Needle roller for self-leveling floor: how to choose?

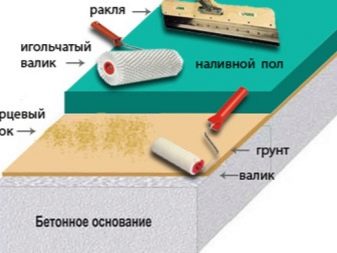

In recent years, self-leveling floors have become a trend in the design world of residential and commercial premises. Thanks to innovative technology, you can get a solid and perfectly smooth surface without spending a lot of effort. However, to create this kind of coating, you need to have on hand some tools, the main of which can be called a needle roller for the self-leveling floor.

Special features

A roller with needles of modern production is a handy device for performing internal work on the finishing of a room. To date, several types of useful building tools are being produced - for gypsum boards and forself-leveling floor. The main part of the product is a movable shaft worn on the handle, the entire surface of which is covered with needles. The appearance of this device resembles a magnetic roller for massage.

Needle levelers made of plastic or metal. Metal models are much heavier than plastic ones; they are intended for bulk work, designed to level the floor of large areas.

Almost all manufacturers provide a universal holder for the improvised tool, in which you can build a stick without any effort. It facilitates work with bulk liquids, eliminates the attachment of additional physical activity. As well as the main part of the product - a cylinder, a handle with an extension can be made of wood or polyvinyl chloride.

In addition to the material of manufacture, needle rollers differ among themselves in thickness (shaft diameter), needle width and length.

The width of the working surface ranges from 150–600 mm.

Different width indicates the use of the tool in a certain type of room:

- The device with a size of 15-25 cm and a diameter of 100 mm or more is intended for rolling the bulk mixture in hard-to-reach places.

- A cylinder with a thickness of 25-40 cm is used for a self-leveling floor in residential premises and offices with an area of 10-20 m2 rooms.

- A shaft with a width of 400-600 mm is used for leveling screeds in rooms with an area of more than 50 m2.

Where is it used?

Roller with needles for self-leveling flooring can be used for laying any type of building composition:

- for polymer concrete coatings;

- gypsum and cement composition;

- polymeric bulk coverings.

The thickness of the latter is insignificant, about 1.5 cm, therefore, for such coatings, you can use a tool with short spikes that are rarely placed. When pouring other types of flooring with greater thickness, for example, about 3 centimeters, you should choose rollers with longer and more dense needles.

If the instrument is purchased for processing a floor whose thickness does not exceed 5 cm, it is better to work with a roller with sharp spikes. In this case, the final result of the work will be of higher quality and aesthetic.

The bulk of the rollers are made of plastic, so it’s worth a while to clarify with the seller how the roller with needles reacts to the direct effects of chemicals (solvents) and other chemicals used in the design of the floor.

Purpose

The main purpose of the spiked roller is to uniformly roll the liquid mixture over the surface, which needs leveling. Such a manipulation allows you to remove from the building structure all the excess, even the tiniest air bubbles. In the end, after complete drying, it turns out perfectly smooth coating without voids.

Rolling the mixture is a very important process. If even a small amount of bubbles remain in a frozen form in the structure of the mixture, such a surface will be considered defective. Pores and voids will necessarily lead to early wear of the floor covering, loss of its attractive appearance.

Thus, the alignment of the self-leveling floor with a pin roller with needles is an important stage of finishing work, which is unacceptable to ignore. Badly spilled and rolled mixture spoil all the work on the arrangement of the room.

During the repair, it must be remembered that the furniture will continue to stand on the floor, often quite heavy, so it is important to properly lay the floors, in which the needle roller will help.

How to work with a roller?

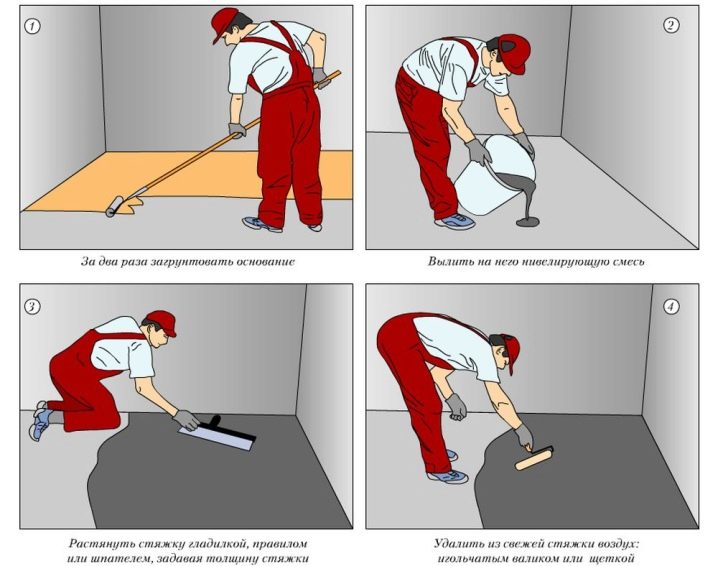

Bulk floor falls very quickly, so you need to be prepared forwhat to work with the roller will have in accelerated mode. The best option is when two people are engaged in laying the flooring.

