Calculation of floor heating

In addition to the standard system, there are alternative heating methods. Separately among them are heated floors. This type of heating is characterized by efficiency, safety, high efficiency and has many other advantages. Improvement costs pay off quickly due to system operation.

Water floor heating can be a major source of heat or auxiliary function. Calculation of its power is carried out on the basis of the scheme of work: whether it will heat a large area or only slightly raise the temperature to a general level of comfort. Compilation involves the knowledge of many technical factors, consideration of the layout and other parameters.

Without a detailed calculation, it is impossible to build an efficiently working system, so you need to carefully consider the process of creating a project.

Factors to be considered

First, a few words about what are heated floors. This is a system located under the floor covering consisting of pipes connected to the water supply through a boiler. Hot coolant, spreading through the pipes, evenly heats the entire room.

The advantage of such floors is that heat flows rising from the floor warm up the air and make the temperature in the room as comfortable as possible. After that, the cooled air drops to the level of the batteries, heats up again and continues to circulate around the room. Moreover, when the legs are constantly in contact with a source of heat, it is almost impossible to freeze, even wearing the lightest clothes.

The calculation always begins with determining the type of heating system. Underfloor heating can be used as an additional source of heat, and can act as a circuit of the combined system. In the second case, a completely different approach is required, since it is necessary to take into account the type of pipe routing, the number of heat sources and much more. The main difference between these systems is the power of work.

Before you start laying the floor should be considered:

- Weather data, that is, the average temperature indicators of the place of residence.

- Detailed floor plan. The materials of which the building was built, the type of glazing of the apartment, the dimensions of the window and door openings of the floor and the area are taken into account.

- The volume of heat loss. To calculate this parameter, it is necessary to calculate the presence of heat sources, the average temperature in the room, the thickness of the floor layer, the type of floor covering and the presence of insulation.

In addition, it is worth taking into account the presence of a carpet product, the type of furnishing of the room. It is important to remember that before embarking on floor insulation it is necessary to work on sealing walls and windows. Basically, heat loss occurs just because of the thin walls and poorly installed double-glazed windows. Taking into account these factors, the cost of arranging a heated floor will significantly decrease.

When calculating the power, the required parameters of the heating circuit, that is, the number of pipes, their length, and also the characteristics of the coolant circulation are determined in parallel. The result of a competent calculation will be a ready-made installation scheme and the exact cost of construction work in an apartment or a private house.

Pipe types

A floor is a connection of pipes connected to a manifold. Correct data measurements are the basis for calculating the power of the work of thermal equipment. To calculate the distance between the pipes and the length required for installation, it is worthwhile to get acquainted with the main types of structures and their features. For the installation of a warm water floor used pipes made of the following materials:

- Crosslinked polyethylene. This material is difficult to install and has a fairly high cost. However, it has many advantages, for example, it has a memory property, does not corrode, and is resistant to temperature changes.

- Copper. One of the most resistant materials, characterized by high strength, corrosion resistance. The downside is that copper is quite expensive, such pipes are difficult to install.

- Metal plastic. The advantages of the material are in its efficiency, durability and safety, in terms of ecology.

- Polypropylene. Pipes from polypropylene differ in low cost at high technological characteristics, including low heat conductivity.

To calculate the required number of pipes required to take into account the featureslaying, which will make the operation as efficient as possible:

- the average diameter of the pipe is 16 mm, and the thickness of the screed is 6 cm;

- the average stacking pitch in a contour helix is 10–15 cm;

- the length of the pipe in the heating circuit should not exceed 100 meters, while it should be borne in mind that the pipe should go out and enter the collector without breaks;

- the distance between the pipe and the wall should remain between 8 and 25 cm;

- the total length of the contour should be 100 meters with a total area of 20 m2;

- between the lengths of the coils is to observe the difference, not exceeding 15 meters;

- the minimum allowable pressure inside the reservoir is 20 kPa;

- the shorter the pipeline, the less need to install a powerful pump, as the level of pressure drop decreases;

- inlet temperature should not differ from the outlet temperature by more than 5 degrees.

The length of the laying step also depends on the individual parameters of the room and the weather conditions in a particular region. In addition, the stacking step is directly related to the calculation of the contours.

Difference in piling patterns

Before determining the length of the pipeline, it is necessary to determine the method of pipe installation.There are two main options.

