Shelving for the garage: types of structures for storage

For many people, a garage is not only a parking lot and a repair for motor vehicles, but also a place to store all kinds of things, from small things like tools to broken appliances and old furniture. All that is a pity to throw away, instantly migrates to the garage, where it lives its time. Over the years of accumulation, the garage room turns into a landfill, where it is difficult to find the desired item when it is urgently needed.

That the car quietly drove and drove away without encountering unexpected obstacles,in order not to stumble over junk and avoid unnecessary cluttering up of space, in the garage they often use convenient, roomy and versatile storage systems - shelving.

Special features

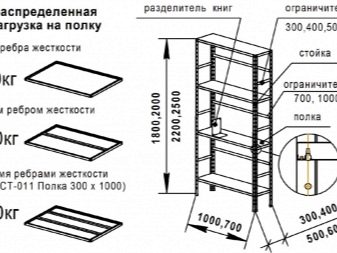

Shelving for the garage is an open or closed storage system from different heights of vertical racks, crossbars and shelves. For their manufacture using high-grade steel and wood. Wooden products are more fragile and take less pressure than metal, able to withstand fairly large objects. Structures are collapsible, if assembled with bolts, and non-collapsible, if welded and permanently mounted on the wall with nails or screws.

Shelving for the garage remains the best option for storing tools, spare parts and other equipment. Among the main advantages - spaciousness, compactness and affordability. Depending on the type and material of manufacture, large-sized objects, small parts, unnecessary utensils, cans, tires can be laid on them. They will fit neatly along the wall, and the shelves under the ceiling will conveniently arrange everything that makes the garage room cluttered.Spare parts, tools, consumables and other trifles tucked into their shelves look more aesthetically pleasing and neat and will always be at hand.

The rack can be made independently, without making big expenses, or to get in specialized shops. The modern market allows you to choose exactly the product that is right for you. Hand-made racks will not yield to anything bought, if you follow the diagrams and instructions, use quality materials and make a little effort, and will last for the same amount of years, keeping your garage in order and clean.

Purpose

Shelves are designed for storing and organizing tools, parts and other things, make rational use of garage space and save as much as possible free space. Unpacked things are much easier to find and they will always be in the first availability. It also reduces the risk of fire, because flammable substances are usually stored in garage rooms, which can lead to a fire if stored improperly and in the vicinity of other substances.

For order and cleanliness, you can choose separate racks for wheels and tires., small parts, tools, grinders. Above the workbench it will be nice to fix the rack for keys and screwdrivers - the necessary tool will not be lost and you will always be at hand when working on the table.

The cans and tanks neatly laid out on the shelves never prevent the car from leaving and entering the garage.

Manufacturing materials

As a rule, racks and shelves are made of wood, metal or plastic. For a wooden structure, not only wood is used, but also PVC and chipboard, which are strengthened by sheet metal for strength.

Wooden shelves are usually fixed with metal fasteners or chains.

Do not forget that wood is a flammable material. and it is very light, so it will not withstand heavy loads. The tree is also very sensitive to moisture, although the temperature does not affect its structure. At high humidity, it is subjected to rotting, deformation, covered with mold. So if you decide to equip your garage with wooden racks, immediately think that you will fold them and take into account the humidity of the room.Do not put racks and shelves where it is damp. In addition, if you make a wooden rack with your own hands, do not forget to soak it with antiseptics, which will give the material strength and durability, protect against insects, prevent the appearance of mold, fungi and other microorganisms.

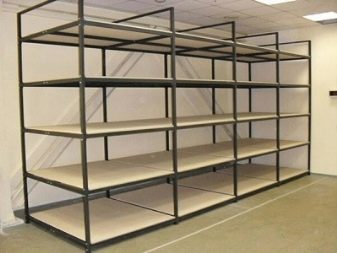

Metal products are made from a perforated corner, shaped pipes, combining them with wooden materials to make the construction easier. Most often racks from a profile which differ in the ease and durability meet.

Metal products are more resistant to the influence of chemicals, withstand heavy loads, and humidity and temperature do not affect its performance, do not rot, do not ignite. If the design is purchased in specialized stores, then it will not be difficult to assemble it.

Metal products are less exposed to mechanical damage and are able to withstand dimensional parts.

Plastic is unstable to strong frosts and heat, but well tolerates moisture. Such designs are flexible and lightweight, but do not withstand heavy loads. They are inexpensive and intended only for light things.

Models and designs

When choosing racks for the garage, take into account the floor space and the space reserved for them. So, some designs may be too bulky for the parameters of your garage or, on the contrary, not large enough. Before choosing a model, immediately think about what will lie on them, because different types of storage systems perform their individual function and withstand different loads.

