All the subtleties and features of laying the floor

The floor is one of the important elements of each house, on which comfort and cosiness depend. In the design of coatings today use a variety of materials and technologies. To get a durable and solid foundation, you should learn all the subtleties and features of its installation. The modern approach allows you to quickly and efficiently construct floors that can last for more than a dozen years.

Construction is desirable to begin with the choice of the type of flooring, as well as an assessment of its technical characteristics.

Features and device

Floor coverings today are used in almost any residential or industrial building. The formation of it can be done at almost any stage of building a house. There are several types of such structures, but they all have an identical structure:

- Support base. For classic floors, it is rammed soil, on which are all the other layers. If the house consists of several floors, concrete slabs are already used as a support. They are designed for the perception of high loads.

- Draft floor or secondary base. The concrete screed, logs and so on are used as such elements.

- Decorative flooring. There is already a huge selection of materials used for finishing floors. All of them differ in design and technical parameters.

Qualitatively made floor surface solves several main tasks:

- The top layer is aligned with the level, which allows you to place furniture and other household attributes on it.

- Some types of floors are equipped with hydro and heat insulating layers that allow you to maintain optimal microclimatic conditions inside the house.

- Inside the draft foundation, you can hide communications, such as sewer pipes and so on.

- The top layer of the floor can be decorated with various materials, which allows you to decorate a room for a particular style.

Necessary tools and mixes

The technology of floor installation depends on its type and structure of the products used. Some reasons are fairly straightforward, while others require serious skills and experience.

For such works you will need a wide range of tools and materials:

- Concrete mixer or special mixer. Using these mechanisms, various cement or polymer mixtures are formed, which are used as bases for floors.

- Laser and water level. The mechanisms optimize the surface alignment procedure in order to obtain ideally flat horizontal planes.

- Tool for working with wood. These include saws, jigsaw, grinding machines, milling cutters and many others. They are used in the arrangement of wooden floors or surfaces based on wood products.

- Mechanisms for grinding concrete.

- Tools for working with concrete. These include leveling beacons, strips, vybropalitniteli and many others.

- Fasteners. The type of these products is also determined by the structure of the floor and the type of materials. Here you can use as usual nails or screws, and special adhesive solutions for fixing baseboards, linoleum and more.

- Building mixtures.In the construction of floors, in most cases, special solutions are used, from which they form rough bases, screeds or decorative surfaces. Almost always used for this composition based on cement. Some of them can be made independently with the addition of water and sand. But self-leveling solutions or mixes for laying tiles are made only in industrial environments. Polymeric components can be added to the composition of some products. These products affect indicators such as the strength of concrete, its resistance to moisture, durability, and more.

Preparatory work

Preparation for installation of floors is not uniform and also depends on the type of surface that will be formed. Conventionally, the preparatory work for such surfaces can be divided into several types:

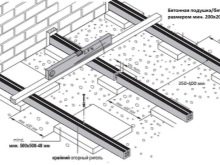

- Construction of the base. For wooden floors, logs or concrete are often used as this attribute. If you choose lags, then they need to be placed on a solid basis. It is advisable to thoroughly tamp the soil under them and fill it with sand.The bars themselves are placed on bricks or concrete columns, pre-poured around the entire perimeter. When you are preparing the ground for concrete floors, then the basic preparation is a high-quality ramming of the soil on which the screed will be located. After that, a draft layer of a concrete screed of a certain thickness is formed on the soil. To get a flat surface, it is advisable to mount beacons at a previously set level.

- Surface treatment. The main method of protection and materials is a primer. Different compounds are used for each substance. For example, wood is treated with impregnations that prevent rotting, moisture absorption and fungal reproduction. Concrete substrates are coated with mixtures that increase surface adhesion with leveling ties.

The preparatory operation for wooden floors can be considered the construction of a rough base on the logs. A similar approach is very often used in the construction of houses from timber or in frame construction.

This layer allows you to protect the main floor from rapid destruction, thus prolonging its service life.

How to lay?

Laying the floor is a complex process that requires a qualitative approach to the processing and preparation of all materials. It should be noted that the installation of flooring is carried out according to different methods. It all depends on the selected materials and the place where the formation of the structure.

View

The floor is a base that can withstand high loads for a long time without loss of strength. Depending on the structure of the floor covering, these structures can be divided into the following main types:

- National teams. When forming the floor is used several materials that form a solid base. This includes both wooden structures on logs, and ordinary parquet attached to a concrete base. Many modifications include a bulk layer that increases strength, heat insulation, or other product parameters. Finishing surface can be formed from almost any finishing materials on the market (carpet, laminate and so on). The decorative properties of these structures are very high, but not every floor can be used on industrial facilities.

- Monolithic systems. This type of floor involves the use of concrete solutions, as well as polymeric binders. Such surfaces may consist of several layers adjustable in height. But they are all interconnected firmly, which increases the resistance of the floor to external loads. Finishing of the base is carried out with the same concrete or polymer solutions. This type of surface is often found in warehouses, large supermarkets and other similar objects.

