What should be the floor in the hen house and what is best to choose?

Many people, having received their plot of land far from urban new buildings, are enthusiastically accepted to build not only greenhouses for their own vegetables, but also premises for breeding domestic chickens. And at first such owners have a huge number of questions on construction. One of such important questions is what should be the floors in these rooms, and if there are options, which one is better suited for specific conditions.

Features and types

Ideally, the chicken coop should be built taking into account its heating during the cold season. In order for chickens to have good productivity, they need not only complete feed, but also good housing conditions. The temperature in the room where they are kept should not fall below +10 degrees. If this temperature norm is not ensured, then the bird begins to ache from hypothermia, ceases to carry eggs and gain weight. Inflammation of the lungs is one of the most common diseases among chickens, leading to the loss of livestock, and in severe frosts they often freeze their legs. Of course, this cannot be allowed.

Regardless of what is the room, which is determined to keep the birds, the device floor in it is the primary task of the owner. The floor in the hen house must be equipped even before the planned number of hens are placed in it. Its reliability from the penetration of predators, moisture and cold from the outside is a prerequisite for the successful management of its own poultry industry.

Most often in chicken coops equip these types of floors:

- earthen, characterized by low costs and major shortcomings;

- concrete, well protecting the bird from uninvited predators, but poorly saves heat;

- wooden, the most eco-friendly, but also, unfortunately, the most fire hazardous.

Of all these types of wood, the best flooring material is the best, and the lowest cost is ground (earth floor).Concrete coating requires material costs not only for the work with concrete itself, but also for those activities that will be aimed at eliminating the main drawback of such floors - the rapid heat loss in inclement summer and its complete absence during all remaining seasons. But let's talk about all this a little later.

Coverage selection

Every owner who decides to start laying hens on his farm is free to choose the floor covering in the hen house for his own reasons. But he can not ignore the unshakable requirements for floors in such premises, depending on the following factors:

- climatic zone of residence;

- depth of groundwater;

- soil type in the area;

- the presence of predators.

For too harsh climate areas of the North and Western Siberia, where in winter frosts often reach the mark of -40 degrees Celsius, earth or concrete floors will not do. On such floors without heating, the bird has no chance of surviving. Therefore, for the owner there are no other options for choosing the floor, except for wooden or concrete with the obligatory heating of the room.

The earthen floor is not suitable for those areas of residence where there are many predators, loose soil and close groundwater storage.In the rainy season, an earthen coop in the area of close groundwater is at risk of being flooded, and this state of affairs may be good enough for a waterfowl, to which the chicken has nothing to do. The wooden floor is also poorly suited to a chicken coop in damp areas - in conditions of high humidity, it quickly rots and becomes covered with fungal growths.

Concrete coating well protects the house from rodents and predators. And if a waterproofing gasket is laid under the concrete (thick polyethylene film in several layers, roofing material or roofing with bitumen filling), neither soil moisture nor ground water will penetrate into such a room. In the southern regions, such a floor is no less good for a poultry house, just like a wooden one. But in wet areas it has all the advantages over other coatings.

In the dry climatic zones, the cheapest option of the floor is earthen. It doesn’t cost much, but in case of loose soils it must be strengthened by paving and pressing the clay layer on top. Clay well holds moisture and creates a fairly dense upper layer of the coating.It is recommended not to arrange such floors in forest areas, where there is a large number of animals that love to hunt both eggs and birds themselves.

When all other conditions are equal or suitable, choosing the material for a floor device in a hen house should be guided by the following requirements:

- safety (from water, fire, predators, diseases from cold or heat, traumatic factors);

- moisture resistance (does not decay, does not freeze through, there is no fungus);

- strength (does not collapse, does not limp, is inaccessible to predators);

- low thermal conductivity (keeps temperature well);

- environmental friendliness (does not harm the bird, does not emit harmful odors).

How to do it yourself?

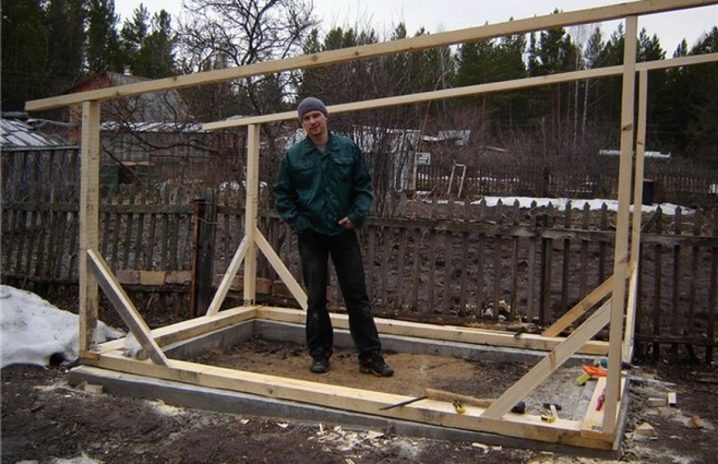

Floor installation should be carried out after the erection of the poultry house walls. And since wooden and concrete floors require a foundation, this circumstance should be taken into account before the construction of the chicken coop. Of course, if the choice of the owner was made in favor of one of these types of sex. If under the chicken coop is planned to use the finished premises, in this case, the foundation will need to be embedded in it. It is possible to use the existing basement under the premises, but this is not always feasible.Besides, it is not known what loads the old foundation was calculated on, and whether it can be a reliable support for the entire building after the alterations.

