Greenhouses made of polypropylene pipes: manufacturing features

The weather is very unpredictable. To be sure as a result of your work, you must have a greenhouse in the garden. It can be bought ready-made, and the right size, it will be brought and collected right on the site. But in order to save, you can build it yourself, you only need to decide on the design and material.

Types of designs

You can make a poultry house with your own hands out of polypropylene pipes, capital or collapsible.

Self-made greenhouses made of polypropylene pipes can be divided according to the following:

- arched frame;

- a rectangular frame with a single or gable roof;

- greenhouse from several sections - combined;

- rectangular frame with arched top.

Choosing the design and size of the greenhouse, it is necessary to determine its purpose.If you plan to grow products only for personal consumption, you can create a greenhouse with a width of about 3 m, a height of 2–2.5 m, a length of 4 to 12 m. It is much easier to make a greenhouse with an arch-shaped frame yourself than a rectangular one. For the manufacture of a greenhouse with a rectangular frame or even more complex shape, you need to make accurate calculations, draw a diagram, providing additional elements for greater rigidity of the structure. A large number of fittings reduces the stability of the frame and makes it more expensive. The simplest version of the greenhouse is to install an arc over the bed and cover with any covering material.

Selection of materials

Having decided on the design of the greenhouse, you should choose the material for its manufacture. You can make a frame of plastic pipes of different diameters from 16 to 110 mm and a length of 2 meters. The pipes are suitable for plumbing, propylene (PP), polypropylene (PPR) or pipes that are made of high density polyethylene (HDPE). You can also use polypropylene pipes with a layer of aluminum or fiberglass, they are stronger, but also much more expensive.

When choosing a material for the frame, the presence of a welding machine must be taken into account., which is designed for welding of plastic pipes, as well as or have the skills to use it. Although it is quite simple to use, you should only know the technical features of plastic pipes. PPR pipes are welded in a diffusion method: the edges melted by means of a welding machine are inserted into each other.

It should also be noted that when welding, pipes and fittings of the same material are used.

The welding process itself is as follows:

- it is necessary to cut pipes at right angles;

- should be cut rations 260 degrees;

- the place of welding must be cleaned and degreased;

- the ends of the pipes are put on the welding machine (heating time, welding time and cooling time depend on the diameter of the pipe);

- the edges of the pipes are connected to each other for 4–8 minutes.

In rectangular frames and parts of the structure, which are the support, it is better to use pipes with a diameter of at least 50 mm. For arched frames you can use pipes of smaller diameter - 25 or 32 mm. Only it is necessary to take into account that polypropylene pipes practically do not bend.To create curves and turns, you will have to use elbows, transition couplings and other fittings, which will significantly increase the cost of the product. Shelves, windows and doors can be made from plastic pipes in a greenhouse.

Plastic pipes have the following advantages over other materials:

- ease of use due to flexibility, you can create an arch, just bending the pipe;

- affordability;

- high resistance to the environment of 10 years or more;

- do not undergo corrosion, rotting, decomposition;

- do not require additional processing (painting);

- fireproof;

- environmentally friendly, do not emit harmful chemicals even when heated;

- not subject to deformation from external factors. Do not break even under strong wind loads;

- maintain both chemical, and biological processing.

But they have one minus. The constructed construction will be very light. So that it is not carried away by the wind, the base will have to be fixed in the ground.

The above-described qualities of pipes allow them to be used to create a greenhouse with their own hands, without possessing special skills. If you make measurements and calculations correctly and buy materials according to them, then you can build a good greenhouse, avoiding unnecessary costs.

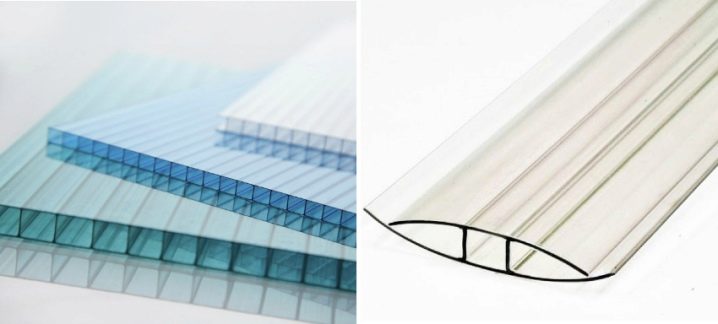

The choice of covering material is quite wide and will largely depend on the function assigned to the greenhouse. Glass as a covering material for a greenhouse made of plastic pipes will not work. It can be easily replaced with polycarbonate, because it does not break, is easy to cut, it is easier to fasten, tolerates a slight deformation, has a smaller heat exchange.

