Floors in a wooden house: the most suitable options

Wooden log, timber, frame houses are becoming increasingly popular. Many construction companies and brigades have emerged that have accumulated extensive experience in the construction of such houses using new materials, tools, accessories and measuring devices. New wooden houses meet all modern requirements for quality housing.

Special features

Our ideas about home warmth, comfort, natural purity and safety are connected with the wooden house. It is clear that for the strength and durability of a wooden house and its some details can not compete with concrete, composite and other modern objects and structures.

Comfort in the house is largely determined by the characteristics of the wooden floor:

- strength at which elements do not bend or creak;

- long-term preservation of the form and original appearance;

- warm sensations;

- has beauty and attractiveness.

The beauty of a wooden floor, not covered with a carpet or linoleum, has its own unique feature.

The device of the floor is not a novelty for people of any generation, its technology has been practiced for centuries and to master the preparation of materials and perform all work in the state of anyone. It is important to familiarize yourself with the order of work, to master one of the many technologies, to get acquainted with the tools and devices and to begin work, observing safety measures.

How to cover?

Several types of wood-based panels and plastic materials are suitable for laying rough and finished floors. Tiled and plywood material can be used in crates, surface cladding and in the formation of rough floors.

Plywood - one of the best finishing and construction products. These are glued sheets of veneer, located in the direction of the fibers mutually perpendicular. Due to the high strength, diverse colorful texture, ease of operation, plywood can be used both for the subfloor and in the finishing of the finishing coating. Available in sizes 1.5x1.5 meters, 1.5x3.0 meters.The thickness of the material can be from 8 to 30 mm. The cost of plywood depends on the original wood from which the veneer is obtained.

OSB - chipboard. It is obtained by pressing flat chips impregnated with a moisture-resistant resin. These plates are used for various partitions, foundations for blocks with shingles, to create a large package and in other similar cases. For floors of wooden houses used as intermediate layers. Thickness - from 9 to 20mm, dimensions - 1.22x2.44 meters.

Chipboard Quick Deck Moisture-resistant in the composition has wood chips, moisture-resistant resin. The surface is hardened, smooth, without chipping and scratching. Can be used in the installation of finishing floors, partitions, ceilings. Thickness and dimensions correspond to GOST of Russia.

DSP (Cement particle board) includes wood chips, cement, binders and other substances. Moisture resistant, resisting fungi, fire resistant, tough, durable, environmentally friendly. Suitable for use in rough floors. Thickness - from 8 to 24 mm, dimensions - 1.2x3.2 meters.

Constructions

By the type of supports used the floor can be carrying or floating. When relying on the bearing or supporting beams, the floor will be connected with the walls of the house and there will be mutual influence during deformations of the walls or floor overlap.For monolithic bundles with walls, beams or metal channels are used. If the support will be on the pillars, then this option is called floating. Most often it is used when laying a house on the ground with a close location of groundwater.

Pillars-supports can be made of red baked brick or use monolithic concrete pillars made with formwork or using asbestos-cement pipes and placed inside their framework from steel reinforcement. In modern construction, supports are used on screw piles, which are fixed in nests in the ground.

Floor structures are placed on a carrier and on the floor. The role of such a foundation is performed by the ground, interfloor, basement or basement ceiling.

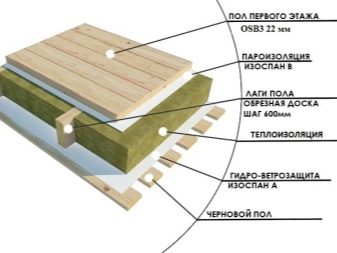

"Pie", or genital decking, is divided into two types:

- Single flooring of prepared wooden boards. This type of floor is simple in construction, use and possible repair in the future. Often used in country houses for seasonal use;

- Dual type of coverage for homes with permanent residence. The technology for this type involves the construction of two decking - finishing with finishing and roughing, or subfloor.The gap between them is the space for insulation and protection from moisture.

When interfloor bases (floors) are equipped, there is no need for steam and thermal insulation, it is enough just to isolate them from noise. If on the upper floors it is planned to install bathrooms, then protection against leakage should be.

Heat protection, insulation and heating pay special attention if the warm second floor is separated from the cold basement floor or basement floor.

Heating

We lay a vapor barrier on the laid black floor, the gaps between the lags are filled with insulation (mineral wool). Above lies the foam or foil polyethylene. In the joints of the walls and the floor apply mounting foam. Before laying the finished floor we lay a layer of vapor barrier material on top. The laid clean layer can be additionally covered with thickened linoleum or carpet.

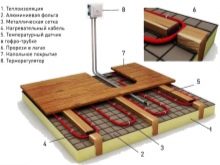

For many tenants, such a scheme is enough to preserve heat, but some also need heated floor heating. Installing underfloor heating is becoming increasingly attractive in home improvement and increasing its comfort.

