Frame garage: advantages and disadvantages, installation features

Every vehicle needs a parking space, reliably protecting from wind and rain, snow and hail. For this reason, the owners of private homes are building garages on the backyards. When there are no extra funds, and the car needs a “home”, you do not need to take a loan, borrow or save money. The way out is to build a frame garage.

Special features

Frame garage, unlike brick, block or concrete, much easier. Built in compliance with the technology, it performs the same functions as the more massive and expensive buildings. In some cases, it is more practical than analogs. For example,to build a standard brick garage of 24 square meters will require more funds than to build a larger frame.

In a larger area you can place not only the car, but also:

- motorcycle;

- snowmobile;

- lawn mower;

- snow removal equipment and much more.

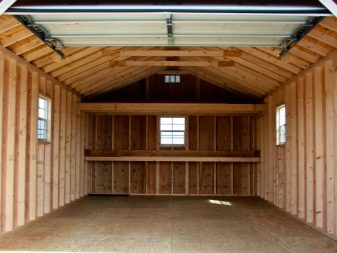

Part of the spacious room is useful for the arrangement of the workshop. In a private house, there will always be cases that are more convenient to perform not in residential, but in utility rooms. Corner in the garage is suitable for such occupations as well as possible. There will be a workbench with a vice, and there will always be a place for tools.

Advantages and disadvantages

The popularity of frame garages due to the presence of a number of positive characteristics. Building a garage using wood or metal costs a very reasonable amount, so it is quite accessible to the general population. Materials for construction are not scarce. They are sold in construction markets, bases and warehouses. As for the work, then everything is quite simple. Frame garage under the force to collect people who do not have the skills of a builder.

To perform the work does not require expensive tools and mechanisms.There are enough household tools, which are owned by every owner of a private house. And those that are missing, for example, the level or screwdriver, you can borrow from friends or neighbors. With a hand-made assembly, the building can be built in a couple of weeks. All that is required is three pairs of strong hands. Especially not have to bother. Each of the individual parts of the garage weighs a little. Installation consists of measuring, installing and fixing the frame, and then in its casing. A little more work will have to arrange the foundation. But this is not as difficult as when building a brick version. Skeptics tend to look for flaws in everything.

The downside of frame garages, they consider:

- Fire hazard (for wooden buildings);

- The fragility of the wooden frame;

- Lack of comfort indoors;

- Low resistance to unauthorized entry.

Indeed, the tree is burning well. However, subject to simple rules before the fire will not come. Raw bars and boards will last no more than ten years. If you impregnate wood with special chemicals, the service life will be doubled or even tripled.In the garage sheathed in profiled sheets, it is cold in winter and hot in summer. But if from within to make a covering from a heater, the situation will improve. And in a completely wooden house is always cozy. In addition, the garage is primarily intended for the car. And he is very comfortable there. To get into the frame garage is easy, only when it is in the suburbs. If the building is located on the garden in close proximity to a residential house, it is unlikely that anyone will try to profit from its contents.

It turns out that the frame of the garage solid advantages, the main ones are:

- low cost;

- ease of installation;

- construction speed.

Projects

Despite the simplicity of the frame garage, before the start of work need to develop a project. Any design office with pleasure will undertake the development of the project. But is it worth to turn to professionals if an ordinary person is able to make calculations and drawings for an uncomplicated garage frame on his own.

First you need to determine the basic parameters:

- the garage will stand alone or close to the house;

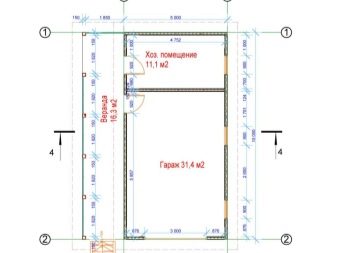

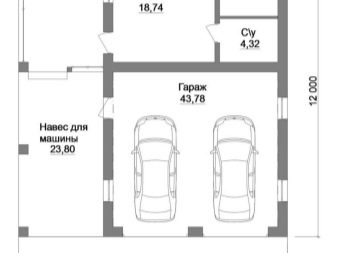

- what is the capacity of the building: for 1 or 2 cars.Perhaps there is a desire to combine the parking machine space with additional space and get an attic;

- how many windows the building will have;

- whether you need a door to the garage or a gate built in the gate;

- are there plans to allocate space for a separate room for a workshop or storeroom;

- what material it is planned to build the frame, than to sheathe it;

- what form of roof to prefer;

- will the building need a foundation, if so, which one;

- Do you plan to lay in the garage of utilities: gas, water, heating.

