How to choose insulation for floor heating?

Due to the rapid development of modern technologies for housing, various devices are increasingly being used to increase the comfort level of residents. One of these devices is a warm floor. And for its productive operation and operation requires a number of materials, among which a special place is occupied by thermal insulation.

Special features

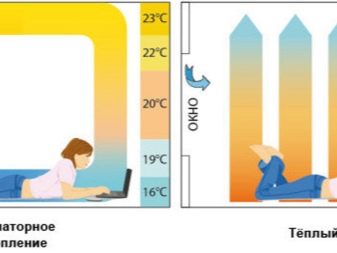

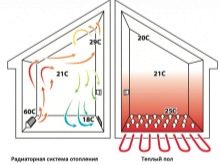

The task of warm floors, regardless of the type and configuration, is to ensure uniform distribution of warm air in the room.Since we all know that cold air accumulates at the bottom, and heated up rises, the difference in temperatures for a person is very noticeable. The system of warm electric or water floors minimizes these temperature fluctuations in the home, creating an acceptable and comfortable heat exchange.

The main feature of the device can be considered a heat-insulating substrate, which, along with the entire heating system, is responsible for preserving heat. Among the proposed assortment of similar products on the current market, a number of materials are presented that are used for the arrangement of the system.

In order not to be mistaken with the choice of raw materials, one should proceed from the tasks that the products in the complex of the entire floor heating device will solve.

Among the main functions of insulation should highlight such moments:

- The presence of thermal insulation reduces the natural loss of heat, going out through the coldest areas of an apartment or house to the outside or into the ground. In the absence of any materials for warming, the level of warm mass out of the room through the floor surface is 20%.

- Thanks to the laying of insulation, thermal energy circulates in proportion to the entire heating area, eliminating unnecessary heating of floors and other components of the building structure,which are located under the floor.

- Due to thermal insulation, you can save money spent on heating homes.

- In addition to the main functions, the material provides additional noise insulation, which is important in high-rise residential buildings.

- The properties of thermal insulation products make it possible to create a protective barrier that prevents moisture from entering from the basement or the ground through the floor to the dwelling.

In addition, there are three types of warm floors, which differ in the principle of operation. Exists:

- electric;

- water;

- infrared system.

The type of raw material for thermal insulation will be directly dependent on the type of device, which will be best used in a particular case.

An important characteristic of the material will be the level of insulation resistance to mechanical loads, which inevitably affect the flooring.

The following features are inherent to heat-insulating materials:

- good compression resistance;

- elasticity of raw materials;

- minimum deformation under load on the base;

- resistance to aggressive substances;

- low thermal conductivity;

- small indicator of moisture absorption;

- high density of the material.

Materials

For arranging a warm floor system, manufacturers offer consumers a wide range of different materials, which differ in cost, type of raw materials (there are natural and synthetic products), as well as the quality characteristics of the products.

It is possible to distinguish the main materials for thermal insulation:

Cork backing

Raw material is a natural and environmentally friendly product, sold in rolls. The specific structure of the material, made in the form of miniature prisms, provides insulation with a high level of compressive strength. Cork does not adhere to cement.

Experts recommend to give preference to such raw materials only if laying is possible, based on the height of the ceilings in the room. A similar limitation is explained by the fact that the installation of cork insulation is associated with raising the floor by about 4–5 cm, since the shields required for such work will be about 30 mm thick. In addition, stopping requires the additional purchase of reflective material in order to use it in the kit.

The positive features of the raw materials include the safety of the operation of products in residential premises due to the naturalness of products. The disadvantages of cork insulation include the high cost of raw materials and low hygroscopicity.

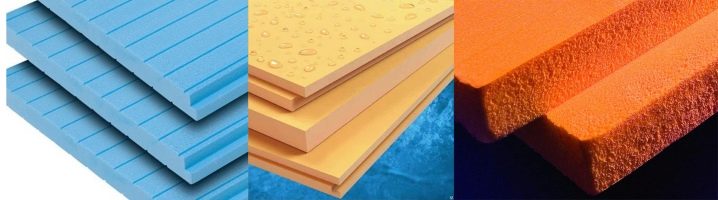

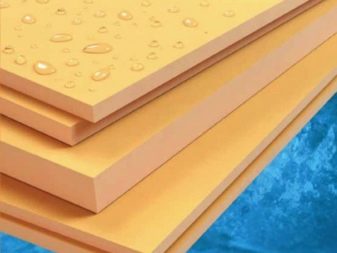

Polypropylene is used as insulation for underfloor heating. The material is used in the form of extruded plates, which have a closed cellular structure. This type of raw material is more popular in comparison with other products for floor insulation. High demand for polypropylene is due to high qualities of raw materials, due to which the coating lends itself well to processing, which facilitates installation of products in rooms with a complex floor configuration. In addition, the products are not hygroscopic.

