Do-it-yourself garage building

Every car owner dreams of a small, cozy garage. This dream is easy to turn into reality with your own hands, building a garage yourself.

Features of construction

Before you start to make a garage, you need to carefully consider and disassemble the plan of construction. First of all, you need to get a building permit.

Special attention should be paid to the following documents:

- SNiP 2.07.01-89 “Urban planning. Planning and development of urban and rural settlements ";

- SNiP 21.01.97 "Fire safety of buildings and structures."

If the fire regulations are not met, then the building can recognize illegal and demolished.

You must also decide what the building will be. It is divided into several types:

- temporary - has a short lifespan;

- mobile - requires a frame structure;

- combined - suitable for subsiding soils;

- capital - has a long service life, but will cost dearly.

It is necessary to consider protection against intruders. It is better to spend money on the alarm than to calculate the losses due to the stolen property and the stolen car.

Dimensions

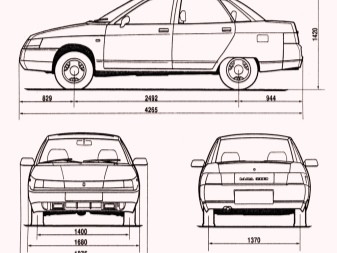

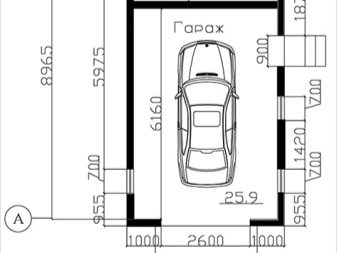

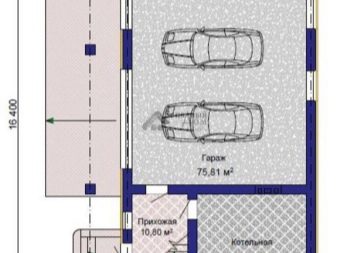

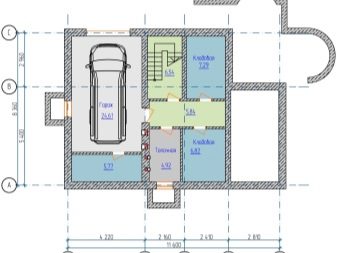

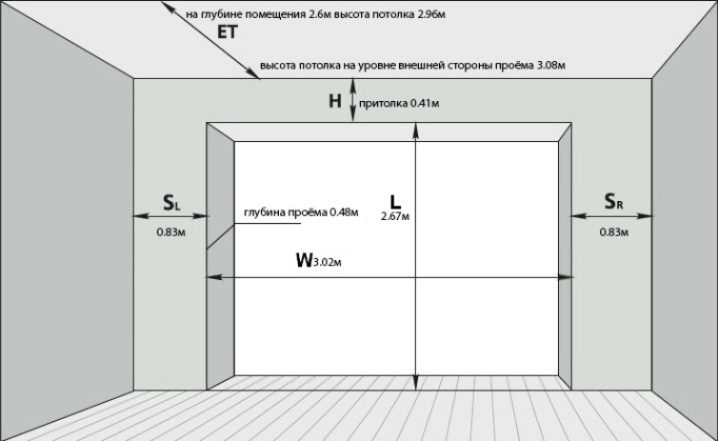

In order to calculate the required dimensions, it is necessary to determine the number and size of cars that will "live" in the building. You should also understand whether any other things will be stored in the garage. It is necessary to consider whether a large car will be bought in the near future. For example, if in the near future the owner is going to purchase a large truck, then the building for a passenger car is meaningless, it is better to immediately consider the option of building a large garage.

For one machine, the size will be calculated on the basis of its dimensions. To this value you need to add half a meter on each side. This is necessary for a comfortable exit from the car and free movement around the garage.It should be remembered that with such small sizes there will be no space for tires and various accessories. Therefore, it is worth increasing the length by 3 meters and adding a few more meters to the width. The height of the building must be more than half a meter from the height of the car.

All measurements are best done with an open trunk.

