Ideas for the garage: homemade accessories for the home master

The word "motorist" today is not just a term denoting the owner of a personal vehicle. Motorist is a lifestyle. A modern garage is a stronghold of the house craftsman.

Special features

The specificity of the arrangement of the garage space is that the layout, height of the ceilings, the number of floors, the area of the garage, the number of cars “lodging” in it are very individual. There is no recipe for all occasions - everyone decides what he likes.

It is only necessary to take care of:

- dryness and heating of the room;

- good ventilation;

- protection from thieves;

- arrangement of desktop and storage systems;

- good lighting.

Depending on the size of the building, the area occupied by equipment, appliances, communications should not be more than 20% of the garage area.And the distance from the side rack to the parked car should be no less than the width of its doors.

Recommendations for space delimitation

The garage is a multifunctional space. To correctly distinguish it, determine the working areas. So you can understand whether you have enough space to accommodate all the necessary. It is better to pre-disassemble things that have accumulated in it and throw out all unnecessary.

Naturally inconceivable garage without a workshop area. The workbench, set against the far wall, will come in handy both in repair and for the hobby. On the shelf right above the workplace, place the tools and finished crafts.

Hardware, dowels and other small items conveniently stored in transparent jars, glued to the shelf with a lid. Another little trick - a magnetic stripe, glued to the furniture, will help save great space.

Where and how to place the tools?

Order in the workshop is impossible without proper placement of tools.

The most necessary position on the shield or hanging shelves above the workplace, so that everything was at hand. It is convenient to store the necessary tools vertically on plywood boards with holes drilled in them.Heavier utensils cozily located on the racks.

Easy to manufacture and convenient holders of PVC pipes.

Homemade shelving

Wooden and metal racks will be the best option for the garage, as the plastic quickly break and can not withstand heavy objects.

Shelves are:

- stationary - fixed on the wall for stability;

- collapsible - if you have not yet decided where to put the rack, it is always possible to disassemble and mount it in another place;

- mobile - on wheels to move without unloading;

- console - for the storage of long-length.

The advantage of wood furniture is the relative ease of manufacture. It can be mounted using a standard carpentry set, without the help of experts. The wooden rack is easy to make in any size and shape, and it is easy to replace a broken shelf without disassembling the entire structure. In addition, to make a rack from wood is cheaper than from metal.

The disadvantages of a wooden product include its fire hazard and stationarity.

It is better to mount the racking from the tree at once “thorough”, since it will loosen from movement.

The most budget and easy-to-work wood is pine. It does not rot, does not crack when dried. But also the pine is quickly destroyed. If you do not want to change furniture every five years, choose wood more firmly. Oak and larch are harder and do not rot.

For the greatest functionality, the rack must be placed in the full length and height of the wall. Just be sure to leave a gap of 5-10 cm between the wall and the shelving, so that it is convenient to install it.

The width of the shelves is made so that it is safe to pass by the rack. with the car delivered in the garage. The greater depth of the shelves should not be done, so they will be inconvenient to use. The optimal value is 50-60 cm.

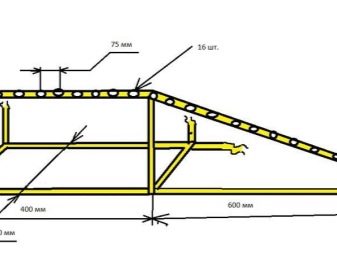

We cut out supports from a bar with a section of 10 by 10 cm, the crossbars from a bar are thinner - 5 by 5 cm in section. The distance between the racks is about a meter and no more, so that the shelves do not bend or break under the weight of the equipment. We make shelves from timber or thick plywood sheet. Apply markings for fixing cross-beams on the wall along the height of future shelves. Be sure to measure the evenness of the marked-up level and tape measure.

Screw the boards securely to the wall with screws using each 40-50 cm. Attach the boards of opposite crossbars to the fixed crossbars.Attach the vertical boards to the horizontal ones, carefully so as not to fasten them to those nailed to the wall. Putting aside the workpiece, cut the transverse crossbar for the shelves. We hang them on the frame through every meter. We assemble the finished workpiece and measure the final size of the shelves, cut it out and fasten it with screws.

Anyone who is engaged in carpentry work, useful mobile shelving for storing lumber.

To build it you will need:

- gon;

- screwdriver;

- electric jigsaw;

- clamp;

- self-tapping screws;

- 4 furniture rollers;

- 4 boards 2.5 meters long.

