Garage case: design features, pros and cons

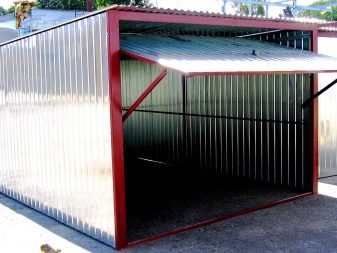

The garage case is a compact, but capacious rectangular design intended for storage of the vehicle and other things. For the production of such a garage is often used profiled, there are buildings of sustainable plastic. But the first option is the most popular. This is due to the design features and with a number of advantages that it has.

Design features

Most car owners have long replaced traditional shell garages with canisters. Their design is nothing complicated.

The box is made in the form of a frame of galvanized profile and pipe. Assembly is performed by welding and bolts, all seams are covered with a special tool that protects against the formation of corrosion.After which the surface is painted with pentaphthalic enamels.

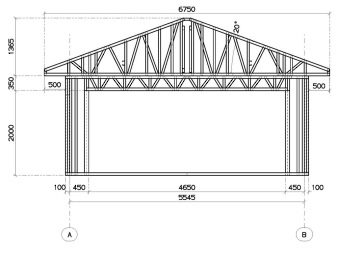

Walls and roof structures are covered with corrugated flooring. To cover the roof used profiled up to 50 mm. The roof is placed on the horizontal ceiling beams without an intermediate lattice.

Gates can be swing or lifting, in this case, the choice depends only on the wishes of the customer. Lifting gates are durable and easy to use, so they often choose them.

The dimensions of the garage-case can be varied and designed for bikes or motorcycles with an area of 7 m2 to 9 m2, or designed for large cars with an area of 4x6 meters or more.

Standard sizes

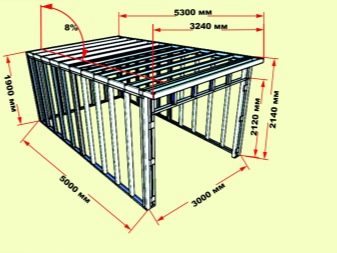

The dimensions of the garage-case directly depend on the size of the car. You also need to understand in advance if you need free space to install the racks. According to the standard, steel structures must have an outlet within 1 meter on each side.

To date, there are 2 types of garages-canisters:

- product per vehicle with dimensions 3x6x2.5 m;

- wide model, designed not only for storing a car, but also for a small workshop with dimensions of 3x9x3 meters.

The choice of design depends on the requirements and wishes of the customer.

Despite the fact that the garage box seems to be massive and heavy, in fact, its weight with a roof without a foundation varies within two tons. Due to the fact that the design parameters are small and compact, it is this model that most car owners choose. Now there is no need to install powerful structures with the foundation.

Note that the weight of the building depends not only on its size and shape, but also on the thickness of the metal. If profiled sheeting with a thickness of 2 mm is used, the garage weight will be approximately 1 ton. If the sheet thickness is within 6 mm, the garage will weigh more than 2 tons. Take this into account when choosing a manipulator on the load.

When is it necessary?

Garage box is an excellent option for those who want to save money. Its cost is significantly lower than the price of capital buildings. Such a garage fits perfectly into any exterior without disturbing the overall architectural plan.

The cost of the garage does not depend on its colors, so the buyer can choose absolutely any shade.

Also a garage box is a good choice to save space. You can choose structures for car storage only, or you can choose a garage, taking into account that other accessories will be stored in it.Before you buy, decide whether you need a place to store spare parts and tools, tools to care for the vehicle, as well as how much space you need to maintain the machine. Given all these nuances, you can choose a design that will meet all your requirements and wishes.

Merits

The undeniable advantage of the design is that it is a national team, which is why you can transport it and install it on another site. The garage will reliably protect the vehicle from the effects of the environment, it will not be afraid of bad weather conditions, strikes and falling branches.

Garage-cases are installed separately or they can be attached to the house. There are standard sizes of construction, but there is an opportunity to make an individual order.