For several cars it will be more difficult to calculate the size. Between them, you need to create a distance of a fully open door, you can add 30-40 cm for comfortable parking. Between the wall and the door the distance should be more than half a meter. The front and back of the car should be positioned so that a person can freely pass. The distance should be about one meter.

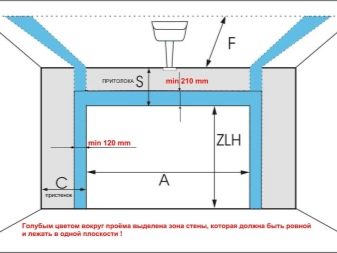

As for the gate, then you need to take the width of the car and add 60 cm from both sides. If there are two cars, it is better to take the width of the gate from 2.5 meters and 20 cm to the reserve on each side. The height of the building is calculated in the same way as in the case of one machine.

These were examples of the simplest little boxes. If the owner wants to use the garage space not only for storing his “iron horse”, but also for other purposes,it will be enough to calculate the dimensions of the objects and take into account the space for a free approach to them. Then add the data to the existing garage sizes, which were calculated according to the above.

Determine the size of the drawing will help, it is carried out on paper or in a special program. For advice, you can turn to professionals, they will help and tell you how best to execute this or that idea. You can take the finished circuit. The main thing is its presence. The drawing is very important for future work.

Location selection

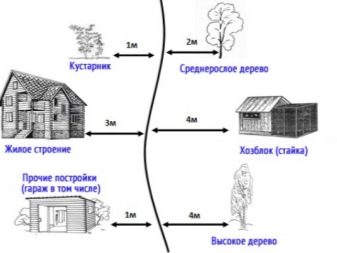

If the garage is located on the summer cottage, you can consider the option of building an extension to the house. There is no need to obtain a permit, the construction does not require special conditions, because such a building is considered part of the house. Here it is possible to make the exit as close as possible to the gate or directly to the street.

With a separate type of garage will have to tinker. The SNiP says that there must be at least one meter distance between the garage and the border of the plot if there are no buildings on the neighboring land plots.In the case when they are, the distance should be at least 6 meters. When erecting a building, one should make sure that there are no sewage pipes, heating, water mains and power lines nearby. Elevation in the lowlands should be avoided - this can lead to flooding. The best option would be a small hill.

If there is not enough space on the plot, then the construction of a garage underground will be the way out. Check out need to do on the street. You can not have a garage directly under the house itself, it would be more rational to make an extension to the strip foundation. The territory under which the building is located should not be used for assembling structures with a basement depth of more than 55 cm. But if underground keys or wetlands are located on the future construction site, then it is better to abandon the construction, for such a ground, an extremely expensive drainage system will be needed.

The room should be located as close as possible to the exit and the motorway, but without sharp turns.

If there is no cottage, and a garage is needed, you can buy a privatized plot of land in the city. After that, having received permission to begin construction. This procedure is very long, so you should be patient. Choose a place as close as possible to the house, but you need to be prepared for the fact that within the city limits there may be no free building land, but only on the outskirts or outside the city. Such a garage needs careful protection from intruders.

Designs

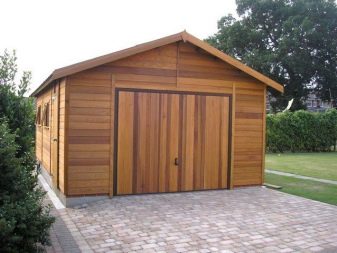

There are many types of garages for every taste and budget. The simplest and cheapest options are “shell” and “pencil case”. They can easily be made with your own hands, and the "shell" can even be moved. But durability, they do not differ.

The next type is a one-storey one, it can be made with a pit or hozblok. In the city, a monolithic variant is most often built, and although it does not look very attractive in appearance, it is very durable. No thief can get into it. If the garage is located on a summer cottage, then a shield frame garage can be an inexpensive option. It is built many times faster than monolithic and brick.

The two-story building can serve not only to store cars, but also suitable for living in the summer. Residential floor should be warm, equipped with light, toilet and kitchen. A second floor with a gable roof can turn into a cozy loft.

