How to align the ceiling with your own hands?

The technologies of recent decades allow creating ceiling coverings with any features of texture, and sometimes with complex 3d-geometry. However, the smooth, painted white or delicate tones of paint surface is still associated with the very concept of "ceiling" and is unlikely to ever disappear from design practice. There are several ways to achieve this result, and they all allow you to cope with the task without the involvement of specialists. To level the ceiling with your own hands, you need to have not the most expensive tool, a few free days, and most importantly, to know for what type of finish is being prepared.And who better can know this than a property owner?

Special features

There are three effective, relatively inexpensive, and also simple to implement technology: plaster, plaster and drywall. To be able to make a choice for a particular case, it is necessary to get acquainted with the distinctive features of each of them.

Hard putty is the plastic leveling structure. The putty mass consists of small particles and a polymer, thanks to which it literally “glues” to the surface. Putty is very easy to apply. They work with spatulas of various widths. Gypsum plaster used for interior decoration, is able to give an even layer with a thickness of 2 to 5 millimeters, this is its main "range".

In some cases, the layer can reach up to 2 cm, but one should not be guided by this as a constant parameter. The so-called starting putty gives a somewhat rough surface. Finishing putty forms a surface as smooth as the human eye can distinguish. After drying, the layer of putty can be treated with emery cloth (which, by the way, allows to correct the flaws that have been made). The color of the material is white, sometimes grayish.

In wet rooms, cement-based putties are used, since gypsum is afraid of moisture. Putties are usually marketed as dry mixes, but there are also ready-made formulations.

Plaster involve, when there is a need for a much more substantial leveling layer. Normal thickness - 2 cm; with additional reinforcement (reinforcement), this value can be increased up to 5 cm. Plastering of the ceilings with a conventional mortar and sand mortar is not used due to the difficulty of application. Lime-sand mortar by today's standards is also not sufficiently plastic and rarely used. Now they are working with either plaster plaster or cement plaster. The names should not mislead you: they are distinguished from traditional compounds by polymer additives that provide high plasticity and adhesion (ability to adhere to the surface).

Plasters are sold as a dry mix in paper or carton. Before applying the mixture is shut with water and stirred. For work use the rule, water and normal levels, spatulas, poluterki and other tools.

It is necessary to understand the difference between gypsum plaster and gypsum plaster.Without looking at the same binder, the particle size and composition of each mixture are selected according to the purpose. If you put a putty layer in 4-5 cm, it will simply collapse after a while. Therefore, it is necessary to act strictly within the framework specified by the manufacturer.

The device of a gypsum ceiling involves the creation of a durable frame of special metal profiles, and then covering them with gypsum plasterboard - gypsum plasterboards. In fact, it is a hard type of false ceiling, a technology that is fundamentally different from the application of leveling compounds. “Alignment” here means the ability to create a completely flat horizontal surface at any given height. For fastening profiles to the walls, a punch (or a drill with a shock mode of operation) is necessary.

In order for the visual alignment of the ceiling to be successful, buy only quality materials for work, then you can level the ceiling yourself.

Advantages and disadvantages

Rarely it turns out to level the ceiling with one putty. As a rule, plaster is needed. Therefore, we can evaluate their quality together. The advantage of the plaster layer is that its thickness is no more than necessary for the leveling itself,that is 2-3 centimeters. Plaster is relatively inexpensive, durable, with the observance of technology does not form cracks.

Plasterboard technology has a number of advantages:

- the ability to hide any flaws in the base ceiling;

- the presence of an interceiling space in which wires, pipes, air ducts can be placed;

- additional functions of the ceiling: the ability to arrange heat or sound insulation;

- any configuration of the lighting system in the room;

- minimum preparatory work;

- speed of installation;

- the ability to easily create a new, geometrically correct plane;

- lack of "wet" processes (all work is carried out in full purity);

- ready-to-use gypsum plaster coating needs only a thin layer of putty;

- different versions of the GKL: for wet rooms and with improved fire resistance;

- the creation of decorative solutions of two or more levels.

The main disadvantage is one, but very significant: the construction of profiles and sheets of ledgers will reduce the height of the room by at least 5 centimeters.

Sometimes there is information about special mastics, which can be used to glue sheets of CC directly onto a concrete base,but here you need to weigh the possible risks. It would be more correct to assume that there are no options for installing the gypsum board directly to the concrete ceiling. The only alternative is possible for owners of smooth ceiling surfaces made of wood, but even here it is better not to get down to business independently.

The owner of the room needs to decide how high the requirements are for the geometry of the plane. Further decisions depend on it.

The magnitude of all deviations from the plane can be divided into two groups:

- irregularities on a small (up to half a meter) area: hillocks or cavities, cracks, seams between the floor slabs;

- irregularities on a large scale (up to the entire ceiling area), including deviations from the horizon.

Defects of the first group are literally striking; if they are not eliminated, the look will come back to them again and again.