Decide on the parameters of the rack and make a working drawing. Measure and cut parts to size. Make two identical side pieces, like a stepladder. The distance between the rungs is equal to the height of the shelves.

Assemble the base frame. It must be strictly rectangular. To align, secure the parts on the table at a 90 degree angle with a clamp and a square. Attach the wheels to the base. Fasten the side elements at a slight angle like a stepladder.

The storage of lengthy gardening equipment is perfectly handled by the simplest rack of two boards.

It is necessary only:

- mark the opening of the holders by the given dimensions;

- Drill through holes in the joinery;

- gently cut the sloping part;

- paint or lacquer the finished holders and hang them at the place planned for the shelf.

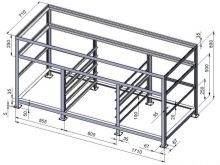

Furniture made of metal can withstand heavy loads and last longer than wood. To save time and effort, you can order ready-made racks, but it is cheaper to make them yourself. It is not necessary to buy a new metal, take what is already there. For example, water pipes that you got on the occasion, but not useful in the economy.

Most often, the frame is welded from shaped pipes and corners.

This is done like this:

- We plan on the vertical racks position of the future shelves. Keep them on par with each other. The distance between the lower shelves is greater than between the upper ones. Upstairs fit to reserve a place under the high shelf for storing light oversized items.

- For rails basics take a corner of 5 by 5 or 5 by 7 cm, it will protect things from accidental fall or slide. The span between the uprights is no more than a meter.

- We weld the corners, control the level of all the corners - they must be straight.

- We check the diagonal of the welded body, and at the back we set the crossings of the reinforcement for additional rigidity of the structure.

- Weld the joints with anti-corrosion agent, prime and paint the furniture with durable paint.

The upper shelves are used for lighter items, overlapped with plywood, the lower ones should be covered with a steel sheet. Shelves for storing especially massive items should be strengthened with several stiffeners.

Store different small and not very heavy things is permissible and in a plastic rack. It is easy to assemble from empty cans.

This option is useful to anyone who does not have enough space in the garage or finances for installing the rack. And small things will cease to “run” in disorder in the room.

To do this, you need to take the cans, wash well, so as not to leave traces of their contents. The same canisters can be used as dividers or sliding shelves on the finished rack, but then the side should be cut off so that the handles remain.

Also for the storage of light objects suitable rack of PVC pipes.

Manufacturing of suspended shelves

For a home craftsman, a garage shelf can be not just a tool storage, but also a place for an exhibition of finished works.

The hinged shelf can be assembled in the same way as the rack. It is even easier to install the shelf from the corners - metal or wood.

Also, the role of hanging shelves can perform hung on the wall of the basket.

It is worth plastering the walls in advance before mounting the shelf. This will prevent condensation on the walls after mounting the shelves.

Attach shelves can be in any place where no one will cling or bump for them:

- above the windows, if any;

- over the workplace;

- under the ceiling.

Today, the market offers a variety of new items such as shelves with a lifting mechanism that can be hung right under the ceiling and lowered down when needed.

Suspended ceiling construction is easy to do yourself, collecting shelves on pins of thick sheets of plywood or fiberboard.

For this you will need:

- large anchors (4 pieces);

- six-sided nuts coupling for a coupler (4 pieces);

- simple nuts (12 pcs.);

- hairpins (4 pieces);

- large diameter flat washers (8 pcs.);

- Grover washers (4 pcs .;

- drill;

- perforator;

- spanners;

- screwdriver;

- level;

- electric jigsaw.

First, cut out from the plywood sheet the shelves of the required size. They can be strengthened at the edges with a metal profile.

We retreat 5-7 cm from the edge of the tile and make holes in which we will thread the studs. This indent is needed so that the edges of the shelves do not crumble during operation. To prevent the shelf from buckling due to its long use, it is better to put bearing studs in 60-70 cm.

Through the drilled holes we make markings on the ceiling in the place where we will hang the shelf. By marking we drill holes for anchors, remove the dust from them, hammer in the anchors to the end and tighten the nuts.

Now we connect the studs with anchors with the help of nuts-couplings. Strengthen the connection with conventional nuts.

Next, attach the shelves:

- we fasten a nut to the stud fastened to the ceiling, after it the washer;

- we string the shelf on the ends of the pins;

- we fix with Grover’s washer and control nut, or better with two lock nuts.