The garage can also be an extension to the main house. The advantages of such a building are that you don’t need to think further about heating and other communications, you can make the entrance to the annex directly from home. But a significant disadvantage is that the exhaust gases penetrate the house upon arrival and departure of the car. This option is suitable for those owners who have not completed the main house, because the extension to the already finished building requires large investments and solid preparation.

For the construction of the underground premises it is necessary to fulfill several conditions:

- When building a deep garage, waterproofing is considered the greatest problem. It will require arrangement of the drainage system of the roof of the garage and enhanced waterproofing of all supporting structures.

- The roof frame of the garage must be made using concrete slabs with a mandatory support system.

- There should be an emergency exit in the event of a house collapse or a fire.

- After choosing the design of the garage, you should decide on the material and find good suppliers of all the necessary attributes for construction.

Materials

The market offers a huge range of quality materials that will last a long time. Each has its own pros and cons, remember this and select the option that will be comfortable to work with.

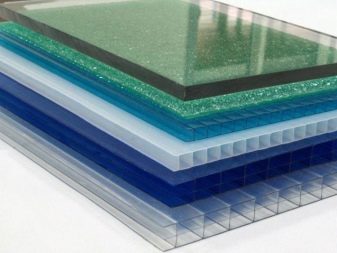

Polycarbonate is a light and cheap material, but it should be used only for a small garage. For example, for the shell.

If metal is preferable to the owner, then you can opt for sandwich panels or profiled sheeting. The sandwich panels in the section resemble a sandwich: there is insulation between two metal sheets. Construction is carried out in a very short time, and the design is lightweight and amenable to any upgrades. Their price is very small, and installation can be carried out at any time of the year. But this material is short-lived, the metal frame requires rust treatment,wooden base must be treated with antiseptic substances.

The professional flooring is a cheap, high-quality and beautiful material. Garages of corrugated are built fairly quickly. It is necessary to pay attention to the brand: it is better to choose C-20 or PS with a thickness of 0.5 mm. In no case do not need to take the brand -8, these sheets will not last for a long time due to poor resistance to wind and low frost resistance.

The construction of red brick will be much more reliable than metal. This material has a high frost resistance, low thermal conductivity. From the point of view of aesthetics, brickwork looks quite decent, but the material has a high cost.

The foam block is cheap and has a small weight, so the construction of it can carry out one person. The only catch is that the gray blocks are not very attractive in appearance. This problem can be solved with the help of finishing materials.

Gas silicate blocks are gaining great popularity. Despite their low weight, they have high strength, they are easily processed.The blocks also have low thermal conductivity, do not require additional treatment with antiseptics. With such material, you can not be afraid of the appearance of mold, bacteria and fungus.

According to the environmental characteristics, gas silicate blocks are on a par with natural materials.

Minus gas silicate blocks - high water absorption. A layer of plaster on the walls can crack and peel off. This problem can be solved by treating the walls with penetrating primers. Since the blocks are a weak base for fasteners, fixing massive objects will be problematic. They do not have high frost resistance. The material has high rates of free lime, which allows to activate the corrosion processes of metallic inclusions: reinforcement, pipeline, carcass and others.

Another artificial, but environmentally friendly material - cinder block. You can buy it or make it yourself. For the second, a vibroforming machine is required. When buying should pay attention to the filler. It is better to choose crushed stone, sawdust, shell rock, expanded clay.The garage of cinder blocks is not terrible natural disasters, it has a high fire safety, is easily repaired. With this material, you can vary the thickness of the walls. In addition, it can not be biodegradable, its price is quite small, and the service life is about 100 years. The unpresentable look, difficult laying of pipes and cables, high heat conductivity reduces the dignity of slag stone.

Wood concrete is known since the times of the USSR. It has low weight and low thermal conductivity. It is flame-resistant material, resistant to stretching. He is not afraid of cracks and deformation during the movement of the foundation. It is invulnerable to rot and mold. Distinguishes material high frost resistance. It is also easy to fasten various structures on it. In this garage will be good sound absorption. Of the minuses - a high coefficient of water absorption - from 40 to 85%, and a rather high price.

