Subtleties of floor insulation

The problem of eliminating heat losses in homes and apartments worries many homeowners. To solve it on the premises, various types of heat insulating materials are used. Modern construction market offers a large number of heaters, each of which has a number of pros and cons. However, in some cases, even after the insulation has been laid, there is no comfortable temperature condition. The fact is that it is important not only to choose the material correctly, but also to apply it correctly.

Special features

Each type of insulating material has its own characteristics and physical characteristics. However, when choosing experts recommend focusing on the following of them:

- Type of room. It can be residential or non-residential.

- Strength.As the insulation spreads to the floor, it will experience certain loads.

- Lifetime. Floors rarely change, which means that the material must maintain its insulating properties for a long time.

- The level of insulation;

- Weight and density;

- Degree of moisture absorption;

- Vapor barrier;

- Fire safety;

- Environmental friendliness;

- Material consumption during cutting (waste should be as low as possible);

- Easy handling and styling.

Professionals note that the insulating material for a concrete screed should have the following qualities:

- High density, which causes stiffness. The latter is necessary in order to withstand the weight of the tie.

- Moisture resistant because the concrete solution contains water.

- Lack of open cells and pores in plates and rolls. In them particles of a coupler are hammered.

- Low degree of heat transfer, which will allow the use of thinner insulation.

The main requirement for thermal protection for wooden floors - vapor permeability.

Heat transfer in the whole room depends on the floors. Depending on the type of residential buildings differ installation features.

Warming of the floor in the apartment frame house on screw stilts has its own characteristics. Buildings on pile foundations are built on wet soil. With a similar design, the house, as a rule, has a blown basement or basement room.

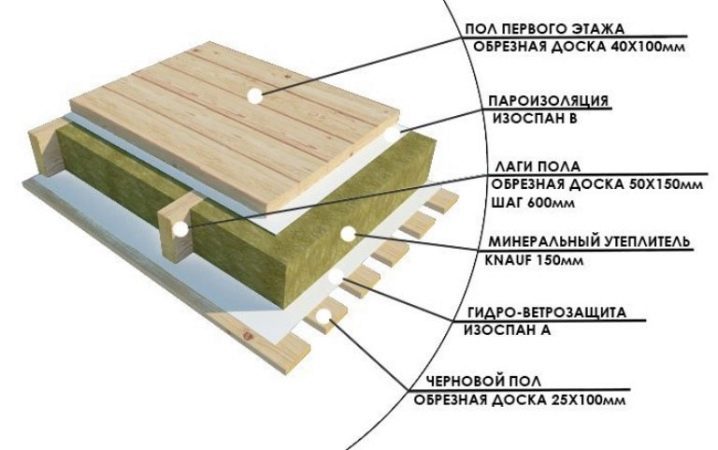

Experts advise to warm the floor with layers:

- Skeleton skeleton, which also serves as a subfloor. Its installation begins with fasteners of wooden boards to the logs, they will be the support for the boards of the rough flooring.

- Wind protection that performs the function of protecting the insulation against weathering. In this capacity, special insulating membranes are used. Since they are characterized by high cost, they can be replaced with polyethylene, which should be laid on top of the insulation.

- The heat insulator, on which, if necessary, additionally fits the waterproof layer.

- Finishing floor, consisting of chipboard, plywood or other material.

As heat insulating materials it is better to pay attention to insulation with high resistance to moisture. For example, the foam is well suited both in terms of cost and in terms of performance, but it collapses in the cold and at high humidity.So, in this case, you need to protect it from exposure from outside.

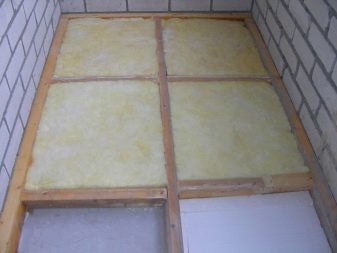

Another option is thermal insulation mineral wool, produced in the form of rolls or plates. It is very beneficial because it is inexpensive, has a sufficiently high thermal protection and is resistant to fire. However, experts note that when water gets inside all the insulating properties are reduced to zero. The most suitable option for a building on screw piles is cotton wool in the form of blocks, which has a more dense structure.

