Rockwool cylinders: types, advantages and characteristics

Reliable thermal insulation of the pipeline is an important element of any building. This applies to all communications, regardless of their belonging to the type of carrier. The building materials market is rich in special materials for insulation. Among them, Rockwool cylinders stand out in particular, about the merits, types and characteristics of which will be discussed in this article.

Special features

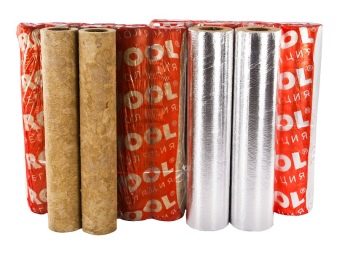

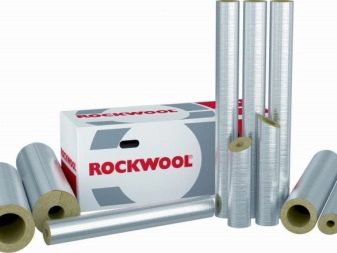

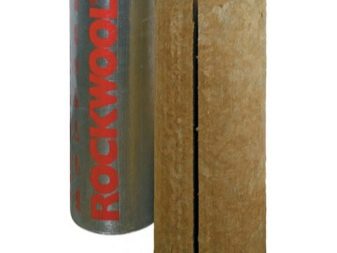

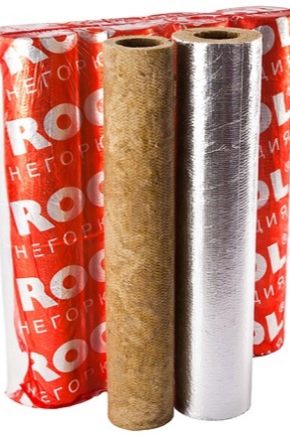

For many years, Rockwool has been a recognized leader in the production of thermal insulation materials for pipes. The production uses modern equipment and the latest technology, thanks to which the product quality significantly exceeds the analog products on the market. Cylinders are available in several versions: with and without aluminum coating.

Rockwool mineral wool cylinders are different from analog products by the special construction of the product design, which is based on a longitudinal section. Due to this, quick installation of products became available.

Products should be mounted close to each other, keeping the horizontal seam running apart. Fixing simple products is carried out using a special bandage. But the foiled cylinders require additional sealing (most experts use aluminum tape).

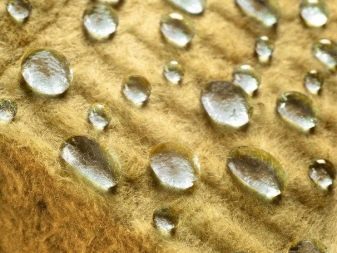

Rockwool cylinders are resistant to ignition and moisture. This was made possible thanks to the unique composition of products, which includes special fibers that allow you to maintain mechanical properties even when wet.

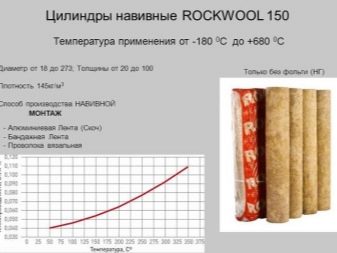

Operation of Rockwool cylinders is allowed at temperatures ranging from -180 to +650 degrees Celsius. Thus, the possibility of using insulation increases.

It should be noted that with their help it is possible not only to increase the level of thermal insulation, but also to provide excellent noise and sound insulation of pipes. This is especially important when using cylinders as insulation for pipes with circulating gases and liquids.

Rockwool products do not lose their strength properties even after contact with alkaline, chemicals and oils. The material is not subject to attacks of insects and is not a favorable environment for the occurrence of fungus, mold. With proper installation and operation, mineral wool products retain their strength properties for many years.

To extend the life of the product, it is important to store the material only outdoors, eliminating the possibility of wetting. To preserve the properties and protection, it is enough to cover the products with a vapor-impervious film.

Products are transported using shrinkable film or cardboard boxes, which is more reliable.

The company Rockwool has taken care of the breadth of the range: today on the market are many models with different parameters and at different prices. At the same time, the length of the products never changes - regardless of the product modification, this indicator is always equal to 1 meter.

Advantages and disadvantages

Rockwool mineral wool cylinders have a number of advantages:

- ease of installation;

- fire resistance;

- moisture resistance;

- possibility of use in different climatic conditions;

- high level of sound and noise insulation;

- resistance to chemicals;

- biological resistance;

- long service life;

- easy storage and transportation.

Of the minuses, one can single out a rather high cost of basalt insulation and a high probability of the formation of cold bridges at the seams.

Purpose

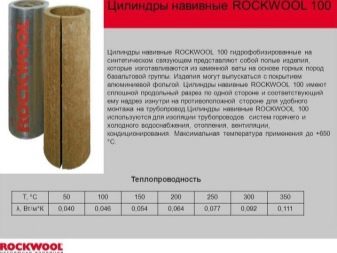

Mineral wool cylinders with an aluminum outer layer (laminated) are often used in the industrial sector, where the resistance of insulation to various factors is particularly important. Conventional products are suitable for insulating water pipes and pipes of the heating system. Often they can be found on the pipes of ventilation, air conditioning, gas pipeline, drain pipes. Condensate does not form under the insulation layer; therefore, pipes protected by mineral wool do not cause corrosion.

