Mats for a warm water floor: types and device

Heated floor consists of many components, but the most important are insulation and waterproofing. High-quality waterproofing allows you to avoid flooding of neighbors or structural components in case of breakage, and good thermal insulation - to reduce the cost of utility bills. One of the modern materials for warming under a warm floor is special mats, which are very easy to install and operate. But they are different and it is important to be able to distinguish them depending on the task.

Features: pros and cons

The main function of the heat-insulating material for a device of any type of heating, including a heated floor, is to reduce heat losses, as well as redirecting heat to the room itself, where such a floor is mounted.When installing pipes without insulation, the efficiency will be extremely low, because most of the heat will go to the floor below: to the neighbors or to the basement. This is precisely why thermal insulation exists, which not only fulfills the task of maintaining heat in the room, but also prevents the penetration of cold air from below, especially from the basement (mainly on the ground floors in private residential buildings).

Also, heat insulation performs the function of uniform distribution of heat throughout the room.

Competently chosen and, importantly, mounted heat insulation directs the flow of warm air mainly upwards and prevents the accumulation of condensate. It is also important property of thermal insulation, which almost completely prevents the appearance of mold on the walls and partitions.

Previously used quite classic varieties of insulation, such as foam and ecowool. At the moment, these materials have not lost their client, since their cost is relatively low, and their technical properties have hardly changed, if they have not improved due to new technologies.But at the same time, with the progress of technical progress, more convenient and practical options for thermal insulation materials appeared - mats for floor heating (water).

The main material for the production of modern mats is polystyrene foam.

It is distinguished by its excellent thermal insulation properties. But, in addition to this, it has another advantage - a good vapor barrier. In other words, polystyrene foam does not allow steam and does not accumulate moisture, which leaves it in a dry form all the time, and this prevents the appearance of condensation. It also has a low thermal conductivity, which has a positive effect on the preservation of heat in the room.

One of the properties of this material is sound insulation. For country houses, it is also notable for the fact that it is an “inedible” material, due to which it prevents the appearance of various rodents and microorganisms. The average service life is 50-60 years subject to the temperature thresholds indicated on the packaging by the manufacturer. The density of this material reaches 40 kg / m3, which makes it adapted to large loads. This has a good effect when installing a heated floor, as the mats not only fit the mesh of reinforcement or rods, but also pour a layer of concrete and leveling mortar (on top of water pipes).

For the construction it is better to use carbon cable.

Mats for a heat-insulated floor (water) are the modern heat-insulating material which is made according to the European standards (quality and safety). They are produced on the latest advanced technologies. The technical characteristics combine the advantages of conventional insulation, rejecting the disadvantages.

The main advantages of mats are:

- decent thermal insulation and sound insulation properties;

- allow both semi-dry styling and laying in a wet (even wet) tie;

- during long-term operation are not subject to deformation and resizing;

- on modern mats there is a system of locks, which allows them to be connected much faster and more qualitatively and does not allow construction congresses;

- most of the materials produced have a markup, which significantly facilitates the installation of pipelines;

- do not rot, do not save bacteria;

- not exposed to moisture;

- non-toxic (at normal temperatures, from -180 to +180 degrees), safe for humans;

- the service life is about 50-60 years.

It should be borne in mind that untreated polystyrene foam is considered to be a combustible and flammable substance and during combustion it separates the poison gas.

In order to reduce this feature, flame retardants are added to the material during production, which makes it self-extinguishing. In Russian-made products, this kind of material is marked with the letter C in the ending.

The heating element must be used with extreme caution. Among the minuses can be noted that it can cause a fire.

Species

There are 4 types of mats that are suitable for arranging underfloor heating. Each of them has its own characteristic features and is used for laying in specific situations.

There are the following types:

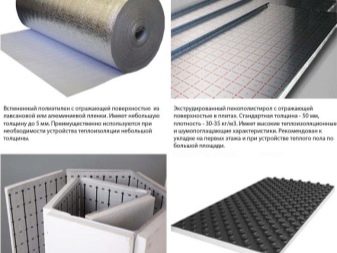

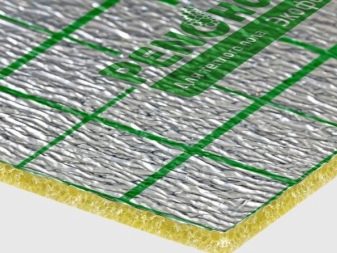

- narrow-web materials equipped with a foil formation;

- foamed polystyrene plates consisting of expanded polystyrene with foil-coated, sometimes film-coated;

- profile mats with special design features (lugs).