Buy polycarbonate is not a problem. Polycarbonate with a thickness of 4 to 6 mm will be excellent for a greenhouse, only pipes must be polypropylene with a diameter of 32 mm or more.

Tip! Having decided to use polycarbonate as a covering material, it is necessary to calculate the size of the sheets and their joining together depending on the area of the coating. Cellular polycarbonate with a thickness of less than 4 mm will not withstand climatic loads. To fix the polycarbonate will require screws with washers.

As a covering material, you can use cheaper options:

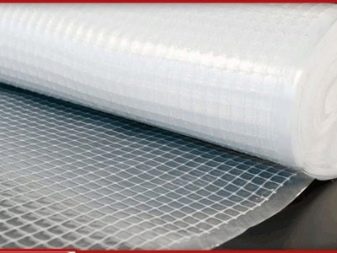

- plastic film is the cheapest material;

- reinforced film is preferably 11 mm thick, it is stronger than polyethylene and will last longer;

- bubble film, which is an excellent heat insulator;

- nonwovens: agrospan, agrotex, lutrasil, spunbond, agril. They are stronger than polyethylene film, retain heat better, let the rain through, but are opaque, although this will save plants and fruits from sunburn.

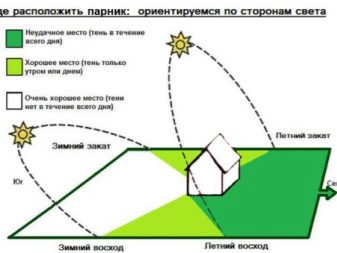

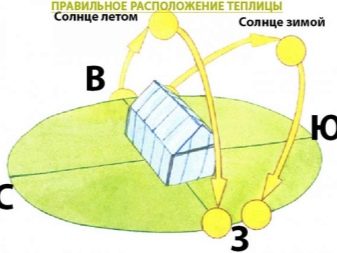

For the correct location of the greenhouse on the site and eliminate unnecessary costs, you must make a drawing, diagram, or at least a sketch. The location of the greenhouse on the site should be selected depending on the light of the territory and the wind rose.

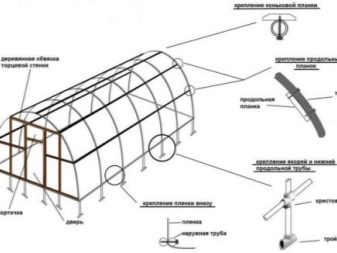

Below is an example of a greenhouse with an arched frame, made of plastic pipes, reinforced with wooden slats, mounted on rods fixed to the ground.

You can use the above drawing or find a greenhouse diagram on the Internet. It will not be difficult to draw a diagram or drawing yourself. In your drawing you can take into account all the nuances of the site and the required size of the greenhouse. Having thought out the shape of the frame, having decided on the material and drawing the drawing of the greenhouse, you should create a plate for the calculation of materials and their cost. It is also necessary to make calculations of covering material and foundation. The choice of materials for the manufacture of the foundation will depend on the selecteddesigns.

Plate form:

N п / п | Name products | Dimensions | amount | Price | Cost of | Note |

Assembly

After preparing the drawing, choosing the design and materials, buying all the necessary components, you can begin to assemble the greenhouse. If the base of the greenhouse is wooden, and it is small, then you should start with the assembly of the foundation - a rectangular box. Since plastic pipes are lightweight, the foundation must be fairly strong and level, therefore boards of at least 25 mm thickness are used. The box can be made of flat slate, fasten the design with screws. Boards should be treated with antiseptic.

If it is small and low, then it is convenient to make it open. It should be attached to the box frame with a frame, covered with a covering material, on the one hand, loops, and on the other - connected with a chain or rope. To protect plants from moles and other pests, it is possible to fasten a metal grid on the basis of the box.

