Making shelves and racks for the garage with their own hands

No motorist can not do without equipped garage space. Provide a comfortable arrangement of tools and parts and quick access to them will be able to shelves and shelving systems that can be made by hand.

Design requirements

Before starting work, you should familiarize yourself with the basic requirements for a self-made design:

Reliability. Shelves and racks must be strong, as they are designed for storing heavy loads, under which boards should not bend.

The minimum area. The design should be compact, since the main space is not intended for storage.

Availability. The rack should take place that is open access.

It is also recommended to install the adjustment for fasteners, as the tool sometimes requires an individual height for optimal storage.

At the same time, experts propose to adhere to established standards:

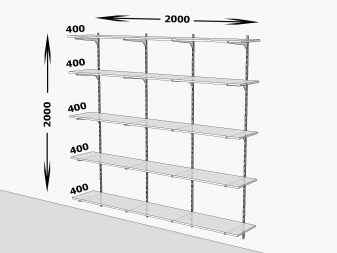

The optimum width of the shelves should not exceed a meter.

Large items are best kept on the lower tiers so that in case of unforeseen circumstances they do not cause damage, falling from a small height. Such an arrangement is necessary for security purposes.

The height of the shelves of the upper tiers is usually regulated from 25 to 60 cm, for the lower levels it does not exceed one meter.

The depth calculation is relevant for multi-level structures and usually reaches 45 cm.

Taking into account all the parameters, you can safely proceed to the manufacture of shelves with their own hands.

Varieties and Purpose

Professionals recommend that you carefully consider all the details for the manufacture of shelves and shelving with their own hands, this also applies to the type of design.

It is necessary to take into account the parameters of the garage room, money and the purpose of the future construction.

Most products are necessary for storing tools or parts of various sizes.

There are several types of classification, the first of which is about the design features:

Open Needed for quick access to a certain thing. Open shelf type is divided into wall and hanging. Wooden or metal bases are hung on the wall with the help of corners, the fastening of which can be dismantled or permanent. Preliminary, special anchors should be installed on the wall to hold the entire structure.

- Closed. Designs are used to exclude the loss of small items.

Separation into cells is recommended for certain types of tools or small parts. For example, it is possible to sort different types of screws.

As a common material used wood or metal. In rare cases, the design may be made of plastic. However, based on the practice, the implementation of the combined type construction will be an ideal option.

For the manufacture of the most suitable options for the following assembly:

Removable or mobile. Shelves form a rack with wheels on the lower tier. Mobile base ensures optimal load distribution.

- Permanent. The rack system is designed for specific places that must be pre-allocated.To do this, initially you should create drawings that involve the separation of the garage into several parts. The standard option includes a one-time assembly and fixing the one-piece design with brackets.

- Collapsible products. They are convenient in that they can be expanded and easily dismantled in case of replacement or repair of the room. The height and number of shelves can be adjusted, and it also becomes possible to rearrange the shelves to a new location.

- Attic-shelf. Suspended shelves are made of a corner and a metal profile that serves as the base. The whole structure is usually attached to the ceiling or beams, thereby saving space in the garage compartment. For fixing you will need to install special hooks, they need to drive or weld with ceiling beams. Thus, they can be easily detached if necessary.

- Rotating products. These designs are not intended for storage of large-sized items. Their main advantage is saving time to search for suitable parts. For example, screws or nuts.

- Homemade shields for tools. The shelves are suspended on a solid back wall, which is attached to the wall through anchors.On the shield can be installed hooks or small stands for mobile access to any thing.

When choosing a product should be based on the parameters of the room. You also need to remember that the more - the better, more spacious and more convenient.

No need to save on the size of the shelves, because the high-rise structures would not occupy a large area.

Selection of materials

Before independent production of shelves and racks, you must select the appropriate material. This question arises before the owner of the garage is quite acute and often able to cause confusion, because the construction market is replete with a wide choice of offers.

There are options:

- wooden;

- metal;

- plastic;

- mixed - are a combination of two or more materials to build a single structure.

Experts suggest starting from the intended purpose of exploitation. For example, garage shelves or racking system for the maintenance of heavy tools must be strong. Consequently, such structures must be made of boards or metal.

Chipboard as a material is not suitable,as it is relatively light and wears out quickly enough.

Metal

Unlike wood, metal is a more expensive material. However, metal structures justify the investment of funds durability and long-term period of operation. Metal racks can withstand a lot of weight, they can store tools and parts of various sizes.

Usually, metal shelves are made of steel or stainless plates welded together. This method of production allows metal sheets to withstand the weight of keys and wheels that exert great pressure, and not to suffer in case of fire.

The disadvantages include the fact that the metal is subjected to corrosion in conditions of high humidity. Modification of the product is carried out using a special anti-rust compound. However, if the structure is made of non-corrosive material, it is recommended only to carry out wet cleaning from time to time.

Tree

Wood is a material that does not require additional welding and is easily processed. Wooden boards can be adjusted to the required size by removing the excess.