Selection of thermal insulation coating depends on the characteristics of the building, the coating on which the masonry is made, the mechanical load that the insulation is to be transferred, as well as the dynamic load on the insulation.The plates have different sizes, including height, for this reason, you must also take into account the thickness of the upcoming screed.

Narrow web foil material

It is carried out from material from 2 to 10 mm wide. At one end, the insulation is covered with a dural foil or polymer layer, whose role is to direct the thermal jet and the distribution of heat according to the total floor area. This type of heat-insulating material is allowed to be attributed to the mats extremely arbitrary, since it has a low thermal insulation quality. This causes a rather narrow area of its operation. It is used only when a warm floor is used as an additional heating structure and the main flooring already contains one or another level of insulation.

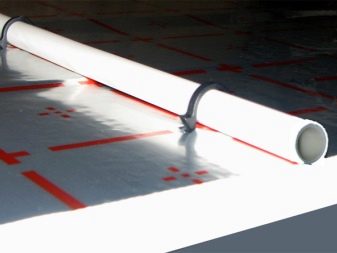

Roll material is not rational to put on the first floors of buildings and in rooms., at the bottom of which there are unheated areas, as the productivity of insulation in this case will be close to the sad indicators. Some difficulty also implies the installation of the pipeline in this heat-insulating material, since it is necessary to use auxiliary fastening components: brackets, clamps, reinforcing mesh, etc.When mounting the web, the covers are flush with each other. In order to provide the best insulation, the seams are glued with a special foil tape. But despite the extremely modest properties, the material in rolls under specific conditions is considered the only acceptable type of insulation, for example, with a small building height, if every meter of the site is on the account.

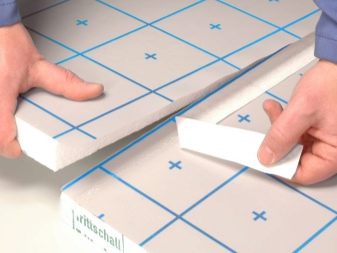

Insulating plates of polystyrene foam

It is possible to use thin polystyrene foam mats as thermal insulation of a heated floor. Very light and inexpensive look - ordinary polyfoam, the most reliable and high-quality material - a tile from extruded polystyrene foam. When the decision is made to stop on the most inexpensive foam plastic, then at its acquisition it is necessary to concentrate interest in the density of the material. This ratio should be no less than 35 kg / m3. If this value is less, then the material may not be enough to hold the load of the heating structure.

You can also use another type that has significantly better performance. The best representative of this series is considered penoplex.It has a closed coarse-grained texture, is durable, and withstands overloads well. In order to improve the thermal insulation characteristics, foil material can be put on top of the mats in rolls.

The sides of the slab are equipped with special locks that simplify their installation. The trade still comes across material with previously applied markup. The pipes are attached with plastic clips, which are easily driven into the plates in a suitable place.

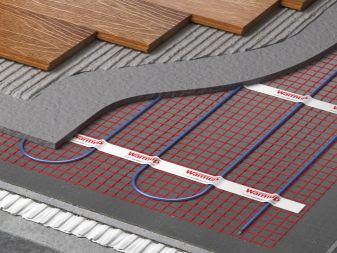

Polystyrene foam panels with foil

This type of insulation is nothing like foam polystyrene mats, where a foil or another layer has already been applied. They are available either in the form of separate tiles, equipped with a castle joint, or in the form of panels, fastened together by a single film coating. In one case, when laying the tiles, they are fastened together with waterproof tape, in the other, the mats are easily laid out on a plane. On the outside of the panels there is a coordinate network with a step from 50 to 100 mm. Marking can help to understand how best to do the laying of pipes, and also provides an opportunity in a short time to lay the pipes according to the chosen scheme.

Brackets can also be used for fastening pipes.

It is also possible the type of laying with reinforcing mesh, which is laid on top.

