The subtleties of using Vetonit LR finishing putty

When finishing putty is required, many prefer Weber products, choosing a blend labeled Vetonit LR. This finishing material is intended for interior work, namely: for walls and ceilings. However, one putty is not enough for high-quality coating. The process of its application has a number of nuances, which everyone who knows how to use this plaster should know.

Special features

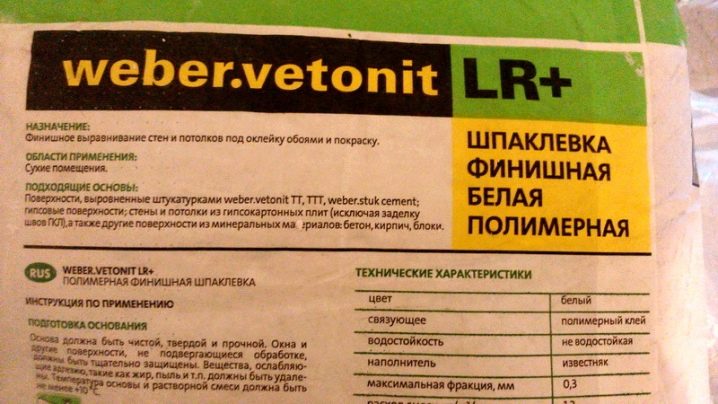

Putty Vetonit LR is a product for finishing alignment of enclosing structures. It is a plaster mix on a polymer adhesive base, which is intended for finishing dry rooms. This is a powder type material with a fine fraction, produced in 25 kg bags.The mixture is a semi-finished product, as it needs dilution with water before the direct application process. It has a basic white color that allows you to change the shade of the plaster coating at the request of the customer.

It can not be used for the design of the facade, as the composition is not designed for the effects of moisture and other weather factors. That composition does not allow to apply this mixture on the base, which can be deformed. She can not finish the wooden houses, which shrink during operation. This kind of putty is not applicable in apartment buildings with a high coefficient of humidity. In such conditions, it will absorb moisture from the outside, peel off from the base, which will be accompanied by cracks and chips.

Due to the low resistance to water and evaporation, this material can not be used in every room. For example, it is not applicable in the bathroom, kitchen, bathroom, on the glazed balcony or loggia. Condensate is the worst enemy of such plaster. Today, the manufacturer is trying to solve this problem, releasing varieties of putty LR. In contrast, it consists of polymers, intended for plastered and concrete substrates.

A distinctive feature of the material is a different number of layers of application. For example, LR is applied in one layer, so it does not perform complex multi-layered decorative coatings, as this can affect the durability of operation, despite the quality characteristics of the raw materials. It does not equal big drops: the composition is not designed for it.

The manufacturer recommends using it for a reason:

- cement-lime;

- gypsum;

- cement;

- drywall.

The material fits well not only on a rough, mineral, but also a smooth surface. In addition, the application, in addition to manual, may be mechanized. This will save part of the composition, apply it quickly, which eliminates the appearance of joints: this surface will look monolithic. The method of spraying involves applying the composition to porous plates.

However, Vetonit LR is not suitable for the floor, which sometimes unfortunate finishers do. You can not use it as an adhesive for the ceiling plinth: this mixture is not designed for weight, it is not universal for all the needs of the master. Buy it must be strictly in accordance with the information specified by the manufacturer on the label.This putty is not a base under the tile, as it will not hold it. In addition, it is not a sealant: it is not purchased for sealing gaps between drywall plates.

Advantages and disadvantages

Like other plastering materials for finishing the floors, Vetonit LR putty has its own advantages and disadvantages.

- It is created on modern equipment using new technologies, which increases the quality and performance characteristics of the material.

- It is easy to use. It is easy to apply the material on the floor, the mass does not stick to the trowel and does not fall off from the base in the process.

- With a small thickness of the applied layer, it flattens the base, smoothing out the minor irregularities of the starting rover.

- The material has environmental friendliness. The composition is harmless to health, coating during operation will not emit toxic substances.

