Rules and recommendations for leveling the floor

Finishing the floor often involves the presence of a flat plane that can withstand significant loads. But not all draft bases have similar characteristics.

To remove these shortcomings, before installing the final coating, surfaces are leveled with special compositions and materials.

This process can occur in different ways, its features will be discussed in our article.

Special features

Alignment of floors in an apartment or a private house is the main stage of preparing a rough base for decorative finishing.Such procedures involve the application of a small layer of leveling materials over the main surface.

This technology has several advantages:

- The possibility of obtaining a perfectly horizontal surface. In some cases, it is also used as a finishing floor.

- Additional strengthening of the structure. This is especially important for rooms where there are a lot of people. The additional layer absorbs the load and does not allow the base to quickly collapse.

Floor leveling is an operation, the technology of which depends on several factors:

- Curvature of the surface. If the base drops are quite significant (from 2 to 8 cm), then it is advisable to correct this deficiency. A similar phenomenon can often occur on concrete floors, where rough casting was not emphasized.

- Finishing material. The most demanding to the evenness of the floor are laminate and parquet, which need a perfectly flat plane. If the alignment of the surface under the linoleum, then there are not so important drops. Such products exclude only large irregularities that will bulge after mounting the sheet.

What is the best level?

The process of leveling the floor involves the formation of an additional top layer, which is laid strictly in the horizontal plane. To get a perfectly smooth base, many experts use levels.

To solve such problems using several types of materials. One of the most popular products are wet and dry mixes.

Depending on the composition, they can be divided into several subspecies:

- Cement. The main components here are cement and sand, which form strong structures during solidification. Today, a similar solution can be obtained by simply mixing these products in a certain proportion. But it should be understood that the factory analogues are much better than the homemade version.

- Gypsum. Smokers of this type consist of gypsum and filler. The disadvantage of such products is that they quickly absorb moisture.

Therefore, they are not advisable to use in wet areas.

- Tile adhesive This substance also consists of cement, but it also contains polymeric plasticizers. As a full-fledged tool for leveling floors, it is used only with minor drops with the simultaneous laying of ceramic tiles.Using the same tile adhesive, as an independent tool is not recommended, as it is quite expensive.

- PVA with sawdust. The mixture of glue with wood is mainly used for leveling wooden structures. The advantage of the product is simplicity and low weight. You can prepare a similar solution even with your own hands.

As an aid can be used and putty. But it is also not the primary means, as it is used to eliminate defects on the basis of floors.

- Polymer formulations. One of the modern products for leveling floors are self-leveling solutions. They are made on the basis of both cement and various polymers. With the use of these substances is polyurethane screed.

In residential areas, it is used quite rarely. With it, get the so-called 3D-floors. But some types of such liquid floors are not always safe for human health.

Some types of floors are aligned with the use of sheet materials, among which are:

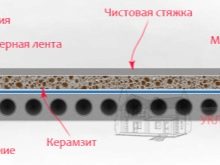

- Drywall The method of leveling plasterboard is used for premiseswhere the minimum load on the base is created. Special type gypsum plasterboards are today used to form dry floors. They are located on a substrate of expanded clay, which is carefully tamped.

- Plywood. Universal material, which consists of several thin sheets of wood. The material perfectly perceives the load, and can also resist moisture. For floors, moisture proof plywood is often used.

- OSB. These products are also produced in the form of sheets, which are produced from sawdust. The material is much like plywood. But it is rarely used to level the floors, as it can release toxic components into the external environment. In this case, the plates are well tolerated by moisture, which makes them indispensable products for arranging floors.

When mounting such surfaces, special tools, various mastics, and sometimes a metal profile are also used.

Regardless of the technology chosen, experts recommend using only high-quality materials that will not harm human health.

Ways

Floor leveling is a fairly simple operation that can be performed even without having a certain experience.But the technology of arranging the finishing base depends largely on the draft coating on which the finishing layer will be mounted.

Type of flooring

The floor surface can be made of concrete or wood, which previously served as a finishing base. All these coatings can be leveled by hand. It is only important to choose the best way to solve a specific problem.

Let's start with concrete floors that can be leveled in several ways:

Construction of cement-sand screeds

This option is the easiest. It involves filling the surface with cement mortar, which after solidification forms a flat plane. In order to perfectly align it, beacons are installed on the same level along the entire perimeter of the room. In some cases, the mixture is compacted using special vibrolaths. But these tools are found only in industrial production.

Dry screed

This type of alignment is also called bulk floor. On the surface of the draft base is placed waterproofing film. After that, pour the filler on it.

Often used for this clay, sand, slag and other similar products. They act as a kind of substrate, which is well rammed. At the very end, sheets of chipboard, plywood and other material are placed on the prepared surface. Between themselves they are fastened with glue or screws. Such a system retains heat very well and serves for more than a dozen years.

Self-leveling floor

Installation of such systems is carried out according to a simple step by step instructions. Initially, the subfloor is thoroughly cleaned of dust and grease. If there are large pits or cracks, it is advisable to fill them with cement based mortar.