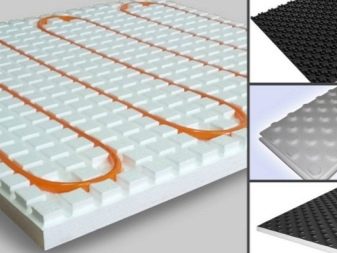

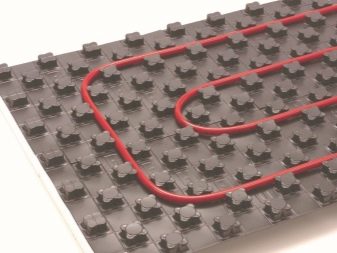

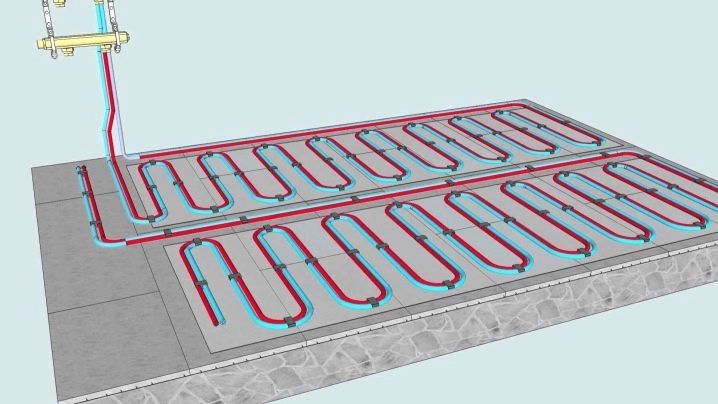

Profile mats with "lugs"

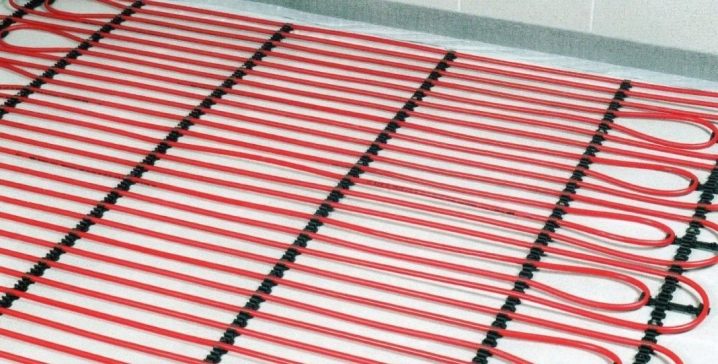

The most ideal, practical and comfortable material. Mats are specially invented for installing underfloor heating. The material from which they are made is still the same - polystyrene, however, due to the use in the manufacture of improved technology of hydropellent punching on the mats, there are special protrusions (lugs).

Lugs can be of various shapes: round, tubular, cubic, polyhedral and others.

The protrusions located at a specific distance from each other, guarantee a safe connection and fixation of the pipeline in the desired position. When using these mats, there is almost no chance of pipe displacement during their installation and further pouring with concrete.

Coating mats depends on the modification and manufacturer. Certain types of thermal insulator are produced in principle without any spraying, but it is possible to purchase models with a top film layer or a stretched waterproofing shell. On the properties of the product, this coefficient has no greater impact.For comfort and simplicity of installation, the material is equipped with special locking connections, which, among other things, guarantee excellent tightness of the joints. Mats form a continuous plane in the absence of slots and gaps, on which it is possible to lay any type of tie.

Another indisputable advantage of foam polystyrene profile mats is that they form an excellent anti-noise barrier: the material makes it possible to significantly reduce the degree of hum to 25 dB.

How to choose?

Today, you can choose any heating element and mat, for example, with clamps, with pimples, foam, two-core, thermoplastic (thermoplastic), etc.

When selecting a heater, it is necessary to pay attention to its characteristics, such as waterproofing properties and the ability of a material to carry constant and dynamic overloads.

It is also necessary to take into account the diameter of the pipes and the properties of the building in which the laying of the heated floor is performed. Thus, the roll material due to its own low waterproofing data is not suitable for laying on the lower floors. He should also be used with caution in apartments where people live below.as in the case of leakage of pipes, he will not be able to hold back the water, and moisture will flow directly to the neighboring living space.