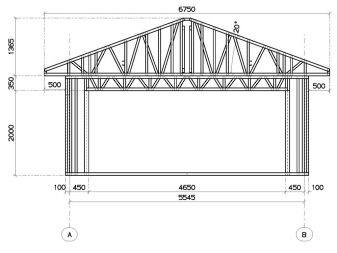

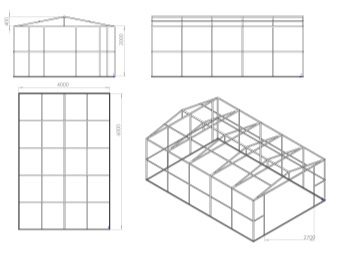

For one car with a sedan, it is enough to allocate a territory of 6 by 4 meters. The SUV will be more comfortable in a 6x6 meter garage. And in order to place two cars at once, a building with dimensions of 6x8 meters is suitable.

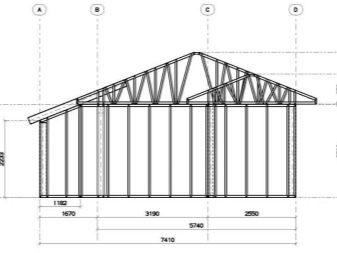

For a standard wooden frame structure, square or rectangular beams can be used. (100x100 mm, 150x150 mm, 100x150 mm). For a steel frame, a pipe is suitable, for example, with a diameter of 40x40 mm. Individual assembly units (walls, strapping, roofing) are drawn on a scale drawing. The distance between adjacent racks should not exceed 1.2 m.Knowing the number and size of the components, you can make an estimate, determine the size of the upcoming material costs.

When choosing the type of roof should focus on the location of the garage in relation to the house. Attached garage is better to cover a shed roof. From it the water will drain away from the residential building. For the attic will have to build a high roof with two ramps. And if you have the desire and experience of construction work, you can make a beautiful outhouse with an intricate hip, tent or gable roof from the garage.

You should not begin work without a project or a simple drawing-scheme and the calculation of the required material. Lack of preparation is fraught with delaying construction and other troubles.

Materials

The frame of the garage can be made of two materials: wood or metal.

For the use of wood speak its characteristics:

- ease of processing;

- ecological cleanliness;

- energy saving.

Unfortunately, this option is the most expensive.

Those who still decide to build a frame of wooden bars, you need to consider a few nuances.

- Bars can be solid and glued. Solid cost several times cheaper than glued.Cheapness turns serious shrinkage and warping. Glued laminated timber is practically not deformed. Its dimensions remain unchanged after the construction of the structure.

- Non-profiled timber during processing may cause cracks. In addition, its treatment requires significantly more antiseptic and other protective agents. Profiled timber more expensive, but it lacks the above disadvantages

- For garage construction is not suitable for any wood. When making a choice in favor of one or another species, one should be guided by the properties inherent in wood.

- The cheapest material is pine. The material is suitable for regions with a dry climate. Pine can not withstand severe loads, so for a solid garage will require a more durable version of the building material.

- For areas with high humidity suitable larch or oak. The lack of durable and reliable oak - in the complexity of processing. However, such a garage will last for many decades.

- Frameworks of garages of shaped pipes require not so significant financial expenditures as in the manufacture of the skeleton of laminated veneer lumber. The service life of the frame of the pipework is an average of 25 years.

- For the arrangement of a metal garage, square or rectangular pipes are used with dimensions in sections of 40x40 mm or 40x25 mm. If necessary, the pipes mate. At the same time, strength, stiffness, and resistance to mechanical loads increase. Robust construction is obtained from previously used tubing tubing in the oil and gas industry.

- The larger the area will have a metal frame garage, the more racks it will need. Particular attention is paid to supports intended for fixing the gate. Often, they use twin pipes from the same metal profile as the usual racks.

Metal frame will get good rigidity when installing additional elements (stiffeners) between racks. For this, metal of various profiles is used: pipe, angle, channel bar. Any cladding building material is suitable for cladding. On the shield garage cladding is attached end to end. Often used profiled. It perfectly maintains mechanical loading, is steady against blows. Sheets of corrugated flooring overlap, therefore, in determining the need to take into account allowances.From the nominal size, they will be about 20%. The exact parameters of the material are determined depending on the size of the sheets.

Internal lining may occur, but you can do without it. It all depends on the material possibilities.

Foundation

A solid structure requires a solid foundation.

The foundation can be of three types:

- monolithic slab;

- columnar, including on screw piles;

- ribbon.

- An excellent option for a frame garage would be a monolithic slab. Reinforcement will make the foundation reliable and durable. A screed made on the monolith will provide a level floor inside which a boardwalk can be made for heat. The lack of a monolith is that the plate dries for a long time, which does not allow for the remaining work. Filling the slab requires additional costs for reinforcement and the involvement of mechanical devices.

- The base column is not too suitable for garages. This type of base is chosen only on soft soils.

- The most profitable is the foundation tape. When the step-by-step instructions for the arrangement of the strip foundation are observed, a solid, solid foundation is obtained.