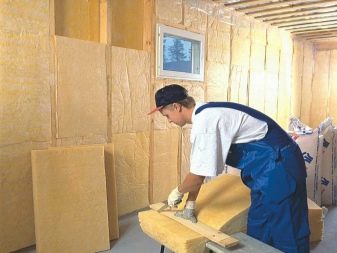

Also worth noting is the durability of the product - the service life reaches 70 years. If necessary, the owner can insulate the walls, make inside the shelves or racks, which will store small items.

There are other advantages of garage case:

- the object does not need to register;

- the surface is covered with a special tool that protects against the formation of corrosion;

- there is no need to make a powerful foundation, which saves not only finances, but also time;

- Attractive appearance, regardless of color.

When choosing a design, stop on models with a sloping roof, so it will not stagnate water after precipitation.

Car storage

The demand for such a design has long proved that the garage box is the best place to store vehicles. With proper assembly and installation of the car receives protection from winds and various precipitation. According to the manufacturers, the roof is designed for a maximum load of up to 100 kg per m2. As a rule, there is no insulation inside, there is no condensate and water vapor in the room, which makes storage even better. In the summer, due to the heating of the roof, the ventilation of the structure only improves. Small weight allows you to install a garage without a foundation, so it is considered a temporary building.

The only drawback of this design is poor resistance to cracking, so the owner must take care of additional protection of the structure.

Assembly

The price of the assembly and installation of the building is 10% of the value of the object.But most people who have ever encountered construction work, prefer to assemble this structure on their own.

Initially, you need to prepare the site for installation, remove the sod and carefully level the site horizon using tamping and leveling. As a rule, initially the site is sprinkled with gravel and tamped with a beater made of wood. Then a layer of sand is poured, after which you can begin to assemble and install the garage.

- First of all, the base and side walls are assembled. Before assembly, they are calculated according to the scheme and steel sections of the required sizes and shapes are harvested. According to the installation scheme, every detail is marked and signed according to its position in the frame.

- The lower contour is assembled, the installation pegs are hammered into the soil, then the lower contour rectangle is laid out, connected with bolts and the points are fixed with welding equipment. If all the diagonals are clearly aligned, then they are finally welded. Then transverse bottom segments are welded.

- Vertical posts are attached to the bottom, they need to be leveled with a tape measure, a plumb and a level.

- Horizontal pipes are mounted on bolts.They also need to fix the welding machine.

- The top contour from pipes and a profile is welded. On the vertical racks are mounted side segments and fastened after alignment by welding and bolts. The same work should be done with jumpers front and rear walls of the garage-case.

- On a frame the professional flooring is fixed by screws and gates are established.

Professionals advise after completing the assembly of the screw head to brew or remove the screwdriver groove with a grinder. Choosing a gate, pay attention to the lifting model. They reduce and evenly distribute the load on the front wall of the building. The cost of swing gates is less, but after a few years they will often have to be leveled and bend over the frame, so they will not last as long as we would like.

If you are not sure that you will be able to cope with such a large-scale work, then it is better for you to immediately seek help from experienced specialists who will assemble the structure as quickly as possible, thanks to which it will last a long time.

Garage box, if desired, can be insulated with mineral woolThis will reduce the temperature drops and improve ventilation, with the result that inside there will be optimal conditions for storing the machine.You can use the foam in the situation, if the garage will be installed on a protected site, otherwise detractors can easily set fire to the structure. Also, be sure to keep water and snow from collecting inside. It is recommended to close the gap between the bottom of the cladding and the ground with a pavilion of sand cushion and tile for the pavement.

To successfully complete the construction of the garage-case, you must first carefully consider even the smallest details and be sure to indicate them on the drawing. Drawing a chart will help you to determine the required amount of material with maximum accuracy and will save a lot of money. Provide indoor space for all sorts of compact but roomy cabinets in which to place tools and spare parts.

How to collect garage from a professional flooring, look in the following video.