Sheet mats and foiled polystyrene structures, on the contrary, have excellent waterproofing properties, which eliminates the possibility of leakage. In addition, they belong to materials whose thermal conductivity is very low, because of which their use guarantees the highest degree of heat transfer to the floor.

At the organization of a heat-insulated floor, such a property of the material as load retention is not the least important.

Profile mats made from expanded polystyrene with a density of up to 40 kg / m3 will perfectly cope with this. Thin plates and foil mats still have considerable density. These heaters can be safely used in an apartment or in an individual building when laying a heated floor that will be used as the main heating. But the narrow-web material loses from the point of view of this position: its density is not enough to hold loads, so it can be used only for the purpose of organizing auxiliary heating.

One more parameter which needs to be taken into account is the thickness of the mat. If this or that thermal insulation is previously laid on the floor, it is allowed to use the thinnest plates. In addition, the choice still needs to take into account the level of the room, the diameter of the pipeline, the layer of the upcoming screed and the outdoor flooring.

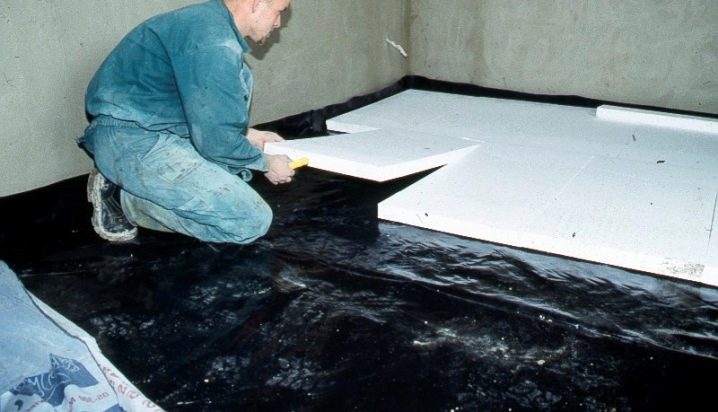

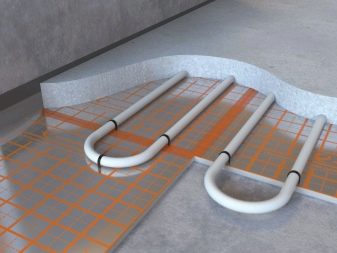

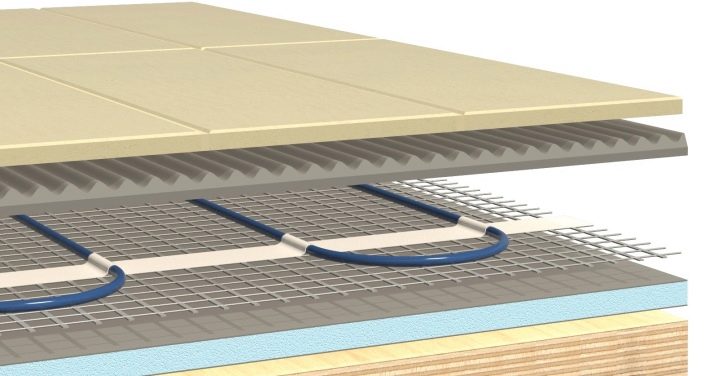

Device

Regardless of what type of mats will be used for floor heating, a layer of waterproofing should be put under it. This is necessary to preserve and protect the lower layer from the ingress of moisture, and also to form a durable barrier that can prevent flooding of the lower floors of the building in the event of a leak. Waterproofing can serve as a very compacted polyethylene layer, bitumen coating or passing insulation. If the film is used, it should be attached to the walls of the damper tape. This strip is installed along the entire perimeter of the building after laying the mats.