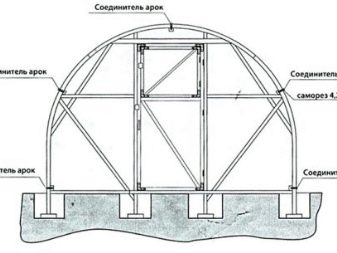

To assemble a greenhouse frame, you need to cut pipes of the required size, as in the drawing. To do this, you can use special scissors, a hacksaw for metal or a grinder.The assembly must begin with the ends, it is easier to do it on the ground, and then set and fasten to the frame or foundation. Plastic pipes can be connected using fittings for screws, welded using a welding machine, or glued.

Before you should make a markup on the frame at an equal distance from each other. On one side, attach the pipe to the wooden frame with special fasteners. You can bend it yourself into the arch of the desired height and fix the opposite end of the pipe with the same attachment to the other side of the frame. Thus, it is necessary to seal the required number of pipes. For durability, the structure must be covered with metal or plastic mesh and attached to the frame.

If the greenhouse is large enough, it is better to assemble it on site. But some details can be prepared in advance. In a large greenhouse it will be uncomfortable without doors and air vents. To assemble the doors, you need two pipes for a rack about two meters high, three for bars from 50 to 70 cm and fittings: four corners and two tees for connecting pipes.

Attach tees and angles to the rack, insert transverse parts into them.Attach hinges to one of the racks. The door should be covered with a covering material or polycarbonate, depending on the design. Tees can be used to improve structural strength. With their help, you can horizontally install additional pipes on the arch, which will make the frame stronger.

Installation

Before installing a greenhouse should prepare the site. Even if the plans are to make the simplest model, covering the bed with arcs, and the foundation is not required, you still have to start by creating the bed itself.

The simplest method of making an arched greenhouse from plastic pipes above the garden includes the following steps.

- the arcs are installed above the beds at an equal distance, as a rule - 50 cm from each other, so that the covering material does not sag;

- it is necessary to cut the pipes. If the bed is not wide, then 1.5 m is enough. The number of pipes will depend on the length of the bed;

- you need to bend the pipes in the shape of an arch, drop them into the ground at an equal depth. The arches must be the same height and well buried;

- should be covered with a bed of film or non-woven material. It is necessary to cover with a margin to prevent cold air from entering under the greenhouse, and it was possible to sprinkle the edges of covering material (about 20 cm) with earth or fix it with bricks.

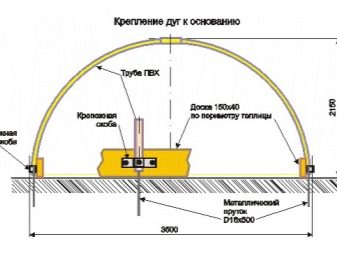

If the plans for the construction of the capital construction of a greenhouse, you must start with the foundation. It can be made from materials such as concrete, brick, blocks, stones, sleepers, bars or boards. It is better to use a bar with a size of 50x50 mm or 100x100 mm, boards - 50x100 mm or 50x150 mm.

To build a durable foundation on a prepared, leveled, more illuminated and protected from the wind place you need:

- markup on the drawing;

- pegs are driven in along the perimeter in the corners, a regular rope is attached to them;

- if the land under the greenhouse is not very good, you can remove the top layer of 1-2 spade shovels;

- by marking a trench is dug approximately in width and depth of 30 cm;

- the trench is compacted, rubble is poured to a third of the depth, sand is on top of the same depth. If the foundation is concrete, you must first block the reinforcement where the pipes will stand. Then make the formwork, fill the sand, gravel and pour the solution or immediately ready concrete. Do not forget to tamp everything consistently;

- from the top of the trench you need to put roofing material in two layers, the wooden foundation is closed and from the sides;

- boards or timber for the foundation should be treated twice with an antiseptic or liquid bitumen.When they are dry, you should lay them in a trench and attach them to each other with long screws, bolts or galvanized corners;

- using the level the foundation is checked.

The foundation can be done in another way.

