The better to cover the roof of the garage?

One of the important elements of any building is its roof, which is subjected to various physical and climatic influences. Its reliability and service life depends on the material chosen for its coating - the roof. The modern market offers many types of such finishing materials that can be selected for specific climatic conditions and features of the building on which they will be used.

Special features

The roof of the garage and its roof is practically no different from other standard structures of this type: they are used to protect the main building from moisture. But those that are on the "houses" for vehicles, almost always are easy. This is due to the fact that during the construction of such systems there is no need to create beautiful designs for the purpose of decoration.The materials usually used are the same products that are used in the construction of standard roofs of industrial or residential buildings. Very often, instead of the usual today do warmed attic roofs, the premises under which in the future can be turned into a small housing. But such designs are relatively expensive and are rarely found.

Materials

Arrangement of the roof in the garage involves the formation of a reliable protective layer that will prevent the penetration of moisture into the building. Therefore, for such purposes, in most cases, coatings of several layers are used.

As the top roofing you can use such products:

- Ceramic tile. The material can be classified as environmentally friendly and durable. Among the advantages should be distinguished anti-corrosion resistance, minimal destruction by microorganisms, as well as the ability to withstand significant temperature extremes. The disadvantages include a high cost, as well as considerable weight, forcing the laying of ceramic tiles can only be on strong frames, the slope of which does not exceed 12 degrees.

An alternative to this product today is metal, characterized by low weight and ease of installation.

- Ondulin perfectly proved as roofing material. The roof of it can serve for more than 20 years, and he almost never collapses under the influence of external negative factors. Differs in rather small weight and small cost. This combination allows you to create a roof not only cheap, but quickly. The only drawback can be considered the ondulin flammability, but if you minimize the probability of its ignition under the influence of external factors, then it will become the best option when building a garage.

- Decking appeared on the market for a long time, but only recently gained immense popularity. This material is a thin sheet of metal, which give a certain shape, increasing its strength. To protect steel from rapid corrosion, the upper layers of the product are coated with galvanized and polymeric compounds that prevent the ingress of moisture on the metal itself. Products of this type are light weight, easy installation and durability.There are many color options on the market. Such coatings are very durable, but if the upper protective layer is damaged, then the metal starts to rust very quickly. Therefore, for roofs, it is desirable to use only quality products of well-known manufacturers.

- Slate receive from various slate rocks which are pressed in special cars. This roofing material is well resistant to temperature changes, and is not afraid of the effects of various chemical agents. It does not sustain burning. However, slate sheets are heavy. This, in turn, complicates installation. They are also very fragile, so it is advisable to work with them carefully and with the help of a special tool.

- Galvanized Steel Sheets Externally, they are flat webs that are attached to the base with special screws or nails. The disadvantage is high “noise” - the material makes loud sounds with strong wind and rain, as well as the likelihood of corrosion processes with constant exposure to moisture.

- Soft tiles. Outwardly, it resembles a ruberoid, but differs in a more beautiful pattern.It is produced in the form of small parts of various sizes and shapes. The material is very durable, but requires an ideally flat surface for installation, so you need to nail additional sheets of moisture-resistant plywood or OSB to the rafters, and to install such tiles on them.

Waterproofing materials should also be considered.

This category includes such well-known coatings:

- Ruberoid Available in rolls that cover the roof to prevent their occurrence. Please note that it can be used as a substrate or as the main roofing material. Apply it quite rarely on wooden grounds, as the canvas has no design decoration, and also is highly flammable. At the same time, this universal product is almost indispensable for flat roofs, where concrete bases are protected by it.

- Bikrost. This is another kind of waterproofing substance. Use it as a substrate. In many properties resembles a ruberoid.

- Bitumen or liquid rubber. Such materials are obtained from petroleum-based substances, and used to protect single-pitch concrete roofs.In molten hot form, these compounds are simply applied to the substrate. This leads to the formation of a uniform layer that fills all the cracks and does not allow water to penetrate into them.

Types of designs

Today, when building garages, you can use one of several types of roofs:

- Flat. The angle of inclination of such a plane is minimal (up to 3-5 degrees) or completely absent. Such structures in most cases are monolithic concrete floors. They are found on large industrial garages, which are built of brick or other durable material. In everyday life, a flat roof can be made of wood, but it will not be able to hold a lot of snow for a long time in winter.

- Single Shed The roof of this type is characterized by the presence of a single plane, which is located under a slope relative to the frame. The device of this design is the simplest. You can even build it yourself without having the appropriate skills. The angle of inclination here often does not exceed 30 degrees. This is due to the fact that the width of the roof is significant and if you increase the slope, then the base simply can not withstand the load.