Ceiling shelf will facilitate the use of the garage. She has only one drawback - a movable design. It is better to fix the shelf with an iron corner. We attach one edge to the wall, the second - to the base of the shelf.Now it will not loosen and last longer.

Shelf shield for storing tools do-it-yourself

A shelf-shield is a more compact alternative to a conventional wall shelf, it will help to streamline the tools inside the garage so that they are all visible.

Quite simply to put together a shield shelf of plywood and wooden bars.

Process description:

- cut the shield of the required size out of plywood and mark the position of the shelves;

- pound shelves with side walls along the length of the shield;

- fasten the shelves to the shield with screws;

- Then there are two options: install the bracket on the back wall and hang it on the hooks mounted in the wall or fasten it on the support legs of the desktop.

The locksmith's workbench is more suitable not for a wooden shelf, but for a shield made of metal with holes, on which it is convenient to hang both the shelves and the tools on the hooks.

How to make a workbench yourself?

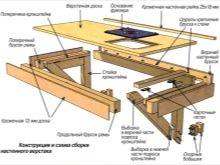

A workbench is a must for a garage workshop. On it it is possible to sort out the machine parts, solder the radio equipment, and cut it out with a jigsaw.

Making workbench usually start with a detailed design drawing.

Measure the working area and the height of the workbench.

The optimum height of the workbench is usually 90 cm, but this is not an absolute value and depends on the height of the master and whether he prefers to work standing or sitting.

To make the workbench yourself, you will need:

- jigsaw or hacksaw;

- drill and a set of drills for wood and metal;

- screwdriver;

- joiner's square;

- roulette;

- level;

- spanners.

When choosing wood, check that it is free from cracks and knots.

Getting started, prepare:

- bars 10 by 10 cm for the legs;

- two thick plywood sheets;

- boards with a section of 5 by 15 cm;

- bolts (take furniture with a square head, so as not to turn);

- nuts and washers;

- self-tapping screws.

Draw a drawing according to your measurements, specify the exact dimensions of the parts, so as not to be mistaken.

First we make the frame of the top with a spacer in the center. Strengthen 6 supports on the frame. Place the leg in the corner of the frame and drill two through holes through the leg and side plate. Then fasten with long bolts. Measure thirty centimeters from the lower edge of each leg and secure horizontal boards at this height for greater stability of the structure. They will become the basis of the lower shelf or drawers.

Screw the countertop flush with self-tapping screws. We will cover the finished tabletop with a layer of hardboard. For greater wear resistance, you can replace the hardboard with a steel sheet.

We measure the gap from the central to the end supports, according to the measurements set the shelf. Grooves under the support legs cut out a jigsaw or hacksaw. Instead of the lower shield, you can install drawers. To do this, you will have to purchase guides, pens and more plywood sheets. Screw the guides to the supports with self-tapping screws and install the cracked boxes on them. Watch for matching sizes.

Instead of a shelf, drawers can be installed. Above the workbench, install a shield or hinged shelves with a margin for new tools that will appear in the future.

If the plumbing works are supposed, only a metal desk is suitable.

To build it will need:

- "Bulgarian" with cutting and grinding discs;

- level;

- electric jigsaw;

- measuring instruments;

- small rack beams of profiled pipes - for the frame part;

- steel strips - for welded struts in the corner zone;

- profile tubes with a wall thickness of 3-4 mm;

- corner;

- CLAIM;

- plywood one and a half centimeters thick and guides for boxes;

- drill;

- screwdriver.

Rama weld first. To prevent the frame from leading, beams should be welded by spot welding, laid out on a flat surface. Welding seams in turn are made from one side and from the other side at the joints.

To the basis of the mount rack and horizontal beam from the back side. Check the evenness of all angles. If the corners are not straight, they can be corrected with a hammer.

A tabletop is assembled from the boards and soaked with a refractory compound. Bars are screwed and glue. Overlaid steel sheet.

The shield for placing the tools is mounted on vertical rack-mount details, wooden drawers are equipped in the pedestals. Wood elements process fire-resistant composition.