- A mixture of small fractional. Due to this, it is uniform, different pleasant texture and smoothness of the finished coating.

- In some cases, with sufficient experience, it does not need to be further ground.

- It is economical. At the same time due to the powder type, it practically does not form an overspending.Portions can be diluted in parts, which will eliminate the excess mixture.

- The composition has a long life cycle. After preparation, it is suitable for working during the day, which allows the master to perform the finish without haste.

- The material has noise and heat insulation properties, despite the thin layer of application.

- It is suitable for further finishing surfaces for painting or wallpapering.

- The mixture is available to the buyer. It can be purchased at any hardware store, while the cost of finishing putty will not hit the budget of the buyer due to its cost.

In addition to the advantages, this material has drawbacks. For example, Vetonit LR putty cannot be re-diluted. From this it loses its properties, which can adversely affect the quality of work. In addition, it is important to consider the storage conditions of the dry mixture. If it is located in a room with high humidity, it will dampen it, which will make the composition unsuitable for work.

Vetonit LR is picky. Putty simply will not stick to the surface, which is not prepared properly. In the vast World Wide Web, you can find reviews that talk about poor grip.However, few of the network commentators in this case describe the preliminary preparation, considering it to be a useless stage, a waste of time and money. They also ignore the fact that there should be no drafts in the room during work.

In addition, exceed the layer of application, considering that the mixture will withstand everything. As a result, such coverage is obtained short-lived. A prerequisite, which draws the attention of the manufacturer, is that the characteristics of the material construction work. This mixture is not ground leveling, it does not mask serious defects, which newcomers in the field of repair and decoration do not think about.

If non-compliance with the rules of preparation in future work with such a basis may be difficult. For example, according to the masters, when trying to plywood wallpaper, the canvas can be removed partially with putty. It is necessary to strengthen the adhesion, even if the base is good in appearance, and the overlap is made according to all the rules of erection and does not have a porous structure with shedding. Sometimes an ordinary buyer with a limited budget may not like the price of a large bag (approximately 600-650 rudders), which makes it necessary to look for cheaper analogues on the market.

Specifications

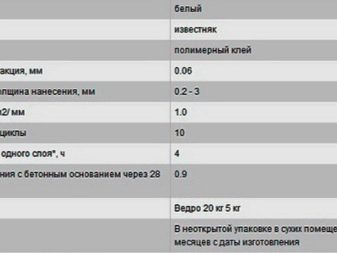

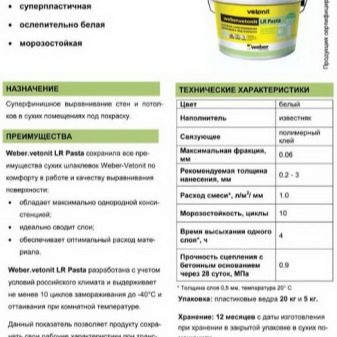

The physicomechanical characteristics of the Vetonit LR putty are:

- moisture resistance - not moisture resistant;

- white limestone aggregate;

- binding - polymeric glue;

- the life of the finished solution - up to 24 hours after dilution;

- optimal application temperature - from +10 to +30 degrees C;

- drying time - up to 2 days at t +10 degrees, up to 24 hours at t +20 degrees C;

- maximum layer thickness - up to 2 mm;

- fraction of grains in the composition - up to 0.3 mm;

- water consumption - 0.32-0.36 l / kg;

- full load - 28 days;

- adhesion with concrete after 28 days - not less than 0.5 MPa;

- resistance to pollution - weak;

- dust formation after grinding - no;

- application - a wide spatula or spray;

- the volume of three-layer packaging - 5, 25 kg;

- shelf life - 18 months;