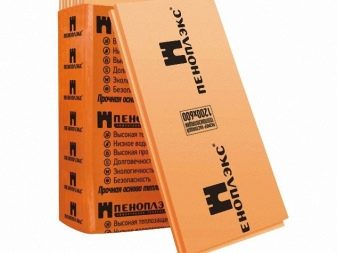

For houses on the frame is also used penoplex, but it is more expensive compared to the foam and mineral wool. It is necessary to pay attention to its advantages: reliability, durability and almost zero water absorption.

It is quite often possible to see expanded clay as a heater, but it loses to the above materials in terms of heat-shielding functions.

In the case of housing arrangement, professionals insist on protecting the pile foundation with a permanent base, as it will provide additional protection from wind and snow. If this is not necessary, it is enough to install a decorative option.

In addition to the existing standard technology, there areothers:

- Double thermal insulation. The technology is a double decking installation.

- Cross thermal insulation. The method involves the perpendicular arrangement of the insulating layers.

It is very important to comply with all the technology when warming a frame house on stilts, otherwise you can get poor-quality insulation with raw underground, mold and fungus.

In an apartment brick building, the first-floor residents often complain about the icy floor. Experts recommend that before you mount the thermal protection, clarify what type of coating is available.

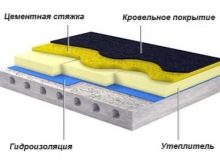

In brick houses, as a rule, there are either wooden or concrete floors. In the presence of a concrete surface, the warming process must necessarily include a waterproofing to prevent mold.

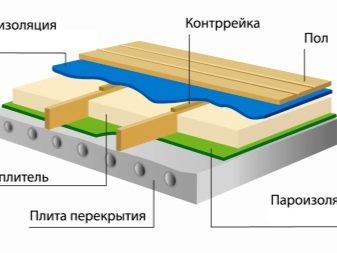

Work begins with the preparation of the foundation: the elimination of cracks and cracks using cement mortar. Then the floor is impregnated with a strengthening composition. Next, lay a layer of waterproofing, which in the simplest form can be a polyethylene film. Its role should also be handled by primer with deep penetration properties.After the ruberoid is spread, a frame is installed of the longitudinal bars and transverse lags in which the heat insulating material is poured or poured. You can put mineral wool or foam over the insulation layer inside the frame. The last is fixed with a vapor barrier film, on top of which the draft floor is mounted.

The entire structure takes a certain distance between the floor and the ceiling, which should be considered when repairing.

You can use the less expensive option without an insulating bulk “pillow”. It is enough to use one of the polymeric heaters laid on concrete, but waterproofing is required in any case.

In the presence of a wooden floor, it is first recommended to replace the old floors and eliminate gaps, treat all elements with antiseptics and dry thoroughly. Then install a rolled or block insulation and cover it with vapor barrier. The final stage is the installation of the finished floor.

The apartment on the first floor can be insulated not only from the residential side, but also from the basement. To this end, the basement ceiling sheathe heat insulator, which can serve as a foam or penoplex.They are convenient in terms of mounting, because they are simply glued to the ceiling. It would be appropriate to use mineral wool, but for its installation you need to make some effort.

For insulation of concrete floors, it is better to choose protective agents with a high density: expanded clay, mineral wool mats, expanded polystyrene. As a heater of wooden bases, eco or mineral wool, as well as rolled materials are appropriate.

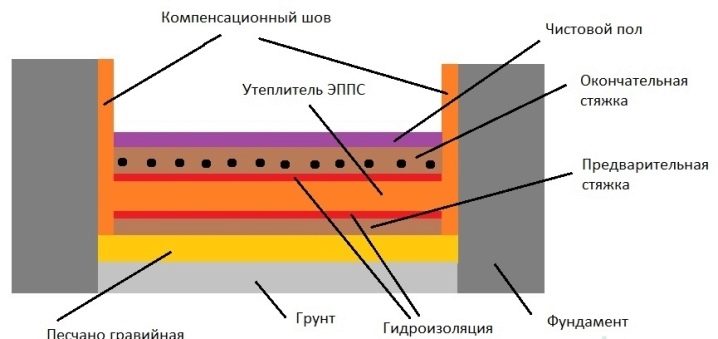

Features of floor insulation in the "Khrushchev" are different from previous versions. The main design feature of "Khrushchev" are reinforced concrete slabs on the floor. For their thermal insulation they use a screed, but it must be remembered that its layer should not be thick, since the overlaps are not designed for this. As a rule, to obtain a warm floor, it is enough to lay out the surface with polystyrene foam and pour a thin screed. Experts do not prohibit the use of self-leveling floors.