However, this type of material has significant drawbacks:

- With increased humidity in the room, the tree begins to swell, thereby losing its original shape and collapsing from the inside;

- wood is an organic material that is subject to decay through the formation of mold fungi;

- The material has a low resistance to high temperature. In the event of a fire, fire will easily switch to a wooden structure.

It is easy enough to avoid some unpleasant consequences - it is only necessary to coat the surface of the product with varnish or special paint. It is important to remember that this procedure should be carried out from time to time, updating the outdated layer.

For the manufacture of boards are taken as the basis for different types of wood: oak, pine, ash.

Required tools

Different materials require a special set of tools:

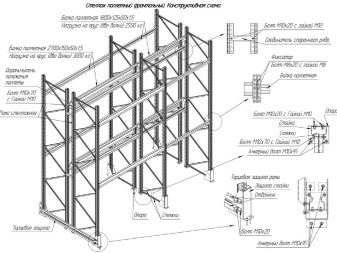

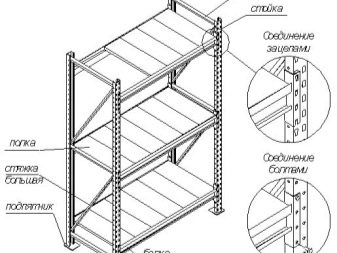

- Metal constructions need the help of welding and a secluded place without flammable materials to get started. Details of the metal frame can be fixed to each other by means of bolts and special angles.

- Wooden structures will not go far without screws, screwdrivers and drills. Wood products can also be fastened with a special glue.

- Combined designs require special training. For cutting parts of a structure, a grinder or a handsaw will be required, since usually the metal component acts as a skeleton.

- Both wooden and metal materials that do not possess anti-corrosion properties should be coated with special compounds. For example, wood will require lacquer, and metal solution against the formation of rust.

Fixing the finished product to the wall is carried out by means of brackets and dowels, which can be driven with precise hammer blows. An alternative to the brackets are special anchors that can be purchased in any construction market. With their help, it will be easier to dismantle the structure if necessary.

Further, when fastening wooden blocks to the wall for a stationary shelving system, level assistance will be needed to align the boards and control the parallelism of the shelves relative to each other.

For ceiling materials, you must additionally purchase studs or ironsuspensions.

How can I do?

At the preparation stage, one should focus on the height of the intended product. If the garage has low ceilings, you should make racks that will not leave a millimeter of free space under the surface of the ceiling.

Before starting work, measure the width and height of the shelves. The lower tiers should be roomy for large items, while the upper ones should be lower so as not to sag and save space. This principle guarantees the stability of the structure.

A simpler version is a wooden shelf. Most garage owners choose the most accessible and simple method of making a racking system with their own hands using wooden boards.

The choice is due to the advantages of wooden construction:

- affordable price. Metal is valued in the construction market much higher than wood;

- quick and easy assembly method allows not to use the welding machine;

- natural material is much more environmentally friendly;

- the tree is rather strong and not inferior in reliability to metal structures;

- long service life.

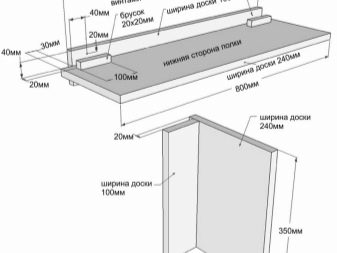

The material must be strong, which implies a choice in favor of hard rock. For example, oak is perfect for the manufacture of racks for both strength and style. Vertical boards are made with a section of 10x5 cm, and not only wooden bars, but also chipboard sheets can act as shelves.

To prevent the risk of fire and prolong the life of the possible treatment with antiseptic all parts before assembling the structure. Next, on the vertical bars, it is necessary to mark the shelves, which can be attached to the supporting racks with self-tapping screws or special glue.

However, the most relevant option is to mount through the corners.

After assembly, it is necessary to thoroughly coat the entire structure with a clear varnish. These manipulations are necessary to prevent swelling and damage to the tree structure by a mold fungus under conditions of constant humidity.

After drying, it is necessary to install the structure in a specific place. In order to increase stability, the shelving system is fixed to the wall of the garage with the help of dowels and metal brackets.

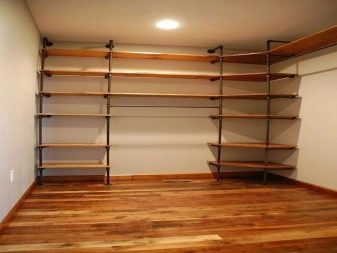

A successful combination of wood and metal - wooden shelves, equipped with a metal skeleton.

The best and most popular option is a steel frame with shelves of wood.Materials will be much more expensive, but will compensate for the loss of funds with obvious advantages. They are resistant to moisture and fire, without requiring replacement for a dozen years. The tree "facilitates" strikes on the wallet, as it costs much less steel.

The base will require profiles or steel pipes with a width of up to 5 cm, which are mounted with transverse components using metal corners up to 30 mm in size. These parameters are taken with the calculation of shelves up to 2.5 cm wide.

It is more practical to fix the corners with bolts, because such a system will be easier to dismantle to change the height of the shelves. The option with welding is also possible, however it is irrational.

