Greenhouse "Breadbox": drawings and dimensions

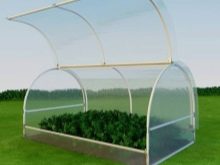

The greenhouse "Khlebnitsa" received such an original name due to the similarity with the usual bread bins, when the upper parts of the object can be closed according to a similar principle. Its design is compact and practical to use, does not require a lot of space for installation. With this configuration, it is possible to process plants without any difficulties.

Specifications

If you want to get a rich harvest, you can easily make a similar object with your own hands. It is not necessary to spend money on the purchase.

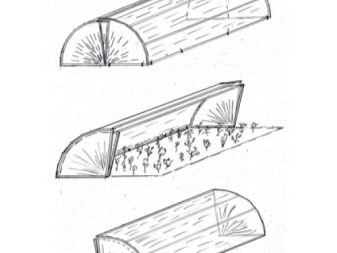

There are two options for installing the top, namely:

- with the opening of one part - this design is called "Snail" or "Shell";

- with the opening of both valves at the same time - the design is called "Breadbox".

More popular the second option, but also the first option has the right to exist. Greenhouse "Breadbox" is ideal for a small suburban area.

It takes up little space, is easy to install, and is easy to use.

Inside the "Breadbox" gardeners grow the following low-growing crops:

- flowers;

- vegetables;

- greenery;

- roots.

The design of "Breadbox" has several basic technical characteristics.

- The simplest structure provides mobility, you can change the place every season.

- It is possible to build an object on its own, it does not require a lot of time and special tools.

- The opening top allows easier access to seedlings, the area can be used very efficiently.

- Small cost. The frame can be installed from about 1500 to 3000 rubles.

To begin work on the production of the object, you must first make the right drawings. The size of the greenhouse can vary within very different limits.

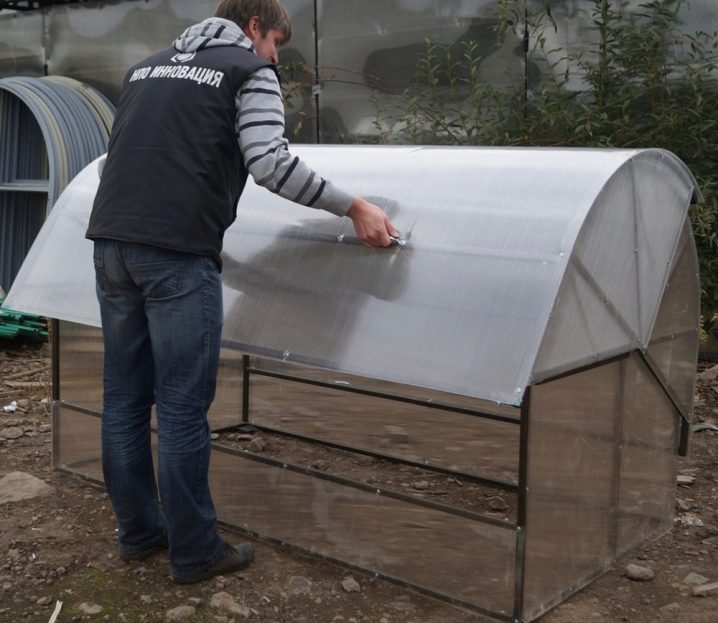

Such objects made of polycarbonate are very popular. Greenhouses from this material are quite durable and at the same time light and compact.

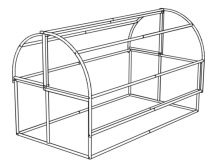

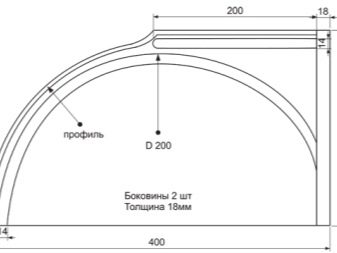

Most often you can find "breadboxes" in the form of an arch, consisting of three parts, namely:

- left half;

- right half;

- foundation.

Movable elements on both sides provide temperature control inside the greenhouse.

Design features

The basis of the greenhouse is made of polypropylene pipes using plastic panels. To make such an object can be literally in one day, and it will serve flawlessly throughout the season. To fix the frame most often set the material from wood on the end cut, with the scheme can be found on the Internet.

Since the construction is arched, then films or polycarbonate are used for coating. Polycarbonate is preferable among summer residents, as it is more rigid, durable, keeps its shape well, and reliably protects the crop from temperature drops.

In operation, the film is more laborious, it is necessary to tighten and fix it, which significantly increases the installation time.

Greenhouse is of two types.

- An overhead structure that can be moved to any convenient place. For sufficient heat, soil is fertilized with manure.Installation dimensions reach a length of 2 to 4 meters, a height of 1 to 1.3 meters. The design has a small weight.

- The recessed structure retains heat longer, as it is driven into the ground to a depth of 60 centimeters. The temperature after a week of installation of the structure has + 45– + 60 ° С. The roof is mounted in the form of an arch, the walls are made of wood. This type of greenhouse is used for the production of early plants.

Dimensions

The release of this type of greenhouse can be engaged in many manufacturers. Their dimensions are very different, there is no single standard.

