Cork floor: the pros and cons

Cork floors began to come into fashion not so long ago, so the debate about their positive and negative qualities still does not subside, since for a number of ordinary people such coverage is absolutely unfamiliar.

Special features

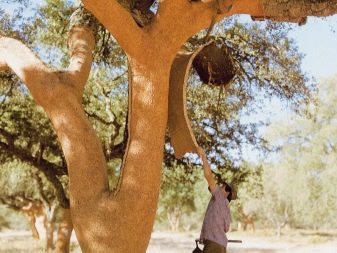

The bark of cork, which grows in countries located near the Mediterranean Sea, is used to produce various products that are necessary in everyday life. But the most original product can be considered a cork flooring.

For the release of this floor is used:

- Solid veneer - minimum upper bark cut. It is used not only as a product for floors, but also to decorate ceilings and walls of the house.

- Agglomerate. It is made from ground bark and glued into sheets using high temperatures and pressure. A special feature of a cork is its structure, since it consists of a multitude of cells that are filled with air. It is this property that guarantees you the elasticity of the coating under severe loads.

- Combining sinter with veneer. This product uses unselected veneer, which is glued with agglomerate under pressure.

Composition and manufacturing process

Cork is the bark of the cork tree, which grows in countries with very warm climates. To obtain raw wood is not destroyed. Experts remove the topmost layer of its bark, after which it can calmly grow further. The crust is completely crushed, gets into special forms that are heated in furnaces, and then it gets under the press with high pressure. As a result, the original material comes out, which is called "suberin" (ground cork + air bubbles). After layer 2, the materials are glued together with resin in a mixture with wood dust, becoming a dense monolith.

Corks produce a board or tile that has its own excellent characteristics and thickness. Today sprayed coating is also popular - excellent finishing material, which includes cork bark and acrylic binder.

Kinds

Cork flooring is divided into 3 types:

- Glue;

- Castle;

- Technical.

Floors that are mounted on a glue base are completely natural. They are presented in the form of whole pressed panels of various sizes, the thickness of the products reaches 6 mm.

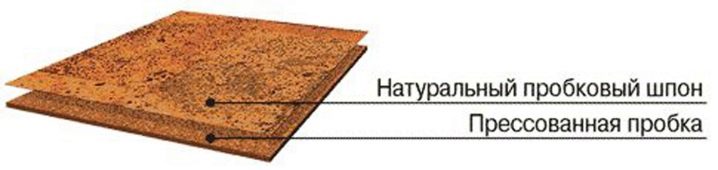

Such tiles themselves have two layers:

- The bottom cork layer is compressed crumb;

- The front layer is high-grade veneer.

The adhesive-based cork coating is highly moisture-resistant, does not fear sudden temperature fluctuations, as it is impregnated with a special substance. Applying a cork of various colors, you can lay an original mosaic on the floor and thanks to this you can make an exclusive finish. These panels do not need a substrate and are fixed with universal glue.

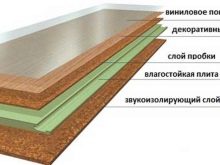

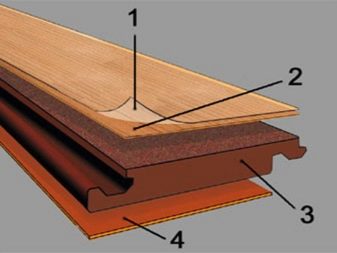

Castle floors are often called cork laminate (sometimes “floating” - well-damped). This product is made of many layers. Below is a layer of compressed crumb (agglomerate), in the middle of the product is MDF, and on top - a veneer or a number of layers of crumb. The thickness of such a plate can be 1.2 cm. Like the usual laminate, such a floor has locks, which makes it much easier to install it. No glue or sealants will be needed here, only a special substrate is used.

The floors of the technical plan are not used for the final finishing of the floors, as they are essentially just remnants of cork production. Such a product is produced in plates; it can be rolled or granulated.

Usually, a special layer (facial) is applied to the upper part of the coating, which will protect the material from harmful effects and give it a stylish look.

You can choose several options for such coatings:

- Thin veneer. Companies often use this material to glue it onto a cork base. It allows you to get excellent decorative properties.

- With a layer of varnish. It uses traditional veneer, and on top of it put a good varnish for the highest quality protection.

- With vinyl. A layer of veneer is applied on the material, and then it is covered with a special film to protect the product from moisture and various damages.

- From expensive wood with vinyl. Here, the most exotic tree species are selected as veneer.

