Armstrong ceiling: advantages and disadvantages

When it is necessary to urgently arrange the ceiling in an apartment or a public room, but there are restrictions on time and budget, it is recommended to pay attention to Armstrong ceilings. They differ in a variety of design and simplicity of a design, are easily mounted and serve for many years.

Special features

Armstrong ceiling is one of the most common types of coverage, which can be seen in residential and office buildings. From it he is a construction of plates, located in the form of cells on a metal frame. Such a ceiling is quite easy to install and does not have a high cost - that is why it is widely popular.

It is worth noting that the name was obtained in honor of the manufacturer, who was the first to bring such ceilings to Russia.

The design of the coating is different, which determines not only the appearance, but also the acoustics of the ceiling. For some time, the company offered to use two types of plates: square - with a size of 600x600 and rectangular - with a size of 1200x600 mm. However, the second type caused some concerns, because there was a threat of a collapse of the structure, so the decision was made to abandon them. In addition, there are such technical characteristics of Armstrong plates as thickness (8-25 mm) and weight (from 2.7 to 8 kg / m2).

In one pile there are from 8 to 22 plates that can be stored at a temperature of from 15 to 30 degrees Celsius and with air humidity up to 90%. According to GOST, Armstrong should be operated at a temperature not lower than 12 degrees Celsius and not more than 70% of the humidity in the room. The limit of fire resistance is calculated in several minutes.

Such a coating may be soft or hard. Soft ceiling is either mineral or organic. Hard plates are very heavy, so they need to be strengthened with expensive fasteners and treated with special tools.. From this it follows that they are, as a rule, chosen exclusively for the decoration of expensive apartments or country houses.

The characteristics of the mineral plates also play against them - the experts found out that such a ceiling is not environmentally friendly and harmful to health. Now, most buyers turn their attention to organic plates, because they are created from paper waste and therefore virtually harmless.

It should be added that it is possible to correct such a plate using an ordinary knife - you will not have to spend extra money on tools.

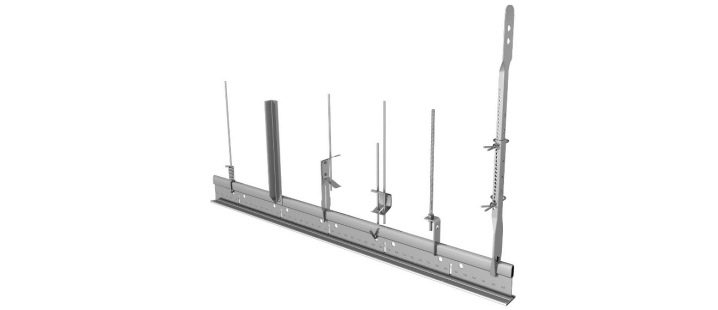

The suspended structure consists of ceiling plates and profiles of four types: transverse, wall, carrier and longitudinal, as well as of suspensions and fasteners. Armstrong profiles are made of various materials and various forms: either it is painted metal or metal-plastic with holes for suspension.

The surface does not require repair for a long time and is cleaned of dust using ordinary dry brushes or damp cloths. If the ceiling is located quite low, then it can even be vacuumed. When replacing a structural element, it is impossible to remove the suspensions or to change its length in any way.

Advantages and disadvantages

Like any other type of ceiling, the Armstrong ceiling has its own advantages and disadvantages. Among the advantages are the following points:

- Pretty low cost.

- It is possible to install independently and not overpay for the services of specialists.

- High quality heat and sound insulation, which is especially important for the space located in a house with thin ceilings. The coating eliminates unnecessary sounds and retains heat in the apartment.

- After installation of the suspended structure between the original ceiling and the new coating, a fairly large free space is formed. It can accommodate various communications, wires, Internet cable, as well as lamps. Due to the ease of access and mobility of the structure, they are easy to repair and, if necessary, replace them.

- If the choice fell on reflective plates, then the amount of light in the room will increase.

- Ecological safety - organic plates made from natural materials are practically harmless.

- You can make your own wood slabs, if required by the design, and fix them on the profile frame.

- The coating itself is also easily repaired and easy to maintain.

- It is possible to use Armstrong for warming the garage, balcony and utility rooms.

- There is no need to tidy up the original ceiling.

- For Armstrong produce a variety of components that are suitable for design.

- The elements are made of non-combustible materials.

- Attractive appearance.

- Maintains up to 6.5 kg per 1 sq. M. square meter.

However, Armstrong isolated and a certain number of minuses. For example:

- Components of structures do not have high strength - the material is very fragile.

- He will not save from flooding, if the neighbors above break through the pipe. In addition, if a coating type consisting of fibers was chosen, the ceiling would be damaged.

