How to choose and lay the rubber tiles for the playground?

Coverage of playgrounds should ensure the safety of children's active games. It is necessary that the material absorbs impact, does not slip, while being made of environmentally friendly materials and has good wear resistance. All these requirements fully comply with rubber plates.

Technology

The basis of the technology of manufacturing rubber coatings for sports children's corners lay processing recycled tire covers. To begin with, they are ground to a size of 1–5 mm, special fillers are added to the resulting mass, as well as polyurethane, then subjected to heat treatment and pressing under increased pressure. At the exit dense, wearproof and very long material in use turns out.Thus, two tasks are solved at once: making a safe covering of the playing area and recycling recyclables, which is important for the environment.

As a rule, two basic technologies are used:

- hot pressing;

- cold pressing.

In the first case, the molding of the tile and the polymerization of the crumbs occur simultaneously. Thus obtained plate has a low density, so it has good drainage properties. This procedure takes no more than 15 minutes. Cold pressing, however, implies a longer exposure, when the initial mixture is first pressed, and only then placed for 7–9 hours in a drying cabinet. Such products have a higher density, but the price for them is significantly higher.

Merits

Rubber tiles became a real hit, and The reasons for this are obvious:

- high resistance to abrasion;

- the tile does not form chips;

- under the influence of blows does not crack and does not deform;

- retains its original appearance for several years;

- has a long service life (can serve up to 15 years, and in the open air and, accordingly, under the constant influence of adverse weather factors);

- water resistance (the material does not absorb and does not accumulate moisture, as a result, does not form mold and does not contribute to the reproduction of fungi);

- the rough surface causes an anti-slip effect, so the material is optimal for laying near pools, and in winter no frost forms on the surface, so it is often used for arranging steps;

- high amortization capacity (the surface of the tile upon impact acts according to the spring principle, due to which the risk of injury is significantly minimized);

- simplicity of operation (the product is easy to clean, for which it is sufficient just to periodically rinse with water from a hose);

- resistance to direct sunlight, temperature fluctuations and aggressive environments;

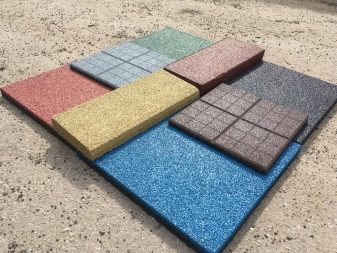

- manufacturers offer a wide range of rubber crumb of various colors and shades.

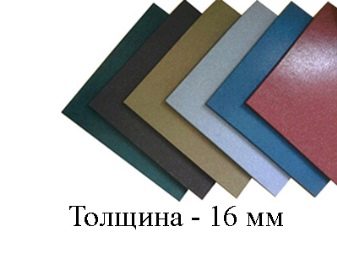

Thickness

From the size of the material significantly depend on the operational characteristics of the coating. The modern market offers tiles with parameters from 1 to 4.5 cm, and the acquisition of a particular model depends on the functional purpose of the future coating.

- The thinnest tile 1 cm thick is suitable for arranging the local area, walking zone and car parks.A similar tile is fixed on a pre-leveled base of dense material (concrete or asphalt) and fixed to a durable polyurethane adhesive. Despite the small thickness, the wear resistance of the product does not suffer, so the coating can be laid on any site where there is no constant industrial or simply increased load.

- Tile size of 1.6 cm and 2 cm is optimal for areas with significant point loads. These areas include areas near the pool and under the gym, as well as coating used in the arrangement of bicycle lanes. This tile is also mounted on an asphalt or concrete coating on a polyurethane adhesive.

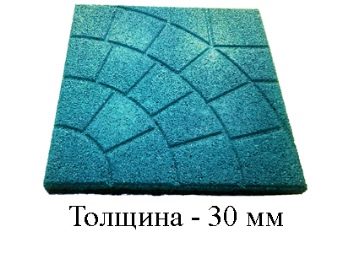

- The tile with a density of 3 cm is distinguished by its high springiness, and, therefore, by its high safety level. In addition, the material effectively absorbs noise and vibration, therefore, as a rule, it is taken for decoration of sports areas, as well as running and cycling paths, playing zones. This type of slab requires an even dense base, however, it may be imperfect: with small cracks, dents and chips.

