Metal barn: types and features of construction

An outbuilding is an integral part of any backyard. It serves as a repository for things that have no place in the living room. When we farm, we use garden tools, lawn mowers, water hoses. When building a house, you need to put tools and building materials from the rain somewhere. For the winter to clean garden furniture and details of the barbecue. The garage does not always have a place to store bicycles, boats, baby strollers. All these economic issues are solved by an ordinary barn - a covered room for storage of various property. In the barn you can also arrange a small workshop, store hay, firewood, seedlings and feed for domestic animals, if any.

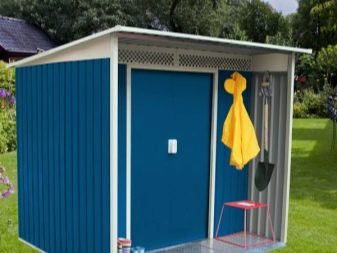

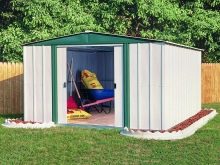

The construction of the building does not take much time and does not require any special skills of the construction business. If you wish, you can do it yourself, or you can purchase a ready-made design. The last option is good because the sheds from the manufacturers can be chosen for every taste - the material, color and shape of the structure, taking into account the style direction of your country house and landscape design. Today, metal sheds are especially popular due to their durability, ease of installation and durability.

Special features

The functions of an outbuilding are reduced to preserving things from precipitation, as well as ensuring order for each thing to have its own place.

Of great importance and the strength of the building. The roof must withstand the heaviness of snow and winter winds, and walls and doors must protect property from intruders.

These qualities are fully met by modern metal boxes, having an attractive appearance as a bonus.

- In comparison with analogs from a tree, the galvanized sheets of metal used in modern designs do not rot and do not pass moisture. This will keep things in the barn all year round, without worrying about the formation of mold or rust on the details of sports and agricultural machinery.This also implies that the metal shed can also be used as a compact garage for motorcycles or mopeds.

- In front of plastic boxes, a metal shed also has a number of advantages. The structure is installed on the surface of the earth, which means that it will be exposed to the active influence of the sun in summer and low temperatures in winter. Not every plastic sheet can withstand such loads. Plastic can be deformed from overheating, lose color in the most inappropriate places for appearance. Plastic products are very sensitive to low temperatures, especially since the shed is a hollow container, and not just cladding panels on the facade. Everything else quality plastic is quite expensive. For metal sheds such problems do not exist: the metal transfers any frosts, is not deformed into heat, and metal sheets have a reasonable price. If desired, such a metal structure can be made by hand.

- A serious rival of metal sheds in terms of quality and reliability are concrete and brick outfits, but their construction is a rather laborious process.A shed of bricks and concrete will be built according to the technology of a small house, starting with the development of the project and pouring the foundation. This is a durable capital construction.

Kinds

A variety of models offered allows you to choose the barn that is right for you in size and shape, but in design they can be of two types.

The difference is determined by the way the connections of the units of the hozbloka.

- Mobile. Collapsible boxes are assembled as a designer with fasteners, grooves and fittings. They are easy to install, if necessary, such a barn can be dismantled and moved to another place of the site. Prefab shed is convenient for those who have not yet decided on its permanent location. For example, in the process of building a house, the final version of landscape design has not yet been determined, and a place to store things, tools and materials is already needed.

- Stationary. The welded structure is mounted by welding the frame elements. It is more reliable, will last for many years, but it is not possible to disassemble and transfer it entirely. For this reason, welded frames are installed on a preselected place, taking into account the location ofbuildings on the site. This may be a detached barn, and a common frame with a summer kitchen, a shower compartment or a garage. Welded structures can be made by hand with a welding machine, the necessary materials and a little experience.

Location selection

It is advisable to plan a place to install a shed, taking into account some important nuances. This applies primarily to stationary buildings, and for a temporary prefabricated structure it is important that it is convenient to use, it does not block the light, passages, does not spoil the design of the site and is not itself exposed to negative environmental influences.

- The finished prefabricated structures have an attractive appearance, so it is not necessary to hide them in the far corner of the plot or behind the house. You can choose a color that matches the color that will harmonize with the whole dacha ensemble.

- Access to the barn should be easy. Roll out the cart, unwind the hose, take out the boxes with the seedlings - on the road should not interfere with standing next to the building, the fence or adjacent flush beds that can easily be damaged.

