Penoplex floor: characteristics of insulation and mounting technology for different surfaces

At the stage of planning the construction or repair of the building, it is necessary to take care that the inside was always comfortable. One of the most important aspects of comfortable living is the temperature of the air and the surrounding surfaces, in particular the floor surface.

Features and properties

Depending on the location of the building and its construction, heat loss through a cold floor can reach 15–20%. Such a cold surface can increase the humidity in the room and serve as a breeding ground for various fungi and mildew. Regular contact with a cold floor can cause hypothermia and, as a consequence, an increased risk of colds.In order to avoid all of the above, it is enough to simply warm the floor with the use of penoplex.

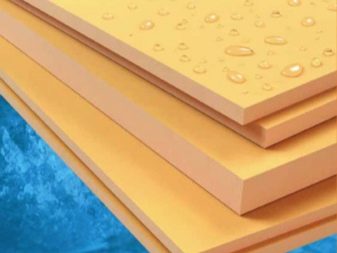

Penoplex is a special material with a high heat-insulating indicator used in construction. It is produced by the method of extrusion - foaming and pushing into a special form of polystyrene, which allows to obtain granulated material with micropores. Cells of such insulation for the floor contain voids with gas, which allow it to reliably retain heat and not allow moisture to pass with minimal weight. This heater is available 600 millimeters wide and 1200 or 2400 millimeters long.

Advantages and disadvantages

More recently, the surface was insulated using ordinary mineral wool or foam. Nevertheless, the use of such materials is associated with many inconveniences, which was the reason for the development of higher quality penoplex plates. The advantages of the new heater are as follows:

- low weight and compactness with increased compressive strength;

- durability and ease of use. It is not at all easy to lay such plates on your own, even without any previous work experience;

- high thermal insulation and almost zero water absorption. The material does not pass water and does not absorb it;

- The plates are resistant to mold and mildew.

It is possible to mount such plates both on the floor and on other surfaces: walls, roof, foundation and others.

However, like any building material, Penoplex has its drawbacks, which it will be better acquainted with before making a purchase decision. The disadvantages of lightweight slabs include the following:

- under the influence of ultraviolet rays, such a material is quickly destroyed, therefore, it is desirable to immediately finish the finish over the plates;

- The material is low melting and combustible.

Species

Extruded insulation is used in both civil and industrial construction. It is used even in the construction of roads and airfield lanes. The range of such products is quite large, however, not every type is suitable for floor insulation in a residential apartment under a screed.

- Penopleks "Comfort" is perfect for this task. It is often used in the construction of baths or villas and has a high frost resistance.Its density is 31 kilograms per cubic meter and this is more than enough for a residential house or apartment. You can select a material with a thickness of 20 mm to 100 mm.

- Penopleks "Foundation" - it is more durable (35 kilograms per cubic meter) plate with a thickness of 50 mm to 80 mm. Based on the name, this material allows you to warm the foundation of a dwelling house and its strength does not decrease during the entire lifetime. There are also specialized slabs called “Wall” and “Roofing”, which are used for the respective surfaces.

Thermal conductivity of the former is the lowest among all other types, and Roof has a high fire resistance, which is the most important characteristic for roof insulation.

- Penoplex "45" It should be chosen if there is a small helipad near the country house, since such insulation is used for runways and railroad tracks. Heavy-duty (40–45 kilograms per cubic meter) material is produced with a thickness from 40 mm to 100 mm.

The average price of polyfoam is higher than that of polyfoam or mineral wool, and averages:

- 300–350 rubles for a 100 mm thick sheet;

- 180–300 rubles for a sheet 60 mm thick;

- 150–180 rubles for a 50-millimeter sheet;

- 100–150 rubles for sheets from 30 to 40 millimeters;

- only 50–70 rubles for thin sheets of 20 mm.