Advantages and disadvantages

Insulation is classified according to the form:

- liquid - cement mortar, polymer penoizol;

- bulk - expanded clay, sawdust, foam plastic crumb, penoizol, slag;

- block (in the form of plates and mats) - mineral wool, foam plastic, polystyrene foam, vermiculite, arbolit;

- roll - polystyrene, low-density mineral wool, isolon, penofol.

Liquid materials are good for making seamless screeds. Loose compounds fill the space very tightly. However, their installation necessarily requires a frame, whereas block and rolled insulation can do without them. Liquid solutions require time for complete drying, but have a long service life. The roll has a lower density compared with the block, which is reflected in the difference in thermal conductivity.

The most common types of heat insulators have their pros and cons, which are to some extent inherent in their counterparts:

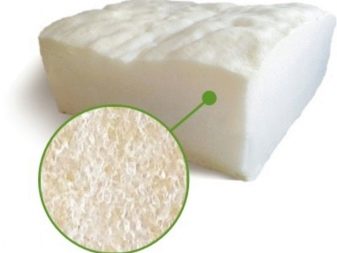

- Styrofoam and foam. These heaters are characterized by average mechanical strength and resistance to compression. Low density contributes to low water resistance. Under normal conditions, the materials are non-toxic and resist burning well; however, under the action of high temperatures, polystyrene foam begins to smolder and releases toxic substances. Experts note the absolute biological stability in extruded polystyrene foam never rodents, insects and microorganisms.

- Mineral wool, according to users, has several advantages, thanks to which it is still the most popular type of insulation. The most important is its low cost, so that it can be used in unlimited quantities. Also emphasize vapor permeability, noise insulation properties, a high degree of fire resistance and low thermal conductivity. Among the disadvantages is hygroscopicity, because when wetted, mineral wool loses its remarkable characteristics.

- Expanded clay and other bulk formulations do not leave waste after installation. They are environmentally friendly, vapor permeable, fireproof, immune to biological agents. Professionals distinguish expanded clay as almost the only kind of insulation that can be used to insulate floors on the ground. As for the minuses, the main one is low hygroscopicity. The second major drawback is the layer thickness, since at least 15 cm is required to achieve the effect. It means that it cannot be used in places with a height deficit.

Materials

All insulating materials are characterized by the presence of air in the body, because it is the best insulator.In general, there are several main groups: mineral, polymeric and organic. Each fraction, in turn, has a classification according to physico-chemical characteristics and biological activity.

Mineral

- Mineral wool. The material has several types depending on the raw material: glass, basalt or granite. The production process is as follows. The melted raw material is sprayed onto the low temperature surface for cooling. From the thin filaments thus obtained, an insulating material in the form of slabs is formed. Minwat of all the proposed options has the lowest hygroscopicity, this means that when wet, the material loses almost all of its insulating ability. It does not withstand high loads, so experts advise laying it between lags. In it rodents are got. The main advantage of the material is its price and environmental friendliness.

- Foam concrete let out two types: constructional and monolithic. They differ in physical properties. The second type is more durable in terms of operation, but inferior in thermal insulation characteristics.In fact, foam concrete is foam, which is obtained from a gas-saturated cement-sand mixture.

- Expanded clay It is a free flowing granulated aluminosilicate composition, which is formed during clay firing. Pros: environmental friendliness, high degree of water absorption, low thermal conductivity, mechanical strength. Minuses: waterproofing is required during installation, since thermal conductivity suffers significantly when wet. Most often used as insulation under the floor screed.

- Foam glass has the highest cost among all heat insulators, which is due to the unique performance properties: absolute biological stability, the practical absence of water absorption, low heat and vapor permeability.

- Vermiculite is a product obtained by burning through secondary minerals. To do this, biotite and phlogopite, which are formed during the weathering of dark mica, are pressed with the help of liquid glass and carbonate filler into special plates with a thickness from 20 to 60 mm. Ground limestone, dolomite or marble is used as a filler. The strength of the material is comparable with foam concrete, has a dense structure.The advantages include the absence of condensate and convection, the disadvantages are the high cost.