After this, level marking is performed along the perimeter of all walls. When everything is ready, the mixed polymer solution is simply poured onto the surface. To remove air and additional alignment using a needle roller. Please note that this method can be applied to the flooring of the boards.

The main thing is to provide high-quality waterproofing base.

Laying the floor of the boards

To do this, lags are placed on the surface of the concrete, between which a heater is placed. After that, boards are nailed to them, which form a flat plane.It should be understood that this option is not universal, since the wood will warp over time and this will lead to its curvature.

Restoration of wooden surfaces can be performed using the following options:

Scraping

This technology involves sanding boards. It is advisable to repair the old lamellae before this procedure. If the wood was fixed with nails, they need to drive deep. Otherwise, the machine will simply break when it hits a metal.

Plywood laying

To do this, you need several sheets of this product, which it is desirable to cut into small squares (1x1 m, 2x2 m). Alignment algorithm involves the creation of a special substrate under the plywood, on which it will rely. This can be done with the help of small pieces of boards or thin lag. The main thing here is to set up the support in such a way that, after fixing the sheets, it forms a horizontal plane.

Supporting elements are placed under the plywood at the corners and a few pieces in the middle. This is necessary to distribute the pressure over the entire surface and reduce the risk of a break. The process is quite complex and requires care and accuracy.But the floors of this type are well suited for laying parquet and other similar materials.

Spackling mixture

Prepare it from PVA glue and sawdust. The result should be a kind of putty. Before applying the solution, it is advisable to thoroughly clean the floor, as well as fix the leveling beacons.

Apply the mixture in thin layers around the perimeter. If the height difference is significant, then several layers should be laid. The thickness of each of them should not exceed 2-3 cm.

It should be understood that some of the methods discussed can be applied to any type of base. It is important to analyze whether the material can withstand high humidity.

The room

When leveling floors, it is important to pay attention to the room where this procedure is planned. Each individual room makes its own adjustments to the performance of such operations:

Bathroom

In this room there is always an increased level of humidity. Therefore, the floors here are formed from materials that such conditions easily transfer. If the surface is made of concrete, then you can level it with glue for ceramic tiles.

This will provide not only a solid and durable base, but also save money in some way.

Balcony

These areas of the house are in limbo, so they can not always withstand heavy loads. The best option for leveling the floor on the balcony can be plywood or wooden logs. If you need to perform a cement screed, it is desirable to pre-assess whether the balcony can withstand a large weight of the mixture.

Kitchen

A room where several functional zones are combined. Theoretically, you can perform any type of alignment, which depends on the draft basis. But the best option would still be a concrete screed, which then fits both under the tile and under the quality parquet.

Floor layer

Leveling floors is done in order to get rid of small differences on the surface. Therefore, the thickness of the upper layer is not large, since it is not the basis. If the screed implies a considerable thickness, then these floors are constructed for specific purposes. The dimensions of the leveling layer often do not exceed 5-100 mm.

The thinnest are the floors of self-leveling self-leveling mixtures. They can spread on the surface with a layer of no more than 4-5 mm.

If the floor is formed on the ground, then it is leveled using expanded clay. Here its thickness can already reach 20-30 cm, depending on climatic conditions. It should be understood that the installation of an additional layer increases the dimensions of the main floor.

Typical mistakes

Floor leveling technologies are improving every day. But the quality of the final surface depends on the observance of a specific sequence of actions. If you do not take into account some specific nuances, leveling the base may not have any effect, and in some cases aggravate the situation.

It is necessary to single out several errors that are often made during the execution of such operations:

- Poor quality foundation preparation. This factor is one of the important, regardless of whether the leveling of concrete or wood floor. All these surfaces must be checked for debris and damage. When such defects have been identified, they should be corrected.

This is especially true of wooden floors, where rotten boards and logs may be present, which will be able to withstand the load for a very short time.

- Lack of primer. Often such operations are used for concrete foundations. If you do not use these solutions, it does not guarantee optimal adhesion of the screed or mortar to the old floor. Primers for wooden substrates allow you to protect them from rapid decay.

- Wrong selection of the mixture. Self-leveling solutions today are made by various manufacturers. In addition, each of them is designed to work in certain conditions and under optimal loads. If you use solutions for other purposes, it can lead to cracking of the screed and loss of its strength.

- Leveling layer installation excluding laying of finishing material. It all depends on what material you plan to use. It also takes into account the presence of warm floors, which imply the presence of a thick layer of screed.

- Non-compliance with styling technologyas well as irregular microclimatic conditions. If the screed or plywood is mounted in the presence of high humidity or high temperatures, this may cause them to bend or crack. Therefore, it is important to perform all operations as recommended by specialists.

Leveling the floor is a mandatory step that allows you to get a smooth and durable base for finishing - laying the selected floor covering. Perform such procedures is desirable only with the help of quality products. To obtain an optimal result, it is necessary to strictly adhere to the leveling technology.

The subtleties and secrets of self-leveling floors and liquid screeds, see the following video.