For a wooden floor, the foundation may be of a light type, for example, columnar or tape with a shallow fill. But it is preferable, for economic reasons, to arrange all the same column foundation for such a structure as a chicken coop. It is made by the method of brickwork on a solid foundation or by drilling (digging) narrow holes to a depth exceeding the depth of soil freezing in the area. Dug out or drilled holes are used as nests into which you can insert scraps of metal pipes with a diameter of about 200 mm, and then fill their internal cavity with concrete. This will result in a sort of reinforced concrete pillars on which wooden logs are laid around the perimeter and at the intersection of the chicken coop partitions.

If there are no pipes in the farm, it is possible to arrange a column formwork in the shape of a square measuring 200x200 mm in each pit with the help of boards.and then also fill them with concrete. It is important that the foundation pillars be at the same height on the horizon and rise above the ground level by 25-30 cm. This applies to pipes and wooden formwork.If the pillars are made without pipes, then you need to remember to reinforce the concrete casting with metal reinforcement (or with simple rods of wire with a diameter of 5 or 6 mm). The pillars will be a fairly solid foundation for subsequent construction, therefore, it is sufficient to distribute them at a distance of 3 meters from each other along the entire perimeter, with the obligatory consideration of opposing supports on either side.

For very small buildings with a planned population of laying hens up to 15-20 pieces, it will be enough to lay columns of bricks in 3-4 rows (3 bricks in a row). It is advisable to pour concrete with a base with a small depth (10-15 cm) into the ground under each brick pillar. Such pillars are installed more often - about every meter. You can meet other recommendations (every 50-60 cm), but this is too often for such a light construction.

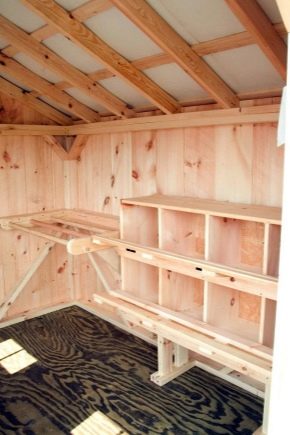

Further work on the device of wooden floors are made according to a strict algorithm.

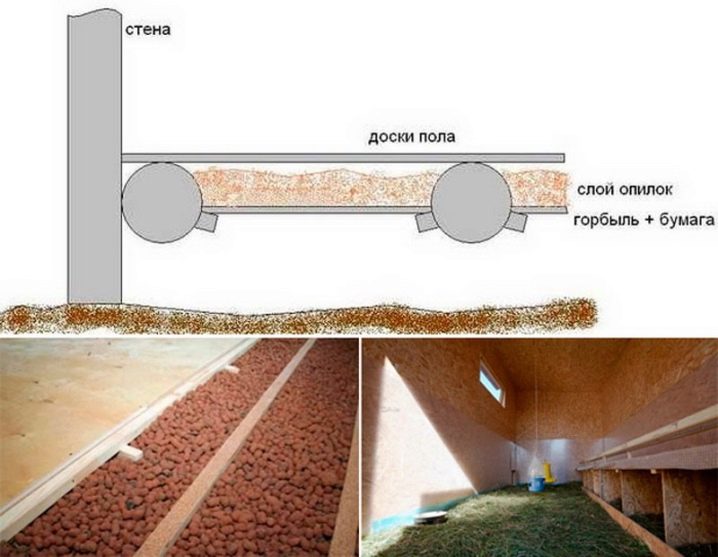

- On the foundation pillars, parallel to the supporting bars are 200x200 mm in size. A waterproofing material is laid between the surface of the pillars and the bars (ruberoid, for example). It is recommended to withstand a slight slope of support bars on one side in order to facilitate later the process of cleaning the room.

- Perpendicular to them, the lags, which are 100x100 mm in size, are laid perpendicular to them with a step of 50 cm.

- Lags and support bars are fastened to each other with a hammer and long nails. For fixing reliability, you can use metal corners as fasteners. The level adjusted according to horizontal lag.

- At the bottom of the lag on the entire area of the chicken coop, you can fix a metal grid, which will be the base of the structure. The space between the lags in the presence of the grid can be filled with insulation (mineral wool, for example, or expanded clay). The mesh will hold insulation under the condition of additional tension. But this operation can not be performed, it is not mandatory.