You can also find this type of product as a “liquid” cork - this is a high-quality insulation, as well as a sealant and an insulator. It is a material formed by a mixture of fine crumbs from cork and elastic material. It can be used to eliminate the gaps between the joints of plates and floor sheets.

Cork floors are divided by type of coating and are:

- Technical traffic jam - most often acts as a substrate in order to make the floor warmer or soundproof it. It is also possible to purchase ground cork granules - they are suitable for filling various voids in different designs.

- Cork tiles. This type of material is suitable for coating on glue and is realized in tiles. Standard options help lay out a unique image and create a moisture-resistant floor.

- Cork parquet. This type is often called the "floating" floor. As a basis, MDF is used on which a cork is glued. This parquet has strong locks to facilitate its assembly.

- Cork floor mats they have excellent antimicrobial and antifungal properties, they are suitable for yoga.

Advantages and disadvantages

The advantages of cork flooring:

- The cork is completely environmentally friendly;

- Anti-static coating;

- Safe for humans, beneficial to health;

- Does not give mold or mildew;

- It has excellent sound insulation;

- It is comfortable to walk barefoot on this floor;

- Ease of care;

- Duration of service is about 10 years;

- The ability to create unique patterns on the floor;

- Without problems transfers various temperatures.

Despite all these advantages, the floor of the cork has its disadvantages, among which are:

- High price;

- Low moisture resistance without lacquer coating;

- Flammability;

- Under massive furniture, the stopper may be deformed, traces may remain from the furniture legs;

- A perfectly flat floor surface is required before installation;

- It is not recommended to start walking or putting furniture on the glued floor immediately;

- Afraid of the direct rays of the sun.

Mounting technique

The main requirement when laying such a unique coating is the creation of a quality base. It should not have cracks, irregularities or strong differences in height.

The technology of laying such a coating requires the prevention of the coincidence of the joints in 2 materials used, since this may sooner or later lead to damage to the surface. After preparing the floor for installation, the cork is carefully glued to it with special glue.

The following professional installation guidelines should be considered:

- it is not necessary to put the cork in as soon as she gets into the house;

- lay out the rolls or tiles in color and texture;

- Try to lay the coating in the form of a tile from the very center of the room to its edges. Better to lay the tile crosswise - then you will be able to get the effect of a solid sheet;

- if you need to lay out a certain pattern or image, then first fold it without glue and move the tiles one to the other as accurately as possible;

- glue should be applied to the tile, and on the very foundation of the floor. Give the glue a couple of minutes to dry well;

- on tiles that have just been glued, you can knock a little with a rubber mallet;

- try to remove excess glue before it dries;

- it will be possible to walk in traffic only a day after installation, and it will be possible to arrange furniture on it not earlier than in 3 days.

Required tools

To install the adhesive floor will be needed:

- high-quality glue;

- jigsaw;

- the pallet for convenient putting glue;

- rubber mallet;

- level.

For the installation of a floating cork cover:

- spacer wedges;

- rubber mallet;

- PVC film;

- special substrate;

- jigsaw.

The sequence of actions when laying

If you want to lay the floor of the cork with your own hands, then first you should know that just before laying the cover you need to prepare the base itself well. It must be remembered that the panels are placed from the cork on a perfectly flat surface; all the differences in the subfloor must be eliminated even before installation, either with a screed or with a self-leveling mixture.

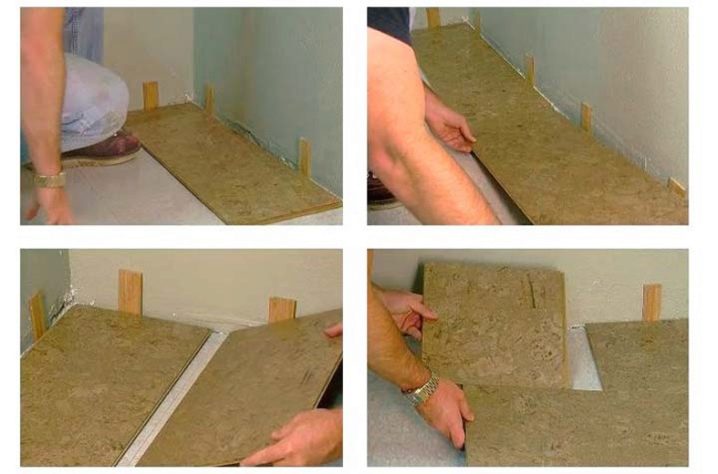

With lock connection

Laying this type of coating is similar to the technology of installation of laminate. Work begins with the assembly of the very first row, then the second one is typed so that half of the already laid tile is offset. It will save your expenses on used materials and allow you to get a bright and interesting picture.