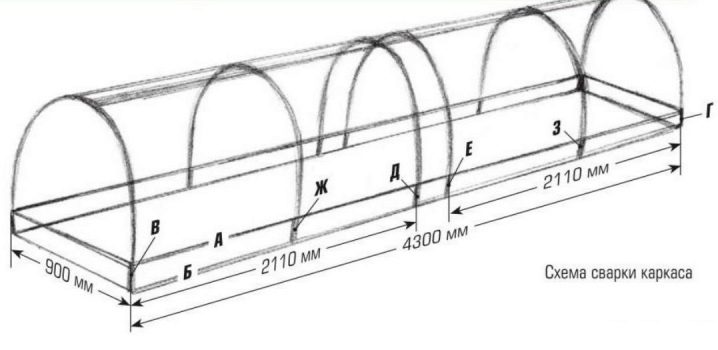

The best dimensions are as follows:

- the height of the structure is modified to 1 m, taking into account the open part it is increased to 1.25 m;

- length varies from 2 to 4 m;

- for convenient access to plants, the width is made from 0.8 to 1.3 m, in case the structure has one opening part.

Double-leaf installation provides an increase in width due to the possibility of access to the bed on both sides. The best manufacturers in most cases make the width of a two-sided breadbasket about 2 m.

Advantages and disadvantages

Universal projects are considered the most acceptable. they have more functional and other positive benefits:

- the presence of small dimensions, can be installed in any convenient place;

- small height provides stability from the effects of wind and snow;

- polycarbonate frame protects against UV rays and supplies the plants with the right amount of light;

- tight closing doors protect seedlings from drafts;

- for airing seedlings need only open the sash;

- construction operation up to 10 years;

- beautiful and neat design;

- automatic cleaning when fixing brushes on the opening part of the frame.

The design of "Breadbox" has the following disadvantages:

- only small plants can be grown;

- greenhouse film coating does not allow to maintain a constant temperature in the cold season;

- if the greenhouse is made of cheap material, then it quickly wears out in the area of the valves.

Maintenance work

As prevention, the following actions should be performed:

- regularly inspect and periodically lubricate the sash;

- if the shutters are not closed in case of strong wind, then there is a probability of their damage;

- to carry out the installation of the object during the day, it takes labor costs of 2-3 people.

Optimal choice of location

To ensure a high yield, you must follow all necessary requirements step by step.

- To ensure a high yield you need to take care of the best installation site.

- One of the important factors for the growth of seedlings is a sufficient amount of light. Therefore, when choosing a place, this factor should be considered first of all.

- In order to evenly distribute the resulting light, the structure should be installed in the direction from north to south.

- You also need the absence of roofs of buildings or trees that can prevent the entry of sunlight.

- The presence of a flat surface. In its absence, the greenhouse may deform over time, which will impede the full development of plants that cannot receive a sufficient amount of light.

Primary requirements

Installation also requires compliance with step-by-step detailed instructions, which include the following requirements:

- assembly at a distance of 5-7 meters from tall buildings;

- distance from the bath, summer shower, swimming pool at a distance of 8-10 meters;

- distance from the toilet of 25 meters;

- install near high fences and fences, as well as near the walls of houses or outbuildings from two meters in order to avoid snow falling into the greenhouse in winter.

Plant species for planting

The most basic condition for the choice of planting culture is its size. Summer residents do not like to plant crops that grow up too much. In this case, they have to be transplanted over time to open ground.

The most popular are such cultures:

- greens: parsley, dill, onion, sorrel, garlic;

- leaf lettuce, arugula, watercress, lettuce;

- berries: strawberry, strawberry;

- root vegetables: carrots, beets.

Manufacturing

The main tools for the manufacture of the object are:

- electric drill;

- two meter level;

- hammer;

- knife;

- Bulgarian;

- self-tapping screws with rubber washers.

During the construction process it is necessary to observe the sequence in the assembly.

- A foundation should be established. To do this, select the material (brick, concrete, wood). Then you can begin to dig a trench, the width of which should be 20–30 cm, and 40–50 cm in depth. Cover the sand or crushed stone 10–15 cm high.

- The next step in the installation is laying out bricks using mortar over the entire area.

- If the foundation is made of wood, then it is necessary to carry out preventive antiseptic processing with a primer.

- Use the scheme to install arcs, frames of the lower base and firmly fasten them to the base.

- Mount the assembled greenhouse to the foundation and tighten with stainless steel screws or thermo washers for durability and durability.

- Assemble the corners on both sides, the sash should work on the hinges.

- Attach cut polycarbonate to the assembled base.

Tips

If you incorrectly make a markup, the coating will be unreliable, leaving gaps for drafts. For the production will need four parts for the side of the base and two parts for moving parts. It is necessary to make and fix the covering with the help of self-tapping screws; rubber washers are also used for reliability.

The polycarbonate coating service rock is 10 seasons.

Greenhouse "Khlebnitsa" has a number of positive qualities that allow it to be in trend, for example, it is convenient and easy to grow seedlings in it.Such an object among summer residents is a huge success due to its compactness, reliability and low cost.

How to build a greenhouse-breadbasket with your own hands, see the following video.