There are following models of racks:

- stationary;

- collapsible;

- mobile;

- island;

- rotating;

- modular;

- mounted.

Stationary racks are stable due to the fact that the pressure of the weight of the loaded shelves falls on the floor. The design is made of vertical beams and horizontal bars, on which the shelves are mounted, has a rigid connection, which ensures safety. It implies installation on the wall to a permanent place without the possibility of moving. They are comfortable to use, stable and durable.

Metal racks are the strongest and can withstand a lot of weight, wooden suitable for light things and easy to self-manufacture.Installation of such a storage system does not require special tools and skills.

Each shelf can withstand up to 150 kg, depending on the material of manufacture.

More common are prefabricated metal racks for the garage, which can also be bought in any market and effortlessly assemble it yourself. Unlike stationary ones, they are made of a perforated metal profile, and the shelves can be fixed at any height, depending on the needs. Such racks are more convenient and spacious and allow you to store a set of spare wheels, and large loads. They can be equipped with drawers that can additionally store the necessary things.

Mobile shelving is made mainly from metal structures. They are equipped with small wheels that allow you to freely move tools around the garage. It will be easy to move the tool boxes to the workbench and continue working.

Although the mobile design is mobile and facilitates the work with the necessary items, its load capacity is much less than that of other racks. This rack is sold unassembled and without much effort and skill is assembled in the garage like a designer. Withstand load - no more than 100 kg.

The metal island rack is a stable system of several shelves that can be interchanged in height. This design is designed for lighter objects and is well balanced to prevent possible collapse of the shelves and the dam due to gravity. There are central racks, which can be approached from all sides, and angular, installed in the corner of the room. The withstand load is not more than 50 kg.

The rotating rack is designed for storing and storing small piece goods, bolts, nails, hooks, keys and other small things that are easily lost and difficult to find in the boxes. Every little thing will be in sight. Such designs are convenient, do not take up much space (will be rationally installed on a workbench) and free up space for more massive parts. Withstand load - no more than 50 kg.

Modular shelving - multifunctional productsconsisting of separate block elements that can be interconnected, like a designer, into a convenient storage system. You can do exactly what you need, and if there is a need for additional space, you can attach more sections and shelves to the existing rack. Withstand load - up to 150 kg.

Suspended shelves can not quite be called shelving, but this convenient and versatile design can be used in garages. They fit all the unnecessary, something that is not particularly useful in the work, small parts, light objects. Wall-mounted systems are practical and affordable, making such shelves is not difficult from any materials at hand, and ceiling ones, if attached with special fasteners under the ceiling at such a level so that the roof of the car or your head doesn’t touch, extra items. The load should not be large, because hinged shelves can hold a weight much less than stationary racks. Withstand load - no more than 100 kg.

Review finished

The modern market offers countless convenient and multifunctional racks, both wooden and made of metal. Universal designs will fulfill their mission completely and fit into any garage room. In Ikea stores you can find excellent options in steel and high-quality wood, complemented by cabinets, drawers, fasteners and hooks for more convenient operation.

Convenient and practical use in the garage space rack for tires. Excellent copies can be found in stores, but some craftsmen themselves assemble a similar design, separately buying metal consumables: a corner or a profile. Shelves and panels for tools that you can buy or make yourself will be useful.

Homemade options

A simple racking system can be made independently if there is no possibility to purchase the finished product. In the public domain there are many schemes that will facilitate your work. If you are at least a little carpentry or own a welding machine, you will not be difficult to make quite good racks yourself, which you can proudly put in the garage. The main thing is to decide which material is better to use. As mentioned above, usually the shelves are made of metal or wood.

It is much easier to make wooden racks, but one should not forget that, in addition to the fact that wood is a flammable material, it is very light and will not withstand heavy loads. If, however, the choice fell on him, do not forget to soak it with antiseptic, so that the wood does not rot over time. Also, do not install such racks in too wet a place.

Metal structures more powerful and stronger, but you have to seriously tinker to make them. Metal consumables are much higher in price than lumber. However, wood for work needs high-quality, processed, without knots, and this in itself is not cheap.

So, in any case, it turns out that the cost of consumables will be almost equal. The choice is yours.

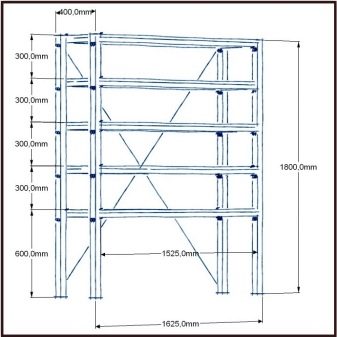

To make a rack of wood, the first thing to do is to draw a design drawing. Determine exactly where in the garage it will fit. Its length is directly dependent on the height of the garage, and the width of the shelves on the things you put on them. Let the length of the shelves will not be more than 90 cm, otherwise they will be bent. It is not necessary to be a talented artist to depict a drawing; a schematic depiction of the future product will also be suitable.