Snake (parallel method)

This method of laying pipes is relevant for small rooms in which the level of heat loss is low, in rooms with internal walls or with a warmed external wall. A one-piece pipe extends along the wall to the collector. The first coils are laid near the windows and walls, so that the highest temperature is concentrated there, the heating tube is bent 180 degrees. The average step of laying is approximately 25-30 cm, and in places of high heat loss the value should not exceed 15 cm.

The advantage of such a scheme is in its economy, and the disadvantage can be considered uneven distribution of heat, since the temperature in different parts of the room can have a difference of up to 10 degrees.

Snail (spiral method)

This method is more suitable for heating spacious rooms and rooms with cold walls. Pipe laying begins along the wall of the room, after which the design changes the angle by 90 degrees and the end of the pipe is near its beginning. Stacking step is calculated individually. On average, its value varies between 10 and 35 cm, in places with greater heat loss, the size is reduced to 15 cm. The length of the contour should not exceed 15 meters.

The obvious advantage of this method is in uniform heating of the surface, and this is achieved due to the fact that the cooled water can quickly heat up.

It is also possible to implement the combined method, where one part of the room will be heated in a spiral way, and the second - in parallel.

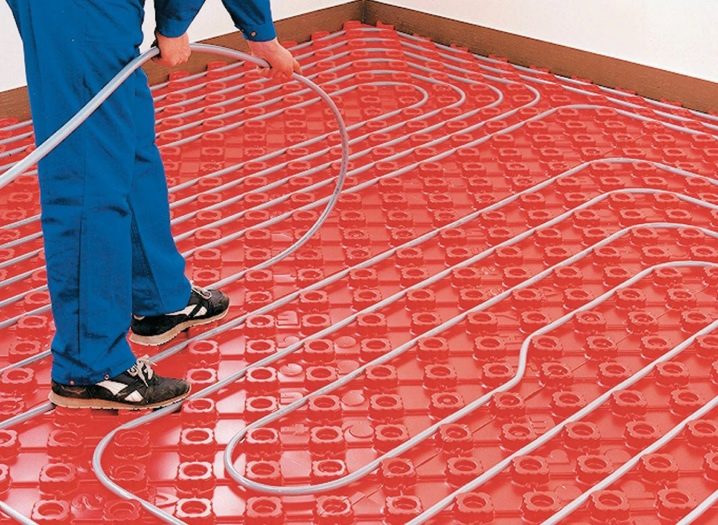

For correct work of warm floors it is necessary to carry out installation strictly according to technology. The main goal of pipe laying is uniform heating of the whole room, to achieve a result, it is necessary to begin the installation from the walls to the entrance (or to the center). If this condition is not observed, you can create cold zones in the room.

Requirements for installation

Prior to installation, the following conditions must be met to ensure quality work:

- Before laying it is worth doing the preparation of the base, that is, completely clean and level the surface. Otherwise, there is a risk of uneven heating.

- It is necessary to stock up with all the required materials.

- When installing the floor under the screed, it is recommended to start the system no earlier than in a month. Starting should occur in stages, with a gradual increase in the temperature of the coolant (within 2-3 days).

- The system is mounted in such a way that the average coolant temperature is maintained at no more than 55 degrees Celsius. The average air temperature in the premises should be 26 and 31 degrees, respectively, for rooms where people are constantly present or where they go periodically.

Installation of heated floor

Staging steps require compliance with certain requirements. If the conditions are not met, then the probability of violations in the work of a warm floor covering increases many times.

Training

Even at the preparatory stage it is important to bring the room into full readiness for laying the floor. This implies a finished rough finish, the installation of doors and windows, the connection of communications, as well as the preparation of floor markings.

Insulation

Laying waterproofing simply required, it provides protection from the ravages of moisture. Most often polyethylene with a thickness of at least 0.2 mm is used as the insulation material. In addition to laying on the floor with polyethylene, the joints of the floor and walls are covered. To avoid the occurrence of a thermal bridge, a damper tape is used.