The market leaders are foreign manufacturers of insulation plates, such as BASF, Nova Chemicals or Styrochem. For a long time, only foreign products were on the market, however, Russian brands Penoplex and Technonicol are becoming more and more popular. They produce high quality material, and its price is significantly lower than their foreign counterparts due to savings on transportation.

How to warm: ways

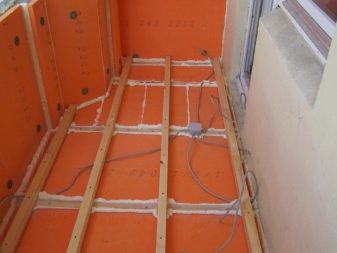

Penoplex is a versatile material and is suitable for installation in a private house or in a bath, and for a small apartment or loggia. Before you begin laying, you need to carry out a series of preparatory work. They may differ depending on the method of installation of the plates, but the basic provisions are carried out before any of them. In the room, a self-adhesive elastic tape is laid around the perimeter so that condensation does not form at the interface of the insulation with the wall. And it also helps to increase the overall rate of insulation of the room.

The surface itself, whether it is a wall, floor or ceiling from the basement, should be flat, without damage and debris.

The surface must be repaired and cleaned, even if laying is performed between lags. Depending on the device of the floor, various communications of water supply or heating can take place in it. They need to be further insulated and waterproofed.

Not the easiest way to lay insulation that you can do with your own hands, but often encountered in the construction of private houses and cottages is laying on the ground. First, the soil must be compacted, covered with rubble or gravel to a height of up to 40 centimeters. A ten-centimeter-thick sandy cushion is placed over the rubble. A damper tape is glued around the perimeter of the room, which prevents the floor from deforming during the expansion of the screed against temperature increase after freezing winters.

In individual tiles of insulation, holes are cut to the size of the laid communications, therefore, it is important to pre-layout all the plates and make a diagram. In this case, those elements that will be cut can be numbered or otherwise marked, so that confusion does not occur. After that, the insulation is stacked in a staggered manner, and the joints between the individual elements are glued with assembly foam.Glued foam plates should be covered on top with a waterproofing film or other material with similar properties.

If the film comes in rolls, its strips can be glued together with the help of adhesive tape, so as not to leave even the slightest uncovered area.

After waterproofing, the soft plates of insulation should be reinforced by putting a coarse metal mesh of 8–10 cm onto the film. Pour the prepared cement-sand mixture over the pre-inserted beacons with a 4–7 cm thick layer. Align the resulting screed and let it harden for at least 14 days. On the hardened flat surface you can lay any floor covering: tile, linoleum or laminate. According to a similar algorithm, the warming of other surfaces is carried out, but each of them has its own nuances.

Wooden

Warming of wooden floors in houses and apartments is carried out in logs. It is best to put new lags, but you can put a heater on the old bars, if they are still quite strong. For a start, the construction cord indicates the zero level around the entire perimeter of the room. On these marks lags are stacked, they must be laid exactly in the level.The step between the lags in length must coincide with the size of the penoplex slab so that they fit and sit tightly in the resulting grooves.

The lags and the surface between them, which is called the “subfloor”, must be covered with plastic wrap or other waterproofing material, forming even depressions. After you can lay out penoplex in them. After laying the insulation along all the seams, you need to go through the mounting foam to minimize the risk of cracks and voids. After the foam dries and hardens, you can lay the floor covering. This method is the simplest, but it is rarely seen, since wooden floors are less common today.

Concrete

Laying insulation on the concrete floor is always under the screed. Due to this, a high-quality insulated floor is obtained, which will not require repair for a long time. First of all, preparatory work is carried out: all rubbish and defects are removed, the floor is leveled with a coupler. In apartment buildings, the floor slab between the floors itself is quite flat, but the height difference should not be higher than 3 millimeters per 1 square meter, therefore it is likely that pouring the screedwill have even in this case.