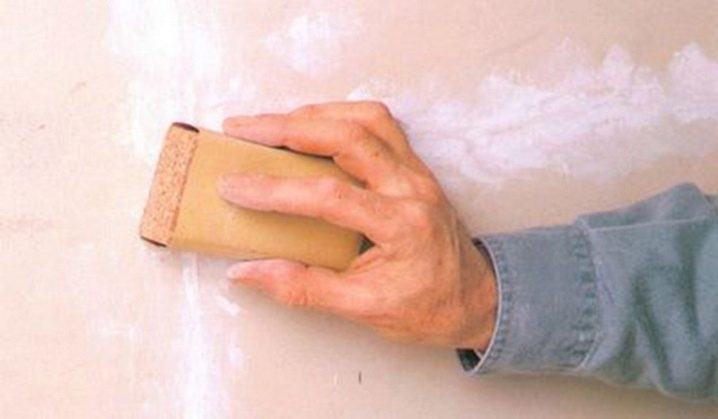

- the final treatment after drying the layer is not necessary for the ceiling, and sandpaper or abrasive paper are used for the walls.

Depending on the variety, the composition may vary somewhat, which is reflected in the quality and performance characteristics. According to the manufacturer, the improved modifications are suitable for all types of bases and are particularly resistant.

Kinds

Today, the Vetonit LR filler line includes the Plus, KR, Pasta, Silk, Fine varieties. Each modification has its own characteristics and is different from the base material. Materials are divided into two categories: for finishing putty of walls for wallpaper and painting, and also mixtures for perfect alignment (superfinishes for painting). However, in conditions of constant humidity, these coatings may eventually turn yellow.

Weber Vetonit LR Plus, Weber Vetonit LR KR and Weber Vetonit LR Fine are polymeric putties for interior work. They are superplastic, they imply a thin layer, they are simple by mixing the layers, which is convenient, since working with this plaster will save time and is suitable even for a beginner in the field of repair and decoration. The materials are easy to sand, characterized by the purity of white and are a good base for painting. The disadvantage of Weber Vetonit LR Plus is the fact that it cannot be applied on previously painted surfaces.

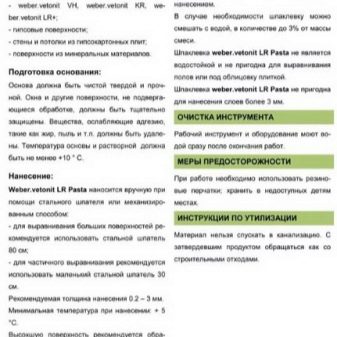

Analogue Fine categorically can not be used for wet rooms. Silk is distinguished by the presence of fine ground marble. Weber Vetonit LR Pasta - ready to use polymeric putty. It does not need to be corrected or diluted with water: it is a mixture in the form of a sour cream-like mass, which is used immediately after opening the plastic container.It allows you to get a perfectly smooth surface and, according to the manufacturer, has an improved hardness after drying. In other words, it is crack-resistant, scratch-resistant putty. The thickness of its layer can be ultra thin (0.2 mm).

How to calculate the flow?

Consumption of material applied to the wall, calculated in kilograms per 1 m2. The manufacturer sets its consumption rate, an indicator of which is 1.2 kg / m2. However, in fact, often the rate at odds with the real expense. Therefore, it is necessary to buy raw materials with a margin, taking into account the formula: norm x lining area. For example, if the area of the wall is 2.5x4 = 10 square meters. m, putty will need at least 1.2 x10 = 12 kg.

Since the indicators of the norm are approximate, and in the process of work a marriage is not excluded, it is worthwhile to take more material. If the putty remains, it is not scary: it can be stored in dry conditions for up to 12 months. In addition, we must not forget that the coating layer is in fact more than recommended by the manufacturer. This will also affect the overall consumption. Therefore, when purchasing it is important to pay attention to the recommended thickness.

Preparation of the solution

Instructions for cooking putty indicated on the package itself.

The manufacturer offers to breed material as follows:

- prepare a clean and dry container and drill with a mixing nozzle;

- about 8–9 l of pure water at room temperature is poured into the container;

- the bag is opened and poured into the container;

- the composition is stirred with a drill with a nozzle until homogeneous for 2-3 minutes at low revs;

- the mixture is left for 10 minutes, then re-stirred.

