Vetonit finishing putty: types and composition

Decorating walls and ceilings provides for their perfect alignment. For these purposes, many professional masters choose Vetonit finishing putty. It is characterized by consistently high quality and ease of use. A variety of types and compositions allows for interior decoration of various bases.

Special features

The putty from the manufacturer Weber Vetonit is a building mixture, widely used for finishing work. The material is suitable for dry rooms with low humidity. However, there are variations on sale and moisture-resistant building materials.

Today it is one of the best solutions for finishing. Various types of composition have been successfully applied to wood, concrete, stone, and drywall.The dry mixture has a gray-white color, low specific smell, a fine fraction (not more than 0.5 mm), which allows for optimal adhesion.

With the help of this material, you can successfully eliminate various defects (cracks, potholes, cracks). The putty is the finish. This means that after processing and drying surfaces, you can begin to paint or glue the wallpaper.

Restrictions to use, depending on the composition, is increased humidity, as well as temperature (+ 10 degrees inside the building). This is because the performance of the material may deteriorate. Moreover, it may begin to turn yellow.

A mixture of Vetonit, which had become popular, is produced by Russia. There are more than 200 branches of this international construction company known abroad.

The trademark gained mass recognition due to the affordable cost of its products and its high quality.

Kinds

Finishing putty unites two main components. It is a filler and a binder. The first is sand, limestone, cement, and even marble. As a connecting link, a special adhesive from polymeric compounds is usually used.It is designed for better adhesion and deep penetration into the surface.

The consistency of Vetonit is of two types. You can purchase the material as a dry powder for a solution or prepared for applying a liquid mass.

Depending on the ligament present, the polymer putty is made of composite plastic, cement putty, and organic composition. A large assortment provides plenty of opportunities for interior decoration.

There are several varieties of Vetonit, differing in composition, properties and purpose:

- "Vetonit KR" - a mixture created with the application in rooms with low humidity. The mixture is made on the basis of gypsum and cement on organic glue, after leveling it is necessarily coated with wallpaper or paint.

- Vetonit JS - polymer putty for all types of base with high adhesion and resistance to cracking. It consists of microfiber, which gives the material a special strength. Unlike other products, it is used for sealing joints.

- Resistant to cracking, plastic and durable polymer blend Vetonit JS Plus it is used both under a tile, and under plaster. The composition is effective for the treatment of joints.

- At medium humidity a mixture can be used. “Vetonit LR + silk” or “Vetonit LR +”. This is a polymeric material with a filler of finely ground marble. Vetonit LR Fine it is intended for the subsequent painting.

- Vetonit VH, Vetonit VH gray applied under the tile, wallpaper, paint. This type is intended for concrete, expanded clay, gypsum plasterboard. The filler is limestone, and the binder is cement, resistant to moisture.

All types of solutions are almost universal, used for construction work and repair of different types of premises.

Mixtures are produced in strong three-layer packages of 20 kg and 25 kg (sometimes 5 kg).

Nuances of application

Compounds Vetonit, suitable for rooms with high levels of humidity, have their own peculiarities in the application:

- best solutions fall on gypsum and gypsum board, as well as on agloporite, expanded clay and other mineral surfaces;

- in spite of the fact that, thanks to the small fraction, leveling is carried out to the maximum, laying tiles on Vetonit is undesirable (except for certain types of product);

- you can not use the mixture on surfaces previously treated with self-leveling compounds;

- sealing joints and seams between plates of plasterboard fragments is recommended with special putty of category JS, they are also used if finishing is required, interior decoration of bathrooms, pools and baths with tiles.

Mixtures can be applied not only by manual, but also by mechanized method. With the help of spraying compositions can be used even for complex grounds. So they perfectly cover wood and materials characterized by porosity. An important condition - the application should occur on a thoroughly cleaned and degreased surface.

Product Benefits Vetonit

The advantages of the Vetonit collection are largely due to its composition, technical and operational characteristics.

Main advantages:

- environmentally friendly, safe composition that includes only natural ingredients;

- implies various methods of application;

- dries quickly enough (no more than 48 hours);

- possesses the increased adhesion concerning the majority of the bases;

- economical consumption (only 1.2 kg per square meter);

- distribution on the surface eliminates the presence of drops;

- the subsequent grinding is made without dusting;

- due to the coating of this product increases the strength and performance properties of surfaces;

- democratic price.

It is possible to continue the work with the prepared solution throughout the day, and drying largely depends on the thickness of the applied layer, air temperature, and its dryness.

In some cases, drying occurs within one day.

Preparation of the solution

Construction and repair require perfect alignment of walls and ceilings, but if a powdered mixture is chosen, it must be properly diluted.

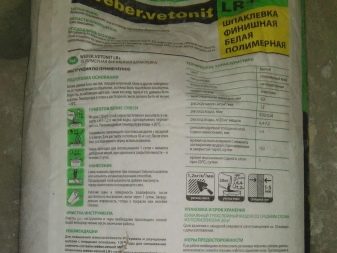

Instructions for use are usually on paper packaging. It shows the exact proportions of water and the building product, as well as the conditions for the maturation of the solution and the time of its action.

A package of 25 kg per 9 liters of water at room temperature is usually taken. The mixture is poured into water and stirred until a homogeneous thick consistency. After it is infused (for 15 minutes), it is mixed again with the help of a construction mixer. The solution must be used no more than a day. Allowable layer of putty - 5 mm.

It should be noted that the nuances of breeding different types of Vetonit putty may differ slightly. Storage should be in a dry, dark and cool place.

Alignment stages

Putty putty either by spraying with special equipment or manually with different size spatulas. For construction work, you will need a plastic container, a grinding and fugovalny machine, rags, a set of spatulas.

Workflow order:

- surface preparation consists in removing the old wall covering, paint, removing grease stains, rinsing and drying the surface;

- then all the irregularities are indicated - the bulges are cut off, and the hollows are marked with chalk or a pencil;

- grooves and cracks are sealed with a medium and long trowel, and take as much mortar for it as needed for one movement;

- Drying should be carried out in a natural way with closed windows and doors (except for interior doors);

- The final putty is applied with the thinnest layer; later on, as it dries, it is abraded and polished, additionally leveling the corners with a suitable trowel.

Consumption of the product is very economical - about 20 kg of material is needed per 20 square meters.

Reviews

Professional builders say that this brand is deservedly respected and is considered one of the best. It is noted that the ceilings treated with “Vetonit LR +” compositions do not need further finishing. The color of the dried putty remains almost white. In addition, it can be applied in two or three layers. A mixture of "Vetonit KR" can be used without prior primer.

Many are pleased that there are waterproof compositions, not afraid of water vapor, which can be used for the kitchen and bathroom. Any of the products of this brand shows high strength, durability and complete safety for health, which favorably distinguishes them from building mixtures from other manufacturers.

To learn how to apply the Vetonit LR + finish putty, see the next video.