To increase strength, the floor can be reinforced with solid concrete slabs.

Laying options vary according to the type of floor:

Laying boards on logs

Classic wooden floors are formed only on the logs. A similar design can be made in an apartment or private house. Step-by-step instructions for arranging such a floor involve the following steps:

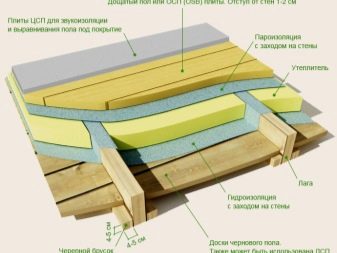

- Arrangement of waterproofing. This step is one of the most important. In most cases, polyethylene films or special solutions, which are applied to concrete, are used as protective materials. It is necessary to fix the substance in such a way as to prevent the penetration of moisture through the lower side of the floor.This is especially important for cement floors that accumulate moisture well.

- Installation lag. It is desirable to lay the timber on a previously prepared surface that can withstand the load. Often for this purpose use the concrete bases or a wooden draft floor. Bars can be installed directly on the subfloor or on special supports. It is necessary to lay them in such a way that they form a flat horizontal surface. Therefore, the walls mark the level at which they are guided during the installation of the lag. The wooden bar is attached to the surface with special screws or screws. At the same time, they are selected according to the type of material of the subfloor.

- Laying heat and vapor barrier. In order to exclude heat loss, a heater is placed between the lags. For such works suitable mineral and basalt wool. If the floor creeps on the ground floor, you can replace them with expanded clay, which also retains heat quite well. On top of the insulation is closed vapor barrier film that does not allow moisture to penetrate from inside the room. However, such a pie will cause a lot of condensation to accumulate in the house.Therefore, it is important to organize high-quality ventilation in the room.

- Fastening boards. For such works, use only well-dried wood. Boards can be equipped with special tongues at the ends or be flat. The first option is preferable, since the installation of such is much faster. Before you do the fixing, you need to calculate the amount of material to cover the floor.

The first board is laid across the lag parallel to one of the walls. Between it and the vertical surface leave a gap of about 10-15 mm, so that the tree can easily expand. If all is well, the board is nailed to the logs or screwed with screws.

After that fix the second element. Both boards are tightly joined to each other and fixed with special designs that do not allow the system to move sideways. When everything is normal, the board is also nailed and installation proceeds in the same manner. The last board is laid with the same small gap between the end and the wall. Please note that sometimes it is impossible to choose the width of the workpiece so that it completely fills the remaining gap. Very often the board is cut along.For such purposes use a jigsaw, circular saw or other similar tools.

- Grinding and painting. Wooden bases at the very end can be scrubbed, which allows you to get a flat floor. But this is not an obligatory step, because, if these elements are laid out correctly, they may not need alignment. Today, varnishes are used as the main protective agent. These solutions slightly change the shade of wood, but do not hide its structure. Thus, the unique design of the material is preserved.

As for the floors of parquet or laminate, their installation is very similar to the previously described algorithm. But the materials are already placed on perfectly aligned surfaces. They are leveled using cement screeds or plywood sheets, which are fixed to the rough substrate. Before laying the lamellae, waterproofing and a soft substrate are placed on the surface.

Between a board of parquet or laminate are joined with the help of special locks located on the ends. It is important to only slightly align the lamellae relative to each other in order to obtain high-quality bandaging of the layers.

This structure is very popular, because if one board breaks, you can change it to a new part, not to lay the whole floor in a new way.

Laying tiles

Surfaces of such materials are quite durable and durable. The tile is not damaged by moisture and fungi. But some of its species can not withstand the cold and can crack, so they are best used at high temperatures.

Tile installation is often performed only on concrete foundations. Theoretically, you can fix it on a wooden backing, but the latter system will not last long, and sometimes it will not always sustain the weight of the decorative layer.

Tile laying technology consists of the following consecutive steps:

- Pouring the base. This step is performed if the floor is built directly on open ground. When tile laying is performed in a multi-storey building, installation is carried out directly on concrete slabs.

- Before applying the adhesive, it is desirable to remove all debris from the surface. If there are large cracks or gouges, it is advisable to close them. Small drops are allowed, as they will be leveled with glue.

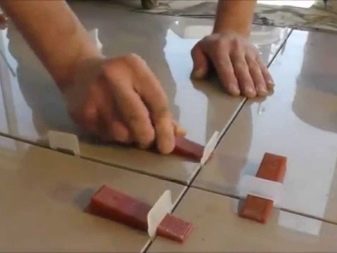

- Laying tiles begins from the corner of the room. A prepared cement glue is applied to the prepared surface with a notched trowel. After that, it is laid tile and align it in all planes.To simplify this task, many experts use a laser level.

