Superfinishing bulk floor of Vetonit 3000

In the process of construction and repair, each material and composition has a certain value. For the final floor design, special leveling compounds are used. A wide range of products gives customers virtually unlimited freedom of choice.

As in any segment of the market, among the levelers there are their leaders. The self-leveling floor Vetonit 3000 is very popular.

A solution of this type is considered to be an ideal choice for floor decoration in various types of premises: residential buildings, public buildings, warehouses, enterprises, workshops and much more.

Special features

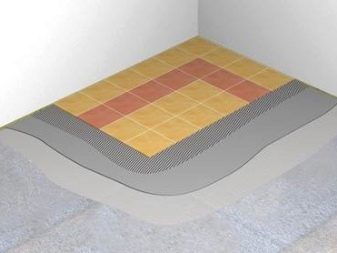

The composition of Vetonit 3000 is used both in the construction of a new building and during the repair of an existing base. Concrete or cement-sand floors are covered with mortar. Using the equalizer, it turns out a smooth, practical and strong finish.Further, if necessary, a floor covering can be laid over the layer: parquet, laminate, linoleum, tile and other finishes.

Experts say that the fill can be used as the final layer for the screeds used when laying the heated floor system. Due to the above characteristics, the product is widespread.

It is possible to put filling by a manual method without use of the special equipment. But also use in rooms with the increased or lowered humidity is allowed.

Short description

Superfinishing fill is sold dry. The product contains fine lime, cement and other special components. They are necessary for excellent practicality and density of coverage.

Material Description:

- composition color is gray;

- release form - paper packaging of 25 kilograms;

- composition of the mixture - for 25 kilograms of dry matter, 7 liters of water are needed;

- shrinkage - one month after application, shrinkage will be max. 0.5 mm / m;

- use - after preparation, the solution must be applied within 40 minutes;

- shelf life - the manufacturer guarantees the safety of products for 6 months, provided that all storage standards are fully complied with.

Remember that the above characteristics have only quality products, made with all the norms.

Technical characteristics of the composition

Before purchasing it is necessary to familiarize yourself with the technical and operational characteristics of the composition. These figures demonstrate the capabilities of the self-leveling floor:

- Finishing layer. With the help of the fill you can make a coating with a thickness that will vary from 0.5 to 5 millimeters. To make the coating denser, the solution is applied in several layers. When pouring be sure to consider the possibility of shrinkage from 0.8 to one millimeter.

- Hardening. The structure completely dries in 28 days. After this period of time, the material acquires the final hardness and strength. Despite such a long interval, you can walk on the floor after only 5-6 hours. Time depends on the indoor climate (temperature, humidity, air circulation, direct sunlight).It is necessary to lay a decorative covering not earlier than in three days.

- Temperature conditions When using the Vetonit 3000 finish fill, the optimum temperature conditions in the room should be 10 to 25 degrees Celsius above zero. In order for the solidification process to proceed as quickly and efficiently as possible, it is necessary that the temperature in the room be from 20 to 23 degrees Celsius with a plus sign.

- Consumption. Experts call the charge of pouring Vetonit 3000 one of the main advantages of the product. On 1 m2 of surface, approximately 1.5 kilograms of composition are necessary, provided that the layer thickness is 1 millimeter. Analogs have a larger volume. To ensure minimum consumption, it is necessary to carefully prepare the surface and mix the composition with higher quality before using. And it is also necessary to clean the base and fix the defects.

Advantages and disadvantages

After analyzing the equalizer, a list of advantages of pouring Vetonit 3000 was compiled:

- increased resistance to moisture;

- advantageous consumption of the mixture;

- refractoriness;

- excellent leveling function;

- fast drying;

- strength;

- resistance to mechanical damage and stress;

- ease of preparation and use;

- excellent flattening of layers;

- esthetic effect;

- the possibility of registration of a thin layer.

Restrictions

Before using the product should be familiar with the restrictions. The first thing to do is to mark the correct proportions when diluting the mixture. Excess fluid levels will affect the performance of the composition. As a result, the density of the layer decreases, possibly the formation of defects.

Features of the composition

Response specifications are achieved due to the presence of special components in the composition. In addition to the basic elements, additional components make the layer durable, wear-resistant, reliable, strong, smooth and durable.