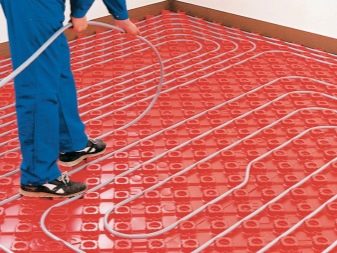

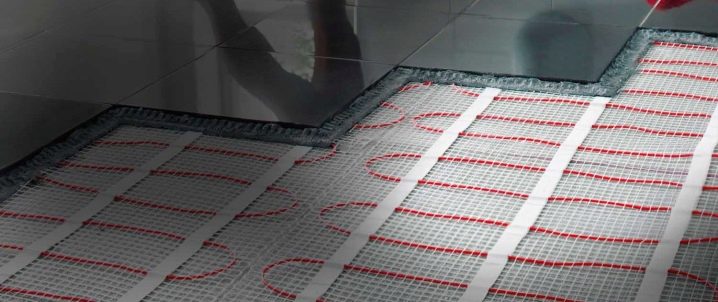

The easiest type of laying is the use of profile mats.

They must be put on a layer of waterproofing and fasten together with a lock. Further, in the openings between the bosses, the pipes are laid using a selected method of laying and are simply fastened with the feet in the required position. Installation of thin polystyrene plates also does not cause any difficulties: the panels are either fastened with locks, or simply glued, and their joints are fixed with waterproof adhesive tape.

Most of the problems in the area of styling are narrow-web material. It is placed in such a way that the foil sheath is on top. The thermal insulator should also be attached to the base, and the joints between the tiles should be sealed with mounting tape. Further marking is applied on it, and pipes are located. Fixation of the pipeline is performed using clamps or clips.

The difficulty of laying is that the thinnest and lightest material is very mobile. For this reason, it is necessary to carry out its tie very carefully in order not to move the system attached to it. It is necessary to take into account that when laying mats of each type it is allowed to use exclusively plastic fastening components - iron parts have every chance to spoil the complete system of mats and break their density.Installation of the pipeline system is allowed to be carried out only after all the work on the installation of thermal insulation has been completed.

Manufacturers and reviews

Mats for underfloor heating are produced by numerous foreign and Russian companies. But the best positions belong to only four companies whose products are in great demand and have many positive feedback from builders and customers.

Good characteristics for the quality of the material have insulation German company Oventrop and Knauf.

On sale there are: profile mats with bosses, plates for a dry floor, prefabricated narrow roll and folding insulation in a polypropylene shell.

Another German manufacturer of thermal insulation - holding company Rehau, whose mats also cause increased attention from buyers. The main product is foam polystyrene mats with bosses, equipped with layers with thermal insulation and noise insulation.

Russian mats manufacturer Neptun IWS produces mats with lugs. Insulation is very inexpensive for its segment. Plates are polystyrene foam, with a special film on top.Included are holders that allow you to quickly and efficiently mount this type of insulation. These mats perform the functions of both thermal insulator and waterproofing, but their sound insulation is much worse than that of competitors.

Which is better: comparison with others

The choice of mat depends primarily on the structure of the structure, as well as on financial costs. The cheapest heat insulator is ordinary mineral wool in rolls with duralumin layer, but the most expensive is insulation with lugs. From the point of view of installation, the fastest is to install mats with bosses, but for the price it is more profitable to take roll material. Sheet mats for a warm floor with a duralumin layer are average in all respects: they are not so complicated, but not elementary during installation, as well as their price is higher than on roll materials.

Warm water floor is the most economical and efficient solution compared to others.

Comparing it with an electric floor, the main difference is safety. Electric floor heating consists of infrared rods, but in some cases these are infrared plates (this is the most maintainable solution).With direct mechanical damage to the water mat, you can flood the lower room, but in the case of damage to the electric floor - a closure may occur (the design will have to be changed completely).

Installation is about the same, hence we conclude that when troubleshooting, the financial costs will be equal, but if you put a patch on the water heating floor is possible, then with an electric one it will not help. The term of operation of high-quality warm floor is 35 years (water) and 20 years (electric). Of the well-known brands can be identified firm Rehau, which has long established itself in the construction market, as well as Unimat. These companies give a long warranty and warranty repair at the expense of the company. And if a marriage is suddenly discovered after installation, construction work is also included in the company's bill, but it is better to check this information with the manufacturer and seller.

Conclusion

For installation of a heat-insulated floor of specialized knowledge is not required. However, for the selection it is better to contact a specialist who will select materials for a particular room. Also a plumber can help in the field of floor insulation,which will install directly the main (pipe) structure.

The process of installing a warm water floor on the mats is waiting for you in the next video.