heated spaces. The plates are fixed with the help of fasteners and profiles, therefore the fixation point is not weakened under the influence of external adverse effects.

The frame is nothing like a crate with a step of 40-60 cm. As a rule, its assembly is performed from wooden slats, metal profile or plastic. Panels are screwed to the crate. This repair is time-consuming, but it can be done by a home craftsman even with little experience.

Frameless fixation is a simpler way, it involves pre-cleaning the base and further fixing the plates on a special composition, that is, the plates can be simply pasted.

This is a fairly simple and fast way to sheathe the surface, but it significantly limits the interior design solutions in terms of lighting, as it does not allow to mount spotlights and LED strips, as well as to work on drywall to build multi-level structures.

Window

PVC panels are widely used when installing slopes on windows. It really is an excellent solution that allows you to quickly, easily and cheaply make an aesthetic decorative coating. Due to the large selection of panels, everyone can choose exactly the modification that can truly transform its windows.

There are several ways to trim slopes.

With the help of a metal profile

With this method, profiles are installed that become the framework for mounting panels.

The procedure for this method is as follows:

- on the edge of the window frame with self-tapping screws set the starting level;

- on the opposite edge of the window are mounted slats, it creates a complete contour.

The prepared panel is cut into the desired size, then inserted into the profile, and attached to the rail from the other edge. Panels need to dock with each other.As the casing use the F-profile. The advantage of this method is high speed and ease of installation. However, this technology requires additional laying of voids, which can be formed in the process of work.

Glue fixing

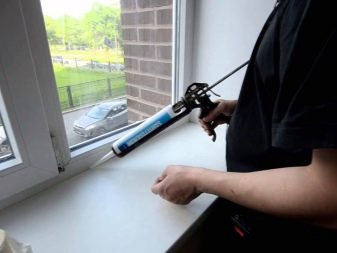

Everything is simple here - the panels need to be glued on the slopes, with the help of foam or glue.

The procedure is as follows:

- First you need to prepare the window well, remove the excess foam, putty and level the surface;

- panels are cut in accordance with the parameters of slopes;

- each part is carefully coated with glue, then the fragment is pressed to the surface for a few seconds and torn off - the final fixation takes place after a couple of minutes;

- at the finishing stage, the seams are treated with a sealant and closed with the corners of a suitable color.

Mounting slopes in this way is carried out very quickly, but requires a perfectly flat base surface.

There are several more ways to lay slabs on the slopes, but they require a longer time and bedroom knowledge.

Peculiarities of care

Argued that plastic panels require special care.However, this does not have any grounds at all - of all types of finishing materials, it is perhaps difficult to find a simpler and “unpretentious” one. Regardless of whether they are in the hallway or on the loggia, it is enough to wash them a couple of times a year with any conventional dishwashing detergent or soapy water.

However, sometimes during service, more serious dirt appears on the surface - drawings made by felt-tip pens and markers, motor oil stains, scotch remnants and so on. For cleaning them, cleaning abrasive cloths will help, and if the markings are significant, then liquid cleaners such as Synto-Forte, Graffiti Flussig, etc.

Before removing the dirt, try to find out how the chosen agent will affect the plastic. Remember that strong acid-base compositions can significantly impair their appearance.

There are several compounds that are not recommended for use when cleaning PVC panels:

- chlorine;

- degreasing compositions;

- alkaline soap;

- nail polish removers;

- acetone;

- polishes of all types.

Recommendations

When purchasing goods, everyone pays attention to the manufacturer.Image and reputation mean a lot and are a kind of indicator of quality. In this sense, PVC panels are not an exception, there are hundreds of manufacturers on the market, but only a few have gained consumer recognition.

- Venta (Belgium). The company is a leader in the market of finishing materials in Europe and around the world. The company regularly opens new production facilities in various countries and in 2003, the plant began operations in Russia. This made it possible to reduce the cost of slabs for a domestic buyer - now Russians can buy European quality models at affordable prices. The assortment list includes a large selection of panels of all colors and shades, products have the property of increased strength, as well as printed panels.

- Forte (Italy). The company is considered one of the largest manufacturers of PVC panels in the world, its products are sold in 50 countries. The company constantly operates the strictest quality control, and technology is constantly improving. In many ways, thanks to this, the company regularly launches new products on the market - for example, quite recently, decorative panels were offered to consumers,made using stone powder. This gives a stylish and highly aesthetic look to the coating, making it elegant and luxurious.

- Deceuninck (France-United Kingdom). International holding company, whose production facilities are located in all parts of the world - the manufacturer of PVC plates has more than 10 plants, which successfully sell their products in 90 countries of the world. The representative office of the holding operates in our country, thanks to which the domestic consumer has the opportunity to get acquainted with the panels from Deceuninck.

- Shanghai Zhuan (China). Chinese products in the last year made a sharp jump in the direction of quality improvement. Of course, not every model marked “Made in China” can be trusted, but the products of Shanghai Zhuan Qin Co. Ltd is considered a recognized example of a reliable supplier. The company sells wall panels of different colors, textures, while the prices of products are available to the general population.

- Green line. And of course, it is impossible not to mention the Russian manufacturer of plastic plates. The Green Line is a plant in the Vladimir region, supplying its goods not only to Russia, but also to European countries. In the assortment list of the manufacturer - more than a thousand modifications of the panels, while the price remains at a consistently low level.

How not to make the wrong choice of panels, see this video.