The positive properties of polypropylene include its thermal stability, which allows it to operate at temperatures up to 130 ° C.

Styrofoam

The most suitable product for thermal insulation of warm floors of water type is products with a thickness of products from 50 to 100 mm. Material is allocated with good indicators of durability, low cost and minimum weight. In addition, polystyrene is quite hard and is characterized by resistance to significant temperature fluctuations, accompanied by differences from negative thermometer to positive values.

This resistance of raw materials is explained by the peculiarities of its structure, it contains air spraying of cells. Products from expanded polystyrene retain their appearance and properties when in contact with aggressive media, including salt solutions and alkali, in addition, they do not absorb liquids and are easy to install.

There are varieties of material for insulation, which are composed of polypropylene film.

To the above characteristics of the raw materials, you can add sound-proofing properties, resistance to decay and bio-resistance. The service life of products from expanded polystyrene is calculated in dozens of years.

However, it should be noted that there are some types of products that, during operation and heating, will release toxic substances.

Metallic polyester film

Such products provide high-quality protection from the negative effects of alkali on the flooring and cement screed.Aluminum products without an additional layer of heat-resistant PVC film are not used. A positive feature of the products is a high level of reflective properties.

The disadvantages of foiled thermal insulation include a low level of insulating qualities. Therefore, when laying products above the basement, standard products with a minimum thickness will not be enough. This problem can be solved with the help of solid insulation mats in several layers. During installation, you should follow the technology of laying sheets so that the seams of the materials below are closed with the seams of the products laid on them. This method will reduce heat loss.

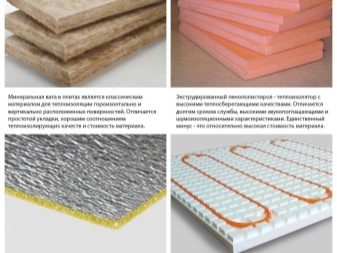

Mineral wool

Sold material in the form of a solid plate, or vice versa - a flexible mat. When installing cotton wool directly into the screed, it is compressed under load, as a result of which the insulating qualities of the raw materials are reduced. Experienced craftsmen recommend combining mineral wool with flooring type structures, which consist of wooden logs.

The advantages of mineral wool should include:

- incombustibility of raw materials and resistance to high temperatures;

- good level of sound insulation of the surface;

- good thermal insulation characteristics;

- resistance to chemical compositions.

The disadvantages of products include the presence of penofol in the composition of cotton wool, which represents a danger to humans, as well as poor resistance to moisture. But high-quality waterproofing of the floor will help to use products for the insulation of underfloor heating.

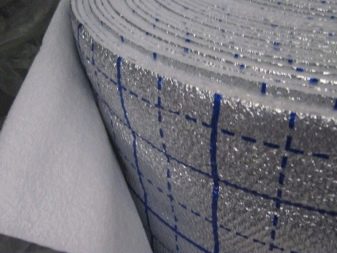

Polyethylene foam

Very often, the choice in favor of insulation for underfloor heating falls on this material. Products are products with a thickness of 3 to 10 mm, which are sold in rolls. On sale there are varieties of polyethylene, which additionally include a foil layer located on one side or on both sides.

This structure makes it possible to create a reflective layer for infrared rays. In addition, the presence of foil provides additional thickness insulation, increasing its properties.

Among the disadvantages is the inability to reflect the IR in a solid, namely, in this form, the cement screed is laid on the floor.

In terms of performance, the raw materials are not inferior to polystyrene foam. However, polyethylene foam is able to absorb moisture, which adversely affects its insulating properties. In addition, some of the chemical elements that make up concrete can destroy the foil layer of thermal insulation products. To exclude the possibility of destruction of insulation during the operation of the floor, most manufacturers began to produce sheets, where the foil is additionally covered with a polymer film.