Each time the mixture is poured onto the floor surface, it will be necessary to pass through it with a spiked roller. The final result of the works largely depends on the quality of the selected device, so it’s better not to risk and immediately buy not the budget version of an unknown manufacturer but more expensive and high-quality models.

Thanks to the roller for pouring the floor, you can evenly distribute the mixture over the surface, it will eliminate excess air bubbles and help to level the floor.

To obtain a perfectly smooth coverage, you need to follow these rules:

- before pouring the mixture from the leveling surface, remove all unnecessary, even the smallest particles of dust, ideally, the floor should be vacuumed;

- use only high-quality tools;

- Allow the floor to dry under the conditions specified in the instructions.

How to choose?

If you carefully examine the needle roller, it is difficult not to mention the simplicity of its design. However, for the correct choice of this construction device, you need to take into account certain points.

Manufacturing material

Release needle rollers from two materials: metal and plastic. More popular are plastic models. They are not as heavy as metal, and cost much less. According to other characteristics, the plastic product for rolling is no different from metal samples.

However, buying a roller made of PVC is to ask the seller whether the roller will withstand exposure to solvents.

The main advantage of the metal tool - smaller needles, which contributes to a deeper penetration into the self-leveling compound.

Other advantages include:

- long service life;

- resistance to chemical reagents.

The advantage of the plastic roller is the low price and light weight. The last factor facilitates the work with this tool.

Width

The width of the rollers for leveling the self-leveling floor varies in the range of 15–60 cm. The wide roller is more convenient in operation, and the mixture under its weight rolls out faster.

The narrow roller is indispensable in hard to reach places. Therefore, it is better to buy several rollers of different widths.

The wide and narrow roller is different and the scope of their destination.Wide tool suitable for industrial liquid floor. With it, you can handle a large area in a matter of minutes. The only drawback - poor maneuverability, wide shafts can not properly roll the floor in the corners and other hard to reach places.

This lack is not in narrow models. They are agile and mobile, with such models the surface in the corners is rolled ideally, however, the time of rolling the filling composition with narrow rollers is increased compared with the use of wide devices. Typically, such options are used in small rooms or rooms with a complex layout.

Needle length

As a rule, the length of the needles of rollers with spikes ranges from 1 to 3.5 centimeters. This criterion is important to consider prior to purchase, since the thickness of the rolling stock in different cases is different, and therefore the length of the spikes cannot be universal. The basic rule when choosing the length of the spikes: it must be greater than the height of the floor leveling mortar.

Rollers with long needles have a protective cover that protects the already finished surface from drops of a new mixture. The protective cover can be built independently.

The shape of the spikes also varies: in the form of a cone and a drop. The latter, as practice has shown, is not very effective, therefore experts do not recommend using rollers with such a configuration of needles.

Roller handle

The usability of the roller depends on the length of the handle - the longer it is, the more comfortable it is for a person to do the work of leveling the floor. Before buying, you need to carefully inspect the handle and make sure that there is a landing slot in it for installing the holder. If the roller is sold with a ready holder, it is better to choose the one with the holder longer.

For convenient work, some manufacturers equip the needle roller with a telescopic handle, with which you can effortlessly handle a large area of the room. This handle is made of plastic or wood.

Alternative tool

The modern market of construction tools has not yet found a replacement roller with needles for self-leveling floor. The use of this particular tool greatly simplifies the installation of a self-leveling coating and provides a high-class end result. The process of pouring the mixture for the floor involves leveling the composition with a special trowel and rolling it with a spiked roller, therefore, the latter can not be done.

The use of a needle shaft is mandatory when pouring floors from a polymer mixture, as well as laying floors on a cement base.

Where can one buy?

If necessary, the needle roller can be searched in any hardware store. In this place, you can touch the tool, inspect it from all sides, check the goods before it is acquired for the presence of defects, defects. This approach is ideal for beginners, with no work experience, who cannot choose a tool without the help of a sales assistant.

Low cost models can be seen in the building markets., but often the production of spontaneous points is not of decent quality. However, a reasonable price allows you to buy several options at once, and if one roller is not satisfied with something, you can replace it with another option.

Those who know exactly which model of needle roller is needed, from which material, which manufacturer is credible, you can safely buy a roller in the online store. In this case, to get the desired tool, you do not even have to leave the house.

You can save money and make a needle roller with your own hands, see the next video for more details.