The details of building a barn of OSB-plate

Supplement the house with various buildings - a very important part in the arrangement of any cottage or auxiliary property. But auxiliary facilities have long demanded not only reliability and durability; aesthetic parameters are now crucial in their evaluation. This requirement fully applies to sheds, to economic blocks.

Special features

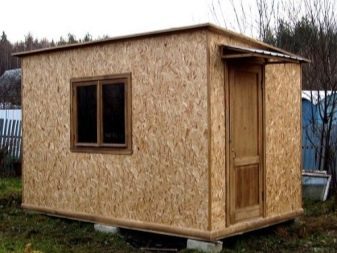

An increasing part of the developers, creating a barn with their own hands, sheathes it using OSB-plates. Awkward padding, as well as painted sheet iron, already look archaic against this background. Oriented plate is affordable and easy to use. Wall lathing is made only after the roofing is completed.However, only after the final wall finishing comes the turn of the installation of doors, windows and so on.

Design and placement

First of all, you should decide whether the barn will stand apart, or it will be adjacent to the house.

In either case, it can be built in approximately the same time, but there are other considerations:

- land should be given the least valuable for growing fruit and for ornamental plants plot of land;

- best of all, if it will be possible not only to approach, but also to drive up to the ancillary building;

- It is recommended to choose a point where it is easiest to get to the house, and to any place in the garden (garden), and to the gate at the same time.

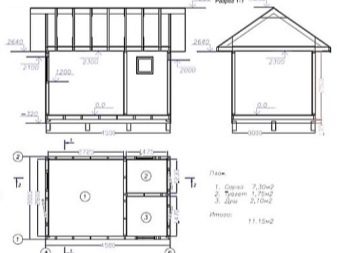

Despite the seeming simplicity of the work to be done, it is not worth doing light outbuildings without drawings. The point is not only that there may be poor visual characteristics. It is a drawing, or at least a sketch, that is crucial for choosing the right place and for estimating suitable sizes, as well as for calculating the total material requirement.

Important: it is necessary first to draw up a general plan of the territory, existing and planned development,and only then start drawing up more private projects.

This will avoid many ridiculous incidents, often overtaking inexperienced builders.

Performance of work

In any case, the step-by-step instruction prescribes first clearing the site and leveling it up to perfect hydraulic readings. It is categorically unacceptable to leave bushes and even grass or single roots. The easiest way to make the foundation itself is to use ready-made blocks. They are laid out on the perimeter. The alternative is a pillar base, here you will have to dig holes and, after filling the sand cushion, put the same constructions inside vertically.

Another way is to pour the concrete solution, which, when frozen, turns into an excellent base.

The next steps in the construction will be:

- assembly of the lower trim;

- treatment with antiseptic;

- flooring of boards that are protected from the occurrence of rot;

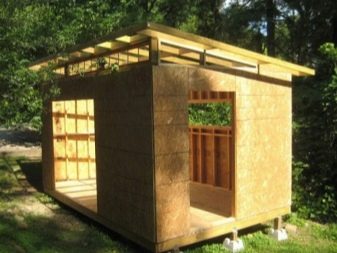

- mounting the original frame stand and fixing it on a metal corner;

- attaching the temporary strut for greater rigidity;

- fastening sheet OSB;

- repetition of the same manipulation with other racks.

When all this is completed, you only need to paint the walls and make the threshold. It is recommended to fasten the sheets to the bottom line of the frame with a space of 50 mm. It is achieved by adding the required height to the initial strapping of the bar. After the sheet resting against this part is fixed, it can be moved to another place and the procedure repeated. The most rational size for the barn - 3x6 m; less impractical, and to increase the area additionally required is not for everyone.

Recommendations

If the foundation is poured using formwork, it is enough that it protrudes by 20-30 cm. Rebar should be inserted into the cushion of a mixture of sand and gravel before pouring concrete. The roof is almost always made shed, more complex options are needed in extremely rare situations.

The distance between the parts of the truss complex is ideally 60-80 cm, and accordingly the number of truss legs is calculated.

Coating the roof with galvanized steel eliminates the crates. Layout of sheets should be made with an overlap. If it is decided not to sheathe the outside with wall siding, but apply a trim board recommended overlap is 2.5 cm.This avoids the occurrence of cracks in the subsequent drying and shrinkage of the material; paint is most often applied to the finishing elements before plating. When designing, one should not forget about the normative distance to other buildings, to neighboring fences and to public roads. For the formation of floors used boards with a thickness of 4 cm, not having grooves.

Warming the floor is often mineral wool. Packing is conducted from the wall to the entrance. If possible, have a barn in the backyard where it will not spoil the view. The location of the entrance should be as free and easily accessible as it is easy to use. The best places are located on elevated sites, and raising the barn above the ground, you can additionally protect it from corrosion and rotting; it is advisable to immediately design everything so that there is no need for an extension.

On how to build a barn of OSB-plate with your own hands, you can learn from the video.