To do this, follow these steps:

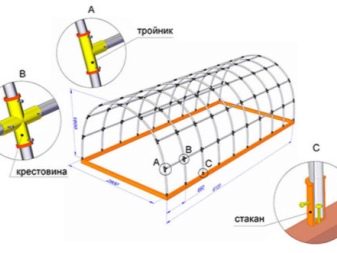

- to mark the site, but to dig not a trench, but to make grooves, where the pipes will stand;

- concretes or reinforcement with a diameter less than the internal diameter of the pipe must be concreted into these grooves;

- to score rods in both cases to a depth of not less than 30 cm, depending on the soil and wind strength in the region;

- on the surface, the reinforcement should be left at least half a meter high, preferably longer, which will be more expensive;

- the distance between the rods should not be less than a meter. If the greenhouse will cover with a film or non-woven material, it is necessary to install the rods more often or to pre-tension the metal or plastic mesh. The edges of the metal mesh should be covered so that the wind does not tear the film.

Now you need to cut the pipe to the desired size. Put on first one end of the pipe on the rod, the other end - on the rod from the opposite edge of the foundation.This procedure should be repeated until all pipes are in place. To keep the pipes tight on the reinforcing rods, they can be fastened with polymer clips or galvanized brackets. Greenhouse gables should be attached to the frame with the same fixtures.

Now it is necessary to strengthen the framework. For rigidity, it is necessary to attach transverse pipes necessarily at the very top in the center and from each side at least one pipe, depending on the width of the greenhouse. The ribs should pass along the entire length of the greenhouse, it is necessary to attach the transverse and longitudinal pipes to each other using clamps, preferably plastic. It is necessary to install the doors and vents, if they are provided for in the drawing. You can cut a hole instead of the door. To do this, cut the covering material of the desired size from the bottom, left and right, and not cut it from the top of the greenhouse.

The gable greenhouse can be assembled using polypropylene pipes with an inner layer of aluminum or fiberglass fastened together with tees. The foundation for such a greenhouse can be made, as for the arch.You can do without the foundation, but only the pipes or fittings will have to dig deeper into the ground, so as not to blow away the greenhouse.

Whatever the construction of a greenhouse, it must be covered. For this purpose, a film or non-woven material is used, which is fixed with a mesh, draped over the top, with ropes, double-sided tape or self-tapping screws. When using self-tapping screws, in order not to tear the film, under them pieces of plastic bottles, rubber or linoleum are enclosed as washers. It is better, of course, to buy special clips, which will facilitate the work and the fastening will be more reliable. You can make the clips themselves from pieces of a hose or pipe, cut along.

For temporary greenhouses, designed for the season or only for the spring, as a protection against recurrent frosts, ideal as a film, and covering material. But for a capital greenhouse such coverage is enough for no more than two seasons. And you have to start all over again. Polycarbonate is the best option for a capital greenhouse.

To cover the greenhouse of plastic pipes with polycarbonate, the following steps should be performed:

- attach polycarbonate to the frame pipes using self-tapping screws 3.2x25 mm in size with plastic washers;

- if the sheet is longer, use a sharp knife to cut the pipes along the edge;

- if one sheet is not enough, then the sheets should be attached to each other with an overlap of 10 cm;

- in order to strengthen the structure, a split profile is used for connecting fastening of polycarbonate sheets; it should be fixed in the same way;

- edges should be closed with plugs.

The best options

Small, portable greenhouse made without the hassle with minimal cash outlay.

Such a greenhouse design will require complex calculations, but it will surprise everyone.

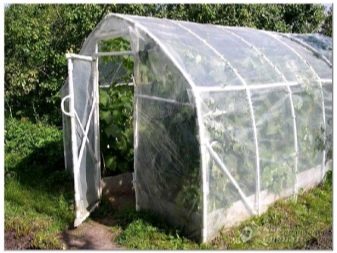

High arched greenhouse, covered with plastic wrap, is spacious and comfortable.

Arched greenhouses with wooden bases, covered with a grid, look beautiful and stylish.

The bed covered with plastic arches and non-woven material is a practical solution.

Arched greenhouses of different sizes, covered with film in one area, will help to arrange different plants conveniently.

A gabled greenhouse made of polypropylene pipes without a foundation is simple and easy.

An arched greenhouse covered with plastic wrap with a door is a reliable solution.

The arched greenhouse of metal pipes with a door covered with polycarbonate is durable and practical.

How to make a greenhouse of polypropylene pipes, see the following video.