Polymer

This class of insulating materials consists of foamed polymers, which are numerous on the market. The following of them are widely used for floor insulation:

- Extruded polystyrene - analogue foam, has sufficient rigidity and low thermal conductivity, its biological activity tends to zero. From the foam differs manufacturing technology by extrusion. The structure of the heater is a small cell filled with gas. The material is able to transmit light, frost and light. It is worth noting that the material has two serious drawbacks: flammability and the possibility of decomposition when ingested with chemical solvents, including paint.

- Styrofoam - sprayed insulation, therefore, forms a seamless surface that does not require additional alignment. The composition is a solid foam, which is 98 percent air. The denser the polystyrene foam plate, the higher its thermal conductivity. Insulation is characterized by zero vapor permeability and an average degree of water absorption.The advantages include high biological resistance. Cons: afraid of chemical solvents such as acetone, drying oil, alcohol, loses durability under the action of sunlight, flammable.

- Styrofoam has a dense structure. Since the composition is solid, condensate does not form on the surface and convection is excluded. Experts note its safety and cheapness. It should be noted that the heat insulator has low strength and resistance to external mechanical stress. Professionals recommend using foam only in dry rooms with a coating of plywood on top.

- Polyurethane - one of the varieties of plastic. It is sprayed on the heat-insulated surface. After spraying polyurethane foam is a cellular structure, due to which heat is retained. The material is resistant to mold and rot, does not decompose by acids, has a low inflammability.

- Penoplex has the characteristics inherent in polyfoam and plastic. The fine-mesh structure allows you to retain heat inside and provides mechanical strength. The material has good density and rigidity, so it can be used for frameless floor insulation.Advantages: water absorption is close to zero, does not rot, is durable, easy to process, eco-friendly, resistant to low temperatures. Disadvantages: high price, fire hazard, because it melts at high temperatures with the release of harmful substances, is afraid of sunlight.

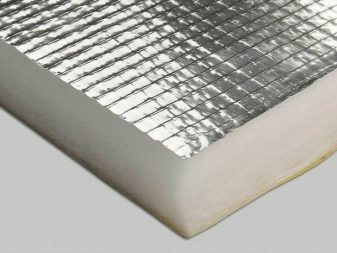

- Penofol - foamed polyethylene, topped with aluminum foil. Available in the form of rolls, has a thickness of not more than 10 mm. Among the advantages can be identified excellent thermal conductivity and vapor barrier. The disadvantages of experts include loss of strength over time and corrosion of the foil.

- Izolon - a heater which in the basis has the made foam polyethylene, the improved analog of penofol. The material has a more extended size ruler - up to 50 mm, due to which it is more durable. As a rule, the isolon is used in cases when the properties of penofol are not enough for operation.

Organic

Fibrous insulation of this class is obtained from synthetic organic fibers, filaments from flax and jute. As a rule, they are in the form of plates or rolls. Characteristics are similar to mineral wool. Experts note environmental safety, low moisture resistance, especially in materials made from natural raw materials.Used mainly as an additional insulation under the laminated or cork flooring in dry rooms.

TO wood chipboard Insulators include plywood sheets, chipboard, chips, ecowool. One of the most common modern materials is arbolit, produced in the form of blocks pressed from sawdust or straw. For the bundles used liquid glass, cement mortar and calcium chloride. The thickness of the insulator varies from 10 to 100 mm. In addition to good insulating properties, insulation has a high bending strength.

Penoizol is a granulated mixture or block. The composition includes urea-formaldehyde resins and glycerin. Block version has a thickness of 10 mm and above.

Ecowool in its composition uses waste cardboard production. It has a low hygroscopicity, so it requires additional moisture insulation.

How best to warm?

Since the basis for floor insulation is different, the technology of laying insulation is also different. If, before starting work, carefully read the instructions and correctly calculate all the parameters,then all the work can be done by hand. There are ways to effectively protect the home from weathering and freezing:

- Warming bottom. For apartments on the first floors of urban high rises, it is better to start the installation with reinforcement of the insulation material on the basement ceiling. This will reduce the access of moisture and eliminate freezing from the bottom. It is enough to use polystyrene foam as a heater, fill the slots with assembly foam. If the basement is damp, then additional waterproofing in the form of ordinary polyethylene is recommended.