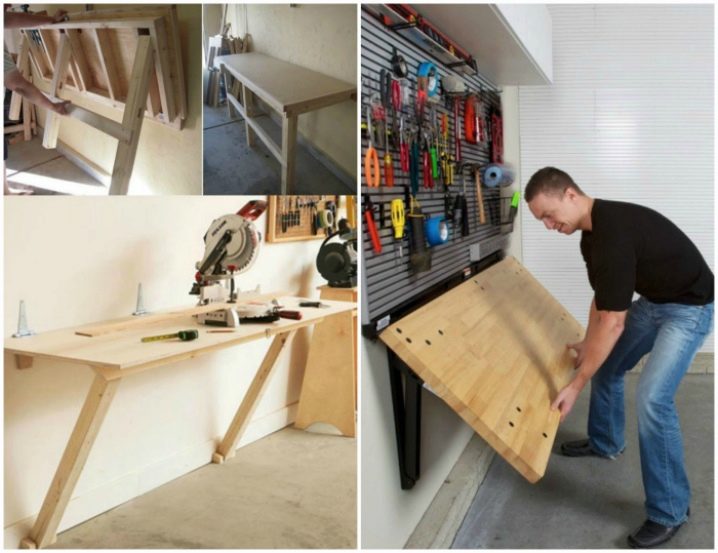

If the garage space is quite small, assemble a folding workbench. You will need a table top, a board along its length, screws, a dowel, a drill, a screwdriver, legs and door hinges.

First fix the board on the wall at the level of the future table top. Fasten the hinges to the board with screws. Fasten the table top on the door hinges so that it falls down.When raised, it will be held legs.

It would be ideal to chisel the grooves for the legs in the tabletop so that they do not slide off.

Tips and tricks

For car owners, property on wheels is a major concern. Today, the castle is no longer the most reliable protection against car theft.

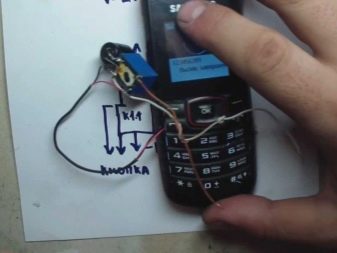

If you have a working old button phone. Make it a simple electronic alarm. When the intruders get into the gondola, the smart GSM alarm system will call you or send a pre-typed SMS.

The alarm is soldered from:

- wires;

- push-button cell phone with shortcut function;

- magnet;

- closed, sealed contact;

- toggle switch or switch type keyboard.

The mobile phone should be hidden more reliably. Also, take care of timely recharging or power the phone from the network.

We mount the alarm:

- set up speed dial to the desired number;

- remove the front panel to provide access to the keyboard matrix;

- We solder one wire to the end button, the second - to the shortcut button, then connect the wires to the reed switch. One wire should be with a switch;

- imperceptibly install the magnet and the reed switch on the doors, so the contacts were closed when opening;

- hide the phone and the wires so as not to be noticed by intruders.

How to store tires?

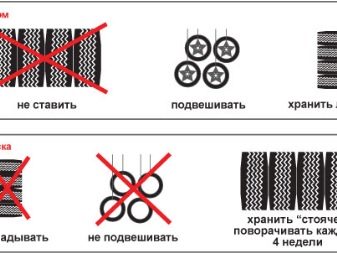

A seasonal tire kit is not only bulky and bulky, but also requires special storage conditions. Sets of tires with discs and without stored in different ways. Tires on wheels better hang. At the same time it is not necessary to buy special hooks for tires. You can collect suspensions from scrap materials.

Combined wheels can also be stored lying, but tires without discs are stored only “standing”, and, moreover, they turn once a month.

Storage space for “lying” or “standing” tires can be equipped under the ceiling or on one of the shelves of the rack or under its lower shelf. Ceiling shelving for tires can be assembled from profiles and corners - only a drill and a “grinder” will be needed, and if you have a welding machine, you can weld it.

Ideas useful devices

Garage masters come up with a lot of interesting inventions to facilitate the work.

For example, a cyclone vacuum cleaner. We take a dense plastic or metal container (or a 5 liter bottle), and make two holes in its upper part - one at the edge and the other in the center.The diameters of the holes must coincide with the cross section of the hoses that will be connected to the device.

Inlet - on the edge. We will install a plastic knee into it, which will provide cyclone air movement. Hose from a conventional vacuum cleaner is inserted into the central upper hole.

Such a vacuum cleaner will easily suck in small stones, sawdust, dried dirt, and all solid contaminants will remain in the tank.

Another useful "homemade" - "bottle cutter", can be made with the help of a drill from scrap materials. All you need is a piece of board or plywood, a stationery knife blade and a couple of bolts and nuts.

Mark the centers of the washers by placing them in the middle of the board. Drill holes, and be sure to drill them on the reverse side, so that the "bottle cutter" does not rotate during use. Screw the bolts.