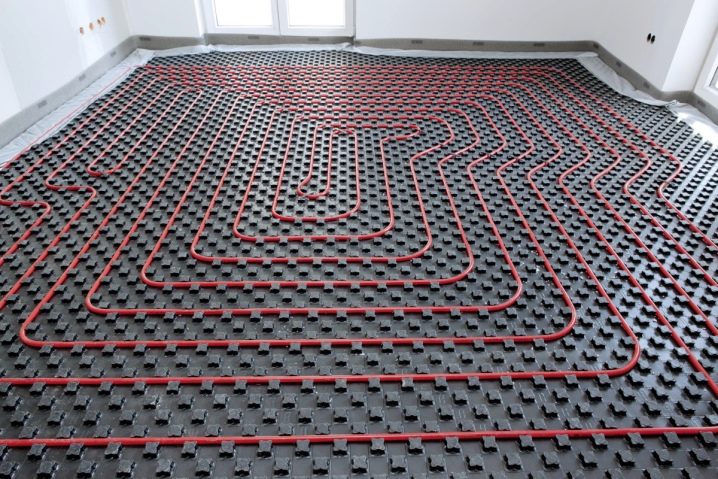

Heat insulation plates

The choice of the required type of plates and the method of their installation is a guarantee of high-quality and long-term operation of the heating system. The plates are stacked without a single gap around the perimeter of the room, which will ensure full heating of the room and the strength of the floor. When laying it is not recommended to step on the structure to eliminate the risk of destruction of the integrity of the elements.

Heating circuit

The level of heat transfer depends on proper pipe laying. It is necessary to carefully choose the technology of laying, pipe diameter and pitch.

Completion of work

After the main steps have been carried out, connect the circuit to the manifold, and then begin the pipe crimping. It happens this way: the coolant enters the circuit, and the air is removed through the taps. The temperature of warming rises from 25 degrees gradually. After the work is carried out on the installation of floor screed, and the launch of the system is made a month after the completion of the work.

Installation of a floor heating system is quite laborious, but in operation this system has many advantages. Therefore, the time and effort spent, as well as the funds, will more than pay off with the economical use and ease of operation.

Calculation rules

In order to simplify the calculation process, you can use special calculators, widely represented on the Internet. Often they are available on the websites of various companies engaged in laying floor heating. In the same place you can find various tables in which there are average calculations and necessary formulas.

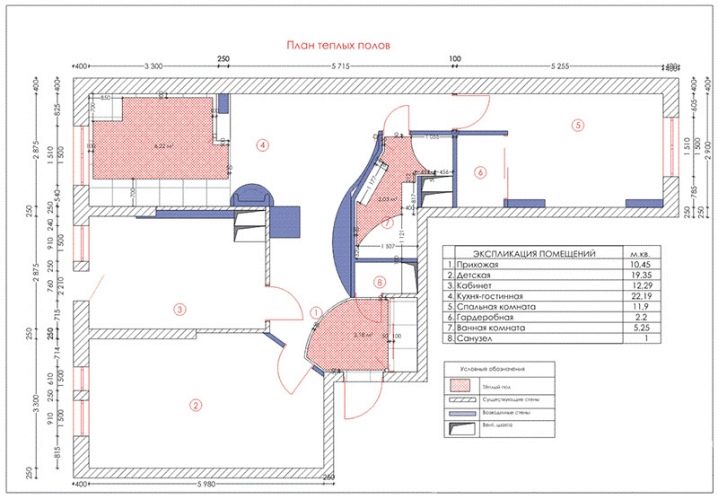

If you have doubts in your abilities, contact the professionals who have the necessary knowledge and means at their disposal. In order for the experts to prepare a competent accurate calculation, you will have to provide current data on the features of the layout of your room, and best of all to show a detailed plan.

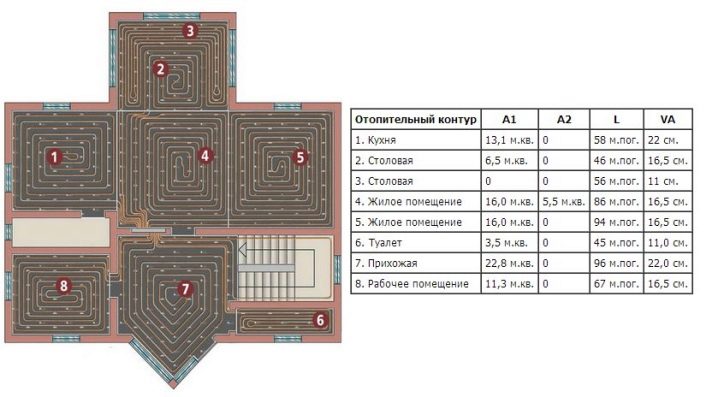

If the decision is made to calculate the power independently, then one should begin by applying the room plan to the special paper with the placement of the heating circuit and indicating the windows and doors. The scale is calculated as follows: 1 cm on paper is equal to half a meter of real area. Prior to drawing, pay attention to the following parameters:

- pipes should be located along walls and windows;

- the area of the room should not be more than 20 m2, otherwise it is necessary to divide it into several parts and calculate a separate heating circuit for each of them;

- there must be a distance of at least 25 cm between the wall and the first loop of the contour.

