Greenhouse-bread box: manufacturing methods

Pleasing yourself and your loved ones with fresh vegetables from your personal garden is a special pleasure. And the sooner this treat appears on our tables, the better. In order to bring closer the moment of meeting with a fresh, fragrant, crispy cucumber or a filling tomato, avid diggers and dacha fans develop various greenhouses in their gardens. But not every summer resident can boast of earthen expanse: sometimes every meter of the site is already planned and built up.

There is simply not enough space for a spacious and large greenhouse. However, there is a solution! A compact greenhouse-bread box not only does not take up much space, but also brings a long-awaited harvest. And make it easier, simple. It is not necessary to spend money on a factory-made design.

Description

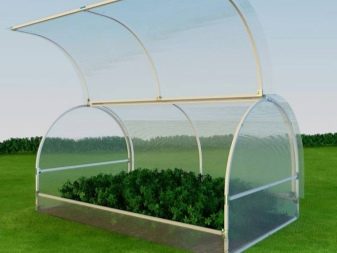

The greenhouse got its "tasty" name due to the similarity in the design with the popular in our kitchens bakers. It has an easily removable flap. Modern masters practice several options for making bread-boxes, but they are all united by a number of positive characteristics: you can close and open the greenhouse effortlessly and even from both sides at the same time (if there are two valves), the frame of the greenhouse is light and, accordingly, mobile, the greenhouse is covered polycarbonate, which means that the rain flows will not flush the lid and, due to the pitched surface, will not damage the plants hiding under it. Since in the greenhouse-bread box there is no through passage, the interior of the structure can be used one hundred percent. No need to provide for a place under the furrow and additional strengthening of the inner ridge.

This type of greenhouse is mainly intended for undersized representatives of the flora: For seedlings, the growing conditions in this “house” will be just perfect. Like a greenhouse greens (parsley, dill, sorrel, garlic), fragrant berries (strawberries or strawberries) and, of course, root crops (carrots, beets).But higher plants are likely to require higher ceilings. For example, tomatoes can be grown in a “breadbasket” exclusively at the seedling stage. Later it is necessary to transplant them into a greenhouse more spaciously or under the open sky.

Design features

The design of the greenhouse includes several components: the base of the greenhouse, directly the frame and cladding. Folding ceilings move up and down due to hinges. This feature gives the gardener the opportunity to independently regulate the temperature and light conditions of the greenhouse.

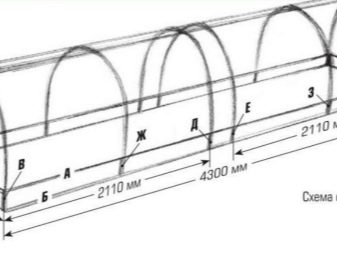

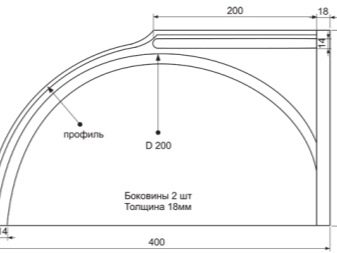

We will dwell more on the “breadbox” frame, since the service life of the shelter depends on the strength of this greenhouse element. The base for the skin is a quadrilateral with vertically arranged triangular sidewalls. The upper part of the frame “breadbasket” is made of half-arcs, which make up the two leaves that are independent of each other. They are attached to the top of the triangles at the ends of the base, with the help of hinged structures. Each leaf of the greenhouse has its own polycarbonate lining. Note that the difference in radius values between the flaps gives a depth of polycarbonate.Thanks to this, the doors open, easily moving under each other.

If you do decide to buy yourself the above-mentioned greenhouse, but the factory assembly, then fold the frame is not difficult. Especially in addition to the purchase there is a scheme-drawing. Such a purchase, depending on the “bells and whistles” and operating features, will cost around 10 thousand. At times the budget to independently develop a drawing and design the structure of the source materials at hand. Yes, and boasting a self-made greenhouse on the backyard is a special pleasure for small business executives.

Making greenhouses from scrap materials is an occupation that requires thorough preparation and professional equipment. Among the tools needed for construction are a hammer, a drill (screwdriver), metal shears, electric jigsaw, and a portable home welding machine (if you decide to use welding to fasten frame elements). From the materials for the “breadbasket” you need to buy bricks, boards or cubes for the base-foundation, metal-plastic pipes or profiles-galvanized, polycarbonate (the number of sheets depends on the selected size), screws.

Among the stages, on the quality of performance of which the further functionality of the greenhouse depends, the right choice of the place to build. Be sure to appreciate the quality of the land under the future greenhouse. With insufficient friability or fertility, it is better to equip the “breadbasket” with a warm pillow like a silage pit. To do this, before installing the frame, you need to dig a rectangular trench, the bottom of which should be laid out with thick paper to protect against parasites and weeds. Put humus or household decomposing non-chemical waste on top of the cardboard, like potato peelings, onion peel. Do not forget the ash. Thanks to this loose substance, the soil will not only become looser and airier, but will also be cleared of parasites.

Another equally important episode in the development of a plan for the future of the greenhouse-bread bins is the most accurate measurement and control of the radius of half-arcs. In case of an error in measurements, all works will be in vain. The design will turn out unreliable and skewed. And the wind inside the greenhouse can easily break the fragile branches of seedlings. If all the side elements of the “breadbasket” are very close to each other, the crops are not threatened by harmful drafts and temperature drops.