- All subsequent tiles are laid in a similar way. Between themselves, they are also aligned to get even rows. To obtain the same seam, special plastic crosses are inserted between the tiles, which are then removed.

Self-leveling floors

The main component of this design is a polymer that is applied to a concrete base. Solutions independently are leveled that allows to receive ideally plain surface. The algorithm for arranging a self-leveling floor consists of such sequential actions:

- Preparation of the base. This process involves leveling and strengthening the surface. The ideal option for such a floor would be a cement screed, the moisture content of which does not exceed 75%. The height difference in this case should not be more than 3-4 mm, as this affects the consumption of the mixture, which is expensive.

- Primer. For such purposes, use special compositions that increase the adhesion of materials. Before applying the polymer, the mixture should dry.

- Fill the floor. The prepared mixture is poured over a small area of the base and leveled.To remove air, all operations are performed with a needle roller. The entire room is filled in sequence. Bulk floor gets cold for several days, which depends on the thickness of its application.

If you want to get a beautiful floor, then you can decorate it. The most common option is to apply the polymer on the previously prepared image. Thus, three-dimensional pictures of any complexity are obtained.

Polymeric compositions in liquid form emit toxic substances.

Therefore, all operations are carried out only in special protective masks, gloves and other means of protection.

Materials

One of the important factors affecting the durability and reliability of the floor are the materials from which it was built, and the correct calculation. Modern man in the arrangement of the sexes uses a variety of substances that perform a particular task.

The main components are cement mortar and wood. From the first type of products form concrete bases, which often act as a rough surface. Material perfectly maintains loadings and is not damaged under the influence of external climatic factors.

As for wood, it is used to solve various problems. A support bar, floor board and other auxiliary products are made of wood. The material perfectly withstands dynamic loads, but needs high-quality protection, as it is damaged by water and various microorganisms.

One of the important factors in the formation of the floor is hydro and thermal insulation. It is carried out with the help of expanded clay, polystyrene foam, mineral wool, plastic film and many others.

All of them have unique properties that allow you to get a warm floor that will last a long time, regardless of the microclimate inside the house.

Sometimes the construction of the floor involves leveling the rough base. For such purposes, apply cement screed, wooden gypsum fiber board, OSB, chipboard, moisture-resistant plywood and many other substances. Special attention should be paid to decorative finishing materials.

The modern market offers many varieties of these products:

- Ceramic and granite tiles. The substance is obtained from natural products by pressing. The material is able to withstand significant temperature differences, so it can be used both inside and outside the premises.Tile - this is the best option for bathrooms, as it is well resistant to moisture.

- Wood and its derivatives. This group includes many materials. The most environmentally friendly and expensive product is a board from the array. It does not emit any harmful substances, and also serves for a long time.

This can also include such popular products as flooring, flooring and laminate. The latter type of products is made of small wood chips, which is covered with a vinyl protective layer on top.

Colour

The final stage of installation of any flooring is laying a decorative layer. It depends on it the design of the surface, which can be obtained as a result of this procedure. The color gamut of these elements today can change in almost any direction. The style of flooring depends only on the characteristics of the market and the capabilities of the manufacturer.

Today there are several main design directions:

- Monochrome surfaces. In this case, the floor is painted only in one color. Especially popular are green, black, white, red and other shades.But to meet such grounds can only be in rare cases, since it is rather difficult to select them for the design of a room without skills.

- Woody structure. Wood imitation is today a very popular flooring option. This applies not only to natural materials, but also products obtained by artificial means. Today on the market under the tree produce laminate, floorboard, ceramic tile and much more.

- Natural materials. This direction involves the imitation of the structure of granite, marble, and other natural substances. Often it is found on ceramic tiles and laminates, the pattern of which is formed during the production process.

- Custom pictures. The type of drawing may vary depending on the desires of the designer. The surface of the floor can be decorated with flowers, children's pictures or three-dimensional images. This group of flooring fits almost any style of the room, which makes it especially popular and in demand.

Successful examples and options

It does not matter if you laid the floor with your own hands, or if the specialists did it - the main thing is that the works should be carried out with exact observance of the technology.This largely refers to the rough coating, and if we talk about wood, tile or a pouring field, then in this case it is important to choose the right one for the interior and the room.

In the frame house, the Provence style dining room with wooden walls is complemented by a plank floor, but ceramic tiles are laid in the work area and under the kitchen group. The interior was very light and airy thanks to the bright colors of the finishing materials and white furniture with wicker chairs. And the idea of using floor tiles in the most actively exploited place is also very practical - the wooden floor area will last longer.

On the terrace of the wooden cottage the floor is made of parquet. It looks very good, especially with well-chosen sofas and armchairs with white upholstery.

As for the apartments, they use various types of flooring, which are now offered a huge amount. Laminate and tile are very popular.

For information on how to properly carry out the installation of wooden floor with their own hands, see the following video.