- Armstrong “steals” almost a quarter of a meter, so it is not recommended to place it in apartments with a low ceiling. It will look good in the Stalin-built apartments, modern high-rise buildings, shopping centers and office buildings, but the owners of the “Brezhnevok” and “Khrushchev” will have to give preference to another coating.

- Mineral plates may turn yellow due to changes in temperature or humidity.

- There are design limitations: it is impossible to create curved elements.

Kinds

Below are some types of Armstrong coatings.

Economy class ceilings, for example, "Baikal" or "Oasis". Most often, such plates are used in shopping centers, office buildings, hospitals and other public places with standard operating conditions, as they are inexpensive, but quite worthy looking ceiling coverings.

- "Baikal" - the most popular economy model. It has a white embossed surface with “wormholes” in the structure. "Oasis" is different original rough texture, pleasant to the touch. It combines two advantages: a pleasant appearance and low cost. There is also an “Oasis Plus” with perforation alternating in diameter, damping noise.

- Tatra is a panel with artificially cracked. It absorbs sounds quite well. In addition, the Norma model with perforation alternating in diameter is also related to this type.

- Functional ceilings, for example, "Prima", are moisture resistant due to the high content of latex in the composition, they are easy to wash and not deform even with an increase in the humidity level up to 95%.As a rule, they are mounted in swimming pools, bathrooms, laundries, baths, catering and wet shops of industrial enterprises. The thickness of all plates is 15 mm, and, in addition, they have increased sound insulation.

- Acoustic ceilings, for example, "Ultima". They consist of tiles with additional protection from external noise: a fiberglass acoustic coating. Due to their high sound insulation, they are chosen to decorate cinemas, night clubs and concert halls in order to soften loud sounds. Also “Ultima” has a high degree of light reflection due to the presence of a smooth white surface.

- Hygienic ceilings, these include "Bioguard". Such panels are coated with a special solution that protects against fat and steam and prevents the growth of bacteria. The surface is flat and white, cleaned easily and seamlessly by wet cleaning. Ceilings of this type are placed in places for which compliance with SanPiN is important, for example, hospitals, kindergartens and food enterprise workshops.

Design ceilings are used in apartments and other premises that require original decor, shapes and colors.However, if it is necessary to maintain the height of the ceilings, then you need to choose a hemmed structure. Usually they are mirror, glass, wooden or patterned.

Wooden plates are made of high-quality MDF, fixed with durable varnish and comply with fire safety requirements.

- Especially distinguished series Graphiswhich is distinguished by white color with decorative embossing in the form of small squares and circles, and graphic design in the form of small stripes and small squares, and Cirrus - with decorative "depressed" circles, squares and stripes, with decorative patterns in the form of a wave, ribbon and comb. In addition, it is worth noting lattice plates, a series of Colorton, Madera wood ceilings (laminate and wood veneer). In addition, metal (lath or cassette) and plastic plates are commercially available.

For heavy slabs, reinforced aluminum profiles are required.

According to the method of installation, there are two types of ceiling plates: the classic type, which are embedded in the frame from the inside, and modern plates that snap into place when installed outside.

Design

When choosing in favor of Armstrong's ceiling, there is an opportunity to choose the color of the plates, ideally suited to the existing room design.Although the varieties of ceilings are striking in their diversity, most often the preference is given to white color and the classic “smooth” model - this is what designers of office buildings, supermarkets and other public spaces do.

However, for cinemas often choose a black ceiling.

Design solutions in residential areas are also varied: you can find colored plates, and patterned, and perforated with shaped holes of various shapes, and exquisite embossed. There are more than ten types of embossing: both of the same type with a pattern from one geometric figure, and combined. Very often, perforated panels are installed in medical facilities.

There are open cells of the lattice type, which are able to hide the suspension structure. Do not forget about the presence of a variety of textures of Armstrong tiles - they can have embossed patterns, acrylic modeling, gilding and other “pimply” decor.

The ability to change the number of levels allows you to arrange the room to your taste. When the decision is made to mount two ceiling levels, It is worth "playing" with lighting elementsto get beautiful designs with 3D effect. You can also alternate plates of different colors: for example, black, white and bright, contrasting. Such a decision will bring double benefit, because the color inserts can not only decorate the interior, but also zone the room.

Making the Armstrong covering the living room combined with the kitchen, it will be possible to distinguish between the rest area and the cooking zone with the help of a bright strip.

System elements

The design of the suspended ceiling includes plates and a metal frame with a suspension. The frame of the ceiling is assembled from standard profiles with a shelf width of 15 to 24 cm and openings for a suspension system. It can be visible or hidden. between the plating elements. Profiles are connected with the help of locks with springs or folded antennae.