The number of pipes is calculated as follows: the total length is measured, after which it is multiplied by the scale factor. The result is added with two meters of distance (connecting the circuit with the riser). The total length is divided by the length of one pipe, since the maximum length of pipes should not be more than 100 m.

The diameter of the pipes depends on the range of the structures: they can not be located more than 50 cm from each other. A pipe spacing of 30 cm implies a heat transfer in a volume of 50 W per 1 m2. The power index increases according to the diameter of the pipes and decreases in the case of an increase in the laying step.

The power of the water floor is a combination of indicators of the total area of the house, pipe and floor materials, and the temperature difference between the supply and the incoming heat carrier. The power rating per square meter should not be more than 25% above the level of heat loss. If this value is not achieved, it is necessary to recalculate, change the diameter of the pipes and the size of the laying step.

Tips and tricks

There are a number of recommendations that will help you properly plan the arrangement of a warm water floor in your home. These factors should be taken into account both when performing calculations, and when installing an already designed heating system. This will help to achieve high quality flooring and full heating.

- Calculations should be treated as carefully as possible. In cases where underfloor heating acts as an additional source of heating, an approximate calculation is allowed. But if the floor is the main element of the heating system, then there can be no errors in the numbers. Any errors can be corrected only by dismantling the screed, which would entail a waste of money, as well as the destruction of the interior decoration of the rooms.

- There are a number of average floor temperatures in different areas of the house. So, for living rooms the temperature is 29 degrees Celsius, for bathrooms and other rooms with a high level of humidity - 33 degrees. About external walls without insulation optimal temperature will be 35 degrees.

- If you plan to heat the old house, it is better to abandon the idea of installing a heated floor as the main source of heating.This entails an increase in electricity consumption, and hence the costs of utilities, but the efficiency of the system will be small.

- As mentioned above, a large area is heated by several circuits. After determining their number, it is necessary to purchase a collector with outlets. The most suitable option would be a device with control valves. They help to change the temperature level and control the flow of coolant along the circuits.

- Thermal insulation of the floor is very important, since otherwise there will be a high level of heat loss. For high-quality insulation it is best to use materials such as glass wool, polystyrene foam, mineral wool. The layer depends on the room below. If there is a source of heating from below, then only a few centimeters of layer thickness is sufficient, but if the lower room is not heated, then the insulation should be laid in a layer up to 25 cm.

- Cutting of pipes is made only before direct connection to the pump.

- When installing this type of heating in an apartment located in an apartment building, it is forbidden to connect to a centralized highway.This can cause a sharp pressure drop along the entire length of the riser. Connecting warm floors in multi-storey buildings can only be subject to the availability of separate risers for connection.

- Laying pipe can change only in the design process. When installing the floor, it remains unchanged.

- Components of the system must be placed and connected in series, otherwise it is not guaranteed tightness. Competent approach to work allows you to minimize financial costs as in the preparation of the project and the installation process, and during further operation.

If you want to be sure of the accuracy of the calculation, but do not have the desire to overpay for the installation, you can order the preparation of calculations without work. Experts will also advise you on the selection of suitable materials and installation technologies that you can do yourself.

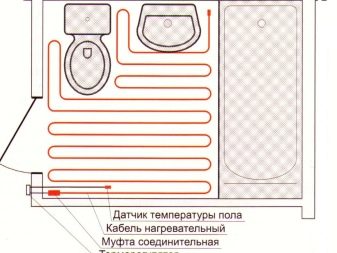

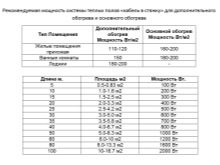

Successful examples and options

Below you can see examples of laying pipes for floor heating, as well as a table for calculating the floor power for different types of premises. Do not forget that these are average values. To compile a competent calculation, it is necessary to consider the individual characteristics of eachthe premises.

On how to correctly calculate the area of underfloor heating, see below.