- Start laying boards perpendicular to the lags. Boards must be of the same thickness - not less than 25 mm. In addition, they are cut to such length that the joint falls in the center of the lag.

- Beat the boards to the logs at a slightly angle.

- When the floor is completely covered, it should be treated against dampness, and a little later - with lime mortar from pests.

For a concrete floor, it is better to make a strip foundation with a pouring depth of 30-40 cm. The height of the ridge above the ground is the same 25-30 cm as with the columnar foundation.

When the concrete completely hardens, it will be possible to take over the floor.

- Level the ground inside the foundation and tamp it.

- Make a small layer of sand (2 cm).

- Cover 3-4 cm with a layer of rubble or large pebbles.

- Tamper a layer of rubble and lay a waterproofing material (film in two layers, roofing material, roofing felt) over it with the edges removed to the foundation.

- Fill the floor area with concrete from a mixture of cement and sand in the ratio of 1: 4 with the addition of water to a liquid state.

- Smooth the surface of the pouring with a special wooden leveler and leave it for at least 7 days until the concrete is fully grasped.

Ground floor is arranged as follows:

- the area is cleared of debris and vegetation, leveled;

- the ground is thoroughly compacted (for this purpose, an improvised device can be made on the basis of a sawn wood block with a wooden bar handle nailed to it);

- top and fill the layer of clay with a thickness of 10 cm;

- Optionally, lay the roofing material in 2 layers or moisture-resistant non-slip linoleum.

How to warm?

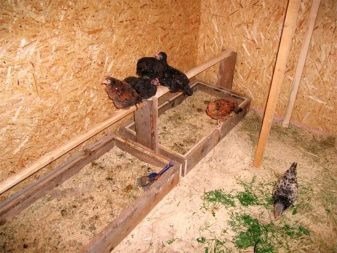

For the insulation of floors in the hen house, organic litter materials are more often used: straw, hay, sawdust, moss.These components of the litter are used not only separately, but also in a mixed form. For example, sawdust is never used for this purpose in its pure form, wood shavings serve as a mandatory addition to it. In some frosty cases, peat or moss is added to them, and in addition this mixture is covered with straw.

Moss peat is an excellent material for warming floors in chicken coops. In addition to warming, it is able to absorb unpleasant odors in the room and has antiseptic properties. Such a moss, spread in a chicken coop in the winter, saves the hens' feet from freezing.

The litter on the floor in the chicken coop sometimes reaches a thickness of 30 cm. Due to the organic litter, the temperature in the poultry housing is kept at 23-25 degrees even on frosty days. No additional heating is required. The thing is that in such a litter, under the influence of bird droppings, the processes of decomposition of organic substances occur, accompanied by an increase in temperature in this layer.

The main thing is to change the old litter in time, which loses its heat-saving capacity, for a fresh portion of organic matter, ready to “work” on heating the room. Usually the litter is replaced with fresh one every 2 months.It should be noted that poultry specialists do not recommend the use of mineral substances, such as mineral wool or wall insulation materials made of chemical materials, that can emit unpleasant odors when heated as insulators for poultry houses.

Reviews and advice of professionals

According to the feedback from the poultry farmers with experience, it becomes obvious that the sympathy prevails in the arrangement in private poultry farming of chicken coops with wooden floors. This is understandable: people want to eat an environmentally friendly product and therefore try to provide their hens with a natural habitat. Some people on this occasion believe that it is better to spend an extra one hundred thousand rubles on good products from their layers, than to give four times more to pay for the treatment of the gastrointestinal tract poisoned by chemical eggs and meat of artificial chickens.

But for now, according to statistics, in our village they live and act in the old manner: the little pig sleeps in his dung, and the chickens dig holes in the dirt floor of their chicken coop. Farming in the poultry industry is more committed to a decent maintenance of its livestock, but such farms are still very, very few per capita.We'll have to take on this business ourselves to eat real eggs with a yellow yolk and chicken meat, which is cooked for 3 hours instead of half an hour, which turns the chicken from the chicken farm into dust.

Starting the choice of floors for your own chicken coop, you need to listen to some useful tips.

- After laying wooden floors in the poultry house, as well as major cleaning in it, the tree should be treated against moisture and fungus again.

- In arranging a chicken coop, do not forget about such a useful thing as room ventilation. The absence of air exchange in the hen house will certainly lead to the formation of condensate on all surfaces, rotting and destruction of structural elements, diseases of the bird.

- If earlier in the house was a concrete floor, then the best solution would be to put a wooden one on top of it.

- For the maintenance of birds in the summer only enough to build a temporary building with a dirt floor.

How to make the floor in the hen house with your own hands, see the next video.