- Insulation with crate Best for beginners. The method is used to warm the concrete floor. At the base of the frame are wooden bars laid parallel to each other with a half-meter spacing. Next, heat-insulated filler is mounted. It can be any bulk, block or liquid material. It is important to choose the right thickness: for slabs of mineral wool, it should be at least 100 mm, for expanded clay or sawdust - from 150 mm, a modern coating with foam plaster or foam should be laid with a layer up to 50 mm. The latter types of material are clearly butted out,while mineral wool blocks are a couple of centimeters wider, since this insulation is porous and some tension is necessary for a tight connection. Experts note that if the ceiling was insulated in the basement in advance, then when installing insulation on the first floor, the thickness of the insulation can be taken twice as thin.

- Dry screed method. Expanded clay - an exceptional concrete insulation with the lowest cost. Fraction matters. For example, the cross section of gravel should not exceed two centimeters, sand is considered to be a crumb with a diameter of up to 5 mm, experts refer to the rubble as all the rest. To make the mixture dense enough, gravel is mixed with sand in the ratio of 1: 1 and laid in layers, shedding cement mortar. Expanded clay is considered to be practically the only insulation that goes to the ground, i.e. the framework can be mounted directly on the ground and the mixture can be poured into it. The main thing is to provide waterproofing.

- The method of floating screed. The composition is a cement-sand mixture. Floating technology is that the liquid layer does not have a rigid connection with the floor and walls.In this case, it is not necessary to mount the frame or the batten, the solution is poured onto the layers of hydro- and thermal insulation laid out in advance. It is important that the insulation went a little on the walls. The advantage of self-leveling floors - the ability to lose weight. As the mixture is laid in a thin layer, the load on the floor decreases. This quality is especially valuable for houses of old construction. It is important to take proper care when drying the floor surface. It must be covered with polyethylene to prevent evaporation of moisture, which is necessary for setting. The solidification process will take at least three days. After this time, it is already possible to walk on the floor, but it is still impossible to increase the load on it. The process is recommended to continue only after 28 days. Due to the long duration of the technology is currently used infrequently.

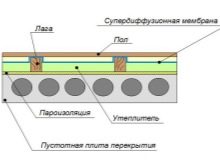

- Design in wooden houses It has a lag base, which the bottom of the subfloor covers the bottom, and the top surface covers the top. Between these levels is heat protection. Wooden floors are warmed with non-combustible materials, for example, basalt slabs or expanded clay.Since they are hygroscopic, it is best to cover them with a waterproofing layer. If this is not done, the insulation will dampen and lose its properties.

- When weathe old log house with a small underground space, repairs are best done in the summer, because the tree will be well dried. Also consider the following points:

- It is better to disassemble the floor before installation.

- If you disassemble it for some reason does not work, then the insulation can be put on top of the old boards that will serve as a subfloor. In this case, it is necessary to understand that the floor surface will rise by the thickness of the heat insulator and the finished floor covering, which may entail a rearrangement of doorways and a decrease in the distance to the window sills.

- If the space between the floor and the ground is more than 70 cm, that is, you can work under the house, only lying on your back, it is recommended to use the third option. To do this, a thin crate is installed on the logs with a screwdriver (cross section not exceeding 30 mm), and then 10 mm wide penofol, foiled on both sides, is rolled over it using a construction stapler.

Modern materials are the ideal option for insulation of all types of floors. However, their cost stops many owners. The floor covered with polystyrene foam does not require the installation of a batten. It is an ideal option as a heater for screed and for laminated flooring. Experts note that Penoplex has one major drawback - it does not tolerate point loads. Therefore, it is recommended to lay it on a fairly flat surface and mount laminate or plywood from above to evenly distribute the load. Stone laying below or smooth concrete will approach as draft level.

Useful tips

For effective floor insulation, you must follow some expert advice:

- Before starting work on the ground floor, inspect the walls and ceiling of the basement. If defects are found, they must be eliminated with cement, foam or other building materials.

- Ventilation in basements for cold periods must be covered, but it cannot be completely closed, otherwise condensate will accumulate on the insulation.

- The installation process of thermal protection must necessarily be accompanied by laying a vapor barrier layer.

- Warming the floor of a private house on a pile foundation requires the installation of a fixed base, as it provides protection from wind and snow.

- In the cottage, in the presence of a basement, it is recommended to warm the floor from two sides: by conventional methods inside the house and the ceiling of the basement.

