How to build a barn of pallets?

A country or town house is wonderful, even beautiful. But no achievement of architecture and design, no accomplishment do not allow to cancel the fact that the outbuildings must be prepared. Sometimes only original materials and structures can be used for their construction.

Special features

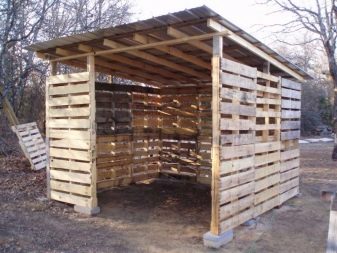

Almost every homeowner can build a shed of pallets with their own hands. Wooden pallets are already used in the manufacture of tables and sofas, beds and flower beds, but there are all possibilities for more serious construction. Theoretically, these structures are not intended for construction work, and externally the structure does not look too solid. However, for simple business purposes, such a solution is quite acceptable, especially considering the minimum costs.

There is no need to buy pallets themselves, they are simply thrown away after the completion of major construction projects, money must be paid for:

- nuts;

- self-tapping screws;

- other fasteners;

- boards;

- roofing products and some other elements.

A typical pallet is 120 cm long, 80 cm wide. Parts placed in the very first row are to be mounted on block supports. They are recommended to be cast from concrete. Since wood elements are used for work, it is necessary to take care of their protection from rotting, from ignition. It is very important to immediately calculate the need for the material used and take into account all the design features of the barn.

Sequence of work

Performing the work step by step, after the formation of the foundation you need to attach the pallets to each other using bolts, drill holes in mutually transverse planks. Through these holes, the blocks are bolted. Accurately select the mount is possible only when considering the design of the pallet. The second row is fastened not only among themselves, but also with the blocks placed in the first line. By calculating the required slope of the roof, you can make a shed roof as reliably as possible, eliminating negative incidents.

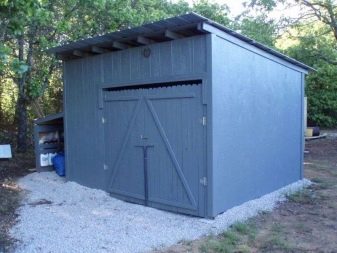

Crate under the roof is made of boards, and on top of them it is permissible to use any kind of roofing material. Most people choose profile metal sheets, because they are mounted simply and without any problems. Next comes the turn of painting, manufacturing and installation of the gate. After that, sometimes the building is painted again. At this work on the preparation of the barn end, and you can already master it, use it.

Recommendations for construction

In most cases, the foundation is formed from typical concrete blocks. They should be poured on the same level, placing them according to the width of the pallet. Then the load level in any part of the circuit will be uniform. The size of the bolts for connecting the pallets is determined individually, focusing on the thickness of the main beam. To tie the tiers, you need to twist them with the same bolts (2 pieces on each side). The front part of the barn is equipped with an insert intended for rafters, so the slope to the rear side is simplified.

Attention: for the formation of the roof it is permissible to use the same pallets or boards with dimensions of 2.5x10 cm. Among the roofing sheets of metal, preference should be given to galvanized options. They reflect the sun's rays well and help to make the atmosphere cooler even on the hottest days. It is possible to increase the resistance of the chipboard to the effects of moisture by covering it outside with oil paints. This is the case when the shortcomings of such materials are not too significant.

For decorative covering of the outbuilding of wooden pallets, you can use chipboard. It is undesirable to use already painted pallets. After all, it is impossible to guarantee that the previously applied paint of unknown composition will be safe for health. Self-painting all surfaces, homeowners save themselves from such a problem in principle. For the same reason, it is advisable to abandon pallets, which are marked with the abbreviations IPPC or IPPS.

Such designations indicate that the material was subjected to sophisticated processing with special reagents. So, by definition, not among the safe for humans. Caution should also be taken when using pallets that had previously been used elsewhere.After all, when used on the market, at an industrial enterprise or at a transport hub, wood easily absorbs extraneous odors. To eliminate them is almost impossible: it will take months and even years to put up with sharp flavors.

Standard instructions for the construction of a barn to give can not ignore the fact that it is very important to choose the right place. For obvious reasons, the storage of tools, firewood and similar objects should not be placed in the most visible place. But to distance it from the house, from the entrance to the site is also impractical. The most rational will be the placement of outbuildings at the same distance from all important places or directly behind the house.

It is undesirable to build a shed in a valley or even in a groove in the middle of a hill. This may result in flooding due to precipitation or snow melting. To realize the plan, pallets will have to be cleaned. The best way to do this is with a hard-haired brush that helps to remove all dirt and dust. It is more difficult to disassemble pallets with a nail puller than to cut them, but it helps to ensure the integrity of the material.

For your information: if twisted nails are included in the design of the pallets, it will not work to remove them with a nail puller. We'll have to cut problematic fasteners with a grinder.

Installation of the tape base with shallow deepening is very simple. The desired site is covered in layers of sand and gravel, after which the concrete is poured. Dismantling of formwork is allowed 14 days after casting.

You can attach the corner posts to the front trim:

- metal corners;

- dowels;

- self-tapping screws.

Lags on the floor are tied to the strapping in the same way, and boards are fastened to them from above, using nails 150 - 200 mm long. The flooring is formed only in the case when the initial concrete floor does not suit the owners. It does not matter which side to start building the barn. The doorway should be formed before laying the second line of pallets. Ceiling overlap is made mainly of timber with a section of 100x100 mm, which is fixed along the perimeter.

The roof of the shed of pallets, as usual, should be equipped with a layer of waterproofing. It is made using roofing material or on the basis of a special film. It is allowed to cover the roof not only with sheet iron, but also with slate, and with any other not too heavy material.Interesting ideas when building a barn from a pallet are very diverse, but all of them need to be carefully considered. It is not necessary to limit yourself only to the selection of attractive colors.

The combination of a shed with a small greenhouse becomes quite rational. Such a solution is especially good when there is enough space on the site, you need to keep a few inventory, and you can’t find a better place for it. Snow-white exterior shed is not recommended, because caring for him will be too complicated. You should always carefully monitor that the appearance and the interior match each other. Lilac and other pastel colors are comparatively little dirty, and at the same time bring joy to the owners of the site.

How to wash a shed of pallets, see the following video.