Bulk floor in the garage: the pros and cons

The flooring in such a room as the garage is constantly experiencing aggressive exploitation. In addition to the weight of the car, he has to feel from time to time the effects of various chemical reagents and withstand temperature changes. That is why, when choosing a material for such a coating, it is necessary to take into account all the influencing factors. Beautiful and high-quality self-leveling floors completely meet such serious requirements.

Special features

To find the best type of floor, do not forget that:

- The garage is not built in order to end up with a good place to store home preservation. In this room is placed a personal vehicle that has a significant weight. This means that the floor will be exposed to a huge impact of this mass.

- The presence of a car means constant care for it and the implementation of repair work in the walls of the garage. This kind of work may be associated with the use of various tools. These rather heavy fixtures can fall out of hands and fall to the floor, spoiling it. The strength of coatings in such rooms should be very high.

- Nowadays it is difficult to find a car that at least from time to time there was no leakage in any of the systems. The garage often repairs the car, recharging the battery. The floor here must be resistant to the effects of various aggressive substances and not be afraid of moisture.

- Technique should not be kept in the dirt and therefore the process of targeting cleanliness in the garage is often difficult. Rough floor with cracks sometimes free from dust and debris is not easy. From this it follows that a properly selected floor must be perfectly level.

- The selected coating must comply with the rules of fire safety. When repairing a car, its owner can use a blowtorch and welding machine. In this case, the selected floor for the garage floor should not have flammable properties.

For these reasons, beautiful and durable self-leveling floors for modern garages are just perfect. They will not be covered with cracks even with very strong frosts. Such coatings are not afraid of temperature differences and are completely safe. They will not stick to dust and dirt, because the bulk material does not have the property of electrification. The surface of such floors is flat, so you can quickly get out of the room, if necessary.

Even a self-leveling film with a thickness of only 1.5 mm is already distinguished by the excellent qualities of waterproofing and heat insulation. The oils spilled here will not be absorbed into the coating and will never ruin the floor.

There is, however, in the acquisition of such coatings and one negative point. Flood floors are quite expensive. Installation of just one square meter may require about $ 100. However, to save money, you can apply this material with the thinnest layer.

Kinds

Manufacturers of building materials today offer special liquid compounds to interested individuals - these are bulk-type coatings that tend to self-level.Today, their role is played by the composition of a single binder component (it can be cement and gypsum), the right amount of additives, additives from polymers and various fillers. When mixed with water, highly mobile solutions are formed, which are actively used for leveling coatings of any kind (can be mineral, wood or soil), as well as for quick installation or high-quality repair of a site with defects.

The main condition for the application - the most even surface, solidly polished with a special industrial grinding machine. The presence of even a small tubercle or dimples - and the filler floor instantly abrades or begins to split off. But if you follow all the instructions, the coating will in fact form a film base that is strong and resistant to aggressive substances and water, which will withstand 5-7 years of active use.

There are many types of self-leveling floor for garage premises:

- The most popular in our time are epoxy coatings with an optimal balance of cost and quality. The quartz sand included in their composition gives the product excellent resistance to abrasivematerials (to avoid abrasion). The presence of resins will protect the surface from exposure to chemical elements. For all the properties to work, you just need to apply a layer of such a floor with a thickness of 0.1 cm. Water resistance and frost-resistant characteristics are obvious advantages in the treasury of the positive characteristics of such floors. But there is also a minus - low elasticity.

- One of the most inexpensive option for self-leveling floors is the so-called cement-acrylic formulations. A durable floor will be formed after a layer of 1.2 cm has been poured. This material will be able to withstand heavy loads, will not delaminate, guarantees no slip effect.

- The highest degree of resistance to wear has a polyurethane coating, which has a lot of positive properties. It is resistant to different temperatures and chemical reagents, lack of fear of vibrations and various impacts. The floor of polyurethane has a high elasticity, and this quality is not always found in other self-leveling floors. However, this whole set of positive qualities will cost a lot. The coating of polyurethane base is very demanding on the base on which it will be poured, for this reason, its use in the garage can be found quite rarely.

- The bulk floor of methyl methacrylate can also be seen infrequently. It differs in durability, elasticity and frost resistance. However, this mixture hardens too quickly, so the installation of the floor in the garage with this composition can be very difficult. In addition, this coating has a too harsh and unpleasant smell during the drying period.

- You can also find this type of coverage, as decorative finishing floors. It is the paint consisting of 1 or 2 polymeric components. It should be laid on a concrete base with a layer of 0.1-0.4 cm to create a coating that is resistant to numerous impact and other loads, aggressive elements, abrasion. As the main base, elastomers (polyurethane or epoxide) are used. The popularity of polymer coatings contribute to excellent quality characteristics. Such a floor will be used for about 40 years, the material is not afraid of fire, resistant to negative temperatures, can easily withstand loads of varying degrees. Installation of such a floor can be done by hand with the help of an assistant, without the involvement of professionals.

- Very often you can hear about the rubber coating of the bulk type (or as it is also called - elastic coating). Most companies producing paints and varnishes, produce this popular product under the original name "rubber paint". She is not afraid of water, the sun's rays and sudden changes in temperature (can withstand from -50 to +60 degrees). However, after carefully reading the instructions, you will see that this coating is not suitable for installation on floors.

Quite often, this kind of flooring is chosen not only as a normal coating, but also used as a base on which other materials are laid. You can lay on such floors linoleum, which requires a completely flat surface. Flooded floor, especially self-leveling type, ideal for this purpose, because it does not have joints.

Which option is better to choose?

To properly select the type of self-leveling floor for a garage room, you need to know that Selected material must fully meet certain qualities:

- Compressive strength and abrasion resistance. An ordinary car can be weighing from 1 ton and much more.This weight will be distributed over 4 points - in those places where the wheels come into contact with the floor. When driving, car tires impact the floor of the room as an abrasive, which destroys its base.