Manufacturers in the process of manufacturing a product using special cements. In contrast to the standard substance, the specialized component has enhanced performance. And also limestone is used. Fraction of the mixture: less than 0.3 millimeter.

Packing and storage

For packaging substances using special multi-layer paper.Three-layer bags reliably protect products during transportation and storage. Polyethylene is also used in the manufacture of packaging in the form of a middle layer. It is necessary in order to protect the composition from moisture and moisture.

It is necessary to store the equalizer in the whole original packing. This is a guarantee that the product will retain all performance characteristics prior to application and during use.

Packages must be stored in a dry place out of the reach of children and animals.

Floor preparation

The key to an excellent result is not only the correct use of the solution, but also the proper preparation of the floor surface. This process is obligatory, regardless of its state and novelty. If the top layer of the base is not strong enough and durable, it is necessary to get rid of it. This is done with the help of thorough grinding.

Without a special grinder is indispensable. It is easy to work with equipment, but you must have some experience in this industry.

And also the base should be cleaned of dirt: old enamel or varnish, stains, greasy marks and so on.If necessary, all defects such as cracks, grooves, chips and other irregularities should be corrected. Only after a full preparation on the floor can be applied fill.

In the presence of defects in the amount of 5 millimeters the composition cannot be used.

Before treatment, the floor is treated with a primer. For more economical consumption, apply two ground coat. Experts strongly recommend using a dispersion composition as a treatment. So the composition of the Vetonit 3000 will be more reliable to engage with the surface.

Advice from a specialist

After application, carefully sifted sand is applied to the primer. An additional component will increase the rate of adhesion of the surface to the leveling compound. Only after that it is necessary to prepare the main solution, because its time of use after dilution is limited.

For each batch of products there is an instruction. Be sure to stick to it while preparing the mixture, carefully performing each item. In this case, problems with the dilution of the composition should not be.

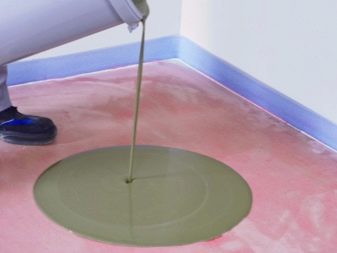

The working process

Superfinishing fill Vetonit 3000 can be used for flooring in rooms of various types, regardless of terrain.Artificial or natural finishing material can be laid on top of the layer.

While working, make sure that there are no drafts in the room. Air flow affects not only the process of solidification, but also the smoothness of the layer. Do not hurry, work measuredly and carefully, especially if you do not have adequate experience in the work of this type. It is strictly forbidden to apply the next layer of the self-leveling floor before the previous one hardens. Despite the moisture resistance of the material, it is undesirable to carry out repair work in a room with high humidity.

It is strongly not recommended to dilute the composition manually. A more effective option is to use a drill with a special nozzle.

Paint is not recommended to use as a decorative coating on top of the fill.

Reviews

To learn more about the effectiveness of the self-leveling floor, you should read the customer reviews. Finding them in the vast world wide web is easy, especially when it comes to a common product. Opinions about Vetonit 3000 are shared by both experienced craftsmen from the repair sector, as well as ordinary customers who have decided to refresh or renovate the floors in the room.

More than all the reviews, about 70% - positive and laudatory. As advantages note such qualities.: profitable expense, wide scope of use, wear resistance, practicality and other advantages mentioned above in the article.

Negative reviews are also available. Some buyers believe that the price of the goods is too high, and a better alternative can be found on the market. And users also complained about the formation of cracks after hardening, however, this disadvantage may be associated with violations in the process of preparing the mixture, its application or hardening.

Conclusion

With proper use of self-leveling floor Vetonit 3000 you get a flat, durable and wear-resistant base. The material has several advantages, due to which the composition has become one of the leaders and continues to be at the peak of popularity. And also the product has a wide scope of use. Due to the distribution of goods can be found in any major store for construction and repair.

In order not to become a victim of counterfeit goods, purchase mixes only in the stores held, which are official distributors of products. Require the availability of appropriate certificates confirming the quality.

To self-pour the floor, it is not necessary to be a professional. Preparation and use of the composition is easy and simple. Conducting repair yourself, you will save material resources.

For information on how to independently use Vetonit 3000, see below.