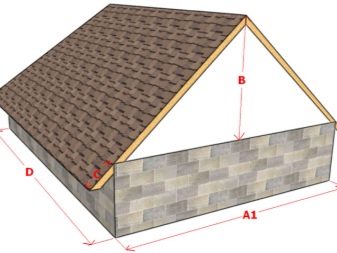

- Dvukhskatnye. Roofs of this kind are the most common and practical. Systems are simple and fast to build. The angle of such surfaces can be brought to a figure of 45 degrees. Note that the slope may be different on each side of the ramp. Such an approach allows the structure to be shaped as an irregular triangle. The practicality of the system has been known for a long time. If you choose the right height, you can create a small attic under the roof to store things. A variation of this design are mansard roofs. They differ in the height of the room under the roof, allowing to place a living room here. But this option for garages, as already mentioned, is not as common.

Slope angle

Today, garage buildings can have a different shape and structure. It all depends on the needs of a particular owner. But during construction or repair it is important to choose the right slope of the roof.

From this parameter depends on the ability of the surface to withstand various loads, as well as the possibility of coating with various materials.

There is no universal angle for the slope of the roof of the garage.

It all depends on the finishing materials with which it will overlap:

- Up to 20 degrees. Such roofs are usually single-pitch. For such surfaces use coatings such as asbestos cement sheets, clay tiles, steel sheet.

- 20-30 degrees. This angle is the best option for most types of garage roofs. Such a slope makes it possible not to linger on the snow, and also to use practically all materials for finishing, from soft tile, slate to various roll coatings. Please note that previously this factor was usually not taken into account during construction, so the rise of the structure does not always correspond to this value.

- 35 degrees and more. This angle is different steepness, which is not always good for roofing material. For these slopes, experts recommend the use of metal tiles that can withstand this load. Laying this material is not desirable roof with a smaller incline. Therefore, if you plan to use this finishing product, you must first lift the entire system if it does not meet the specifications.

When choosing the angle and material for the overlap, it is also important to consider several other factors:

- The power of the wind. It is important to determine the maximum wind load indicators and their direction. For this purpose, special wind maps are applied, on which the percentage ratio of wind loads throughout the year is applied.

- Precipitations Special attention should be paid to snow, as it can accumulate and condense. If there is a lot of similar precipitation, then it is better to use roofs with an angle of more than 20 degrees. When it is not possible to do this, you should maximally strengthen the framework of the structure so that it can withstand the upcoming loads.

How to calculate the amount of materials?

Independent installation of the roof very often involves the purchase of roofing materials. But before you go to the store, you should count the number of these products.

The algorithm for calculating the volume of the material can be reduced to such sequential operations:

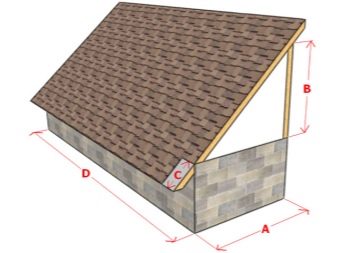

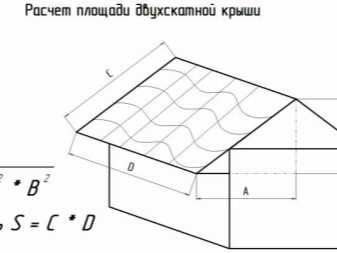

- Finding the angle of inclination. It is needed in order to calculate the surface area. This operation can be performed using mathematical formulas.In order not to use trigonometry, it is easiest to find the width of the slope using the Pythagorean formula. Initially, they measure the height of the ridge and the distance from the center point to the edge of the roof. Theoretically, you get a right triangle. Having obtained the values of the legs, you can find out the length of the hypotenuse. To do this, use a simple formula, where a and b are the legs.

Please note that this approach can be used for both single and dual roofs.

- Knowing the width of the slope, it is easy to get the total area of the entire roof. To do this, measure the length of the garage, along which the material will be laid. The area is calculated by multiplying the width and length on each other.

- At this stage, you need to know the amount of finishing materials that are needed to cover a specific area. For dvukhskatnyh roofs should be calculated separately for each half. The technology is quite simple and involves the division of the total area by the size of one roofing unit, taking into account a certain coefficient. For example, if one sheet of profiled sheeting has an area of 1.1 square meters. m, then to cover 10 square meters. m roof should be taken 10 whole sheets.It is important to bear in mind that during installation, some products are slightly laid on top of each other. The number of sheets may also depend on the width and length of the roof itself. Very often, these numbers are not integers, so the material will have to be cut at the end. In some cases, it is possible to use product residues for this.

Accurately calculate the number of roofing products is not always possible. Therefore, it is better to take a little more materials when calculating. But if you have a familiar roofer, then refer to him, he will help to calculate this figure with a minimum amount of waste.

Waterproofing

Excess moisture inside any room can lead to the rapid destruction of all finishing materials. Therefore, in the arrangement of roofs, including garage, you should take care of high-quality waterproofing.

Today they solve this problem with the help of several types of materials:

- Liquid formulations. This can include all products based on bitumen. They are sold in the form of liquid or solid elements, which should be brought to a liquid state before use. Paint bitumen mainly flat roofs with a slight slope.Apply the composition with a brush or a special sprayer. At the same time full sealing of all cracks is carried out. Apply such products mainly for concrete roofs, but theoretically it can cover other substances. Please note that the mixture can be used both outside and inside the building. Therefore, they can be used as an aid.