High-quality rack needs high-quality natural board. Perfectly fit oak or pine. You can also use chipboard, PVC wall panels or plywood. It is better not to take a chipboard, it will not last for a long time, it will quickly dissolve from the slightest moisture and will not withstand heavy loads. It would be nice if the humidity of the board is not above 12%.

Before using boards, they should be coated with impregnations.

The bottom board - the basis on which the whole structure will be supported, must be thick, strong and wide enough. For strength it can be nailed to the transverse bars. Next, we need walls that will be attached to the side of the base. If you want to save on wood, replace the board with thick plywood - this is an inexpensive affordable alternative. On the side of the tick mark - there will be installed shelves. Height is selected on your choice. Shelves are cut from the same tree. If additional strength is required, the shelves will need to be fixed in bars.

Whether to install the back wall is entirely up to you. It all depends on your taste and the appearance of the wall to which the future shelving will be attached.

If you need to hide the wall, use plywood of the same size as the rack.

When all parts of the structure on hand, processed and ground, go to the assembly structure. It can be glued with glue, attached with nails or screwed with screws. Initially, the lower base is installed on the desired wall and the rear flap is installed on it, if required.On the side boards, where previously there were marks for the shelves, fixed holders made of plastic or metal. Metal at times stronger. If there are no holders, then the shelves can be screwed to the sides. The side walls are attached to the base, and then, holding them from the inside, are fastened to the outside with shelves with screws.

The lower part of the shelf can also be strengthened with metal corners.

This is an example of the simplest wooden shelving. It can be installed in other spaces besides the garage. The design will look harmonious and perform its task anywhere.

For the steel rack, you first need to have the appropriate equipment, for example, a grinder for cutting metal and a welding machine. Do not forget about safety at work.

The choice of consumables for metal construction is much more. Angles, profile, pipes will do.

Shelves to facilitate the design can be made of boards, chipboard, plywood and strengthen the tree with sheet metal.

For a metal rack, the profile or angle is cut according to the drawings sketched before. Grinders cut off blanks for the rack, lintels and shelves. Cut and cleaned items collected.Side frames are created that need to be assembled correctly, as the design may be disproportionate and uneven. To do this, the frames are folded flat on the floor, check that their diagonals are even, and then welded.

Next to the assembled frame grab vertical beams. It is important to respect the proportions, check the diagonals. On vertical racks, as on a wooden structure, make marks for the shelf. You can choose any height.

If you need a universal shelving, markup do as much as necessary, then to move the shelves from one place to another.

The design is painted to prevent corrosion. To do this, paint or a regular primer will do. If necessary, future shelves are also painted - wood or particle board, but before that, with their antiseptic. After the paint dries, a hole is drilled in the racks, a shelf is put on top and a screw is screwed under the bottom so that it passes through the metal and hardens in the wood. For stability and strengthening of the structure it can be installed on the wall.

This is another example of a metal simple and versatile shelving that will put all things into it.If possible, do not limit yourself to a simple option; make a separate rack for tires and wheels - a very necessary attribute in the garage.

Useful tips

Shelving is a great way to get organized in a garage.

Specialist give some tips that will help if you decide to organize the contents of the garage:

- Do not fear the cost and loss of time! All this will pay off many times. Over time, you yourself will understand that ordered things will never interfere with your work and will always be at hand.

- You can make or buy a separate rack, designed for wheels and tires, separate to store canned cans, a separate stand for garden accessories, a dial pad on which keys and screwdrivers can be assembled. Unleash imagination and imagination!

- Before you buy or make your own rack, draw a drawing, measure the width and height of the place where you want to install the storage system, in short, make sure that the product fits in the garage and there will be room for the car.

- Remember that wood does not tolerate moisture, so do not install wooden racks and shelves where humidity exceeds 12%.

- Immediately consider what will lie on the shelves. Remember that many designs can not withstand large objects.

- Self-made wood constructions should be impregnated with an antiseptic to avoid rotting.

- Metal constructions are painted or primed against corrosion.

Examples for inspiration

- A very useful and convenient shelf for power tools will definitely be in place in your garage.

- A universal rack can be a replacement for multiple storage systems. Several sides, movable, special hooks for fastening things - convenient and practical.

- The universal wall will also replace several shelves, help to collect all the necessary equipment in one place and free up a lot of free space. This option is especially good for those who have a small garage.

- Racks for agricultural tools are an indispensable thing if rakes, hoes, shovels and other items that litter the space are stored in the garage.

- Sliding cabinets - convenient, economical and practical.

On how to make the shelves in the garage with your own hands, you can learn from the video below.