An assistant in the embodiment of bold design and architectural ideas will be clay block. Almost all types of finishes, both internal and external, are suitable for it. The material has a low thermal conductivity,It is strong and durable, with high sound insulation. The vapor permeability of the blocks creates a favorable microclimate indoors. The process of building a garage will move quickly because of the large block size. A simple production contributes to an affordable price.

The disadvantage of expanded clay blocks is the formation of cold bridges, but with the help of cladding and additional thermal insulation, the problem can be solved. The material has a low resistance, quite heavy and requires a strong foundation, but you can not use this building material as a foundation.

More natural material is wood. The material is inexpensive, beautiful and allows you to perform bold design decisions. With the help of various impregnations can be achieved fire resistance. Minus - a short life and high thermal conductivity.

Railway sleepers are bars of trees. A special blend that works as an antiseptic to help protect the garage from rotting, bacteria, sun, moisture and small rodents. Buy sleepers can be in the nearest railway department, where the repair of tracks.The garage of this material will be dry and warm, able to withstand even an earthquake. But you should never build a garage of new sleepers. The smell of creosote is very dangerous and can cause chemical burns and poisoning. The term of their use in air should be 12-30 years, for this period the mixture is washed off and loses an unpleasant smell.

Methods for the manufacture and processing of sleepers are different, some products are soaked through and others to 2.75 centimeters. It is better to use the last option. Such a construction requires careful treatment inside, which reduces the risk of contact with creosote residues. Outside, a well ventilated facade should be made.

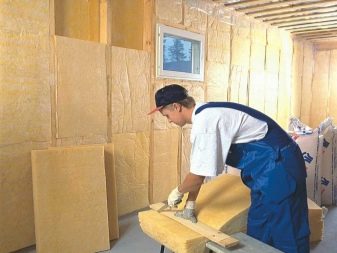

Many building materials do not have high frost resistancetherefore, it is necessary to warm the garage. The cheapest insulation is foam. It is very easy to install. But we must remember that this is a fragile material that wears quickly.

Another cheap insulation - mineral wool. It is safe for health, has high thermal insulation and a high level of sound absorption.This material must be covered with an additional layer of vapor barrier.

More serious insulation - reflective insulation. The material consists of a layer of heat insulator, the top is covered with metallized film. Of the advantages - low thermal conductivity, excellent sound insulation, low weight, immunity to moisture. Such material is easy to install. The disadvantage is that the material is used not so long ago and all its properties have not been studied. It is only known that this insulation is amenable to corrosion.

Basalt cardboard is a durable material that has a high degree of resistance to temperature extremes, deformation and moisture. The material has a low heat capacity and good sound absorption, is not afraid of fire. It is not cheap, but very high quality and will last for many years.

Additionally insulate the garage will help insulating paint and "warm" plaster.

Finishing outside the building should combine resistance to external environmental influences and have a presentable appearance.The modern market offers a wide range of options that meet these conditions. The easiest and cheapest ways - jointing, plastering, siding. More expensive ways - wooden lining, natural or artificial stones.

If the garage is two-storeyed, the space between the first and second floors is covered with reinforced concrete slabs. It is desirable to make a hollow slab, because it is easier to install and low in price.

Roof covering materials can be divided into two groups: soft and hard. The first will be suitable for a flat roof, and the second - for a duo-pitch.

Soft include:

- Shingles The material is up to 55 years old, resistant to corrosion and rotting and can be of any color. It is better not to use the material in the northern regions - under the influence of frost, it becomes fragile.

- Ruberoid Service life is about 15 years. The material is cheap, resistant to frost and exposure to the sun.

- The self-leveling roof serves for 22 years, it is easy and quick to install, amenable to repair. The application surface should be perfectly smooth.

- Welded roll roofing (waterproofing, glass insulation) has been in operation for about 50 years. The material is durable, does not burn, it has good sound insulation, is immune to temperature changes. The only negative is the high price.