Use life hacking should be as follows:

- we put on the protruding ends of the bolts a few washers. The more of them, the thicker the rope is;

- put the stationery knife on top of the washers, or at least a piece of it, and for reliability fix it with nuts on top;

- we take a plastic bottle, cut off the bottom and make an incision so that you can pull on the resulting “tail”;

- set the workpiece under the knife and pull out the "tail" in a full rope.

From one two-liter bottle you will get about 25 meters of a strong, very useful rope in the household. A sturdy rope from a bottle will be useful to you both for tightening reinforcement for concrete pouring, and for winding sliding tool handles, and even for weaving baskets. In order for her not to cut herself, it is better to work in gloves.

The garage winch is a simple mechanism that will help drag overall and massive loads. The oldest and simplest winch - manual. The cable is wound on it with a long lever. It is relatively compact, does not depend on electricity, is inexpensive, and by increasing the lever, it is possible to increase its sheer force.

The disadvantages include the need to apply considerable physical effort and some inconvenience when working in cold weather, in mud or in cramped conditions.

To build, purchase:

- short pipe;

- axis of rotation;

- lever arm;

- cable;

- hook carbine.

From the prepared elements collect the winch:

- securely drive the axle into the ground;

- weld the pipe to it;

- On one side, fix the cable with a loop on the axis so that it is wound onto it when turning, and on the other, hang a hook.

The device cellar as a viewing pit: the pros and cons

Any motorist who is able to independently maintain his car and who wants to reduce the production costs of repairing it, needs an inspection pit.

Despite the additional costs of arranging the pit, experienced drivers will benefit, as they can:

- independently inspect the steering, chassis and braking part and identify possible malfunctions in time;

- change the oil;

- save on minor repairs that can be carried out by themselves;

- protect yourself from unnecessary costs associated with the dishonesty of car mechanics;

- the presence of a viewing pit increases the cost of the motorhome in the event of its sale;

- For many car owners, self-inspection and repair of a car is a fascinating hobby.

To prevent the organization of the inspection pit in the garage can:

- groundwater level: if it is above 2 meters, the water will flood the pit;

- ground instability;

- the complexity of the organization of the drainage system in the finished garage.

It is ideal to plan a viewing pit at the design stage of a garage, for example, a country house. But often the need for it arises when the garage is already purchased and it is either completely without a cellar, or with the so-called "vegetable pit".

In the first case, it is necessary to carry out a thorough study of the type of soil, determine the level of groundwater, and check for the presence of underground utilities in the place designated for the foundation pit.

All research is better to entrust professionals. This will allow you to quickly assess the situation, saving time and effort.

Works can be started if the technical plan of the area allows digging deeper into 3 meters or more - then the deep foundation will be protected from undermining. Otherwise, the foundation will be flooded.

If the vegetable pit is already equipped in the garage, it can be converted to an inspection part, it will be even easier than digging a foundation pit from scratch.

First you need to move the entrance to the cellar in a convenient place and build the missing walls with bricks.

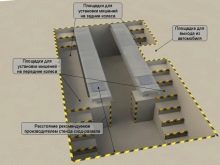

The dimensions of the inspection pit are calculated:

- length - the length of the machine plus 1 m;

- width - in width between the wheels minus 20 cm so that the car does not fall during the ride to the pit;

- depth - the height of the driver plus twenty centimeters.

If the depth of the vegetable pit is more or less than this value, the bottom is better to build on or deepen. All elements of the pit and cellar outside it is necessary to warm the polystyrene foam and carry out the drainage system, if it has not previously been equipped.

Wiring for future lighting is best taken care of immediately.Also, do not forget to equip a niche for tools in the wall.

After completion of the floor will have to redo the garage. The problem will be solved by concrete pouring, which can be done by yourself, if you pre-install the reinforcement or guides.

So we get a separate entrance to the cellar, where you can store the products of a private household, and a separate viewing pit, covered with a boardwalk or a sectional door.

If it is impossible to equip a viewing pit, with a sufficient height of the garage ceiling, a home-made overpass can become an alternative to a viewing pit.

They are:

- full-size (designed for the entire length of the car);

- mini-trestles (allow you to raise the front or rear axle of the machine).

The simplest mini overpass is welded from profiles and fittings.

Lighting

For comfortable work in the garage you need the right lighting. The illumination of the garage depends not only on the number and type of luminaires used and on the grid’s specific power per square meter, but also on its area, height, number and nature of work areas, even on the color of the walls. In a room with dark walls need more bright lighting.