At the preparatory stage of arrangement of the foundation, the territory is cleared of garbage and vegetation using a tape type. The free area is leveled, marking is done. In each of the four corners you need to vertically install strong pegs. The distance of the parties must comply with the dimensions specified in the draft (in the drawing). Correctly determine the size of the laser rangefinder will help, and maintain a right angle - a construction angle. The string on the pegs is tensioned after the marking confirms the correctness of the garage rectangle. Verification is performed by measuring the diagonals. The marking of the internal dimension of the strip footing is carried out in a similar way. The distance between the outer and inner lines should correspond to the width of the ribbon base.

By marking digging a trench depth of about half a meter. The walls of the trench should not deviate from the vertical, and the bottom after tamping - from the horizontal. The next step is to install the formwork. The structure is assembled from edged boards, plywood or chipboard and installed close to the walls of the trench. A cushion of gravel and sand is poured at the bottom.On it the fittings are installed. In order for the formwork to withstand the onslaught of concrete, horizontal struts are attached to the vertical walls. The final stage - pouring concrete mix. Concrete should be so much to fill the entire foundation at a time. This is the only way to get a monolithic tape. And so that it is homogeneous, during pouring the mixture is periodically pierced with a steel bar to release air and prevent the formation of sinks in the foundation.

Until the mixture hardens, you need to level its horizontal surface and cover with polyethylene. It will take several days to set the solution. During this time, the surface should be moistened periodically with water to prevent cracking. After hardening, the film is removed from the foundation, the waterproofing is laid - two layers of roofing material are laid in, and the construction of the frame structure continues.

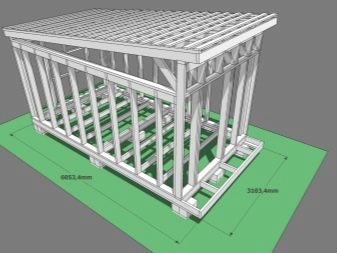

Mounting frame design

Regardless of what material the garage is assembled from, the assembly of its frame can be divided into four stages. Initially, there is a bottom strapping. Parts are fastened together, and the whole structure is connected to the base (foundation).If the frame is made of metal, the connection is made by welding. Wooden components are bolted together. The lower part of the garage joins the foundation with anchors. Often, two types of material are combined into one. When the construction is done with their own hands, and not by hired workers, it is easier to make the bottom trim wooden.

The assembly technology of the frame allows you to combine wood with metal. Often, simultaneously with the bottom strapping, a base is prepared for a wooden floor. Lags are installed on the edge of strong thick boards, of course, pre-treated with an antiseptic. On the logs lay the floor. In the future, it will be much easier to build a garage from the boardwalk than from the bare ground. One person with the construction can not cope. You will need an assistant, as one will hold the next part, and the other will fasten it. But together, not everything can be done. For example, if the walls of a garage are assembled on the ground, which is sometimes much more convenient than in place, a third mate will be required.

Sidewalls made of metal can be assembled in a horizontal position. So it is more convenient to weld, and the assembly can be conducted on the conductor.The assembled wall weighs a little, you can manually install it in its place. If wood is used, the racks are immediately put in the designated points and fixed with the help of angles and screws. For greater stability between the racks install struts and crossbars. In the third stage, carry out the top strapping. Depending on the material chosen, it is made of metal or wood. Works are performed in the same way as when assembling the bottom strapping with the difference that there will be a roof on top.

The construction of the frame is completed with the equipment of the roof frame. Both types of the mentioned materials can also be used here. On roofs with ramps, lathing is done with a board, not metal. It is easier to overlay the roof cladding on the planked crate, regardless of what serves as a roof covering. The most easy to manufacture roof shed. It is not necessary to construct a complex rafter system. The bias is carried out by the construction of walls of different height. The assembly of the frame will be quick if you first prepare the details of each node, assemble them in size and sign them in accordance with the installation sequence.

A gate is installed on the trimmed frame, and the parking lot is ready.

Tips

If for the garage in the country, used only in the summer, insulation is not necessary, then for all-season operation it is desirable to have a warm room. In order to make a warm garage, they carry out heating from the house or install a local heat source. In both cases, the walls of the garage and the ceiling will have to sheathe insulation. As a rule, frame garages are not insulated from the outside, but from the inside. The space between the racks and crossbars is filled with insulation. Foam thickness of 5 mm or slabs of mineral wool is best suited. Close the insulator sheets of moisture-resistant plywood or OSB.

It will be useful to insulate the floor of the garage. The easiest way is to lay a claydite pillow under the wooden floor and make a cement screed on it. Carried away by the construction, do not forget about the need for a ventilation device.

Planned and assembled frame garage will be a reliable vehicle protection from external factors.

How to build a garage with your own hands, see the following video.