Hard include:

- Reinforced concrete slab - has a long life, suitable for flat roofs, can withstand heavy weight. On such a roof, you can even break the garden.

- Flat slate - easy to install, inexpensive, does not lose its qualities in any climatic conditions. It is very easy to fix.

- Polycarbonate - serves for about 25 years, does not burn and does not react with solvents, is low in price. This material is simple to install, resistant to temperature extremes, but under their influence can slightly change shape.

- Fold roofing - does not require a strong frame, durable, resistant to mechanical damage and temperature extremes. Cons of the material - high price, complex installation, low sound absorption.

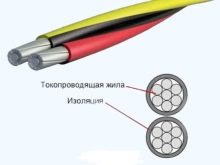

For the garage you need electricity. Here you can use self-supporting insulated wire (CIP).

There are several brands of CIPA and they all have different properties:

- SIP-1, SIP-1A resistant to UV rays;

- SIP-2 is used in the installation of power lines with voltage up to 1000 V;

- SIP-3 is used for overhead power lines;

- SIP-4 is resistant to UV rays;

- SIP-5 is suitable for a temperate and cold climate, resistant to high temperatures.

For the storage and safe movement of building materials it is necessary to have wooden pallets. White acacia, birch or boxwood pallet is a good choice.

To save money, you can buy a used pallet, the main thing - good quality.

The process of construction: the main stages

After creating a drawing, choosing building materials and drawing up step-by-step instructions, you can begin construction.

"Pencil" and "shell" do not require a solid foundation. First you need to make several separate sections and then assemble them.

Assembly steps:

- need to drill technological holes in the structure;

- Ready elements to cover with an anticorrosive means and to paint them;

- assemble the segments into a common construction and fix;

- Protect and paint all welding defects.

In the garage you can conduct electricity. To do this, install the lamp and two sockets, then the wires are passed through the corrugation. Copper wires with double insulation are used for operation.

The construction of a more complex structure begins with the installation of a strong foundation. For the garage are suitable options such as a monolithic slab, pile material, tape shallow or deep foundation. If you plan to pit or cellar, then the best choice - recessed tape. A garage with a quality foundation will last for a long time and will not bring problems, so this stage should be given more attention.

We should also consider the construction of the pit. The size depends on the car itself. For a car, a width of about 70 cm is suitable, for a truck, you need to add 20-25 cm to the standard size. The height depends on the height of the garage owner, but in any case, it is better to make the garage a little deeper.

An important element is the base, its height ranges from 0.5 to 2 meters. There are two types of cap: protruding and sinking. The first option is more elegant, but it will require the construction of an additional low tide along the protruding upper edge - this prevents the ingress of moisture.The second option is more practical and the building receives maximum protection from moisture.

When building walls using two methods, it all depends on the selected material. The first method is building in blocks. With him, the garage will not need to be strongly insulated, but additional finishing will be needed outside. The second method - frame. The framework is made of a metal profile pipe or a wooden bar. The advantage of this method is in the rapid construction of the premises.

The next stage is the preparation of the gate for installation. First you need to make measurements. It is necessary to measure the opening, paying attention to the distance from the right edge to the left. It is also necessary to measure the height of the lintel.

There are different types of gates for garages: simple swing, sectional, automatic or manual. Most car owners prefer sectional. Such products are very comfortable, occupy less space, sealed and strong. But they are high in price and have a complex device.

Before you equip the gate, you need to carefully read the instructions and properly prepare the opening.If the material is light, the opening is reinforced with a special metal frame. For a brick garage such a frame is not required.

The room must be freed, it will help much faster and easier to cope with the assembly and installation of the gate.

The next stage depends on the number of floors: if the garage is two-storied, it is necessary to overlap between the first and second floors with concrete slab and re-erect the walls.

When building a roof you need to be careful and observe safety precautions. The easiest way - a flat roof with a slight slope, about 15 cm. So it would be better to go and drain rain. The only minus of such a roof is the absence of an attic.

The gable roof will be more difficult to implement and the roof for it will take more. But on such a roof it will be possible to make an attic with a lounge. Another such roof needs a heating system. In addition, a carport should be made, under it you can park oversized vehicles and protect the car from the sun and rain without driving inside.