Floor heating is performed by different types of thermal devices,but with the obligatory presence of instruments and sensors to maintain a certain temperature regime.

Heating options:

- Hot water supply to the heating pipes;

- Heated by electric heating cable;

- Heated by infrared radiation.

With the water method of floor heating, heating pipes are placed in the concrete screed. These can be polyethylene, metal-plastic and copper pipes through which hot water transfers heat energy.

A simple solution to supplying hot water to these pipes would be to connect to a common heating system in an apartment building, but this is administratively difficult. Obtaining such a permit from public utilities, ordering a project and coordinating with the house management is not an easy task.

In a private house, solving the problem of installing a warm water floor, you can get a safe, durable and cost-effective support scheme for a comfortable thermal mode.

In electric heating systems, a shielded cable is used as the main source of heat in combination with temperature sensors.

Infrared floors are a thin film with carbonic strips between its layers.These strips, receiving power from the electrical grid, emit infrared thermal radiation, which heats the space around them.

It is better to entrust the installation of the floor heating system to specialists who will do all the work in accordance with the agreed project.

How to choose?

In a log house, the correct choice of floor type is determined by the number of floors, the climatic features of the area of residence, the purpose of the rooms. The first floor requires special attention for all types of insulation, primarily moisture and heat. If possible equip their heating.

The second floor of a wooden house is protected from moisture and cold and will require lower costs for the arrangement of the floor. There may be a greater choice of flooring - from linoleum to parquet from expensive rocks.

For cottage on the first floor better fit floor, made of boards of the same rocks, of which the walls are composed. Boards should be lined so that from the entrance to the opposite window they lay parallel. It is better to put a bathroom or a shower cabin on the ground floor, and if there is a need to use the second floor, then it is best to use ceramic plates for the bathroom,preventing water leaks.

How to lay?

In a wooden house, floor boards can be laid on logs that are best laid with a grid. The step of their laying depends on the thickness of the floorboard. The thicker the veneer board, the less often the mesh lag. As them you can use a bar, half-tier, massive boards, put on the edge. They can be put on the ground, brick supports, beams, concrete base. Before making the logs supports for the floor, they are kept indoors for several days for acclimatization. Then you need to treat them with antiseptic and water-repellent composition.

Colors

The color scheme for the doors and the floor is more limited compared to the walls, but at the expense of shades the choice expands.

Laminate flooring, parquet, linoleum, carpet, plinth and other design elements diversify our choices:

- Light shade reflects light and increases space, adds new sensations of freshness and transparency. For the living room and the bedroom it is a good decision, but it is necessary that the colors of the walls enliven the decor;

- Dark shade gives a sense of stability. It is suitable for rooms where there is a lot of sun. If you pick up accessories that contrast with the tone of the floor,can get quite a harmonious look.

Painting

Sometimes designers recommend painting the finished floor in accordance with the overall color scheme of the house. Such work will require initial surface preparation. We check the entire area of the floor to be painted. Floorboards should not creak, they need to be adjusted or restored. It is necessary to remove all irregularities, drive sticking heads of nails and screws into wood. Seal any part of the surface with a defect and grind it.

Putty can be made independently. It is necessary to mix sawdust, linseed oil and oil paint. You can mix sawdust with white glue. After this preparation, you need to rinse the floor with soapy water and allow it to dry for 2-3 days.

Mixture for painting should be oil-based, but you can apply any other, prepared as floor paint. It is necessary to paint in at least two layers. After the first layer, it is necessary to allow 2-3 days for drying, after applying the second layer the drying time is up to 5 days.

When applying the final layer, the movement of the brush should be parallel to the fibers of the floor boards. Otherwise, the general appearance of the coating will look as defective.Technology application of floor paint can be several.

Read carefully the procedure for using a specific paint, which is listed on each package.

Options in the interior

The interior design of a country wooden house differs in many ways from the design of a city apartment. Extensive spaces and natural surroundings make designers, while maintaining the overall style, it is beautiful and convenient to use these features.

It is important to remember that the floors are part of the interior, and you need to choose them, starting from all parts of the interior.

Let's start from the first floor. It is most often a public space in the house. At its first visit, tenants, guests and visitors see and appreciate the style and features of the interior of a wooden house and, of course, the condition of the floors.

Designers can offer more than a dozen options for interior styles:

- Russian hut;

- Chalet or hunting lodge;

- Rustik;

- Colonial;

- Scandinavian.

Each of these and any other styles must take into account the requirements for the appearance and quality of floors.

Russian izba - one of the simplest, but widespread styles for country and private houses.There is no such thing as the design of the walls, because the wooden beam itself is presented as an element of decoration. Floorboards are usually stacked from the same wood species as the walls of a house. The timber is polished and varnished to increase protection against moisture and sudden temperature changes.

Next, look at how and how to paint the floor in a wooden house.