Defects of the second group are hardly noticeable, most often we do not guess about them. For example, the puttied surface may seem smooth, and only if you apply a two-meter or three-meter rule (rail), a gap of 2-3 centimeters (“pit”) is found or, conversely, a bulge (“belly”).A separate case is the deviation from the horizontal plane as a whole (different height of the walls). One corner of the ceiling and the wall (husk) can be 2-3 centimeters higher than the opposite. The eye does not distinguish such a deviation; it is detected using a special tool.

It is easy to cope with small flaws with the help of putty, in the worst case - with a small layer of plaster plaster. But to eliminate the irregularities of the second type, special mixtures are needed, a reinforcing (reinforcing) mesh device, and if there is a large deviation from the horizon, you will have to make a suspended structure. That is, labor needs to be applied much more.

How to prepare the surface?

Finishing decorative coating should be applied on a well-prepared surface.

Most often, the owners initially expect one of the options:

- concrete monolith: irregularities of the concrete itself, uncovered areas of rusty reinforcement, remnants of old putty, plaster, wallpaper, sometimes mold (bathroom) or grease (kitchen);

- the overlap of concrete slabs: all the same, plus deep joints and differences in height between the slabs, (up to 3-4 cm);

- wooden ceiling: boards or shingles.

For plaster and putty, the principle is simple - everything is removed, right down to pure concrete:

- The remains of the old putty, emulsion, wallpaper, twice moistened with an interval of one hour, then removed with a spatula.

- Plaster and loose elements are knocked down with a pick or a hammer.

- The seams between the plates are embroidered to the maximum depth.

- Oil paint is removed grinder with a wire nozzle (cord-brush). If there is no tool - make a high-quality notch with a chisel. Do not use chemical washes.

- Rusty stains are removed with a solution of highly diluted acid.

- Mold and fungus require careful treatment with antiseptics.

- The “penetrated” reinforcement is painted over with oil paint to prevent rust stains on the surface of the finish.

It is worth visiting a household chemicals store: there are special compounds for sale to remove old wallpaper, rust stains, fatty dirt. During the work it is necessary to apply means of protection: building glasses, gloves. For the grinder it would be good to find a casing with a pipe for a vacuum cleaner.

A dry cleaning is enough for a drywall ceiling: removing crumbling layers, sealing seams and large cracks.

Technologies and methods

Let us now try to imagine how time-consuming each method is.

Gypsum plasterboard

The construction of the ceiling of plasterboard sheets (GCR) is not a particularly difficult task, however, it requires careful familiarization with the norms and recommendations at each stage of work.

Along the perimeter of the room, guides, - profiles ud, are nailed at a given height. A grid is laid on the ceiling, on the lines of which hang suspensions. Ceiling profiles cd lead at a right angle to the rails, and then attached to the suspensions. To the profiles cd fasten sheets of drywall.

If it is necessary that the plane of the suspended ceiling is as close as possible to the real ceiling (this option is desirable if the goal is to preserve as much room height as possible), the task of the first marking stage is to transfer the level of the lowest point of the ceiling to all walls.

Working under the ceiling with a water level is inconvenient, so circular markings can be performed at the bottom and then transferred back to the top.

This is done in the following sequence:

- find the lowest point of the ceiling, transfer its level to any wall and make a mark;

- from the mark using the level and rules draw a vertical line down;

- on this line, approximately at eye height, make another mark. Measure and record the resulting distance between the lower and upper marks;

- using the water level transfer the height of the lower mark on all the walls of the room. At least from each of the two sides of the corners between the walls should be on the mark;

- from each received mark measure vertically upwards the distance that was recorded;

- According to the found marks, the dyeing construction cord repels the line along the perimeter.

Of course, having a laser level, one could not do all this, but such a special tool is, in the main, only among builders.

When the level of the lowest point of the ceiling is transferred to all walls, at this level, along the whole perimeter, profile guides ud are mounted. Their upper side is set at the level of the broken line. To fix the ud-profile, holes are drilled in them with a puncher in steps of 45-50 cm and hammer dowel-nails.

The length of the ceiling cd profiles should be equal to the width of the room (or the length, if they will go along), minus about 5 mm.Profile cut grinder, metal shears or hacksaw. Ready-made cd-profiles are slid into guides on two opposite walls, set at a right angle and fastened with self-tapping screws (or, in common parlance, “flea”). Ceiling profiles have exactly the same distance - either 60 or 40 centimeters. In this case, the joints of drywall sheets will fall on the profile.

At this stage, the frame is made of ceiling profiles parallel to each other. Now, over each profile with a pitch of 50-60 centimeters, mounting plates-suspensions (U-shaped brackets) are screwed or nailed to the ceiling base. They will give the whole structure rigidity and the ability to retain the total weight of the sheets GK.

Before attaching cd profiles to suspensions, they must be aligned exactly in one plane. This problem is solved quite simply: in the middle of the room, across the profiles, a strong silk thread is pulled and fastened to the ud-guides. The profile is above the thread; it is raised just enough to form a millimeter gap, and then fixed with screws to the suspension, first on one side, then on the other.You need to make sure that the other profile does not touch the thread at this time and does not knock down the markup.

By the time of installation sheets of drywall should lie in the room for several days. It now remains to fasten them with screws to the finished frame.