- Model 4 cm is used for children's areas, which impose enhanced security requirements. This coating exhibits exceptionally high damping properties, provides perfect vibration and sound insulation. The advantages of the material is that it can be mounted on any loose basis: from rubble, pebbles or sand.

- The thickest tile, 4.5 cm thick, is practically unparalleled in its user features. It is used for areas with excessive loads of any type.

Appearance

From the point of view of design, tiles are chosen according to individual taste. As a rule, they take into account the colors of the surrounding houses adjacent to the playing area. The most popular are dark tones of red, blue, brown, green, as well as terracotta and less often - black. However, manufacturers constantly produce tiles in new shades and can even arrange products for personal orders. As a rule, within each site combine rubber tiles of several shades.

As for the form, there is also a large choice:

- square is a fairly universal type of tile, which is suitable for designing a platform of any type;

- wave - this model resembles a typical pavement, each new layer is mounted with a slight offset from the previous one;

- brick - looks like a familiar pavement, has a rather laconic configuration and is good for arranging narrow lanes;

- Spider web - got its name due to the peculiar pattern that is formed when attaching 4 tiles.

Piling

Training

If the tile is placed on a dense base, then in preparation it is sufficient to clear it of large debris. But the preliminary work with the ground requires more trouble.

First you need to remove all the weeds, better together with the roots. Then you need to completely remove the top layer of earth at 15–20 cm, after which the freed ground must be properly tamped down.

Cover the surface with fine gravel so that the height of the cushion is 5–7 cm for a regular walkway, 8–10 cm for a playground and 20 cm for placement of a car.

The next layer is a mixture of cement and sand. This composition should be filled with rubble. You can, of course, do without cement, but it gives a special strength to the formed coating.

After that, the surface level and proceed to the installation of tiles.

Piling

There are several rules obligatory for execution when laying a rubber tile on the sports or playground.

- Mandatory installation of curbs is required.

- For coatings laid on a solid base of concrete or asphalt, be sure to do a small angle of inclination of 2-3 degrees to ensure the flow of rain and melt water. It is not necessary to do this on ground coverings: moisture penetrates through rubber itself and is absorbed into the ground in a natural way.

- If the tile is mounted on a sand mixture without adding cement, it is necessary to use a coating with bushings that adhere to the groove-thorn principle.

- If during the installation of tiles between them and the borders formed free space, you should lay it pieces of the base material.

- After laying the tile, the finished coating should be plentifully covered with sand - the bulk material will fill all small joints and gaps.

Manufacturers

When arranging a playground and choosing a rubber coating, it is better to give preference to products of manufacturers who have gained a good reputation in the market. Among the leaders of this market segment can be identified several domestic companies.

- EcoSplineEcoSpline - a Moscow-based company operating on the market since 2009. The company's product line includes tiles of various sizes and shades, and the products are sold not only in Russia, but also far beyond its borders.

- "Dmitrovsky plant RTI" - also a Moscow-based company engaged in the processing of tire covers and the manufacture of rubber covering tiles. The range of products, in addition to coatings for the listed sites, includes anti-slip pads for street stairs.

- "Good deal." The company with such an optimistic name is located in the Tver region. For more than 10 years, it has been successfully producing and selling tiles designed for children's and sports areas, which is characterized by exceptional wear resistance, practicality and durability.

- "Ecostep". It produces tiles using a patented unique technology, which leads to obtaining the highest quality products, while the range includes not only standard versions of the plates, but also panels with drawings.

In conclusion, we note that soft rubberized tiles are a good coverage for children's playgrounds. It is environmentally friendly and safety, and its installation does not present any difficulties - and this is also an advantage, which explains the high popularity of the material.

Instructions for installation of rubber tiles, see the following video.