- Resistance to all sorts of loads. Garage - a place where you can put your car, it is also a workshop for repair, as well as a storage room for tools, spare parts or other things. Such a floor should quietly tolerate frequent wet cleaning and any kind of load, not reacting to the effects of gasoline, oil, antifreeze.

- Resistance to temperature difference. Temperature changes in garages are significant. So that there is no need to permanently repair the cracked covering on the floor, it must have frost-resistant type additives in its composition and belong to materials intended for external work.

- Ease of use. Experienced ordinary people know that some materials are quite difficult, and sometimes it is simply impossible to remove stains from gasoline, oil or tire tracks. Therefore, this criterion is as important as all the others.

Determine what characteristics are most important to your garage.and on the basis of these conclusions make your final choice in favor of one of the modern types of self-leveling coatings.

Base arrangement

Before you carefully start pouring the floor in the garage, you should prepare it well for this difficult process. Cracks and other defects should be completely absent on the surface of the base, the floor should be durable and smooth. The application of the floor occurs on the concrete screed, if defects are found, they are urgently removed. Significant deviations or the presence of many detected damage will require an urgent replacement of the foundation of concrete with a more even coating.

Installation of a floor of a bulk look for the room of garage from scratch is a whole system of the preparatory stages:

- Need to prepare a garage pit. To do this, remove the soil layer (depth 0.3 m).

- The surface is equal to and 15 cm generously filled with fine gravel. You can drive in pegs with marks to clarify the height of the pillow. Layer well rammed, stakes are removed.

- A layer of sand (0.15 m high) is poured over the pillow. To better tamp it, it is first well soaked.

- Not less important stage in the formation of a quality base under the floor of the flood - ensuring its waterproofing qualities. For this purpose, you can choose roofing material, and even better - polyethylene, the density of which should not be less than 100 microns. Cloth cover the entire area of the room with a small spade on the walls. The connection near the existing lanes should overlap by 10-15 cm.

- Above the waterproofing must go reinforcing material. In order for the filler floor to calmly withstand serious loads in a garage as long as possible, it is better to choose cells measuring 15x15 cm. The diameter of such reinforcement will be 0.8 cm, it is connected with wire, you can also connect the reinforcement by welding.

Installation of fittings is performed on supports. They are plastic or brick. Follow the level of the tie will allow special beacons. They are made of pipes or profile.

Installation is carried out 5 cm above the framework of the reinforcement on the concrete layer, which is distributed through the 0.2 m guide length. The very first beacon is placed 50 cm from the wall of the garage, the distance between it and the next will be about 1 m (if the length of the rule allows).

- The strength of the future coating depends on the quality characteristics of the concrete itself.To create a mortar, select cement types M400 or M500, by the way, the choice of a particular brand will affect the proportions of the solution. The distance between the beacons is filled with a solution of cement. Concrete is first equalized with the help of a spade on the floor, after which it is drawn by a rule that must slide along the guides.

- A day later, the beacons are removed, the floor area of the concrete is filled with a similar solution.

- It is permissible to begin the installation of a self-leveling coating only after the concrete screed has completely dried, and it will dry for a month.

Fill technology

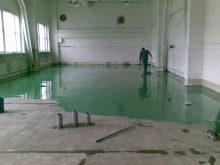

The self-leveling floor has a composition of 2 components, which are connected before the start of the pouring process. If you want to mix the mixture with a drill, you need a tool with a power of 800 W, and the process itself should be carried out at a speed of no more than 500 revolutions per minute. You can fill it up with your own hands, without the help of a specialist, or by entrusting this process to experienced professionals.

Mixing should be carried out at a temperature range from 14 to 25 degrees. The pouring process must be started from the furthest point of the floor surface of the garage, moving step by step to the doorway. The solution is bottled parallel to the walls.Equal bulk floor with a notched trowel. To squeeze out air bubbles and achieve the desired layer thickness, it is best to choose a needle roller for surface treatment.

The joints between the strips of the filler cover gently reduce using a needle roller. It is impossible to stop the installation for a minute, so it is much more convenient to fill the coating together over a large area, one will spill the mixture, the second one will level it. Only half an hour the quality of the finished solution will be maintained, after which it will begin to harden. You can walk on the finished floor only after 1-2 days, full use can be started 7 days after the fill.

Tips

- When buying self-leveling floors for garage conditions, experts advise to stop the final choice on epoxy or polyurethane compounds. To save money, it is better to limit the impregnation of the base of concrete with polyurethane. Clearly, this floor, of course, will not, but for the garage is not the most important factor.

- To calculate the costs You can rely on such approximate expenditure indicators:

- primer composition - 0.4 kg per square meter;

- "Fill" - 2.8 kg per square meter.

- When arranging the "finish" floor on concrete (without a screed), it is best to first walk on the surface with a grinder. This will help remove all sorts of particles from it (rubber from tires).

- Bulk floor is different from the usual in that it has no seams and joints. Glossy coating will not lose its shine. Cleaning will be an unsophisticated affair, you can just walk on this floor with a vacuum cleaner or a wet mop. You can care for the self-leveling floor in the garage with electric brooms, steam mops, brushes and a variety of detergents and disinfectants.

- Despite the fact that methyl methacrylate self-leveling floor is considered to be the most budgetary, many experts oppose its use - when pouring, the mixture releases carcinogenic components, which may be unsafe for health.

- To increase the wear resistance of the floor surface and protect it from stress and other effects, a protective varnish coat can be applied. With it, the life of the floor can be significantly extended.

On the pros and cons of the self-leveling floor in the garage, see the following video.