After complete drying of the solution, it is possible to lay the plates themselves. It is made in such a way that the locks of interplate joints are located closer to the center of the room. At the same time, the installation itself is carried out in a staggered manner. For more reliable fixing, the penoplex is laid on a special glue, which will also provide additional waterproofing.

Nevertheless, it is still necessary to lay the polyethylene on top of the glued plates. The edges of such a film are wrapped on walls to a height of 5–10 centimeters.

At the very end, the floor is filled with a finishing screed, which is at least 6 centimeters thick. After the concrete has completely cured, any decorative covering can be laid, including parquet or carpet. The protruding edges of the film on the walls can be cut off with a regular stationery knife and the resulting edge can be hidden with ordinary skirtings. If everything is done correctly, then this method of laying in the section is a multilayer coating, the lower and upper layers of which are a concrete screed, and in the middle there is a waterproofing and insulation.

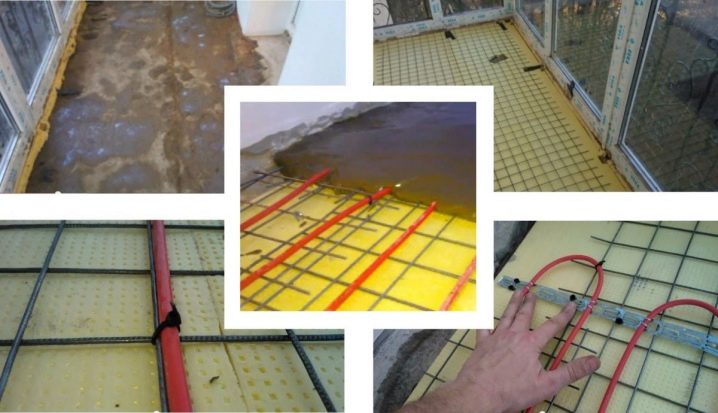

Under the system "warm floor"

Laying penoplex under the warm floor is very similar to insulation under the screed, however, has its own characteristics.After leveling the base, the material can be laid thinner than under the screed, as there will be additional heating with the “warm floor” system. On the laid plates polyethylene creeps, and already on it a warm floor is mounted. After this, a finishing screed is performed and the concrete is coated with linoleum, laminate or any other decorative floor covering.

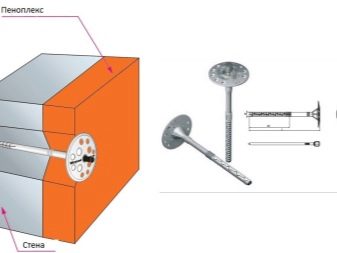

Separately, it is worthwhile to dwell on the weatherization of other surfaces with the help of penoplex. It is quite simple to glue light plates with a special composition onto the prepared wall surface. Depending on the type of finishing material and type of work, various adhesive mixtures are selected. In cases where landing on glue is an unreliable method of installation, it is possible to additionally fix the plates with the help of long dowels.

To fix the foam plastic on the facade, only metal dowels are used, and inside it can also be fixed with plastic. Ordinary screws - this is also a great way to fix the insulation on the wall.

Warming the ceiling is an even more complex process. In this case, even glue and screws are not enough, since the plates, no matter how light they may be, will depart under their weight.One of the ways to fix the penoplex at a height is the use of special suspensions. Special openings are cut into the insulating plates, into each of which a metal suspension plate is inserted, which holds and presses the bottom plate to the ceiling.

The second method of installation is fastening on the batten. This method resembles laying on logs and is performed in a similar way. Plates are put on the glue between the bars of the frame, all slots are foamed with mounting foam.

Summing up, it can be noted that Penoplex is not for nothing considered the best solution for insulating any surface. It is perfect for both outdoor and indoor work. It can be put in the bathhouse in the summer cottage, and under the screed in the office of a high-rise modern office. Easy, inexpensive material is presented on the market by both foreign and domestic manufacturers, it is easy to assemble it independently, and the result will last for many years.

For how to warm the floor with penoplex, see the video below.