Manufacturers

In the construction market, the products used for arranging the insulation of underfloor heating are represented by a wide choice of types, as well as various trademarks.

Among the proven companies selling their products in the domestic and foreign markets, the following companies are distinguished:

- High-quality polystyrene is produced by trademark. Knauf.

- Mineral wool is marketed by brand. URSA.

- Also, the consumer is offered thermal insulation for the floor. Thermo.

- In addition, it should be noted technical plug Amorim and polyester film from the company Daewoo enertec.

Tips for choosing

To make a choice of material that justifies the money spent on it, it is necessary to pay attention not only to the characteristics of the raw material and its parameters, but also to the operational life of the material.

Many types of products that have high performance and properties, unfortunately, have a small service life. As a consequence, the replacement of the insulating material with a new one will need to be carried out much earlier than the need to prevent any elements of the underfloor heating system. This is especially true for the floor, where the coating is made using tiles, for example in the bathroom, as a result of which it will be necessary to disassemble the products. Therefore, the minimum period of products for floor insulation should be 10-15 years.

As for the material properties that are worth paying attention to first of all, the following should be highlighted:

- coefficient of thermal conductivity;

- level of resistance to mechanical stress;

- resistance to dynamic effects;

- vapor permeability;

- hygroscopicity;

- material density.

For rooms with high ceilings, which height exceeds 250 cm,You can opt for durable insulation with a rigid polymer base. For wooden floors, it is best to purchase an environmentally friendly and non-flammable material. Mineral wool may be a good option for thermal insulation in this case. For floors, where the heating system is equipped with a cable, the main property of the heater is the presence of a heat-reflecting layer, regardless of the form in which the material will be made.

How to lay?

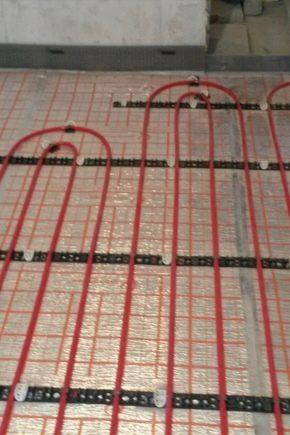

On the basis of the foundation, various raw materials for thermal insulation are used for work, and the method of its installation can vary significantly, some types of insulation have special clamps - bosses, which make it easier to lay pipes.

All installation work should be carried out starting with preparatory activities that concern the floor surface:

- repair of large cracks;

- base leveling;

- laying of a waterproofing layer;

- laying of polystyrene damper tape around the perimeter of the room.

The technology of laying plates with chamfer is reduced to fastening products to each other according to the principle of the designer.Adjustment of products to the required dimensions is carried out by simply cutting products with a knife into plates of the appropriate size. For the final fixation of the plates, the joints between them are additionally glued with construction adhesive tape.

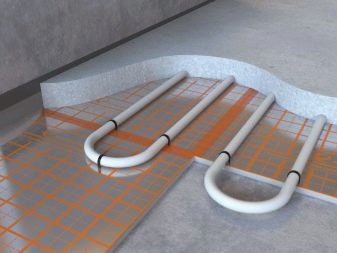

To put a warm floor, the work must be carried out according to the following scheme:

- Plates are laid on the prepared surface using the available fasteners - brackets, dowels, adhesives.

- Foil film and a reinforcing mesh are laid on the products, followed by pipe laying.

- In the case of work with uneven floors pre-equipped with a frame made of wood.

Work with a wooden base and mineral wool is carried out on the subfloor, between which is left an air cushion that provides condensate outflow between it and the clean floor.

- Laying roll insulation is carried out when the products are fixed to the surface with glue and double-sided construction tape. To increase the insulating properties, the foil layer should slightly overlap the walls. For ease of installation, roll products are marked on the surfacewhich helps to indicate the distance between the contours of the system.During the work special attention should be paid to the seams between the products, they are additionally sealed with tape.

- The cork is placed on a pre-equipped film hydro and vapor barrier. Mats are fastened with the help of special fasteners of the castle type. In the course of working with cork material, the use of fasteners made of metal should be avoided. They can deform not only heat-insulating raw materials, but also waterproofing material located below.

All about thermal insulation for floor heating, see the video below.