WPC siding: advantages and disadvantages

Wood-polymer composite, also called "liquid wood" - a new product on the market of building materials. Its properties are a unique combination of the best qualities of natural wood and polymer plastic. This material has positive feedback and is perfect for covering the house.

Special features

The main components in the process of creating the WPC siding are sawdust and various wastes of the woodworking industry thoroughly milled to a dusty fraction. They constitute about 60-80 percent of the total mass of the wood-polymer composite.

The polymer component is represented by natural and synthetic thermoplastic materials and their derivatives. The percentage of polymers varies depending on the specific type of WPC siding. Pigmenting ingredients are responsible for the uniform color of products and their resistance to UV rays.

Reinforcing modifiers are added when creating a specific type of product in order to improve performance in a particular environment, for example, with increased water or frost resistance.

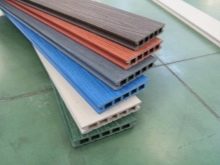

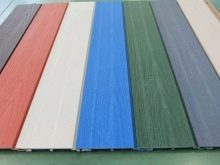

According to the release form, WPC finishing materials are presented in various versions: slats, boards, panels, terrace boards, etc.

From an aesthetic point of view, the texture of wood-polymer canvases almost indistinguishably imitates natural wood and at the same time offers an extensive selection of color performance.

The most popular panels made in the color of natural wood. To distinguish the texture of such siding and natural wood is possible only with careful and detailed examination. The wasteless production of panels from wood-polymer composite will delight all supporters of environmental protection.

Positive and negative qualities

WPC Siding Coating combines all the best properties of wood and polymeric materials.At the same time, standard material deficiencies are compensated both by composite use of two components, and by additional synthetic substances that make up the panels.

The main advantages of wood-polymer composite are.

- Ease of processing. The material inherited from the wood component is the ability to be easily processed, for example, by cutting, planing or grinding, it can be mounted with nails or self-tapping screws.

- Good thermal conductivity. This indicator is slightly inferior to natural wood, but exceeds the corresponding parameter of the remaining facade finishing materials.

- High noise insulation. Panels made of wood-polymer composite, due to the dense structure of the WPC significantly reduce the sound coming from the street.

- Excellent moisture resistance. Unlike natural wood, KDP is not afraid of water, does not swell, does not "lead" it. A high rate of waterproofing is provided by polymeric compounds that are part of the siding.

- Fireproof. Despite the combustibility of wood material and plastic polymers, special substances make KVA non-combustible.Panels can smolder, but they will not burn with fire.

- Temperature stability. The siding structure, even at extremely low (up to -60 ° C) and very high (up to + 90 ° C) temperatures, does not deform and does not lose its positive qualities.

- Biological inertness. The material of the WPC panels is not suitable for food for insects and rodents, aggressive microorganisms such as mold fungi do not multiply on its surface, it is not destroyed by oxidation.

- Resistant to sunlight. UV rays do not destroy the structure of the material, and infrared radiation does not lead to a fast fading of the siding color. In cheap versions of WPC panels based on polyethylene, this quality is absent, as a result, the coating quickly loses a pleasant appearance. Qualitative

- Products begin to fade with time and evenly over the entire area of the lining.

- Ecological composition. Does not contain toxic compounds, composite microparticles do not cause allergic reactions.

- Aesthetic quality. Wood-polymer products look great, completely imitating the texture of natural wood. The minimum dimensions of the joints are practically invisible and create a feeling of solidity of the finish.The surface, due to the processing of fire retardants, is very smooth.

- Durable structure. WPC well tolerates mechanical effects on pressure and shock, as well as vibration.

- Easy handling. Panels do not need special care, they do not need to be painted, polished or looped.

- Durability. Under optimal operating conditions wood-polymer coating will last from 10 to 25 years.

The disadvantages of the WPC can be counted:

- Cost High-quality panels will cost dearly, and cheap will not please long life.

- Small selection of product shapes. This minus can be called conditional. Although WPC siding is made in approximately the same format, due to its peculiarity, it can be easily compensated for processing partially.

- Prone to scratching. Despite the high strength of the wood-polymer composite, which withstands pressures up to 500 kg / m2, under the mechanical influence its surface easily acquires scratches and scuffs.

- Difficult installation. The cladding technology of wood-polymer panels is similar to that of other types of finishing materials, but it also requires knowledge and skills.Self-installation is likely to lead to material damage.

Kinds

There are several variants of wood-polymer panels for facade wall finishing.

The main difference is the shape, composition of the material, as well as appearance.

- "Nut".Panel dimensions: 2 × 16.5 × 400 cm with a face thickness of 0.6 cm. Siding stands out for its embossed texture, in the color plan is represented by brown color and its shades.

- Lwn.Overall dimensions of the product: 1.4 cm × 13 × 300 cm. The expensive quality option on the market is represented by various textural designs, including ones imitating wood, and colors ranging from dark to light tones.

- "Molded from KDP with embossed." The size of siding panels: 1.6 cm × 14.2 cm × 400 cm, the thickness of the edges is 0.4 cm. The texture of the panels is made in the form of embossing under a tree, a wide choice of colors.

- "Folk". The size of the siding is 1.6 cm × 4.2 cm × 400 cm with a thickness of 0.4 cm. This type is distinguished by enhanced insulating properties and enhanced noise insulation, and the certificate confirms the absolute environmental friendliness of the composition. In the color range, the products are presented in black, brown and terracotta colors with a textured surface.

- "Block house". The standard dimensions of the panels are 6.2 × 15 × 300 cm; dimensions may vary depending on the specific manufacturer. It is used for finishing ventilated facade walls. The texture of the products imitates a wooden bar, color performance in a wide range from light sand to dark shades of brown. Produced in compliance with European quality standards.

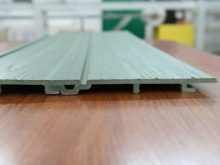

- Laminated KDP with embossed. The surface texture imitates the wood texture, visually resembles a standard lining of several large sizes. Mounted on the wall by vertical or horizontal method using mounting clips.

The main criteria for the selection of WPC siding

To choose a suitable product, you should consider several factors in order of their importance:

- Manufacturer. The established manufacturers of quality panels include brands: DeckMayer, Legro, Tardex.

- Polymer component. Despite the fact that its percentage is significantly less than wood chips, it is he who determines the basic qualities of WPC panels. If polyethylene is used, the price of such a product will be significantly lower, however, and operational properties are worse.If PVC is used, the guaranteed high price is accompanied by excellent characteristics.

- Individual product specifics. Wood-polymer siding is very similar to each other, however, for example, the presence of an air pocket in the construction of the panel significantly enhances the heat and sound insulation. When selecting a finishing material, pay attention to details.

- Cost Cheap options are outwardly indistinguishable from the quality ones, however, the period of their use is much shorter, and over time, the deterioration of the operational and aesthetic qualities of the siding panels is likely.

The question of choosing WPC panels with a large number of positive qualities, rests on the understanding of the main source of their advantages.

See below for installation tips for siding.