- Roll materials. Products of this kind are long sheets that cover the roof frame. They are located directly under the finishing material. Their classic representative is ruberoid. But today, special membrane webs are increasingly used for such purposes. Attach them directly to wooden logs with a stapler and staples. It is important that the adjacent sheets fit with a slight overlap. All joints are insulated using cold welding or special tape. Please note that all sheets of waterproofing must form a kind of discharge. Therefore, the lower ends necessarily protrude over the edge of the lags.

Waterproofing is an important step that should be carried out when the roof is set up.

The service life of the whole structure depends on how well it will be performed.

Subtleties of installation

The technology of finishing the roof depends on the design itself and the selected material.

We begin consideration with the coating of reinforced concrete floors, consisting of such sequential actions:

- Concrete cleaning. On the surface of the material should not be dirt and large patches, as cleanliness will contribute to better adhesion of materials.

- Application of liquid bitumen. Please note that some formulations need to warm up. Cover the surface with special brushes or sprayers.

- Laying ruberoid. It is laid immediately after lubrication of the roof with bitumen. This is important because the composition hardens quickly and loses viscosity. During installation, the roll is gradually spread and evenly pressed against the base. You can simplify this task with the help of special rollers.

- Installation of subsequent layers. Their number is often equal to 2-3 pieces. The algorithm of the application is similar to the previously described principle. But when placing the following sheets, it is important to consider the location of the joints. It is desirable that the upper layer of roofing material overlaps them.At the very end, the entire surface of the roof is carefully lubricated with bitumen mastic.

Now consider the principle of mounting structures, located at an angle. These operations have many nuances.

Covering these roofs has several common actions:

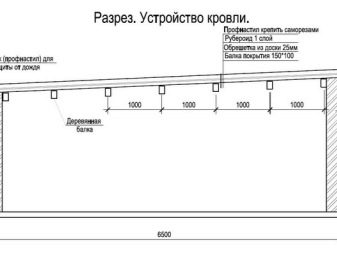

- Arrangement of crates. Technically, it is a few wooden planks, which are located throughout the roof area. They are needed to create the foundation to which the decoration will be attached. The step between the boards is selected individually. Some finishing materials require a completely solid base without gaps (soft tiles, etc.).

Close lags in this case should be sheets of moisture-resistant OSB.

- Laying waterproofing. This step involves covering the lathing with a special film. Please note that some types of waterproofing are mounted directly on the logs, and then begin to cover it with crate. It all depends on the selected finishing materials, as well as on the presence of insulation of the roof from the inside.

- Fastening finish. Installation of sheet materials such as profiled sheet, slate or metal tile, starts from the bottom corner.But if soft shingles are used, then laying is done directly from the ridge. Installation begins with the location and alignment of the first element. To do this, it is attached to the crate with special fasteners. Then a second sheet is laid next to it and both of these systems are already aligned. If the roof involves two rows, then the upper elements are mounted in a similar way. After complete alignment, all products are fixed. Fastening is carried out with special screws or nails, and sometimes with adhesives. Do not use products not intended for this, as they will quickly lead to cracks and leaks.

Installation of such systems should be carried out very carefully. It is advisable to lift the sheets together with several assistants, as they are rather heavy and can easily injure a person.

Try to carefully align all the elements, since replacing them after fastening is a difficult operation.

Tips and tricks

The service life of the garage roof depends not only on the selected materials, but also on the quality of their installation. Very often after the installation of such systems, owners complain that the base is leaking.

To prevent such situations, you should follow a few rules:

- If the concrete base of the roof has many cracks, it should be reinforced with concrete. The thickness of the screed should be minimal so as not to increase the load. After that, the new base is covered with roofing felt.

- During the operation of wooden structures, it is important to control the presence of deflections. If they appear, it will eventually lead to the formation of a leak, as well as the need to rewrite the entire surface. When you have discovered this phenomenon, it is desirable to immediately strengthen the frame.

- When choosing a roofing material, be sure to consider its weight and the load it will create in the future on the frame.

- When laying waterproofing (especially roofing material), you should start at the top and move down. But all layers need to overlap in such a way that the water flowed to the ground, and did not fall under the joint.

- If the roof of the garage flows, you should identify the problem at the initial stage. This allows in most cases to completely eliminate it without disturbing the condition of other materials. When a technical error was made, it will be necessary to completely block the entire roof.Therefore, it is desirable to check the quality of installation, as well as the reliability of the docking of all elements. After all, it is in these places in most cases that a leak appears.

Choosing the material for the garage roof, it is important to focus on the tasks that it must solve. If you need the usual protection, use slate or roofing felt. Creating the same decorative coating requires careful selection, involving the use of ceramic or metal tiles.

For how to properly roof the garage, see the following video.