- When choosing a heat-shielding material, it must be remembered that the lower the density, the greater the porosity, and hence the higher the insulating properties.

- If you plan to lay the insulation under the concrete screed, it should be more rigid and dense, so as not to be crushed under the weight of concrete.

- For installation work on floor heating using floating screed, masters without experience should use edge banding.

- Before pouring the concrete mix, make sure that the insulating material is laid flat. Otherwise, cracks may form on the screed after drying.

- If the insulating material had defects in the form of punctures or cuts, i.e., its tightness was broken, then sound bridges may appear. Paul will be echoing.

- When insulating using floating screed technology, it is recommended to use wire reinforcement. The cross-section of the rods - from 1.5 mm, the cell size - from 4 cm. If the mixture contains fiberglass, the steel mesh is not needed.

- Cement-sand mortar should not be too liquid, because it is difficult to level and rub, resulting in cracks.

- In humid climates, the insulation material should have a high moisture resistance.

- A low degree of heat transfer will allow the use of thinner insulation.

- To avoid unnecessary costs and waste, before starting work it is necessary to become familiar with the technology, calculate the dimensions of the heat insulating materials based on the parameters of the room, the type of insulation and the method of installation.

- It is better to warm old wooden houses in summer so that the wood dries out.

- With a warmed field in the old house, the feeling of dampness will disappear, in the future there will be no fungus and mold.

Reviews

There is no ideal way to warm the floor, for each case it is individual. However, before starting the installation work, it is better to get acquainted with the reviews of those who have already undergone this procedure in order to avoid the mistakes of others and minimize costs and effort.

According to reviews, expanded clay is a good enough insulation for private homes. It additionally provides sound insulation, economical and efficient. Also, users note its biological stability: it does not start rodents and insects.

In general, the tree itself is a good protector of heat, and the insulation is designed to eliminate weathering through the gaps between the boards and eliminate the appearance of damp. Experts recommend in this case to establish a good vapor barrier, to make antiseptic wood processing, as well as use the installation of double floor.

Residents of apartment buildings say that if there are neighbors below, the floor does not bring much discomfort, therefore, a sufficiently thin layer of insulation under the floor to eliminate boominess and add noise insulation. Another option - problems with heating in winter, which causes a desire to install a "warm floor" system. In this case, it is recommended to use polymer variants, as they are convenient, moisture resistant, do not conduct electrical current, are fire safe.

Concrete floors in cottages or on the first floors of high-rise buildings offer to make flood or usecement screeds. In no case can not do this in the "Khrushchev", because there is no overlap designed for heavy weight.

Penofol or isofol are rarely used as a separate insulation, and most often as an additional heat-reflecting layer.

Warming of the floor in a frame house involves the location of an insulating material between the lags. This design is the easiest for such an operation. Between profiles it is easy to lay both bulk and block or rolled insulation. When choosing users recommend to build on the type of base of the floor. Wooden logs as a framework perceive plates better, concrete overlap - more rigid options.

According to reviews, has the right to life and this method - ruberoid is spread onto the foundation and a fine, low layer of sand is poured on top, which must be leveled. Next to the base with a construction stapler mounted technical polyethylene as a waterproofing. Over the top end-to-end slab foam plate.

Many respondents suggest using roofing material not polyethylene for waterproofing.However, experts claim that it has a service life of no more than four years.

Some complain that even after warming floors, they remain cold. Masters recommend to pay attention to the plinth. Loose fit to the floor or walls can cause drafts. However, experts warn that the joints can not be completely sealed, and you need to partially zapenit mounting foam or tape to stick.

Forum users complain that not all craftsmen primed the subfloor before weatherization, which is a mistake. Unfortunately, it comes to light much later. The primer improves adhesion of the adhesive to the base when installed with modern types of materials, such as polystyrene. It also strengthens the upper layer, as it penetrates all pores and seals them. The same primer reduces the moisture permeability of the insulation.

According to reviews, it is not enough to warm the ceiling in the basement, it requires competent ventilation. Lack of "traction" leads to dampness and, as a result, mold.

Experts advise in case of ineffective internal thermal protection of the foundation to carry out external insulation.However, it should be understood that this is expensive, time consuming and not always doable.

How to quickly and cheaply warm the floor, see the following video.