After cooking, the composition will gradually begin to change its properties. Therefore, despite the assurances of manufacturers that it is valid from one to two days with a sealed package, it is worth using it immediately. Over time, its texture will change, the mass will become thick, which can complicate the lining of surfaces. Drying putty in different ways, which depends on the conditions in the room at the time of work.

Application Methods

Plaster can be applied manually or mechanically. In the first case, it is picked up on the trowel in portions and stretched over the surface, using the rule and the treadmill. This option is especially relevant if the customer uses plaster as a decorative coating. In this way, different shades of the mixture can be mixed together, making the basement look like marble. However, their total thickness should be minimal.

The second method is convenient because it allows you to perform work in a short time. To do this, you can use a spray nozzle with a large nozzle, some masters manage to apply such putty with a building hopper-hopper of their own making. The bucket is emptied in seconds, while the composition can cover the entire room in a short time. A lot of stretch on the surface of the rule. This method is convenient when a large amount of work is planned.

Analogs

Sometimes an ordinary buyer is interested in what can replace the finishing putty of the company, so as not to lose in the quality characteristics of the material. Specialists in the field of construction and decoration offer several options for plaster material.

Among them, the products of the following brands have been particularly highly rated:

- Sheetrock;

- Dano;

- Padecot;

- Unis;

- Knauf.

These materials have characteristics similar in quality and application. However, experts note that in an attempt to save you can lose in quality, because the difference between the analog and Vetonit will be small. If you choose an analogue on a plaster basis, such plaster will not be moisture resistant. Some experts are confident that if you have the skills you can work with any finishing plaster.Builder reviews are contradictory, because each master has his own priorities.

Useful recommendations

To work with putty no problems, you can consider the main nuances of the preparation and application tricks.

Usually, preparation by all the rules looks like this:

- the room is free of furniture;

- conduct a visual inspection of the coating;

- remove old coating, grease, oil stains;

- dust is removed from the surface with a semi-dry sponge;

- after drying, the base is treated with a primer.

These are the basic steps for the base material. At this stage it is important to choose the right primer, since it is from it will depend on the alignment of the structure of the floor and the level of adhesion of all layers. The primer is needed so that the starting material and then the finishing material does not fall off the walls or the ceiling. The base is treated with a primer with greater penetrating power. This will make the wall structure homogeneous.

The primer will bind dust particles and microcracks. It is applied with a roller on the main part of the ceiling and with a flat brush in the corners and hard to reach places. The application should be uniform, because when the soil dries, a crystal lattice will form on the surface,reinforcing adhesion. After the primer has dried, the surface is leveled with a starting material. If necessary, it is trimmed after drying, and then re-primed. Now for bonding start and finish layers.

After the primer is completely dry, putty can be applied. The use of the ground is not a useless procedure or advertising move sellers. It will prevent chipping of putty if you have to, for example, adjust the wallpaper when sticking. The type of tool used is important in the process of finishing planes.

For example, so that the putty does not stick to the trowel, you should not use a spatula made of wood. It will absorb moisture, and together with it, retain the mixture itself on the working canvas. If the area of the room is small, you can try out a metal spatula 30 cm wide or a two-handed tool. The mixture should not be applied on wet floors. It is necessary to dry the wall (ceiling).

Matters and antiseptic treatment. For example, to prevent the formation of mold and mildew on the surface of the wall or ceiling to be finished, the floors can be initially treated with a special composition.In addition, in the process it is important to observe the temperature conditions in the room. If the plaster mixture is applied in several layers, it is important that their thickness is minimal.

If you are polishing the surface, you need to wipe the dust every time, which is easier to do with a semi-dry sponge. She will not scratch the trimmed plane. When applying each new layer, it is important to wait until the previous one is completely dry. The ironing device is used in the case of decorative application, and even relief. In this case, the pressure on the tool should be minimal.

A comparative review of Vetonit LR finishing putties with other manufacturers can be found in the following video.