Such a seemingly insignificant element of arrangement affects the comfortable living in the entire building. For example, after warming pipes for hot water supply, the water temperature during transportation remains unchanged. Insulation has a positive effect on the economical consumption of energy resources, so the pipes of power communications are also subject to insulation.Insulation for a gas pipeline located outside the building is necessary for the preservation of gas. Condensate does not form inside the insulated pipes and the gas flows in its original quality.

Specifications

For the manufacture of Rockwool cylinders, basalt rock wool is used. Thus, the characteristics of products for one hundred percent coincide with the features of the materials of this group. However, Rockwool products have their differences.

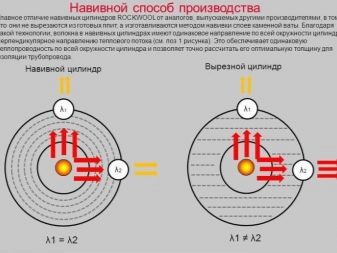

The company has developed a unique method of manufacturing cylinders, so that the products are so strong and durable. The production technology is based on the manufacture of shells - pressed mats of mineral wool, the fibers of which are stacked in different directions. The use of this technology has made it possible to achieve high strength and stability of the fibers, even under tension. In addition, the area of the entire material is equally strong, without flaws and deflections.

Of course, the mineral wool pipe is practically not threatened by mechanical impact. Few people know that a material can break even due to thermal expansion. Therefore, the integrity of the entire product is particularly important.

Rockwool cylinders do not need shrinkage.Canvas material is not subject to deformation. This suggests that throughout the entire service life of the product will remain in its original form unchanged.

Specifications:

- internal diameter 18-273 mm;

- the thickness of the insulating layer is 25-100 mm;

- length of all products 1 m;

- the density of the material is 100-145 kg / m3;

- thermal insulation level 0,035-0,09 W / m2;

- low level of water absorption (no more than 1%);

- aluminum foil-coated cylinders; vapor proof;

- chemical resistance;

- resistance to high temperatures (up to +1000 C);

- refractory, but able to smoke (basalt cylinders belong to the combustibility group NG, kashirovannye - G1).

It should be noted that the amount of material required in each case is individual. You can calculate the required amount using the formula S = 2r (h + r), where:

- r is the radius of the base of the pipe;

- h is the pipe length parameter.

Kinds

Rockwool cylinders are available in a wide range. According to the method of production, the products are divided into two types:

- navivye;

- carved.

Navivy are produced by winding the layers of material around its axis, after which the product is sent to the polymerization chamber, where the hardening of synthetic resins occurs.The peculiarity of such winding makes the products more durable around the perimeter of the entire canvas.

Cut (or ordinary) cylinders are produced by cutting material from the mineral wool layer. Such products are inferior in strength to the previous one. Since the fibers of these products are arranged in parallel, and the heat flux of the pipes goes in all directions, the fibers may break. Cut cylinders are mainly used to protect against fire.

For insulation more suitable kashirovannye products, which are characterized by a higher level of sealing. These include Rockwool Flexorock density of 77 kg / m3, thermal conductivity - 0.041 W / m2 and a diameter of 1-133 mm. Often they are used as a supplement to conventional cylinders. When choosing, it is important to know that Rockwool Flexorock does not tolerate temperatures above +250 C.

At the moment, there are two types of navivnyh cylinders:

- wound semi-cylinders 100;

- wound semi-cylinders 150.

Navivy semi-cylinders 100 are designed for insulation of pipes of heating systems, ventilation, air conditioning, water supply and drainage. External diameter of a pipe is 108 mm, thickness is 30 mm. They are products of stone wool with a longitudinal incision on one side.For more convenient installation inside the product an incision is made on the opposite side. There are foiled products.

Cylinders 150 (CONLIT SL 150) are made in the form of rigid slabs of stone wool. Subject to plastering and use, coupled with a reinforcing fiberglass as a refractory coating. Their intended purpose is to protect the pipeline from ignition.

The 150 product line offers a wide range of sizes: 20x35; 25x40; 42x30; 60x50; 108x30; 273x30 and others. Kashirovannye products in this series are not available.

Dimensions

Rockwool profiled pipes have the following parameters:

- internal diameter 18-273 mm;

- the thickness of the insulating layer 25-100 mm;

- length of all products 1 m.

Tips and tricks

It is possible to cope with the laying of cylinders even without having experience and skills in handling insulating material. The speed and ease of installation due to the special design of products.

Experts identify several nuances of installation of products, knowing that it is possible to achieve high-quality coverage:

- the surface of the insulating layer on the pipes should look ideally even; for this, the products should be tightly fitted to each other, avoiding "humps";

- when using non-laminated cylinders, the coating should be additionally fixed with wire;

- when mounting vertical products, cylinders are fixed with special locks every 4 m, which will prevent material from slipping.

In the next video you will see the installation of Rockwool insulation cylinders.