With an independent production of the breadbasket, the framework is made of any pipes, which, in turn, can be both plastic and metal. Choose the "black" metal should not, because it can rust. And if you stopped at this option, handle it before installing water-repellent paint. The shape of the pipes used also determines the ease of assembly of the frame. It is better to choose consumables that have a square shape in the context. It is much more convenient to work with them, to fasten among themselves and to connect with a shelter. The frame is made of pipes of maximum strength. Cut polycarbonate (preferably with UV protection) is inserted into the finished frame or tensioned film.

Dimensions

Dimensions should not be very cumbersome, because before us is not a permanent shelter of plants from the weather, but a temporary greenhouse. Equipping an eight-meter greenhouse is undesirable. And not only for reasons of space. First of all, the construction of impressive dimensions will create shade on the plot, which will adversely affect the rest of the non-individual crop.

It is advisable to follow the following guidelines:

- with one cover - width up to 1.5 m;

- with two slopes - width up to 2.3 m;

- greenhouse length - 3-4 m;

- height - up to 1.6 m.

How to build yourself?

- First of all, you need to familiarize yourself with the installation scheme in detail. They are in huge quantities can be found on the Internet. The installation of the frame is made on a flat surface (a level is very useful here). In order for the seedlings to get more sunlight, it is advisable to place a greenhouse in accordance with the sides of the world: the length is to the south.

- If you put the “breadbasket” firmly on the ground and secure the base with pins or sticks, you do not need to pour any foundation, because the construction itself is light. Base slats must necessarily be bolted together.

- However, if the site is located in open space and strong gusts of wind, a simple, but weighted foundation is still better to build. To do this, you can lay a series of bricks in a shallow ditch around the perimeter of the frame or put bars, the tree is better to be protected from rotting with a protective coating. By the way, the wooden base is a good option for making the foundation; if you wish, such bases are very easy to disassemble in order to change the location of the greenhouse.

- After installing the frame, close it with a 4 mm thick polycarbonate.or film, but in this case, the structure will be less wear-resistant. Sheet polycarbonate should be leveled on a convenient and clean area without bulges and mark the necessary elements. To divide a sheet into blanks is best of all with an electric jigsaw. The edges of the material is sure to overlap with special plugs. So you will save polycarbonate from pollution from inside the cells. The cover is fixed on the frame with self-tapping screws. Unnecessary parts are cut off. Please note that when assembling the frame there should not be a waist of bolts or skews. Otherwise, the construction will simply be unstable and at the first gust of wind will collapse on the neighboring beds.

- If the gardener is planning a removable cover, put it on last, fixed either by hinges or bushings. A greenhouse covered with a covering material should always be checked for ease of opening and closing. If the work is done correctly, the sash will open easily and without interference. Also, the convenience of opening and closing the greenhouse will provide comfortable fittings. The handle for a greenhouse, it is desirable to choose from lightweight and durable materials. Attach it to the frame need screws.

Opinion of the owners

Typically, these structures operate smoothly for several seasons. There are no special comments or complaints about their use by the owners. Basically, the majority of users of "breadbox" notes the profitability of the greenhouse. After all, modern greenhouse is a costly pleasure.

Of the special wishes voiced by experienced gardeners, it is worth noting the following:

- For an excellent harvest for the envy of your neighbors in the area, as well as for the health of your plantings, try not to have shrubs or trees near the greenhouse, which will not only darken the territory, but also complicate the cultivation process with its roots;

- Keep distance from large buildings (baths, garages, country houses), as well as from the cesspool (at least 20 meters);

Operation Tips

Mini-greenhouse "snail" basically has only positive feedback. For buyers, it can grow a lot more products.

Professionals give several recommendations for use.

- Under the base of the greenhouse is better to put organic fertilizer, dry foliage or grass. All this will pret, providing seedlings with additional heating.

- Green areas will be grateful for the constancy of the climate under the arches of the structure. To guarantee such stability is obliged to polycarbonate, which is applied a specific protective film against ultraviolet rays. When purchasing cladding materials, you should consult with the seller on this topic. At the time of choosing coverage for a greenhouse, each owner must decide what goal is being pursued. If you want to save money, it is better to buy a plastic film of maximum strength. Now on the market, these products are represented in the broadest abundance. The film also perfectly cope with their covering duties. But, perhaps, give way to polycarbonate in durability.

- Since this greenhouse is particularly light, with a strong and gusty wind with a speed of 7 m / s, it can overturn, especially in the opened form. Pay special attention to fasten the structure to the ground.

- Periodically lubricate the hinge system with oily substances to reduce creaking and friction.

- Ramps can be equipped with an additional "gadget" - brushes for cleaning natural pollutants: twigs, leaves, dust, fallen or settled on the greenhouse during operation.

- With the onset of spring, fill the "breadbasket" with snow.Moistening the land with melt water favorably affects the quality of the seedlings.

With proper use, the bread box will delight you with its functionality, versatility, compactness and environmental friendliness. The miniature appearance of such a structure harmoniously fits into the landscape of any backyard plot, without violating any author's decision. Have a great harvest!

On the methods of making greenhouse-bread bins, see the following video.