Perimeter profiles have the shape of the letter "G", and the rest - the letter "T". Bearing elements have a length of 3.6 m, and the transverse - 0.6 and 1.2 m. Each profile is easily trimmed to the required dimensions.

The finished grille is suspended with metal bars 6 mm long. One of them must be smooth, the second with a hook, and both of them are connected by a special spring - “butterfly”. If you squeeze the "butterfly" and start moving the rods, the ceiling height can be adjusted. When the "butterfly" is lowered, the bars are finally fixed. If it is necessary to carry out work in the ceilings between ceilings (with lighting or communications), one of the panels is lifted and moved, and at the end is returned to the site.

Armstrong has the usual disassembling mount with the base node, as well as a dowel or metal collet required for a reinforced suspension. The second option is usually chosen by the owners of supermarkets, since, in addition to the gravity of the coating itself, numerous lamps, air conditioners and ventilation grilles provide additional weight.

There are several options for installing the ceiling: with a two-axle frame on one or two levels, with or without a single-axis frame. When choosing the third option, it is necessary to fix profiles without suspensions on the original ceiling. If preference is given to the biaxial frame at the same level, then the profiles are mounted in such a way as to obtain sections of 600x600 mm. In the case of two levels, additional elements are used to connect the profiles.

The choice of suspensions depends on the type of ceiling.

There are three types of luminaires that are used in Armstrong ceiling structures. The first ones are raster ones, they are produced for ceilings of this type and represent a slab of 600x600 mm in size. Such lamps are staggered instead of ceiling tiles when using additional suspensions.

The second ones are LED ones, which are 600x600 mm or 1200x600 mm plates, and the third ones are point plates. For them, special holes are cut in the center of the ceiling tiles.

Installation

Armstrong ceiling assembly begins with a thorough preliminary calculations.

Firstly, it is necessary that the coating harmoniously fit into the interior, and, secondly, it should be determined how much material is needed and what the price will be. First, it is recommended to calculate the perimeter: for this, the length of the walls is measured, and the numbers are rounded to a number that is a multiple of three. We must not forget that perimeter profile can be bent and shortened in the corners.

Some masters prefer to do additional pruning in order to deprive the coating of a strictly appearance.

But still the plates need to be cut very carefully: no more than half.If their width is less than 30 cm, then additional cells will be required. Cutting row must be placed at the far from the entrance wall.

With direct installation it is taken into account that the profiles, which will have to take on the main weight, are fixed only parallel to the short walls.

The first stage begins with the installation of profiles along the perimeter with a mounting step of 0.6 m in the case of soft plates and 0.3 m in the case of rigid ones. A covered cord creates a contour, or the height is measured by a bubble or laser level, after the profiles for the perimeter are cut and fixed to the screws in the dowels or nails. Then marking is carried out, and holes are drilled for the remaining profiles and suspensions.

The next step is trimmed bearing profiles and finished elements are connected in strips, and then into the perimeter on a horizontal surface. The slats are moved apart along the length, and suspensions are also mounted in the supporting elements.

The installation of the transverse and longitudinal links begins in parallel and in a cross pattern that provides strength. The suspension is mounted after the profile in 1 m 20 cm increments with the help of holes drilled in the ceiling.

Nodes should be placed no farther than 45 cm from the walls.. But this may be impossible - then they are mounted in a staggered manner. If the design assumes the presence of heavy fixtures or engineering equipment, then additional suspensions are used diagonally. The load itself is located closer to the walls and corners.

Placing the plates begins only after all the construction and installation works have been completed, including the installation of the flooring and the glazing of the windows. As for the temperature, it needs to keep within 20-30°C, and the relative humidity of the air should be no more than 70%. The plates themselves, in which the luminaires are inserted in advance, rise and are installed at an inclination into the cells at the last stage, but if there are additional weights, then they must first be installed. The assembly is completed by the placement of "deaf" plates. The last of them rises on the hands, wound up in the opening of the cell, leveled and lowered.

Tips and tricks

If there is a desire to purchase Armstrong for premises with low ceilings, for example, "Khrushchev", then it will be necessary to reduce the interceiling space and abandon the use of hinges from pins and springs in favor of wire harnesses and corners attached to the screws.In the case of attachment of the suspension to the concrete floor, preference is given to dowels with "fungi" at the inlet - they will avoid falling into the air voids present in this type of walls.

Installation of the ceiling system begins only when all major communications have already been laid, since otherwise it will be very inconvenient. Parameters are calculated using a special calculator on the site of the Armstrong installer or manufacturer.