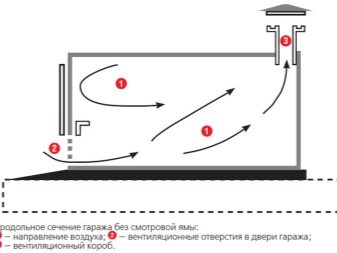

Do not neglect the ventilation. It is needed to remove moisture, removing harmful fumes. This is a rust protection of metal products and surfaces, creating a microclimate. The cheapest way is natural ventilation: air flows out through the intake and exhaust vents. But in hot weather, such ventilation does not work. Expensive installation methods - forced and combined ventilation. They provide proper air circulation at any time of the year, and in winter they can even heat it up. In addition, they are easy to install with your own hands.

Then you can go to the internal and external decoration. It is necessary to take care of waterproofing, treat the floor and walls of the garage with special mixtures. For walls, Penetron will be an excellent tool, and the floor can be covered with polymer varnish or bitumen.

Before starting to cover the surface, it must be thoroughly cleaned and sanded.

For the floor using materials such as paint, self-leveling compositions, ceramic tile, wood or rubber coating.Walls can be faced with the same materials as the floor, or plastic panels can be used. The material must withstand temperature extremes and direct shocks. A ceiling must be resistant to evaporation.

Exterior finishes should not be afraid of bad weather. You should carefully monitor the quality of the material and reliably perform the lining. And you can decorate the look with the help of decorative elements.

The progress of work with the underground garage is very different. At the planning stage, it is necessary to decide whether the building will be fully or partially in the ground. Next, you need to dig a pit of the desired size and place the plates on the bottom or make a fill with reinforcement. It is important to take high quality concrete. With the help of reinforced concrete slabs the foundation of the walls is formed, then the overlap is established on the side slabs.

Ceilings and walls are covered with waterproofing, reinforcing mesh is installed on them and plaster is put. Additionally, surfaces are treated with antifungal agents and primed.

After that, you can proceed to the installation of garage doors and the formation of the driveway.

It is important to consider several conditions:

- entry slope should be 140-150 degrees;

- retaining walls should be on the sides, they prevent the collapse of the soil;

- the length of the entrance depends on the length of the garage - the longer it is, the longer the driveway;

- for a safe exit and descent to the garage should be made a path with a handrail;

- you can not use sliding materials for the track, but in addition you need to make braking serifs, they will be useful during rain and ice;

- near the gate you need to make storm sewer with heating to prevent the water from freezing;

- after completion of construction, heating, electricity, ventilation and additional waterproofing are equipped.

Waterproofing is performed in several stages:

- a drainage system is installed on the outside of the garage, and the surface is once again covered with waterproofing material;

- a filtering pad is formed on the sides and under the floor;

- the final stage - interior decoration. The material is better to use waterproof and warm.

Useful recommendations

Here are some more tips for creating a cozy garage:

- the house and garage will look more harmonious and more beautiful if they are designed in the same styles and colors;

- if there is an inspection pit in the garage, then a small service can be arranged there, after receiving official permission for it;

- from the garage you can make a small workshop and do what you love or hobby;

- outside you can equip a basketball ring;

- you can rent a garage and get a good income every month;

- You can organize the space with the help of various shelves, holders and stands;

- the curtains on the shelves will give the interior the additional comfort;

- folding chair and chairs will allow to gather here with friends, they will also be useful for a snack during a long stay in the garage;

- shelves and racks need to be done at a distance of 20 cm, it will be easier to clean the floor;

- a lean-to screed at an angle and drains for water out of the room will make it possible to wash the car without her pasture on the street;

- signed boxes make it easy to find the right part;

- for additional insulation in winter, you can use an electric heater or a stove-stove.

Taking into account all the recommendations, tips and picking up quality material, you can build a strong and reliable garage with your own hands from any material. This garage will serve for many years.

How to build a garage with your own hands from sandwich panels, you can learn from the video below.