The system of multi-level lighting for the garage is considered the most optimal. It involves the installation of a central luminaire in the middle of the room and spot lights in work areas.

Calculation of height for multi-level lighting:

| Level | Height, m |

| 1 | ceiling base |

| 2 | 1,8 |

| 3 | 0,75 |

| 4 | 0,4 |

It is easy to check the installation of the fixtures - just look at the car. She should not cast a shadow in one direction.

The formula for calculating the power of ceiling lighting: "P = S x W / N":

P - total required power, W / m2. W - power of one lamp, W. N - the number of lamps (lamps), pcs. S - area of the room, m2.

For LED and halogen type lamps the best indicator is 16-20 W / m2. This value is suitable for rooms with a ceiling height of not more than two and a half meters. For higher ceilings, this figure should be multiplied by 1.5.

Halogen lamps work like incandescent bulbs, but they give more light. They also have a longer service life - 4 thousand hours. The flask of a fluorescent lamp is filled with inert gas. Inside the glass is covered with a phosphorescent composition that glows under the influence of an arc discharge.

Lamps must be in the ceiling. You should also take care of the system voltage stabilization.

The most expensive lighting - LED. But it is more economical than fluorescent lamps by 50%, and the service life of LED lamps is 50 thousand working hours. And they do not need the ceiling, because the LEDs do not contain toxic components and provide light that is closest to natural.

Lighting a viewing pit, low-power LED or halogen lamps can provoke an electric shock due to condensation deposited on them. LED bulbs are more convenient because halogen heat up a lot. Retract the lamp and it will not suffer from the accidental fall of the tool into the pit.

Heating devices

Before you choose the device itself, determine whether you will heat the garage around the clock, maintaining a certain temperature, or turn it on only for the duration of the work.

It is necessary to make high-quality ventilation in advance. When installing any kind of garage heating it is necessary for safety and the norms of Russian legislation.

A great option is to connect the garage to the house heating system,but it is only suitable for a private building on the territory of a private land plot.

The most popular option is compact heaters. Many motorists prefer to buy them, thinking that their self-assembly will cost more.

In fact, it is possible to assemble a compact heater from quite budget materials. The overwhelming number of self-made thermal units operate efficiently through the use of thermal film. Thermal film is a multilayer electric heater that can be assembled from laminated plastic or carbon. It heats up quickly with low power consumption.

To check the performance of the assembled device you will need a multimeter. The rest of the items can be bought in the store of household goods or found in the home pantry.

You will need:

- strong wire with plug;

- laminated paper plastic (the area of one element is 1 m2);

- epoxy based adhesive;

- graphite, crushed to powder.

First, prepare the epoxy-graphite mixture. The amount of graphite chips depends on how well it will heat the device. On average, the temperature reaches 60-65 degrees.

Apply the mixture on the rough side of plastic sheets with zigzag strokes. We fasten the sheets with epoxy glue facing each other. Make a frame around the contour of the sheets to further fix them.

Next, attach the terminals to the graphite conductors on opposite sides of the heater. If you want to regulate the temperature, you can build in the wire dimmer. To avoid short circuit, the assembled device is thoroughly dried. Then test the device (a multimeter is useful for this), measure the resistance and power. If it turns out that a homemade heater is safe enough, you can use it.

An electric heater, made independently of a type of thermofilm, can be used both in vertical, and in horizontal and inclined position.

The main thing - to comply with safety:

- do not leave the heater turned on unattended;

- should not be assigned to supervise children;

- Do not place the device near inflammable objects.

In case you decide to arrange heating of the stove type in the garage, you must obtain permission from the fire department and the garage association without fail.

However, fire inspections rarely give permission for the use of improvised “stoves”, and in the case of their unauthorized installation, all responsibility for any damage will fall on its owner.

Examples and options

Options for the use of free space in the garage a lot.

The most popular ones are:

- Workshop. The garage is an ideal place to practice, which has no place at home - noisy locksmith, flammable lamp-working and soldering with the unpleasant smell of burning rosin, finally, will find a cozy haven.

- Stock. In each house there are a lot of necessary things that you don’t want to keep at home - seasonal sports equipment, children's sledges, even non-seasonal clothing and family photo albums.

- Garden corner. The garage is often used by amateur gardeners to store bulky and oversized garden supplies.

- Storehouse home billets. As well as a strategic supply of potatoes, carrots, cereals and salt.

- Rehearsal base.

Useful ideas for the arrangement of the garage, see below.