- The shed is installed on a flat platform, then it will be stable, and the hull will not bend over time.It is desirable that the building is not in the lowlands, where water will be collected with the onset of spring floods.

- The intended function of the shed is also important. If you plan to store garden tools and equipment in the power unit, then it’s hard to think of a better place than the way from the house to the garden or field. For storage of building materials, fodder for livestock or garden furniture in the winter season, the shed can be easily removed to the far corner of the site.

Installation of prefabricated structures

By purchasing a ready-made block, you get the opportunity to easily assemble the product with your own hands, even without having enough experience in the construction business. However, you still need an assistant, because the design is quite voluminous. Installation takes several hours and is carried out on a previously prepared flat platform. It is desirable that the base should be a concrete slab or asphalt, but you can also get along with guides from a bar. In some models, the kit includes a ready-made base for installation on the ground.

Combined hozblok is a frame made of galvanized profile (pipes of iron of small diameter) and corrugated steel sheets. The product is assembled as a designer.In order to build a barn correctly, in the process of work it is necessary to follow the attached instructions.

Installation of welded hozbloka

Erection of a metal shed by welding will require some skills in the welding business, and will also take much longer. But this method will save on materials, especially if they are already available from old steel structures.

In addition to the welding machine, you will need the rod of the profile tube for the frame, galvanized canvas on walls, corrugated roofing sheets, cement, gravel, materials for waterproofing and fasteners.

Installation is carried out in several successive stages.

- Definition and calculation of the place. Drawing up a detailed plan and drawing of the future design. In the drawing you need to make all the sizes, and in the plan - to calculate in detail the amount of necessary materials. This will avoid mistakes and troubles during construction.

- Installation of vertical supports. The main four supports dig in the ground and concreted. The distance between them will depend on the estimated size of the shed.

- When the concrete hardens enough, you can start welding.Vertical beams are welded between the pillars at the top, in the middle and at the base. Consider that on one of the sides of the rectangle you will need to leave an opening for the entrance door. Using the same technology, the roof frame is mounted, roof trusses are welded. You will need a stepladder and at least one assistant.

- The next stage is poured floor. The space around the perimeter is laid out with wooden formwork, filled with rubble and filled with concrete. Subsequently, the concrete floor can be covered with boards or paving slabs.

- The lining of the shed begins with the roof covering, not forgetting to lay waterproofing material under the metal sheets. Waterproofing can be a regular film. All corners are tightly sealed with slats or corners so that moisture does not penetrate into the shed.

- Upon completion of work on the metal sheets must be applied anti-corrosion compounds, if the material used is not originally galvanized. Here will come to the aid of modern compositions sold in spray cans, and in a more budget version of the metal can be painted or primed.

Advantages and disadvantages

The practicality of iron sheds makes them popular in the market of household goods, and this is completely reasonable.

If we talk in general about metal constructions, first of all it is necessary to single out several advantages.

- Reliability and durability. Iron is resistant to precipitation and temperature, is not subject to the harmful effects of insects and rodents, resistant to chemicals and fumes.

- Economic benefits. Metal sheets or finished construction will be cheaper than analogs made of plastic or structures made of brick and concrete.

- The high class of fire safety is also important.

As for prefabricated hozblok, then the advantages of metal structures added a few advantages.

- Ease of transportation. The folded parts of the shed do not take up much space and can be transported even by car.

- Corrosion protection of all metal parts and sheets. Galvanization and powder mixture.

- Ventilation device that comes bundled and indicated in the assembly instructions.

- Sliding doors of modern configuration.

- Aesthetic appearance.A large range of colors and textures of the coating can be selected as shades for siding at home, natural shades of wood or greenery in the garden.

For completeness, it is useful to identify some of the shortcomings of metal sheds.

- The metal does not keep heat, which means that the shed will freeze completely at low temperatures. It does not make sense to carry out heating in the shed, but this deficiency can be partially eliminated with the help of wall and roof insulation. As the insulating materials suitable roofing material, mineral wool or foam.

- Exposure to metal corrosion. Despite all the protective measures taken by the manufacturers or independently, there is a risk of mechanical damage and scratches on the walls. A deep scratch can remove the topcoat and expose the metal that will be exposed to moisture. In order to avoid such troubles, an inspection of the premises should be carried out in the spring and autumn; timely treatment of the damaged areas with anti-corrosion agents.

For information on the types and features of the construction of a metal shed, see the following video.