From the wall to the coating, small gaps of 1 to 2 cm should be left. This is necessary, since cork is a “breathing” material, and its parameters may change slightly with time. The gaps will then be hidden by the plinth.

To prevent moisture from entering these gaps, it is recommended to apply a specialized wax sealant between the panels on the part of the board where the lock is located.

Glue-based

This floor is mounted only on a very flat surface, ideally, if it is a cement screed. You can lay the cork on the old linoleum, if it is well preserved.

Work on the installation of cork begins with the center of the room, which is different from the installation of laminate. First, the floor is laid out in order to know exactly where to lay the tile. At installation the special glue intended for work with coverings from a cork is used.

Glue is carefully applied to the tile, the product is carefully pressed to the floor. The difficulty of this process is to evenly lay the tile for the most even joints. At the end of the work, it is necessary to ventilate the room and wait 36 hours before the glue dries completely. Do not forget about the varnish - if you paint the base of the cork with high-quality coating, then the durability of the coating will increase significantly. During operation, it is often the lacquer that is damaged, and not the cork.

Where better to use: interior examples

The scope of such floors is very extensive.

- In the bathroom cork is laid under the tile, but at the same time it will not be as cold as ordinary tile.With the help of toning an interesting color can be presented to the product. This will facilitate the choice of the floor for the interior coloring of the desired room.

- In the kitchen, hall and hallway it is better to use a glue plug, and for a living room, bedroom or a nursery it is better to choose a lock item.

Glue cork without varnish will be an excellent option for virtually any space. And choosing a cork with 2-3 layers of lacquer, you can not be afraid of floods or awkward damage.

- Cork floor can be used in the kitchensdecorated in different styles. Everywhere he will look amazingly stylish.

- Cork floor can be laid even in the hall, if at the same time to use rugs against dirt.

- And it can also be exploited. on the cold balcony - in these cases, experts advise adhesive cork floor.

- You can easily use cork floor in the nursery - The advantages of this material over others are so obvious that today it is increasingly possible to see a traffic jam on the floor in the room where children live.

The surface of many coatings of large companies are painted in different colors - white and cream, terracotta and espresso, black tone is very popular.

In addition, some manufacturers, in addition to the natural color of cork, will be able to offer products of the brightest colors and with unusual textural effects. If you have a special desire, you can order cork floors with original patches or a floor with photo printing. If you wish to create your own color in the house, you can always buy a special paint for cork coatings.

Popular manufacturers

- Corkstyle offers a huge range of cork flooring products, as well as all the accessories for their installation.

- German cork laminate Egger Laneo Cork has good reviews, prizes from exhibitions of flooring.

- Choosing a cork floor Wicanders, you choose modern technology and quality assurance from a reputable manufacturer.

- Sovremennye Tekhnologii LLC sells the NanoCork liquid spray cork, which is popular with consumers all over the world.

- Cork maestro club covers harmoniously combine modern technology and the unique properties of natural cork.

- Granorte cork is one of the best and most prestigious flooring in the world.

- Cork "cork" floating floors are made using technologies that have not been previously used and always comply with international quality standards.

- The company "Korkopt" offers exclusive cork floors of the most popular colors.

Rules and recommendations for care

Cork flooring is very easy. It is recommended to only protect the canvas from stresses with the help of flooring protective rugs (in the hallway or the hall) and sticking special plastic linings onto the furniture legs.

Cleaning can be done with a vacuum cleaner or a soft, slightly damp cloth. Abrasive products for washing products, brushes with a hard pile and solvents can not be applied to the cork.

If you notice serious damage requiring repair on such a floor, be sure to contact the professionals for help - only they can carefully replace the damaged element with a new one.

Owner reviews

Some buyers always follow fashion trends and are willing to try everything new in the construction world, while others are rather critical of emerging news. If you consider yourself to be in the second category, then reviews from those who have cork floors already laid at home will help you. The main majority of consumers speak well of such types of sex, but only if they did not save on their purchase.That is why it is so important to initially buy a product of a famous manufacturer and high quality.

Successful examples and options

Using high-quality photo printing on the cork, you can change the decor of any space and make it more interesting and attractive.

Often in a modern interior a stylish cork floor can imitate marble and even natural wood in order to bring the spirit of solidity and comfort into the room.

What are the pros and cons of the cork floor, see the following video.