Shelves are made of plywood sheets or chipboard, having previously measured their parameters. However, the width should not be less than one and a half centimeters, since the shelves must be strong and strong in order to perform the main function and not to bend over time under heavy weight.

The assembly must be performed on a free area, clearly following the instructions:

- metal parts are divided by a grinder according to preliminary calculations and room parameters;

- on the vertical supports perform the layout of the future location of the shelves;

- corners are carefully screwed or welded with a vertical frame. At the same time it is necessary to strictly observe the markup in order that the multi-tiered product does not warp;

- if a material that is not rust resistant is purchased, all metal parts are coated with a special anti-corrosion compound;

- carved shelves are applied across the structure, undercutting excess parts;

- further it is necessary to grind and varnish wooden components;

- firmly attach the tree to the metal with screws.

At the end of the work the entire structure is attached to the wall. Brackets with dowels are ideal for this purpose.

The permanent storage system is a structure of shelving, which is mounted on site, then attached to the wall. Such an installation in some cases is much more practical and is implemented much easier mobile systems.

The assembly algorithm is carried out in six stages:

- the markings are made directly on the wall, in which holes are immediately drilled and screwed in the dowels;

- metal or wooden frame is cut according to pre-verified drawings and set parallel to each other;

- long-distance wooden bars are fastened to the wall by marking, strictly adjusting the level position using a level;

- the skeleton of the structure is attached to each other in width with the help of horizontal corners;

- front (front) parts are connected with horizontal beams, on which shelves will be located;

- the latter are fastened with vertical supports and placed wooden shelves in previously designed slots.

Thanks to the effort, you can get a stable structure that will serve for many years. However, this structure has a drawback - in case of repair or replacement of the garage interior, it will not be easy to dismantle the sturdy construction.

For storing tools and various parts, the shelving system is almost indispensable.

The only requirement for the design is that the shelves do not bend under the pressure of great weight.

To create a wooden product you will need to comply with the standard parameters:

- for the upper tiers is required to comply with the height from 30 to 50 cm;

- the width of the shelves should be 1.5 m in size for safety reasons, thereby contributing to the stability of the structure;

- The optimal depth of the niches is 50 cm.

As a preparatory stage for independent production the accurately verified drawing and approximate design acts. The next step is to create a frame and vertical supports from 10x10 cm bars.

A polished wooden board or a piece of plywood will be suitable as a material for the shelf. Racks are attached to the transverse frame through the corners, and made boards to the frames with self-tapping screws. At the end of the manipulation it is necessary to completely varnish the entire structure and attach it to the wall.

The metal construction is heavy, which is reflected in its storage conditions. Exerted load requires a durable material for the manufacture of shelves, which implies the purchase and creation of a metal shelving system. To connect the components, you must have a welding machine.

However, the first stage is the creation of a drawing, which is a diagram of the product and its dimensions. Following the calculations, it is necessary to make a strong frame that must withstand heavy loads.

To reduce the cost of the product, you can use wooden materials that will replace the shelves. However, when using them, it is recommended to cover non-metallic parts with a flame retardant in order to avoid the unpleasant effects of fire. The thickness of the supporting structure should not be less than 2.5 cm.

The final stage is to cover the structure with a refractory compound, as well as installation in a pre-prepared place.

Space saving - suspended shelves. Such structures do not come into contact with the floor and are initially divided into wall and ceiling:

Wall mounted are open and closed constructions. In the latter case, they have a back wall, which is firmly attached to the wall with dowels. In the alternative case, the entire suspended structure is mounted on the anchor, which makes it easy to dismantle the product.

- Ceiling constructions do not occupy space in the garage, as they are hung from the ceiling with hooks. Hooks are firmly welded or fastened to the ceiling with steel studs. However, ceiling shelves can not store fragile products due to the fact that they are quite shaky.This type of hanging products is designed to save space and quickly access the necessary parts.

The unsteadiness of the structure can be eliminated by fixing it on the corners, one part of which is attached to the wall, and the other part to hooks or pins.

Self-made shelves will provide not only comfortable access to tools, but also help to put things in order by sorting things according to their places. A rational and creative approach to business will help not only save money, but also provide the garage with stylish and modern interior objects.

Examples of garage equipment

In the presence of free space in the garage, you can not only store things, but also exploit it as a small workshop. To do this, you can purchase additional devices, such as a workbench. It is a table equipped with valves and technical devices, comfortable for repairing various household utensils. For a workbench, they usually equip a special shelf-shield for open access to tools.

As a creative idea can be the embedding of the cabinet in the rack system.

This method will not only allow you to accurately place things, but also serves as a closed vault, which can be locked with a lock if necessary.

High humidity spoils shelves and shelves made of steel and wood. Unprotected elements are quickly destroyed. To eliminate this lack of space, you can equip the garage with a ventilation system.

When arranging a garage, professionals recommend starting from their own needs and means. Despite the fact that the manufacture of shelves and racks for the garage with your own hands will take a lot of time and effort, the result is worth the money and effort spent. Buying finished products will not bring such pride as making your own interior.

How to make the shelves in the garage with your own hands, see the next video.