Thus, you can also repair sagging ceiling in a private house or apartment.

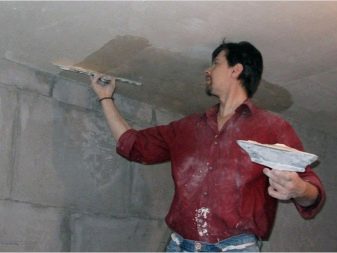

Stucco

After cleaning the base and sealing the seams proceed to the alignment of the plaster mixture.

It includes a number of operations:

- Padding. Plastering of concrete ceilings is never performed without prior surface treatment. On a clean, dried base put one of the special primers such as Betonkontakt. This mixture not only serves as a deep penetration primer, but also covers the surface with a layer of particles that provide a strong bond with the plaster layer. (To the touch such a rough surface resembles emery).

- The device beacons. The lighthouse is a special metal profile with perforations along the edges and a flat edge in the middle. Its length is 3 meters, and the “height” has a pitch: there are beacons 8, 10 millimeters or more. The greater the height of the lighthouse, the thicker the plaster layer will turn out.For the ceiling it is better to buy beacons with a height of 6 mm.

Lighthouses are laid on the level and “freeze” the solution. When the painter leads the rule in two beacons, the excess solution is cut off and a flat surface remains. By showing patience when installing beacons, you can then plaster the surface of any area with an accuracy of one to two millimeters.

Lighthouses set parallel to each other. With the help of construction cord beat off a line parallel to the wall. The distance to the wall is about 30 cm. Further they are guided by the length of the existing rule: for a two-meter instrument the distance between the beacons can be taken 160-180 cm.

It is necessary to calculate that the distance from the opposite wall should not exceed this.

Lighthouses expose, using the water level. Hang up the whole plane. At the lowest point they drill a hole for the dowel and screw in the screw, leaving 6 mm on the surface. Then on the marked line they find another point, screw in the screw, and, controlling the level, twist it just enough so that the caps of both are on the same level. Then, advancing along the line, they screw in the third level, and so on. 2-3 screws are screwed on two meters.At the end of the work, screws are installed on all lines, so that all their caps are on the same level. After that put on the line a little plaster, put a beacon and sink it with the rule, until it rests against the caps of the screws. In this position, it should remain until the solution reliably grabs it. The accuracy of the installation is rechecked many times, as the success of the whole business depends on it. Installed beacons leave to dry until the next day.

- Add a solution. Professionals believe that it is better to throw a plaster mix, but for a beginner it is quite suitable to spread it with a spatula. The solution is applied between two lighthouses, and then they usually follow the lighthouses, removing the excess. When finished, they go not to the next lane, but through one. When the solution is dry, fill the remaining strips.

Plastering on beacons allows you to bring a fairly flat surface at a time. For the next layer, a more liquid solution is prepared, and this time the rules are leveled with circular movements or rubbed with a scraper. After drying, such a surface is ready for finishing puttying or for pasting with dense wallpaper.

- Reinforcement. If a plaster layer thickness of more than 2 cm is required, it is necessary to use reinforcement with special nets (made of fiberglass, plastic, galvanized steel, etc.). When applying the first layer, the mesh is “ground” to the base, in other cases it is screwed with screws. If the thickness should be 4 or more centimeters, another mesh is laid between the layers.

Putty

To avoid further cracking, the seams between the plates at the preparatory stage are filled with one of the special elastic compositions.

Thicker layers causing starting putty. The finish layer should not exceed 2 mm.

If the putty is made in two layers, a fine-meshed mesh (“cobweb”) is rubbed between the layers. Seal the seams with putty can be perfectly smooth. The main thing - the lack of dirt in the seams.

Tips

- If there is no rule or good slats, you can use a drywall profile.

- Aluminum beacons can not be removed after the plaster, as they are not subject to corrosion.

- Liquid expensive paint is better to take in stores, because in the markets you can buy a fake.

- If you set the beacons not across, but along the slabs, you can reduce the consumption of plaster.But this should be done only if the geometry of the plane of the ceiling is clear, otherwise the savings can result in losses.

- Cement-based plaster mixes are often cheaper than plaster. However, it is enough to recalculate taking into account the material consumption, as it becomes obvious: their price is almost the same. In this case, gypsum is considered more environmentally friendly and suitable for housing material.

If the last layer to perform the finishing plaster putty, it will greatly facilitate the gluing of light wallpaper or painting with white paint.

- To calculate the number of drywall sheets and profiles, it is convenient to draw a picture, noting all the details.

- For marking it is better to buy a black thread, as it can be better seen.

- If the guides ud-profiles in the "Khrushchev" lay on special gaskets, it adds insulating properties to the ceiling.

- You can not use acrylic primers for gypsum plasterboard, this leads to a violation of the structure of the sheet.

- Priming compositions with "filler" need to be stirred from time to time so that the heavy particles do not remain at the bottom.

Putting the curve of the ceiling is necessary quickly in order to obtain a complete ceiling leaf as a result of the repair.

How to level the ceiling with plaster, see the following video.