When planning the lighting, it is important to think about what functionality it has. 10 square meters. m 2 lamps are usually used, but this number can be both reduced and increased.

For Armstrong fit modular and raster fixtures, overhead design with double grille, fluorescent devices with 4 lamps, lamps with a mirror surface that reflects light, "Grilyato", "Ringo", point and LED.

Besides, ceilings are supplemented with diffusers - special thin plates installed in the lower part of the lighting devices. Diffusers can be opaque, opal, coated "crushed ice" or "prism".

The installation of ceiling tiles is carried out with clean gloves so as not to stain the surface. Laying starts from the center.

The safest and most convenient to use is the Armstrong Hydroboard. The degree of flammability of the plates is almost zero, and the permissible humidity reaches 100%. In addition, this ceiling is quite cheap - it is chosen for the design of wet areas: swimming pools, showers and storage facilities.

Holes for round luminaires can be cut with a socket nozzle. Wires and cables should immediately be brought out and the bare ends carefully insulated.. The cell into which the luminaire is inserted must be equipped with four additional hangers in the corners.

When planning a suspended ceiling, the weight of all embedded equipment is taken into account, which will be located in the false ceiling.

With a great desire, Armstrong plates can be painted only by observing certain rules: it is necessary to use only water-based paint and primer. Before processing it is necessary to remove the panels and place them on a flat surface.

At the end of all work, the lattice is adjusted horizontally - this can be done using a level. After a few days, the alignment procedure is worth repeating.since the ceiling for these days will already receive a full load.

To independently assemble the ceiling, you will need at least two people. - one will be placed at the top and will be engaged in fixing and joining profiles, and the second will help with tools and materials.

Before starting work, all parts should be sorted by color and size, discard damaged samples and prepare all auxiliary elements.

Production

Today, Armstrong plants are located throughout Europe: 42 factories operate in 12 countries of the world. In June 2015, production was established in Russia. It was there that they began to create a model of economy class "Baikal", designed specifically for our country. Such coatings are high-quality material, user-friendly design and easy assembly.

Armstrong ceilings are called any suspended ceilings, which are usually installed in offices and are filled with a cell size of 600x600 mm. This is not entirely true, since it is necessary to use exclusively the panels of this manufacturer, and not just the principle of creating the structure.

When components are made by other companies, it is no longer Armstrong, so all other coatings are considered “Armstrong-type structures”.

The basis for Armstrong ceiling tiles is mineral fiber with latex, starch, cellulose or gypsum impurities. The most cost-effective samples contain more starch, and expensive ones contain latex, which increases moisture resistance. The strength and ability of the material to resist moisture depends on the ratio of starch and latex.

The tiles are folded into bales, laid with thick paper, and sealed in polyethylene using vacuum, so that the material maintains an ideal state during transport and storage. The maximum number of plates in a package is 22 pieces, which is enough for the design of almost 8 square meters. m ceiling.

The panels are stored and operated at specific temperatures and humidity.

There are three types of tiled edges:

- Microlook. It has a not very wide stepped edge. Designed for suspended structures whose width is not more than 1.5 cm.

- Tegular. Edge endowed with a wide stepped edge. Used in suspension systems whose width does not exceed 2.4 centimeters.

- Board - This is a multifunctional edge with a smooth edge, suitable for both types of mechanisms.

The thickness of the plates is from 0.8 to 2.5 cm, and the weight can reach 8 kg. The best-selling panels have a white color, but buyers are available all kinds of colors and textures. The reflective ability of the ceiling does not exceed 90%.

There are the following manufacturer requirements:

- the type of transverse strips should correspond to the side profile of the plate;

- assembly is best done "ladder";

- additional moving parts, such as tiers, are attached to the original ceiling on separate hangers that are not part of the main structure;

- individual lamps are also attached to the base ceiling;

- work is carried out using stepladders, and at high altitude - safety belts.

Armstrong's standard ceiling technical layout governs everything from preliminary drawings to installation, including lighting.

Beautiful examples in the interior

- Silver-coated mirrored surfaces will give any bathroom an atmosphere of magic and mystery. The milky glass with the backlight behind the ceiling will continue the theme, which will create a soft diffused light and will perfectly fit into the hall decorated in sandy colors and classic style.

- The alternation of white and red plates, which are embedded in lamps, diversifies even the most boring and elongated kitchen. The noble interior of the living room will complement the wooden plates "under the laminate."

- Large plates with a printed photo of tree crowns will be a bright accent in the hallway, and cartoon characters settled under the ceiling will decorate any nursery. However, if the room is already overloaded with bright furniture and objects of decor, then it is worth staying on a white ceiling.

See the video below for mounting the Armstrong ceiling.